SmartLine RotaScope G Series User manual

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

1

© Copyright Smartline Medical Pty Ltd All rights reserved

RotaScope™

Vertical Hanging Scope Drying Cabinet

FEATURES:

•Endoscope capacity = 9 (suits most flexible scopes)

•X-ray or standard pass through options

•HEPA Filtered Air Drying - Independent air supply via Shared Air

Box (for up to 2 cabinets); or

•Remote Air Generator for multiple cabinets

•Vacuum channel drying reduces hook-up cross contamination

•Small footprint: 600mm(w) x 600mm(d) x 2335mm(h)

•Hygienic acrylic cabinet construction

•Interlocking RFID door locks

•Airflow, temperature, pressure and humidity monitoring and

reporting as per EN16442 Standards

•RFID Scope Data Monitoring and Display:

oCountdown timers for each scope.

oElectronic data backup and integration to other

software packages via CSV or MySQL.

oLive view of cabinets via software

•Data management system allows printing of labels to report

scope status, cabinet cleaning status, error status

•Discrete lighting indicates cabinet hygiene status and prompts

when cleaning or service is required

•Scope validation label with ‘Expiry Date and Time’ information

for Washer to Patient validation

•Stainless steel hooks and vacuum hose kits supplied (nine sets

including scope connectors)

•12 - 168 hours storage time –configurable

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

2

© Copyright Smartline Medical Pty Ltd All rights reserved

CONTENTS

CONTENTS...........................................................................................................................................................................2

NOTICE AND DECLARATION................................................................................................................................................6

PREFACE..............................................................................................................................................................................7

EN16442 COMPLIANCE REQUIREMENTS............................................................................................................................7

CABINET OVERVIEW ...........................................................................................................................................................8

Interlocking.......................................................................................................................................................................9

Storing Vertically ...............................................................................................................................................................9

AIR OPTIONS .....................................................................................................................................................................10

Benefits of Shared Air System..........................................................................................................................................11

Benefits of Vacuum Through Channels............................................................................................................................14

CABINET SPECIFICATIONS .................................................................................................................................................15

Cabinet Conditions.........................................................................................................................................................16

SpeCifications Table........................................................................................................................................................ 18

OPERATION INSTRUCTIONS..............................................................................................................................................23

Before Storage ...............................................................................................................................................................24

Hanging a Scope.............................................................................................................................................................24

Adjusting Top and Centre Disc Heights........................................................................................................................... 25

Connecting Vacuum to a Scope: .....................................................................................................................................26

DATA SYSTEM ................................................................................................................................................................... 28

Data System Overview................................................................................................................................................... 29

Count Down Timers ...................................................................................................................................................... 29

Scope and Staff Tags ....................................................................................................................................................... 30

Tag Programmer ................................................................................................................Error! Bookmark not defined.

Washer Station ...............................................................................................................................................................31

Sequence for Washing Scope: WHO, WHAT, WHERE ..................................................................................................32

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

3

© Copyright Smartline Medical Pty Ltd All rights reserved

Adding and Removing Scopes from the Cabinet ..............................................................................................................32

Printer Station.................................................................................................................................................................32

Replacing Labels ............................................................................................................................................................. 33

Laptop Kit....................................................................................................................................................................... 34

PC Operating Systems.................................................................................................................................................... 34

Software –Installed onto Laptop.....................................................................................................................................35

Positions of Components and Cable Distances................................................................................................................ 36

Closed Network –tcp/ip ................................................................................................................................................ 36

Cabinet Reset Button......................................................................................................................................................37

Printing Labels ................................................................................................................................................................38

INSTALLATION REQUIREMENTS........................................................................................................................................39

Information to Gather.....................................................................................................................................................40

Room Layouts, Ceiling Heights and Wall Construction ....................................................................................................40

Bulkhead ........................................................................................................................................................................ 42

Access and Route for Install.............................................................................................................................................43

Lifts / Stairwells ............................................................................................................................................................... 43

Install Dates, Work Hours...............................................................................................................................................43

Power Needs.................................................................................................................................................................43

STAFF TRAINING AND EDUCATION................................................................................................................................... 44

Standard Workflow......................................................................................................................................................... 45

Cabinet Reporting Conditions.........................................................................................................................................46

In-Service Training for Site .............................................................................................................................................. 47

Additional Training and Setup..........................................................................................................................................47

MAINTENANCE AND CLEANING........................................................................................................................................48

Vacuum Hoses –Cleaning IFU .......................................................................................................................................49

Cleaning ......................................................................................................................................................................... 49

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

4

© Copyright Smartline Medical Pty Ltd All rights reserved

Internal Surfaces .............................................................................................................................................................49

Exterior Surfaces.............................................................................................................................................................49

Cleaning Data Validation .................................................................................................................................................50

SAFETY .............................................................................................................................................................................. 51

Safe Operating Procedure...............................................................................................................................................51

Pre-Start Checks............................................................................................................................................................. 51

Turning On The Cabinet ................................................................................................................................................ 51

Maintenance Contracts ...................................................................................................................................................52

PQ –Performance Qualification......................................................................................................................................52

Compliance.................................................................................................................................................................... 53

TROUBLESHOOTING .........................................................................................................................................................54

PHYSICAL TESTS AND CHECKS...........................................................................................................................................56

Air Flow Check............................................................................................................................................................... 56

Endoscope Condition ..................................................................................................................................................... 56

Power Outages ..............................................................................................................................................................56

ANNEX A –VALIDATED SCOPES FOR STORAGE ................................................................................................................ 57

Validated Scopes Overview ............................................................................................................................................58

Olympus Colonoscopes .................................................................................................................................................58

Olympus Gastroscopes...................................................................................................................................................61

Olympus Duodenoscopes ..............................................................................................................................................62

Olympus Bronchoscopes................................................................................................................................................63

Pentax Scopes ................................................................................................................................................................64

Fujinon Scopes ...............................................................................................................................................................65

ANNEX B –INSTRUCTIONS FOR USE –ENDOSCOPE HOSE KIT CLEANING........................................................................67

Manual Cleaning .............................................................................................................................................................68

Batch Washers ...............................................................................................................................................................69

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

5

© Copyright Smartline Medical Pty Ltd All rights reserved

Sterilising for Sterile Storage ............................................................................................................................................ 69

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

6

© Copyright Smartline Medical Pty Ltd All rights reserved

NOTICE AND DECLARATION

This manual and any examples or images contained herein are provided “as is” and are subject to change without notice.

Smartline Machinery makes no warranty of any kind with regard to this manual, including, but not limited to, the implied

warranties of merchantability, non-infringement and fitness for a particular purpose.

Smartline Machinery shall not be liable for any errors or for consequential damages in connection with the furnishing,

performance, or use of this manual or the examples contained herein.

© 2017, Smartline Machinery

Product designed and manufactured by Smartline Machinery Pty. Ltd.

PO Box 532, Buderim, Qld 4556

Australia

Distributor Details:

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

7

© Copyright Smartline Medical Pty Ltd All rights reserved

PREFACE

Products made by Smartline Machinery Pty Ltd are designed to meet specific needs in the healthcare industry and we

manufacture in Australia under ISO 9001 quality system standards. Before our products leave the factory they undergo quality

assurance testing to ensure that they meet our quality standards. Should you experience problems with this product, please

contact us for support or repairs.

This User Manual covers the installation, general use and maintenance of the RotaScope™ Scope Drying Cabinet designed

and supplied by Smartline Machinery or approved distributors.

In countries outside Australia, our products are supported by local distributors which are always ready to help you. See

Distributor details on Page 5.

If the local distributor is unable to assist you, forward your support requests to Smartline Machinery at

tech@smartlinemachinery.com

This product has been designed to dry and store up to nine flexible Endoscopes. The construction and assembly is configured

to do so reliably and effectively in conjunction with European and Australian Standards and Guidelines.

Number of Scopes stored per cabinet: 9 Endoscopes. Capable of storing Gastroscopes, Colonoscopes, Bronchoscopes,

Duodenoscopes, EUS Scopes, Enteroscopes, ENT Scopes and more of most brands.

EN16442 COMPLIANCE REQUIREMENTS

Continuous monitored air-drying cabinets complying with European Standard EN 16442:2015 –for drying

Thermoliable Endoscopes. Globally this standard currently represents the highest documented level indicating best practice of

Scope storage at time of publication of this document.

EN16442 requires the cabinet to monitor, report and print various parameters including airflow status indication, cabinet

pressure, temperature, humidity, door open parameters and power outages.

All events are logged in the Data Management System for log retrieval and reporting

Maintenance: It is an operational requirement to have an up-to-date Maintenance Contract in place.

Validation: To maintain the accuracy of the environment monitoring equipment, the system needs to be recalibrated and

checked annually by an approved service agent. A Certificate of Compliance will be issued upon each annual recalibration. A

Validation Contract is separate to a Maintenance Contract, and is also an operational requirement.

RotaScope™ Cabinets meet current 2017 GENCA Guidelines and Position Statement March 2017 and are Compliant with

EN16442.

Australia: According to the GENCA Position Statement, March 2017, all cabinets must comply with EN16442 by December

2020.

This product is TGA listed –Article ARTG 140018. According to GESA/GENCA/ACIPC August 2017, “Statement 7a, “All

endoscopic instruments, except those in sterile packaging, should be stored in TGA-approved forced air drying cabinets”. And

Statement 7b, “Endoscopes stored in TGA-approved forced-air drying cabinets may be used for a period of up to 7 days

without reprocessing, unless otherwise stated by the manufacturer.

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

8

© Copyright Smartline Medical Pty Ltd All rights reserved

RotaScope™

CABINET OVERVIEW

Acrylic Side Panels (white standard)

Clean Spot (inside door-

visible when open)

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

9

© Copyright Smartline Medical Pty Ltd All rights reserved

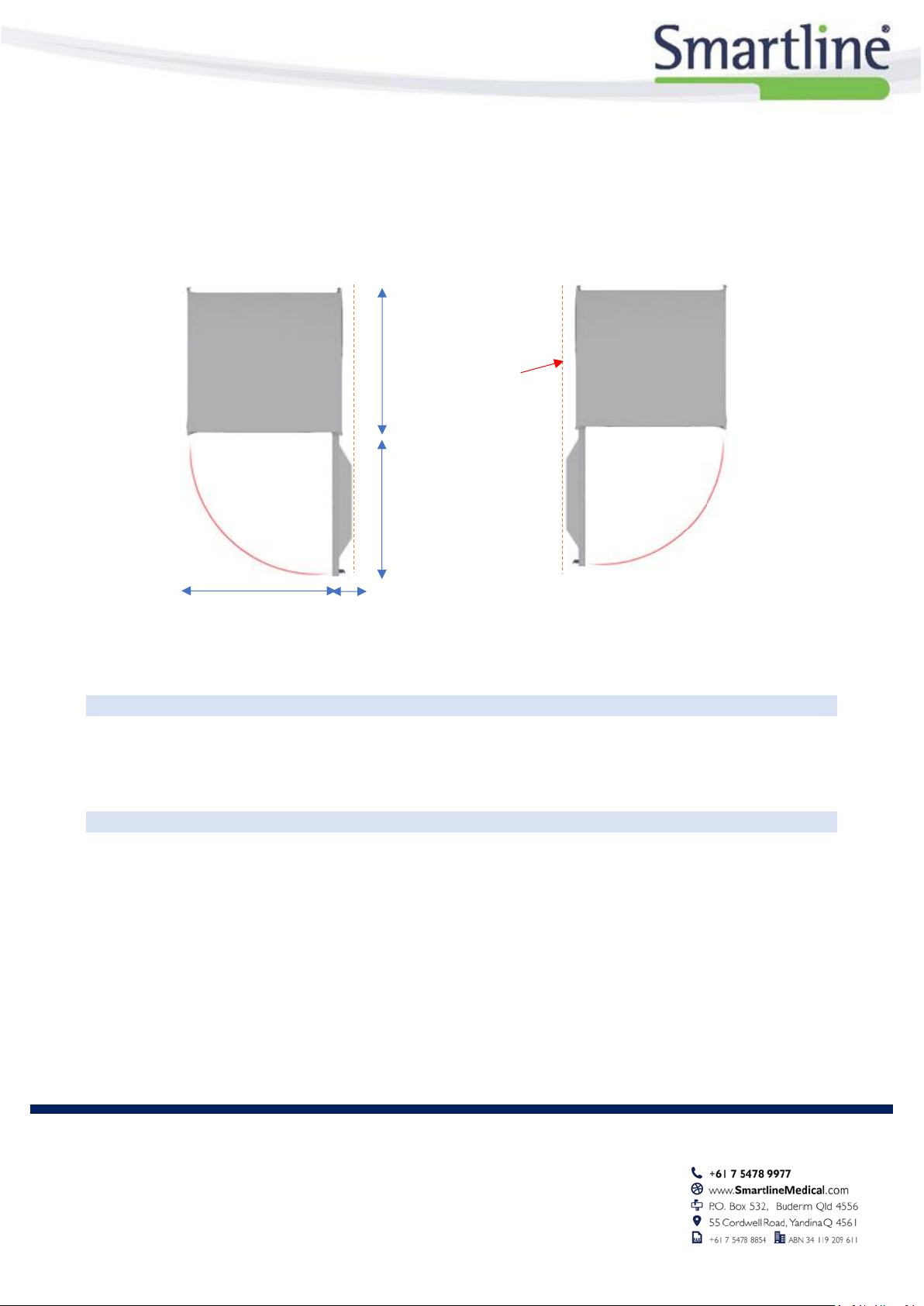

Door Opening Directions and Door Style Selection

RotaScope™ Cabinets come standard with doors hinged on the right. If there is a requirement that doors be hinged on the

left, this needs to be shown in the room layout drawings and be noted on all documentation. It is very important that this

information is detailed in the quoting stage, as although it is possible for the doors to be changed onsite, the client will incur

additional charges if changes were not requested in the original specification.

Right Hand Hinged (Standard)

Left Hand Hinged (upon request)

Right Hand Hinged (Standard)

Left Hand Hinged (upon request)

INTERLOCKING

If the selected RotaScope™ Cabinet is of the pass-through variety, the standard door locking mechanism will prevent both

doors from being open at the same time. This interlocking function will therefore prevent air from passing between the

cleaning and procedure rooms.

STORING VERTICALLY

By hanging scopes vertically, the detrimental memory effect produced by coiling scopes is reduced significantly.

600mm

600mm 80mm

565mm

Allow enough space

next to wall for door

with screen to fully

open

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

10

© Copyright Smartline Medical Pty Ltd All rights reserved

RotaScope™

AIR OPTIONS

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

11

© Copyright Smartline Medical Pty Ltd All rights reserved

BENEFITS OF SHARED AIR SYSTEM

The cabinet will provide an environment fit for drying qualified scopes stored inside.

Air flow into cabinet

Air flow out of cabinet

Air Flow Schematic

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

12

© Copyright Smartline Medical Pty Ltd All rights reserved

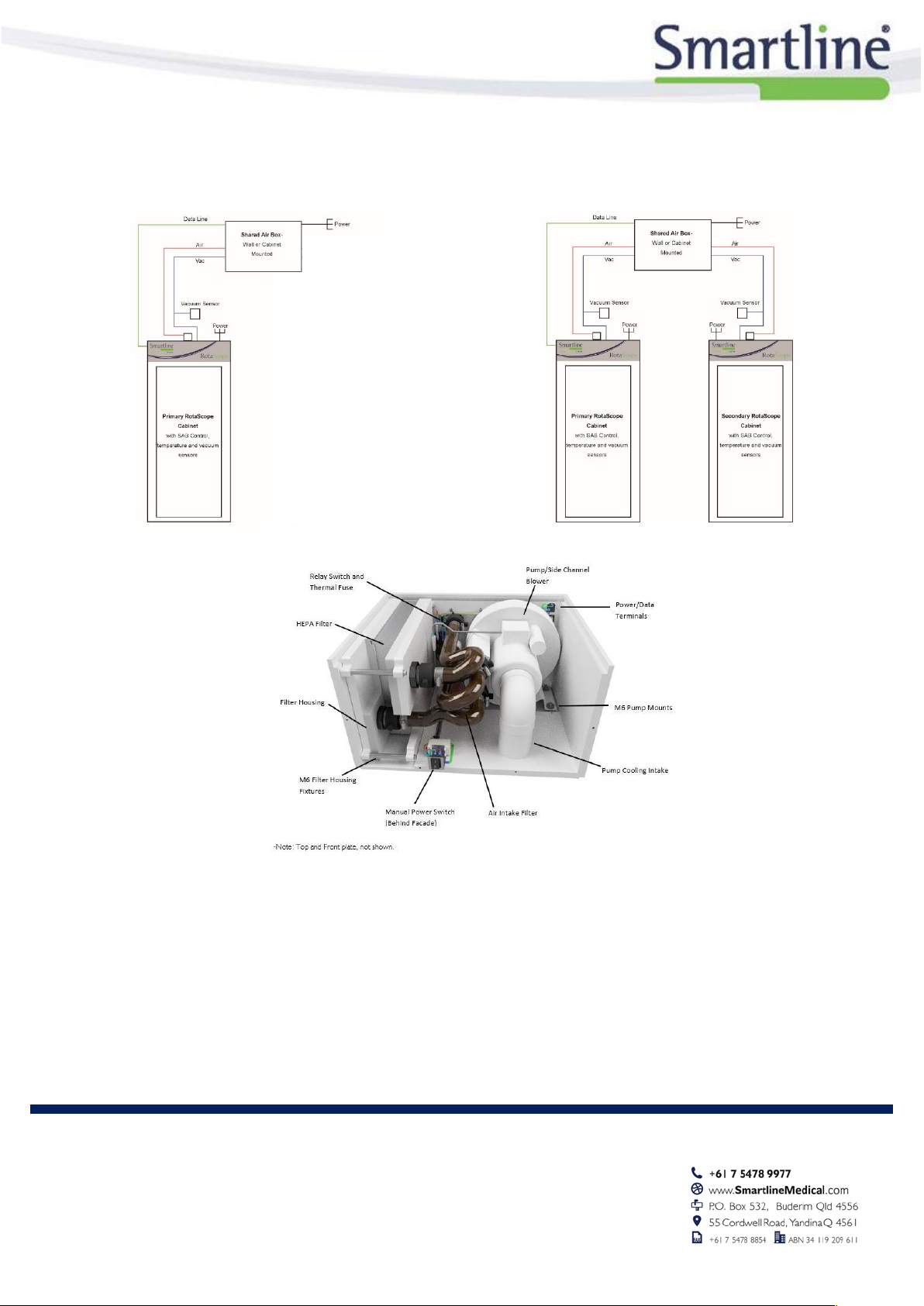

There are two options for the air generation for the RotaScope™ Cabinet. Both options are an inexpensive air supply and do

NOT connect to the hospital, medical grade, air supply. Low servicing costs of filters (annually) and pumps (bi-annually)

creates a cost-effective solution to airflow.

1. Remote Air System (Multiple Cabinets Use –Each site needs independent evaluation)

The Remote Air System can service 1 -7 cabinets and will require air ducting from the pump system (Remote Air Generator)

to the cabinets. The largest pump will require a 3-Phase power source.

2. Shared Air Box

The Shared Air Box can be positioned on top of a RotaScope™ Cabinet if the ceiling height is 2700mm. If the ceiling is lower

than this, it will have to be wall mounted using the SAB Wall Mounting Kit (09.SC-SB -WMK).

If a wall mount kit is used, there is a possibility that a 5-10 metre hose extension kit will be required to connect the SAB to the

RotaScope™ Cabinet. Similarly, a hose extension kit may be required to connect air to the secondary RotaScope™ Cabinet if

positioned up to 10m away from the primary cabinet that holds the SAB.

Shared Air Box

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

13

© Copyright Smartline Medical Pty Ltd All rights reserved

Single cabinet install schematic

Double cabinet install schematic

The Shared Air Box (09.SAB) will generate HEPA Filtered air and vacuum for up to two cabinets.

The Shared Air Box is located with the cabinets (no plumbing or construction work required)

The ongoing costs of this product is low, and it only requires basic servicing.

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

14

© Copyright Smartline Medical Pty Ltd All rights reserved

PUMP REPLACEMENT FILTER REPLACEMENT

The following table details replacement parts:

Year

1 Cabinet

2 Cabinets

3 Cabinets

4 Cabinets

5 Cabinets

1

1x

1x

2x

2x

3x Filters

2

1x

1x

2x

2x

3x

3

1x

1x

2x

2x

3x

4

1x

1x

2x

2x

3x

5

1x

1x

2x

2x

3x

1

N/A

N/A

N/A

N/A

N/A

2

1x

1x

2x

2x

3x Pumps

3

N/A

N/A

N/A

N/A

N/A

4

1x

1x

2x

2x

3x

5

N/A

N/A

N/A

N/A

N/A

BENEFITS OF VACUUM THROUGH CHANNELS

The RotaScope™ Cabinet uses vacuum which ensures enough airflow passes through each endoscope channel to assist with

drying the internal surfaces. The clean HEPA Filtered air is passed into the cabinet and across each scope, the air is pulled

through the distil tip of the scope and returns through the various hook-up manifolds.

QUANTITY OF CABINETS (One system can service two cabinets)

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

15

© Copyright Smartline Medical Pty Ltd All rights reserved

RotaScope™

CABINET SPECIFICATIONS

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

16

© Copyright Smartline Medical Pty Ltd All rights reserved

CABINET CONDITIONS

Cabinet Mounted Touch Screen Interface

Sensor Status Key

= Value out of range

= Scope Storage details (Expired in RED)

The RotaScope™ Environmental Monitor measures and records the following cabinet conditions:

•Temperature

•Humidity

•Air (Cabinet Pressure)

•Vacuum

•Door Status

•Shared Air Box Temp

•Routine Cleaning Status –Clean Due

•CONTROL –SAB and Alarm Status

•Scope Location Button –Detailed Storage Info

The air system automatically maintains a positive pressure within each cabinet. Having a positively pressured cabinet,

minimises external airflow (cleaning room / theatre air) into the cabinet. All the Environmental Conditions are measured and

recorded by the Data Management System as required to meet EN16442 Standards. If a deviant reading level is received (in

the Warning or Alarm values of these conditions), the following will occur:

•An automatically generated printout identifies actions for Cabinet Clean Completed and Alarms

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

17

© Copyright Smartline Medical Pty Ltd All rights reserved

•Cabinet lighting will change colour (each fault has an assigned colour, see: Warnings and Alarms section)

Cabinet Mounted Touch Screen Control Screen

Sensor Status Key

= Alarm Acknowledge Button

= SAB on/off

Cabinet Mounted Touch Scope Storage Details Screen

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

18

© Copyright Smartline Medical Pty Ltd All rights reserved

SPECIFICATIONS TABLE

Topic

Answer

Notes

List of endoscopes that can be stored in

the storage cabinet;

See: Approved Scope List.

Endoscope accessories (e.g. valves) can be

stored inside the storage cabinet but it is not

the intention of the storage cabinet to

maintain the microbiological quality of these

accessories.

Storage temperature band

10 –40degC

Maximum storage time

168hrs

7 days maximum storage

Drying function

N/A

Cabinet is not equipped with a drying function

Drying temperature band

N/A

Not Applicable as cabinet does not use

elevated temperatures to dry load.

Time required to dry the endoscopes (if

applicable)

3 Hours (MAX)

Dryness may be achieved in less than 3 hours

Channel aeration

Tested at IQ, OQ and PQ Intervals (Install

and Annual PQ)

Testing with use of Smartline Medical Aeration

Testing Device inline between scope channel

and vacuum manifold to check air circulation

through different channels.

Manifold Test with Oxyview

Automated channel flushing control

N/A

Automated channel flushing NOT used

Air Flow circulation diagram

See: USER Manuals

See: Benefits of Shared Air System

RotaScope:Page 10

SlidaScope: Page 10

Cabinet Flow Rate (Ports at Manifold)

>1.0 l/m

Minimum detectable flow rate is .5 l/m

Cabinet Flow Rate (Total)

200 l/m

10x Air Exchanges p/h

Minimum detectable flow rate is 20 l/m

Total Vacuum Flow Rate Per Cabinet

170l/m

Cabinet Pressure Band

-1–27pa

Differential Pressure (above 27Pa is possible

but not recorded.

Endoscopes that one or more channels

is below the detection limit

N/A

Currently there are no endoscopes that can be

stored in the cabinet that have a flow rate that

is below the detectable flow rate of 1 l/min.

Air Quality

99.99% @0.3µm Filtration Rate (HEPA

Filtered Supply Via SAB)

Third party air is not used by the storage

cabinet. A Shared Air Box draws required air

from the surrounding environment of which it

is situated and therefore standard office

working conditions need to be provided at all

times. Room temperature range 10 C° to 30 C°,

relative humidity between 40% and 70%,

environmental room pressure greater than 102

kPa.

Humidity Band

3.0 –90.0 %RH

Oil Content

N/A

Compressed air not used

Air Quality Testing Frequency

Annually –Service and PQ

HEPA Filter replaced Annually

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

19

© Copyright Smartline Medical Pty Ltd All rights reserved

Cabinet Cleanliness Level

N/A

A specific cleanliness level is not claimed –

Clinical Clean at commissioning/handover is

required by HSO required

Cabinet Cleaning Limits

<168hrs

Weekly cleaning required for cabinet and

accessories (Vacuum Hose Kits)

Cabinet Cleaning IFU

See: User Manual

See: Maintenance and Cleaning

RotaScope: Page 47

SlidaScope: Page 48

Accessory Cleaning IFU

See: Vacuum Hose Kit IFU Document

Microbiological Alert Levels - Airborne

See: PQ Contract

<50 CFU Acceptable

>50CFU = Failure

>1CFU must be identified

>1CFU Identified as Pathogenic = Failure

Testing carried out as part of Annual PQ in

accordance with AS4187 and EN16442

Microbiological Alert Levels - Surfaces

See: PQ Contract

<25 CFU Acceptable

>25CFU = Failure

>1CFU must be identified

>1CFU Identified as Pathogenic = Failure

Testing carried out as part of Annual PQ in

accordance with AS4187 and EN16442

Preventative Maintenance

See: Service Agreement and/or User

Manual

See: PQ –Performance Qualification

RotaScope: Page 52

SlidaScope: Page 51

Annual Preventative Maintenance of Cabinets

and Shared Air Systems are Recommended –

To be done by a Smartline Medical Accredited

Service Technician

Selectable storage cabinet cycles

Out of Cabinet Time –3hrs

Non-alcohol Cycle –12hrs

Alcohol Cycle –168hrs

See: Staff Training Manual

See: Wash Validation of Scopes

Transferring Endoscopes

See: User Manual

See: Storing/Hanging A Scope

RotaScope: Page 22

SlidaScope: Page 22

IFU for Power Outage

See: User Manual

After a power outage a cabinet will illuminate

purple and a label will be printed with

associated information.

See: Cabinet Reporting Conditions & Power

Outages

RotaScope: Page 46 & 54

SlidaScope: Page 45 & 53

Model Numbers and Serial Numbers

See: Cabinet

See: Compliance Page 53

Environmental Conditions

Standard office working conditions need to be

provided at all times. Room temperature range

10 C° to 30 C°, relative humidity between 40%

and 70%,

MAN-0901 RotaScope

VALID DATE: 01/2019 to 12/2020

Model: RotaScope G & Upgrades

20

© Copyright Smartline Medical Pty Ltd All rights reserved

Correcting, resetting and acting on

faults

See: User Manual

See: Cabinet Conditions

RotaScope: Page 16

SlidaScope: Page 16

Over and under pressure stabilisation

band

Instant

Cabinet Air pressure requires no time for

stabilisation

SAB Over Temp,

Instant

Alarm:

•Subtracts time from OoC

•Causes SAB to Shutdown

Self-rectifying –attempts to run again after 2

minutes.

Note: Alarm Acknowledge required at Cabinet

interface for normal operating function (Yellow

Cabinet Lighting) however, OoC will only count

down whilst the pump is not running.

Cabinet Temperature, Humidity, Air

Pressure, Vacuum and Door Alarms

3 Minutes

Warning Mode:

Yellow warning light for first three minutes

Alarm:

•Subtracts time from OoC

Self-rectifying Alarm, once cabinet reads in

normal status, the cabinet will return to green

and OoC will cease counting down.

Clean Alarm

24hr Warning (Blue Light)

Alarm:

•Subtracts time from OoC

Requires Cabinet Clean Function to rectify

alarm

Storage Expiry

Instant

Visible:

•00:00 On Door Screen

•“Re-Process Scope” on Label

OoC Expiry

Instant

Visible:

•00:00 On Door Screen

“Re-Process Scope” on Label

Endoscope Channel Condition Prior to

Storage

See: Automated Endoscope Reprocessor

(AER) IFU or Manual Cleaning Regime

The verification that all channels allow the

passage of air before the device is loaded into

the storage cabinet is required when a scope

has been cleaned and disinfected using a

manual cleaning procedure. For each cabinet,

one endoscope is to undergo an aeration test

(bubble test) as per manufactures instructions

during annual Performance Qualification. In

the case where the endoscope is cleaned and

disinfected using a validated processing

procedure (washers compliant with EN ISO

15883-4:2009) this verification is included

through channel monitoring however,

extensive air flushing of all channels is

recommended before placing the endoscope in

Table of contents

Other SmartLine Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Syneron

Syneron Candela VelaShape III System user manual

Creative

Creative PC-60N Instructions for use

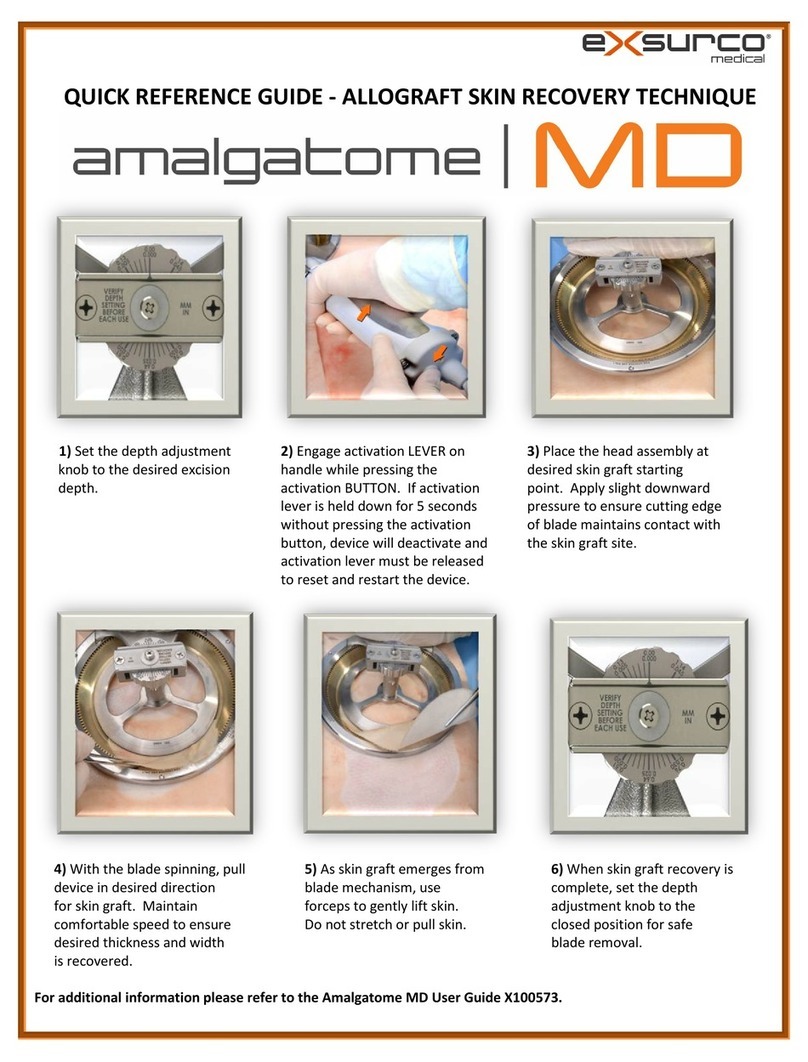

Exsurco Medical

Exsurco Medical Amalgatome MD Quick reference guide

Topcon

Topcon RM-8900 instruction manual

Tecno-gaz

Tecno-gaz ANDROMEDA VACUUM xp user manual

Flight Medical Innovations

Flight Medical Innovations FLIGHT 50 Operator's manual

Boston Scientific

Boston Scientific LUX-Dx manual

GE

GE Centiva/5 Plus Technical reference manual

Stryker

Stryker Power-PRO IT Cot 6516 Maintenance manual

promotal

promotal iQuest 3050 Series user guide

Maxtec

Maxtec SmartStack Assembly instructions/Instructions for use

Otto Bock

Otto Bock 743L500 3D L.A.S.A.R. Posture Instructions for use