TTaabbllee ooff CCoonntteennttss

Warning/Caution/Note Definition ..............................................................................................................................4

Summary of safety precautions ................................................................................................................................4

Pinch points .......................................................................................................................................................4

Introduction for service .............................................................................................................................................6

Expected service life ...............................................................................................................................................6

Contact information.................................................................................................................................................6

Serial number location - Power-PRO ........................................................................................................................6

Serial number location - SMRT ................................................................................................................................6

Preventive maintenance ...........................................................................................................................................7

Lubrication .............................................................................................................................................................7

Regular inspection and adjustments.........................................................................................................................7

Every three months or six hours...........................................................................................................................7

Every month or two hours ...................................................................................................................................8

Every six months or 12 hours ..............................................................................................................................8

Every 12 months or 24 hours...............................................................................................................................9

Maintenance record ................................................................................................................................................9

Training record .....................................................................................................................................................10

Troubleshooting ......................................................................................................................................................12

Electronics and hydraulics locator ..........................................................................................................................12

Hydraulic assembly...............................................................................................................................................13

Hydraulic assembly wiring schematics....................................................................................................................13

Electrical system block diagram - lift and extend (unload) functions...........................................................................14

Electrical system block diagram - lower and retract functions....................................................................................15

SMRT charger power LED is NOT illuminated .........................................................................................................15

SMRT charger will not charge the SMRT Pak..........................................................................................................16

SMRT charger indicator LEDs are NOT illuminated when the Pak is inserted.............................................................16

A fully charged SMRT Pak does not provide sufficient power for cot operation ...........................................................16

Charger indicates a temperature delay (flashing amber LED), but the Pak is within the normal operating temperature

range ...................................................................................................................................................................17

SMRT charger indicates a SMRT Pak error (amber LED), but the Pak performs well on the cot...................................17

Litter drifts (without patient weight) .........................................................................................................................17

Base drifts (without patient weight) .........................................................................................................................17

Litter does not lower in the powered mode ..............................................................................................................17

Litter does not extend in the powered mode ............................................................................................................18

Base does not retract in the powered mode.............................................................................................................18

Base does not extend in the manual mode..............................................................................................................18

Base does not retract in the manual mode ..............................................................................................................19

Litter does not retract in the manual mode (with patient weight) ................................................................................19

Litter does not extend in the manual mode ..............................................................................................................19

High speed retract does not engage .......................................................................................................................19

LCD error codes - main micro ................................................................................................................................19

Safety micro .........................................................................................................................................................20

Main cable assembly.............................................................................................................................................21

Main cable assembly wiring schematics..................................................................................................................21

Control board assembly.........................................................................................................................................22

Control board wiring schematics.............................................................................................................................23

Service ....................................................................................................................................................................24

Head section replacement .....................................................................................................................................24

Manual release cable adjustment ...........................................................................................................................24

Filling the hydraulics assembly reservoir.................................................................................................................25

Wheel locking force adjustment..............................................................................................................................26

Steer-Lock mechanism adjustment.........................................................................................................................26

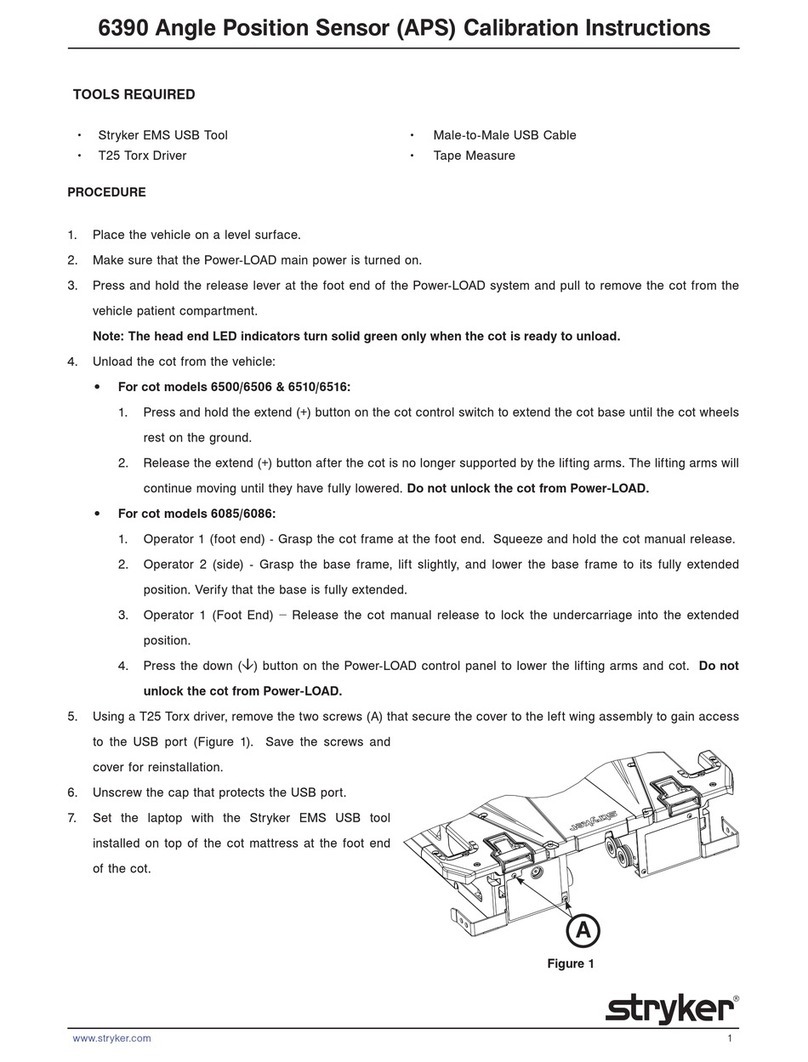

Cot retaining post adjustment.................................................................................................................................27

Cot retaining post replacement...............................................................................................................................28

Cot retaining post screw replacement .....................................................................................................................28

6516-109-002 Rev AB.0 1 EN