SmartPID M5 PRO User manual

SmartPID M5 PRO basic concept

Designed for the industrial and pro market to manage any thermal regulated

application bridging the gap between complex and expensive industrial controller

(PLC) and simple on/off thermostat.

The flexibility, feature richness and smartness make smartPID M5 PRO a unique

product on the market that can replace legacy thermostat and manage any

application in a smart way !

SmartPID M5 PRO characteristics

●Dual Independent control channels (2 in 1 controller)

●Fully configurable PID-PWM control or ON/OFF control

with hysteresis

●DIN 1/16” 48×48 compact enclosure

●Graphical 320×240 TFT colour display with interactive

menu and GUI

●3 push buttons for GUI interaction

●DC 5-36V power supply OR 110/220 AC power supply

●5 different temperature probes type selectable

○NTC 10k

○RTD (PT100)

○Digital 1-wire DS18B20 or

○K-type thermocouple probes (with external

adapter)

○Support of wireless Bluetooth temperature

sensors

●4 different outputs that can be assigned by SW to each

control channel

○2x DC out 5-36V 2.5A for heavy load driver

○2x 10 A realy

●WIFI and Bluetooth connectivity

●Loudspeaker

●uSD card memory support for data logging

●I2C expansion port

●OTA Firmware upgrade

●On Board EEPROM for data persistence and auto

recovery after power outage

SmartPID M5 PRO back panel pinout

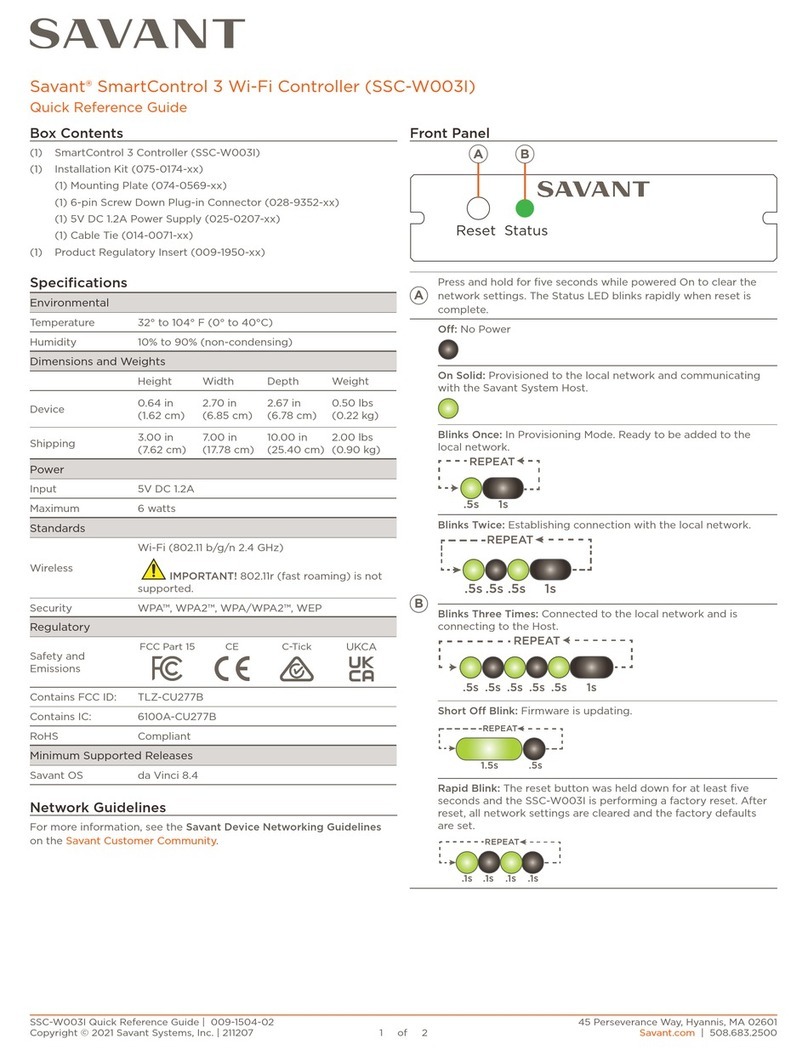

DIP switch configuration for temp probes selection

SW1 SW2

NTC 10K Open Open

PT100 Open Close

DS18B20 Close Open

Thermocouple

MAX31850

Close Open

SW1.1

SW2.1

SW2.2

SW1.2

Temperature probe selection need to be done either via the SW

menu and configuring the back panel dip switch

ThermoCouple Adapter (MAX31850)

AIN0

AIN1

GND

AIN0

AIN1

GND

6 5 4 3 2 1

Connect

1) GND ⇒ GND of CH1 or CH2

2) 3V3 ⇒ AIN0 of CH1 or CH2

4) DATA ⇒ AIN1 of CH1 or CH2

5)6) thermocouple

Select DIP switch for K-type (SW1 close, SW2 open)

Select in SW configuration the K-type temp proble

Bluetooth temperature sensor pairing

● Navigate to the BT Sensor config menu (HW setup)

● Select “Pairing” menu then perform sensor scan

● The BT-05 sensors must be powered on (press central button)

● Select the BT05-xxxxx sensor and confirm

● Check the pairing status in the “status” menu

● In the BT config menu you can configure

○ Sample Time

○ Transmission Power

● Once paired the sensor BT05-xxxxxx will be available in the

HW config/sensor type menu as any other wired sensor

Status LED

Power

on/off

WIFI

● Check wifi connection status

● Select WiFi connection mode

(AP/client/Auto)

● Check WiFi parameters (SSID/PWD/IP)

● Check Server parameters (MQTT

address/credentials

Profile

● add/edit/delete temperature profiles

● up to 10 different profiles with up to 10

ramp/soak valued

Info

● display SW version

● start SW upgrade over the air (OTA)

● display serial number

● display status of various components

(wifi,cloud server)

Start

select standard or advanced mode (profiles), select

the set point and start the control process

Monitor

temperature on both channel is monitored. With

up/down button is possible to select the output (DC or

relay) and with SET activate the output

Setup

●HW setup --> the HW resources are

configured and assigned to I/O process

●Unit Parameter--> the main parameter that control

the PID process behavior are configured in this

menu

●Process parameter--> smart thermostat process

specific parameter are configured in this menu

●PID auto tune--> this is a special section to

configure and run the auto tune process to help

end user to calculate critical parameters Kp,Ki,Kd

that regulate PID behavior

SmartPID M5 PRO main menu

SmartPID M5 PRO - HW set up

Parameter Description

Control Mode Select Heating/Cooling/Thermostatic mode

Heating/Cooling mode Select control algorithm PID or ON/OFF

Multi control Select number of control channels

Out1 Heating/Cooling Assign to CH1 control process output resources (relay or DC)

Out2 Heating/Cooling Assign to CH1 control process output resources (relay or DC)

BT sensor config Configure Bluetooth temperature sensor

T. probe 1 & 2 Select temperature probe for CH1 and CH2 (*)

(NTC/DSD18B20/PT100/thermocouple/bluetooth)

(*) user need to configure DIP switch on back plane

SmartPID M5 PRO - unit parameters

Parameter Description

Temperature Unit Select temperature unit visualization Celsius or Fahrenheit

Probe 1 & 2 calibration Adjust temperature probe reading with fixed offset +-5c

NTC Beta Select NTC probe beta factor

Auto Resume Enable/Disable process auto resume function after power supply

failure or process crash

Button beep Enable/disable button press sound

Clock SetUp Configure real time clock either manually or via NTP

SmartPID M5 PRO - process parameter

Parameter Description

Set Point 1 & 2 Default temperature set point for CH1 and CH2

Timer 1 & 2 Default countdown timer for CH1 and CH2

PID 1&2 Kp Ki Kd Define the proper constant value for the PID algorithm tuning for CH1 /CH2

Reset DT 1 & 2 Define temperature variation from set point to reset the count down timer

Fridge delay 1 & 2 Define the duration of the fridge protection timer (0 means no delay logic)

Sample Time Define the sample time of temperature in ms

PWM Period Define the PWM period/window size for PWM control in ms

Ramp/Soak Define if the control logic is dynamic or static (see proper section)

Sound Alarm Define for each alarms if the buzzer is activated or not

SmartPID M5 PRO - profile definition

In the menu “profile” it’s possible to create/modify/view/delete temperature profiles

to be selected in the advanced running mode.

For each point of the profile user should define:

SP X that is the starting set point temperature

Ramp Time Y that is the time to move set point from X to X+1

Soak time Z that is the time the temperature is kept constant

If the ramp time = 0 the set point is moved instantly (step)

If the next step has soak time=0 (or is the eight steps) the SP

is moved to that value and is kept constant until the process

abort by user

SmartPID M5 PRO - ramp/soak

Ramp/soak = STATIC

Soak time start when ramp time finish independently from

temperature. Each soak period is predefined and is

independently from the current temperature and set point.

After each soak period a new set point is defined and a RAMP

time defines the time needed to reach the new set point. SP is

moved linearly from SPx to SPx+1 with increment of 1c/40f

If the next step hast soak time=0 (or is the eight steps) the SP

is moved to that value and is kept constant until the process

abort by user

Ramp/soak = DYNAMIC

Soak time start when temperature reach the set point. When

the temperature reached the SPx the soak period is started.

After each soak period a new set point is defined and a RAMP

time defines the time needed to reach the new set point. SP is

moved linearly from SPx to SPx+1 with increment of 1c/40f. If

the next step hast soak time=0 (or is the eight steps) the SP

is moved to that value and is kept constant until the process

abort by user.

SmartPID M5 PRO - monitor mode

Monitor mode allows to measure temperature of both channels and activate

manually the output (relay or DC)

CH1/CH2

temperature

DC output status

PWM 0-100%

Relay output status

PWM 0-100%

● Select Output

● Regulate PWM

● Activate Output

● Long press EXIT

wifi/cloud connection status

clock

SmartPID M5 PRO - run mode

In run mode smartPID execute the control loop (PID or ON/OFF) and drives the

outputs accordingly

CHx current

temperature

control

algorithm

PWM output

0-100%

Set Point change

● change view

● pause/resume

● stop

CHx current

set point

Events

notification

output status

heating/cooling/off

wifi/cloud connection status

clock /timer

SmartPID M5 PRO - run mode - graphic view

graphic mode reports the plot of CHx temperature, Set Point , PWM out

Change view

Stop

SmartPID M5 PRO - run mode - syntetic view

in this mode a systensys of both channel status and output is reported

Change view

Stop

CHx current

temperature

CHx current

set point

output status CHx

heating/cooling/off

Other SmartPID Controllers manuals