Megmeet MC100 Series User manual

1

MC100 Series PLC DC Quick Start

User Manual

Thank you for using Megmeet programmable logic controller (PLC).

Before using the MC100 series PLC product, please carefully read this

booklet so as to better understand it, fully use it, and ensure safety.

This quick start manual is to offer you a quick guide to the design,

installation, connection and maintenance of MC100 series PLC,

convenient for on-site reference. Briefly introduced in this booklet are

the hardware specs, features, and usage of MC100 series PLC, plus

the optional parts and FAQ for your reference. For detailed product

information, please refer to our MC100 Series PLC User Manual,

ControlStar Programming Software User Manual, and MC200/MC100

Series PLC Programming Manual. For ordering the above user

manuals, contact your Megmeet distributor or sales office.

1 Introduction

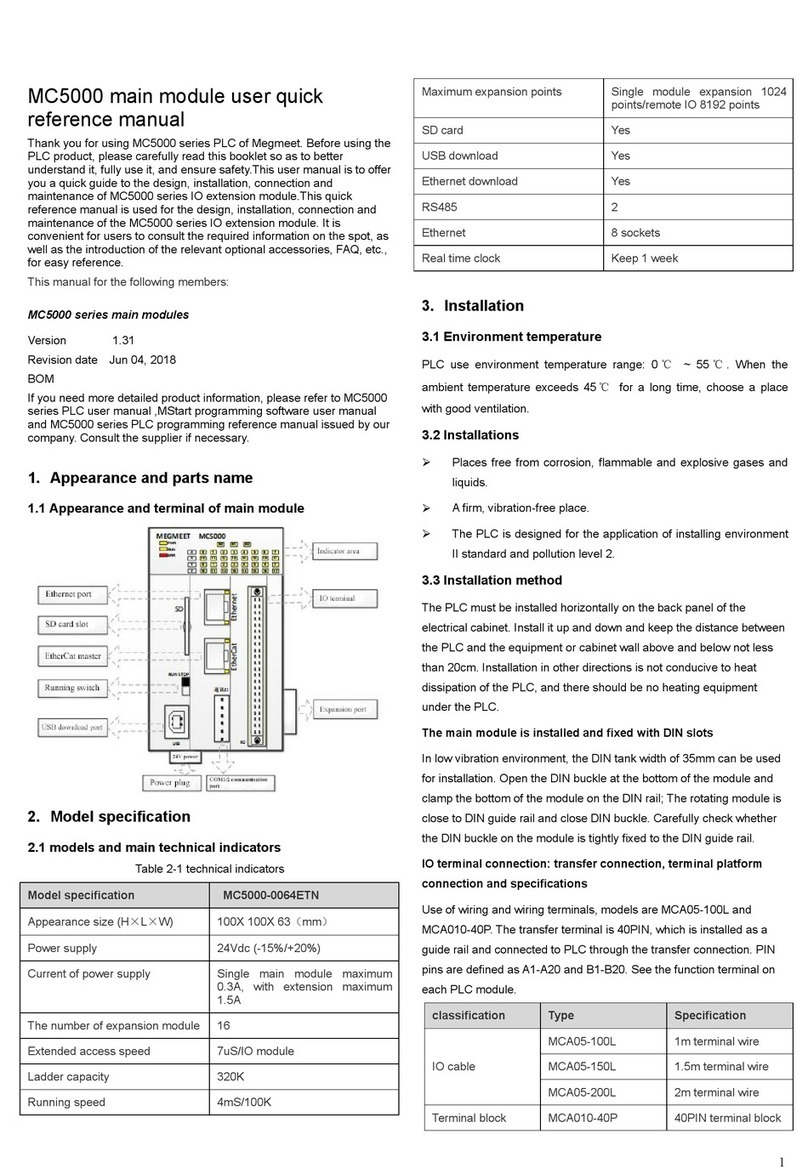

1.1 Model Designation

The model designation is shown in the following figure.

MC

1

0

0

-

16

16

E

T

N

-

X

A: AC220V power input

D: DC24V power input

N: no external power input

Output points: 16

Megmeet Controller module

Serial No.: 1: mini. 2: small. 3:

middle. 4: large.

Version No.

R: Relay mode

T: Transistor mode

Input points: 16

Sub-version, indicating the function/

structural change to the mainstream

module, following the alphabetic order

B: Basic module

E: Extension module

Special function added to

mainstream module (like 2

channels of AD). Starting with 0

1.2 Outline

The outline of the basic module is shown in the following figure by

taking the example of .

PORT0 and PORT1 are communication terminals. PORT0 uses RS232

mode with Mini DIN8 socket. PORT1 uses RS485 or RS232 mode. The

busbar socket is for connecting the extension module. The mode

selection switch has three positions: ON, TM and OFF.

1.3 Terminal Introduction

Different PLC has different terminal layout. Listed in the following table

are the terminals common in all PLCs.

Pin

Function

L/N

220Vac input live line and neutral line

Earth terminal

+24V

Auxiliary DC power for users’ external equipment, work with COM

COM

Negative pole of +24V auxiliary power

S/S

Input mode selection: sink mode when connected with +24V, or

source mode when connected with COM

●

Null, for isolation. Leave it suspended

The input & output terminals of different PLCs are shown below.

MC100-1410BTD

Terminal

Function

X0 ~ X15

Digital inputs, work with COM to generate input signal

Y0, COM0

Digital outputs, group 0

The COMx of different output

groups are isolated from each

other

Y1, COM1

Digital outputs, group 1

Y2~Y11,COM2

Digital outputs, group 2

MC100-1614BTD

Terminal

Function

X0 ~ X17

Digital inputs, work with COM to generate input signal

Y0, COM0

Digital outputs, group 0

The COMx of different output

groups are isolated from each

other

Y1, COM1

Digital outputs, group 1

Y2 ~ Y7, COM2

Digital outputs, group 2

Y10~Y15,COM3

Digital outputs, group 3

MC100-2416BRD, MC100-2416BTD

Terminal

Function

X0 ~ X27

Digital inputs, work with COM to generate input signal

Y0, COM0

Digital outputs, group 0

The COMx of different output

groups are isolated from each

other

Y1, COM1

Digital outputs, group 1

Y2 ~ Y7, COM2

Digital outputs, group 2

Y10~Y17,COM3

Digital outputs, group 3

MC100-3624BRD

Terminal

Function

X0 ~ X43

Digital inputs, work with COM to generate input signal

Y0, COM0

Digital outputs, group 0

The COMx of different output

groups are isolated from each

other

Y1, COM1

Digital outputs, group 1

Y2 ~ Y7, COM2

Digital outputs, group 2

Y10 ~ Y17, COM3

Digital outputs, group 3

Y20 ~ Y27, COM4

Digital outputs, group 4

2 Power Supply

The specification of PLC built-in power and power for extension

modules is listed in the following table.

Item

Unit

Min.

Rated

Max.

Note

Power supply

voltage

Vac

85

220

264

Normal startup and operation

Input current

A

/

/

1.5

Input: 90Vac, 100% output

Output

current

5V/GND

mA

/

900

/

The total power of outputs

5V/GND and 24V/GND ≤

10.4W. Max. output power:

24.8W (sum of all branches)

24V/GND

mA

/

300

/

24V/COM

mA

/

600

/

3 Digital Inputs & Outputs

Input Characteristic And Specification

The input characteristic and specs are shown as follows:

2

Item

High-speed input

terminals X0~X7

General input terminal

Input mode

Source mode or sink mode, set through s/s terminal

Electric

parameters

Input

voltage

24Vdc

Input

impedance

3.3kΩ

4.3kΩ

Input ON

External circuit resistance < 400Ω

Input OFF

External circuit resistance > 24kΩ

Filtering

function

Digital filter

X0~X17 have digital filtering function. Filtering time: 0,

8, 16, 32 or 64ms (selected through user programme)

Hardware

filter

Input terminals other than X0 ~ X17 are of hardware

filtering. Filtering time: about 8ms

High-speed function

X0~X7: high-speed counting, interrupt, and pulse

catching

X0 and X1: up to 50kHz counting frequency

X2~X5: up to 10kHz counting frequency

The sum of input frequency should be less than 60kHz

Common terminal

Only one common terminal: COM

The input terminal act as a counter has a limit over the maximum

frequency. Any frequency higher than that may result in incorrect

counting or abnormal system operation. Make sure that the input

terminal arrangement is reasonable and external sensors used are

proper.

4 Analog Inputs & Outputs

4.1 Usage Of Analog Terminals

MC100 series PLC provides the basic module with integated AD/DA

function, serving as a small-scale total solution with low cost for users

who need to control the analog signal.

The user terminals related to analog signals are defined below.

Terminal

Note

Terminal

Note

Analog input

AV1+

Input CH1: voltage input

Analog output

AVO+

Output CH: volt

signal output

AI1+

Input CH1: current input

AVI1-

Input CH1: common ground

AIO+

Output CH:

current output

AV2+

Input CH2: voltage input

AI2+

Input CH2: current input

AO-

Output CH:

common GND

AVI2-

Input CH2: common ground

Note:

Never input voltage signal and current signal to the same channel

simultaneously. When measuring the current signal, short the voltage

signal input terminal with the current signal input terminal

4.2 Analog Signal Input & Output Specs

The analog signal input and output specs is listed in the following table.

Item

Description

Max.

conversion

speed

AD conversion

4ms/2 channels

DA conversion

4ms/channel

Analog

input

range

Voltage input

-10 ~ 10Vdc (input impedance ≥ 200kΩ), input

signal freq. <10Hz. Warning: the unit could be

damaged with input voltage >±15Vdc

Current input

-20 ~ 20mA (input impedance: 250Ω), input

signal freq. <10Hz. Warning: the unit could be

damaged with input voltage >±30mA

Item

Description

Analog

output

range

Voltage output

-10~10Vdc(external load impedance:2kΩ~1MΩ)

Current output

0 ~ 20mA (external load impedance: ≤ 500Ω)

Digital range

-10000 ~ 10000

Resolution

Voltage I/O

5mV

Current I/O

10µA

Total

precision

Analog input

DC -10 ~ 10V, -20 ~ 20mA:±1%

Analog output

±1%

Isolation

Between analog circuit and digital circuit: optical

coupler. Between analog channels: none

5 Communication Port

MC100 series PLC basic module has two serial asynchronous

communication ports: PORT0 and PORT1. Supported baud rates:

115200 bps

57600 bps

38400 bps

19200 bps

9600 bps

4800 bps

2400 bps

1200 bps

The mode selection switch determines the communication protocol.

RS485 terminal

Mode selection

switch

RS232 terminal

A

PORT0

A amplified

Pin No. Description

Ground

3 GND

4 RXD

Serial data

receiving pin (from

RS232 to PLC)

5 TXD

Serial data

transmitting pin (from

PLC to RS232)

1,

2,

6,

7,8 Reserved Undefined pin,

leave it suspended

87 6

54 3

21

PORT1

Name

As a terminal dedicated to user programming, PORT0 can be

converted to programming protocol through the mode selection switch.

The relationship between PLC operation status and the protocol used

by PORT0 is shown in the following table.

Mode selection

switch position

status

PORT0 operation protocol

ON

Running

Programming protocol, or Modbus protocol,

or free-port protocol, or N: N network protocol

(ECBUS), as determined by user program

and system configuration

ONTM

Running

Converted to programming protocol

OFFTM

Stop

OFF

Stop

If the system configuration of user program is

free-port protocol, it converts to programming

protocol automatically after stop; or system

protocol keeps unchanged

PORT1 is ideal for connection with equipment that can communicate

(such as inverters). With Modbus protocol or RS485 terminal free

protocol, it can control multiple devices through the network. Its

terminals are fixed with screws. You can use a shielded twisted-pair as

the signal cable to connect communication ports by yourself.

Note: Never use RS232 terminal and RS485 at the same time. Besides,

suspend the unused terminals, or communication could be interrupted.

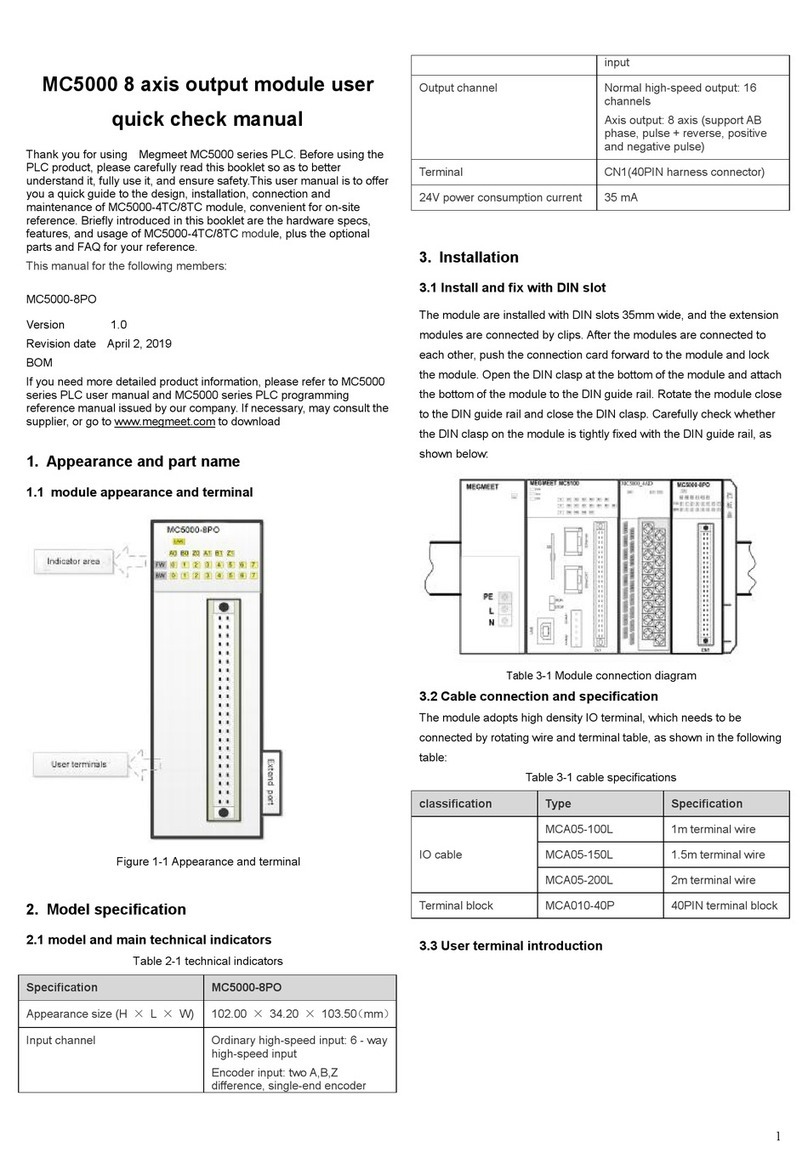

6 Installation

PLC is applicable to Installation category II, Pollution degree 2.

3

6.1 Installation Dimensions (Unit: mm)

The dimensions for the outline and mounting holes of MC100-1410BTD

are shown below:

The dimensions for the outline and mounting holes of MC100-1614BTD

are shown in the following figure:

The dimensions for the outline and mounting holes of MC100-2416BRD

and MC100-2416BTD are shown in the following figure.

The dimensions for the outline and mounting holes of MC100-3624BRD

are shown below:

6.2 Installation Position

Mount the PLC onto the cabinet backboard horizontally. You must

provide a clearance of at least 15cm, both above and below the unit, for

proper cooling. Never mount them to the floor or ceiling of an enclosure

or other directions. See the following figure. No heat generating

equipment should be around the PLC.

6.3 Installation Method

DIN rail mounting

Generally you can mount the PLC onto a 35mm-wide rail (DIN), as

shown in the following figure.

Screw fixing

Fixing the PLC with screws can stand greater shock than DIN rail

mounting. Use M3 screws through the mounting holes on PLC

enclosure to fix the PLC onto the backboard of the electric cabinet, as

shown in the following figure.

6.4 Cable Specs

When wiring a PLC, use multi-strand copper wire and ready-made

insulated terminals to ensure the quality. The recommended model and

the cross-sectional area of the cable are shown in the following table.

Wire

Cross-sectional

area

Recommended

model

Cable lug and

heat-shrink tube

AC power

cable (L, N)

1.0~2.0mm²

AWG12, 18

H1.5/14 round insulated

lug, or tinned cable lug

Earth cable

( )

2.0mm²

AWG12

H2.0/14 round insulated

lug, or tinned cable end

Input signal

cable (X)

0.8~1.0mm²

AWG18, 20

UT1-3 or OT1-3

solderless lug

Φ3 or Φ4heat

shrinkable tube

Output signal

cable (Y)

0.8~1.0mm²

AWG18, 20

Fix the prepared cable head onto the PLC terminals with screws.

Fastening torque: 0.5~0.8Nm.

The recommended cable processing-method is shown in the following

figure.

4

≤ 5.0 ≤ 5.0

UT solderless lug Heat shrinkable tube

Cable SN label

Cable

OT solderless lug Heat shrinkable tube

H type round insulated lug

Tinned cable end Cable

PG

18

47

682

7 Power-on Operation And Maintenance

Startup

Check the cable connection carefully. Make sure that the PLC is clear

of alien objects and the heat dissipation channel is clear.

1. Power on the PLC, the PLC POWER indicator should be on.

2. Start the Controlstar software on the host and download the

compiled user program to the PLC.

3. After checking the download program, switch the mode selection

switch to the ON position, the RUN indicator should be on. If the ERR

indicator is on, the user program or the system is faulty. Loop up in the

MC200/MC100 series PLC Programming Manual and remove the fault.

4. Power on the PLC external system to start system debugging.

Routine maintenance

Do the following:

1. Ensure the PLC a clean environment. Protect it from aliens and dust.

2. Keep the ventilation and heat dissipation of PLC in good condition.

3. Ensure that the cable connections are reliable and in good condition.

Notice

1. The warranty range is confined to the PLC only.

2. Warranty period is 18 months, within which period Megmeet

Network Power conducts free maintenance and repairing to the PLC

that has any fault or damage under the normal operation conditions.

3. The start time of warranty period is the delivery date of the

product, of which the product SN is the sole basis of judgment. PLC

without a product SN shall be regarded as out of warranty.

4. Even within 18 months, maintenance will also be charged in the

following situations:

Damages incurred to the PLC due to mis-operations, which are

not in compliance with the User Manual;

Damages incurred to the PLC due to fire, flood, abnormal voltage,

etc;

Damages incurred to the PLC due to the improper use of PLC

functions.

5. The service fee will be charged according to the actual costs. If there

is any contract, the contract prevails.

6. Please keep this paper and show this paper to the maintenance unit

when the product needs to be repaired.

7. If you have any question, please contact the distributor or our

company directly.

Shenzhen Megmeet Control Technology Co.,Ltd

Address: 5th Floor,Block B,Ziguang Information Harbor, Langshan Rd,

Science& Technology Park, Nahshan District, Shenzhen

Homepage: www.megmeet.com

Copyright © 2011 by Shenzhen Megmeet Control Technology Co.,Ltd

All rights reserved. The contents in this document are subject to change

without notice.

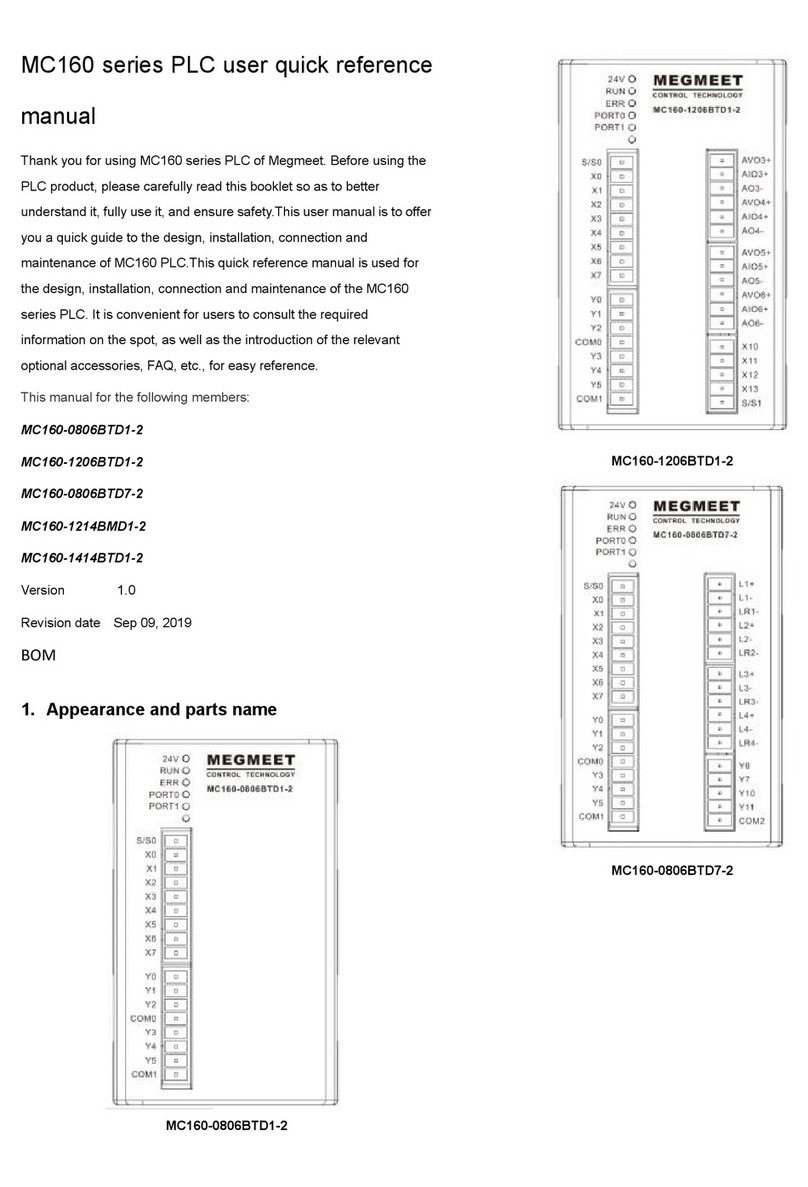

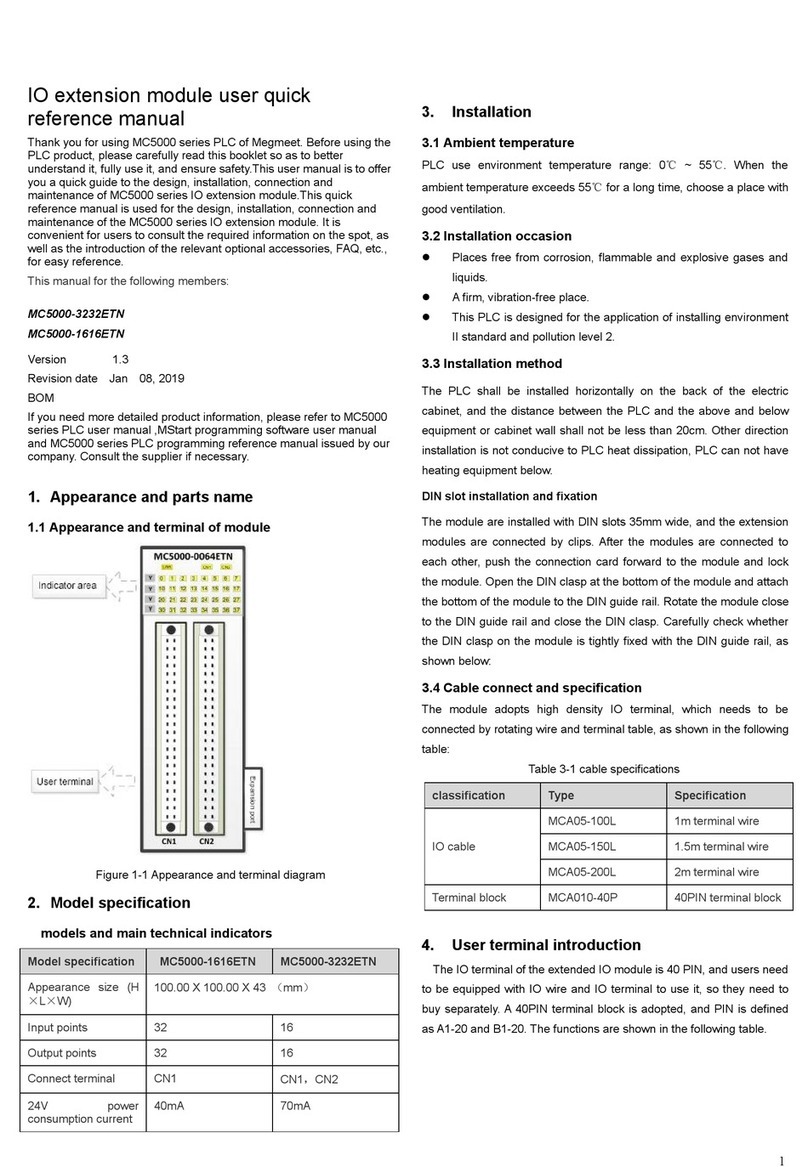

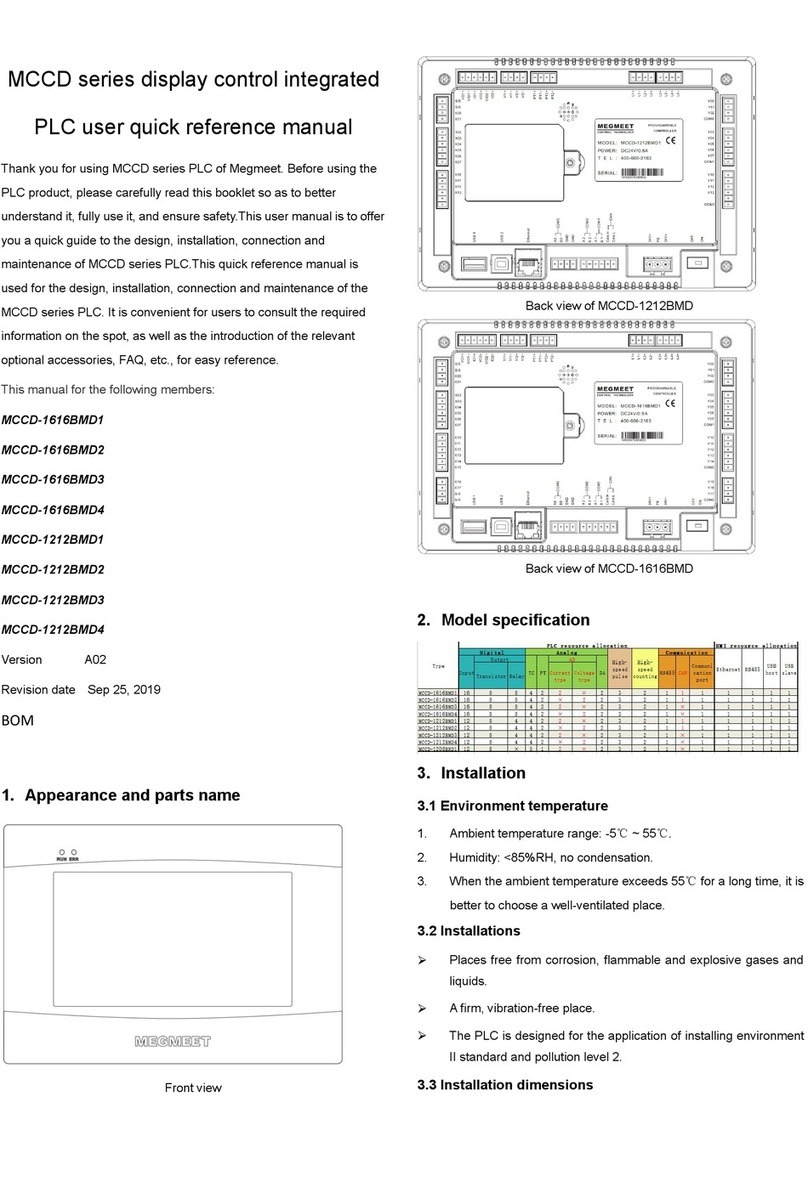

This manual suits for next models

5

Other Megmeet Controllers manuals

Megmeet

Megmeet MV820 User manual

Megmeet

Megmeet MC160 PLC Series User manual

Megmeet

Megmeet MC200E Series Manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet L6 Series User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MCCD Series Service manual

Popular Controllers manuals by other brands

Preferred

Preferred JC-23D2 Installation & operation instructions

Festo

Festo VZXA Series operating instructions

tecatlantis

tecatlantis LUMINUS operating manual

Extron electronics

Extron electronics MLC Plus 84 D Setup guide

Pixel

Pixel EM-181Mu user guide

National Instruments

National Instruments cFP-22 Series manual