Smartpond Filter User manual

Instruction manual

Instruction manual EBF / EBF ECO Page 1 of 19

11/2013

Table of Contents

1Read this first........................................................................................................................................... 1

1.1 Symbols and used terms........................................................................................................................ 3

1.2 Responsibilities ...................................................................................................................................... 4

2Technical Data ......................................................................................................................................... 5

2.1 Control unit box..................................................................................................................................... 5

2.1.1 Control elements............................................................................................................................... 5

2.1.2 Mounting of the control unit box...................................................................................................... 5

2.1.3 Power outputs................................................................................................................................... 6

2.1.4 Control unit circuit board .................................................................................................................. 7

3Model EBF................................................................................................................................................ 8

3.1 Application............................................................................................................................................. 8

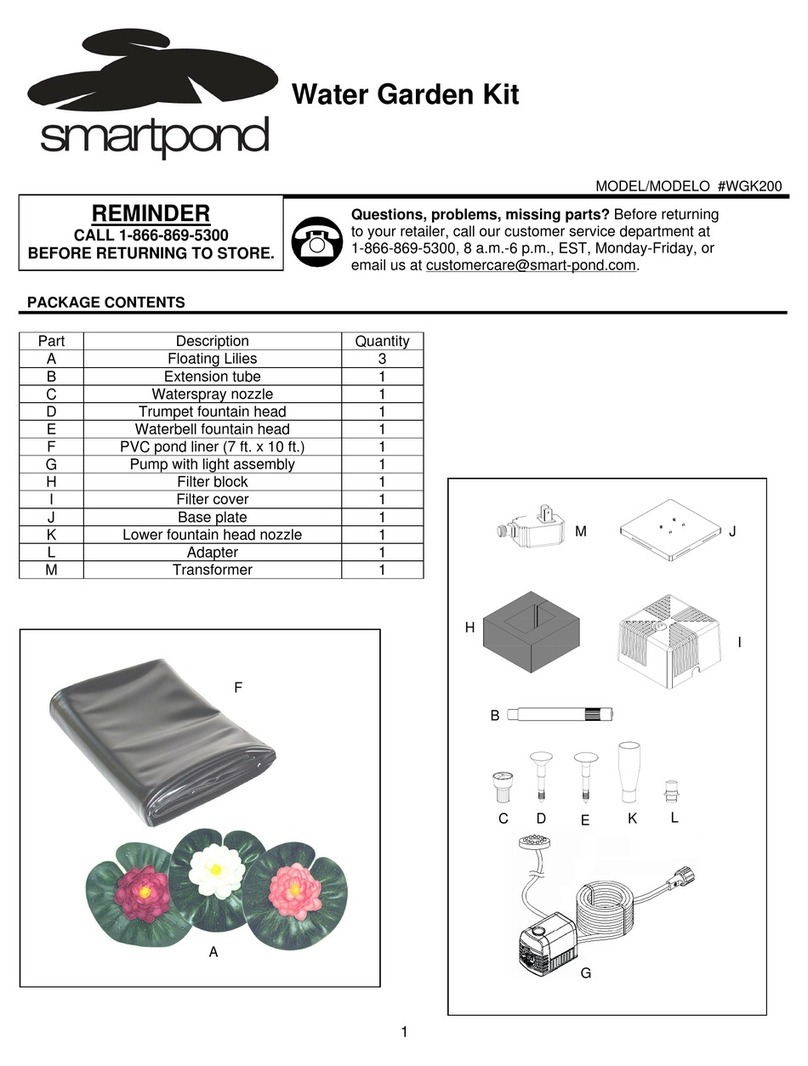

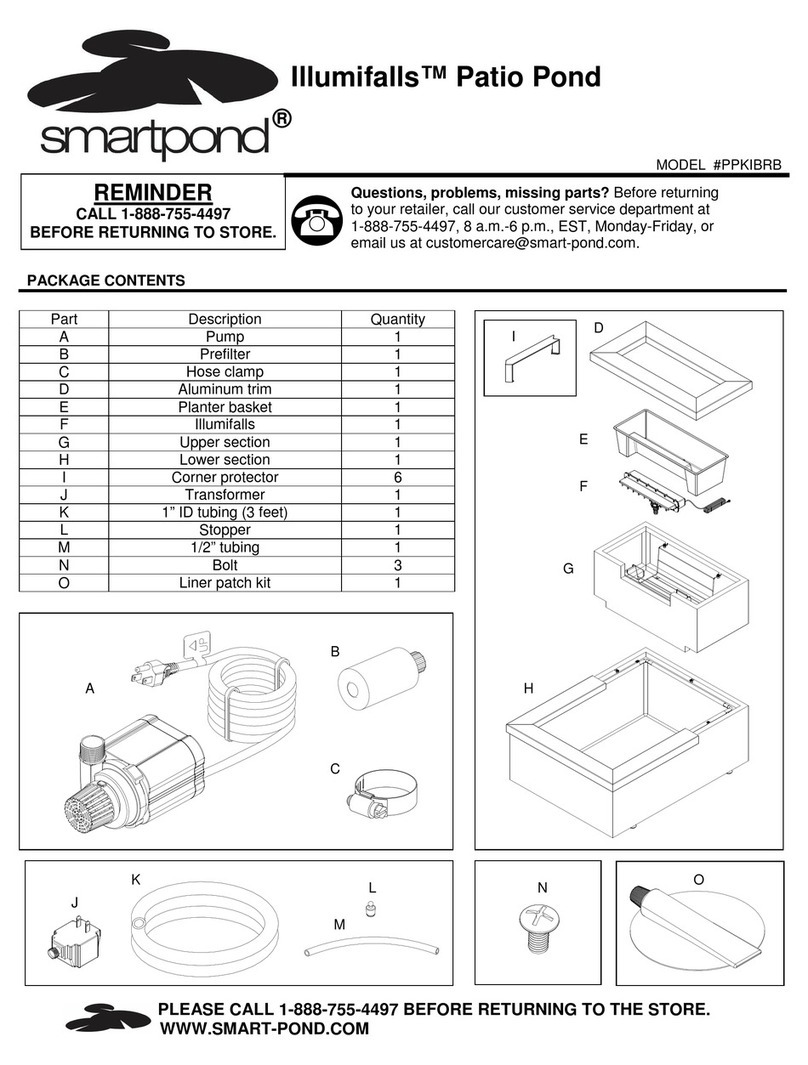

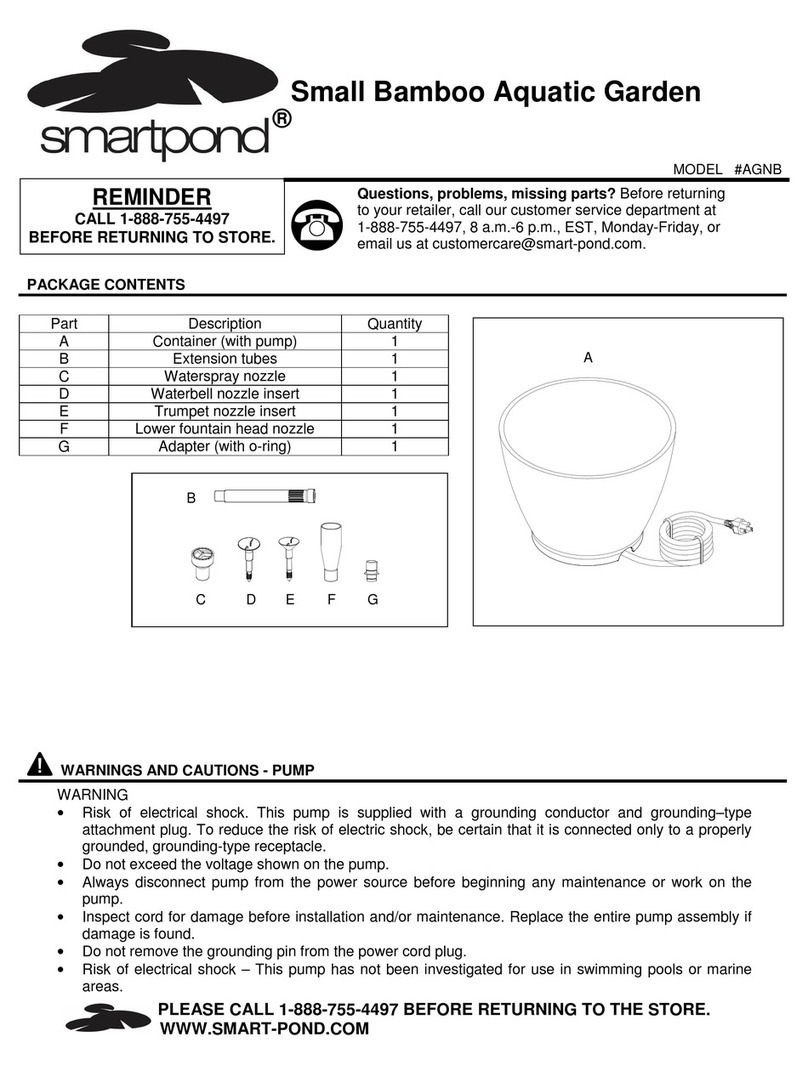

3.2 Delivery form ......................................................................................................................................... 8

3.3 Installation............................................................................................................................................. 8

3.3.1 Mechanical installation ..................................................................................................................... 8

3.3.2 Electrical installation ....................................................................................................................... 11

3.4 Commissioning .................................................................................................................................... 11

4Local settings ......................................................................................................................................... 11

4.1 Running times...................................................................................................................................... 12

4.2 Float gauge .......................................................................................................................................... 13

5Optional accessories .............................................................................................................................. 13

5.1 Drying/Overflow protection ................................................................................................................ 13

5.2 Integrated immersing UV-C ................................................................................................................. 14

6Maintenance and servicing .................................................................................................................... 14

6.1 Cleaning of filter belt ........................................................................................................................... 14

6.2 Replacement of the filter belt ............................................................................................................. 16

6.3 Cleaning of the fine filter and pressure pump..................................................................................... 17

6.4 Cleaning of the float gauge.................................................................................................................. 17

6.5 Cleaning of the belt spraying nozzle.................................................................................................... 17

7Replacement / Guarantee...................................................................................................................... 18

7.1 Further instructions ............................................................................................................................. 19

Copyright: This instruction manual is the intellectual property of the firm AquaFil Teichfiltration. It may only be copied for installation purposes and for operating the Smartpond®Filter.

The Smartpond®Filter shall be used for its intended purpose of used.

Read this first

Symbols and used terms

Instruction manual EBF / EBF ECO page 2 of 19

11/2014

1Read this first

Application of this

instruction manual

This instruction manual provides the installer of this plant, its owner and

the expert personnel with some important information regarding

installation and maintenance of the plant and general information

regarding its safe operation.

Use

The described plant shall only be operated for its intended purpose of use

within the defined field of application. For filtration of special liquids and

any use in the industrial field, the manufacturer shall be consulted.

Intended purpose of use

The Smartpond® continuous belt filters are generally intended for use in

cleaning and filtration of solids from liquids. Field of application includes

industries, fish farming, sewage treatment plants and fish and swimming

ponds.

Liability

If the plant is operated for a purpose beyond the field of application or if

it is modified, it would no longer be considered in use for the intended

purpose. In such cases, the manufacturer will not accept any liability.

We recommend the settings ‘‘dry-run protection with S-version’’ and

‘‘overflow protection with G-version’’ for high pumping output.

Dismantling and

disassembling

The dismantling or disassembling of a Smartpond® filter plant shall only

be carried out by an authorised Smartpond® retailer or qualified

personnel or with their consent/instructions.

Safety

Before opening the terminal box cover, make sure to disconnect the

power cable from the mains!

Read this first

Symbols and used terms

Instruction manual EBF / EBF ECO page 3 of 19

11/2014

1.1 Symbols and used terms

Warning

This symbol gives a warning message which, if ignored, could lead to

injuries or substantial property damage

This warning message shall be taken seriously in any case!

Instruction

This symbol draws your attention to important information. When

ignored, damage to the plant or errors may be caused.

G-Model

Text or description which relates to the G-Model

(pumped version)

S-Model

Text or description which relates to the S-Model

(gravity version)

Plant

Complete Smartpond®Filter equipment as described in this instruction

manual.

Guarantee

For guarantee claims, it is important to leave the plant unmodified in its

original state and frost-proof (verifiable).

Any modification, adjustments, upgrading etc of the plant would lead to

loss of guarantee claims.

Owner of the plant

The person or firm that owns the plant and is responsible for its operation

and maintenance.

Skilled personnel

People who are trained for carrying out installation and maintenance

work. People who are aware of the potential dangers associated with use

of the plant and have the required tools and resources available at their

disposal.

Assembly work

All the work procedures and measures required for safe and proper

commissioning of the plant.

Error

The operating state which limits the operation of the plant or makes its

impossible.

Read this first

Responsibilities

Instruction manual EBF / EBF ECO page 4 of 19

11/2014

1.2 Responsibilities

Obligations of the

owner

The owner of the plant shall assure that:

the plant is kept in a safe operating state,

this instruction manual is provided to the expert staff members,

maintenance work is carried out on the plant after regular time

intervals.

Responsibility

Only expert personnel shall take charge of the following tasks:

installation

connecting the electrical components

setting the electrical components

the maintenance work

Manufacturer

Name AquaFil GmbH

Address Stuben14, 6030 Ebikon

Country Switzerland

Contact www.AquaFil.org

Local retailer /

Sub-supplier /

Distributer

(Factory label)

Technical Data

Control unit box

Instruction manual EBF / EBF ECO page 5 of 19

11/2014

2Technical Data

See www.AquaFil.org : Click on Filter and selected the desired type:

“Explosionszeichnung” (exploded assembly drawing)

2.1 Control unit box

2.1.1 Control elements

Warning

Before opening the terminal box cover, make sure to disconnect the

power cable from the mains!

With the push button T1, the spraying pump AND the conveyor belt can

be manually controlled.

If only the conveyor belt has to be driven, the plug of the spraying pump

shall then be disconnected. As long as the button is pressed, the conveyor

belt will keep moving.

For testing the spraying pump (likewise with push button T1), disturbance

would not be caused normally if the conveyor belt moves alongside.

If only the spraying pump has to be tested, the plug can be inserted into

the spare power socket or the plug from the engine of the conveyor belt

has to be removed (for this, the cover box must be removed from the

engine first).

2.1.2 Mounting of the control unit box

The screws for mounting are provided in the control unit box.

For mounting the control unit box in the plant, there are two possible

ways to proceed:

Pos. front

Pos. right

Technical Data

Control unit box

Instruction manual EBF / EBF ECO page 6 of 19

11/2014

2.1.3 Power outputs

Lower side of the control unit box

At the lower side of the control cabinet, the cable outputs are visible on

the left side (L1 –L5):

L1

Lead for control unit box

Please insert in a 220VAC socket, which is secured with a FI protective

switch.

L2

Lead for belt drive

This cable is connected with the 24VDC motor in the motor box through

the 2 pole crimp connector.

L3

Float gauge sensor

With this 2 pole connector, the float gauge level B1 is connected through

the soldered 2 pole socket (insert and tighten the connecting nuts

securely).

L4

Option: Dry running/

Overflow protection

When the option ‘‘Dry running / Overflow protection’’ is selected, the

float gauge B4 is connected with this 2 pole connector through the pole

soldered socket (insert and tighten the connecting nuts securely).

L5

Option UV-C Switch

When the option UVC-circuit is ordered, the protective switch B2 is

connected with this 2 pole connector through the soldered 2-pole socket

(insert and tighten the connecting nuts securely).

Attention

When the leads L3 to L5 are plugged in, it shall be made sure that the

correct signal generator (float gauge, switch etc.) is connected to the

respective connector.

Technical Data

Control unit box

Instruction manual EBF / EBF ECO page 7 of 19

11/2014

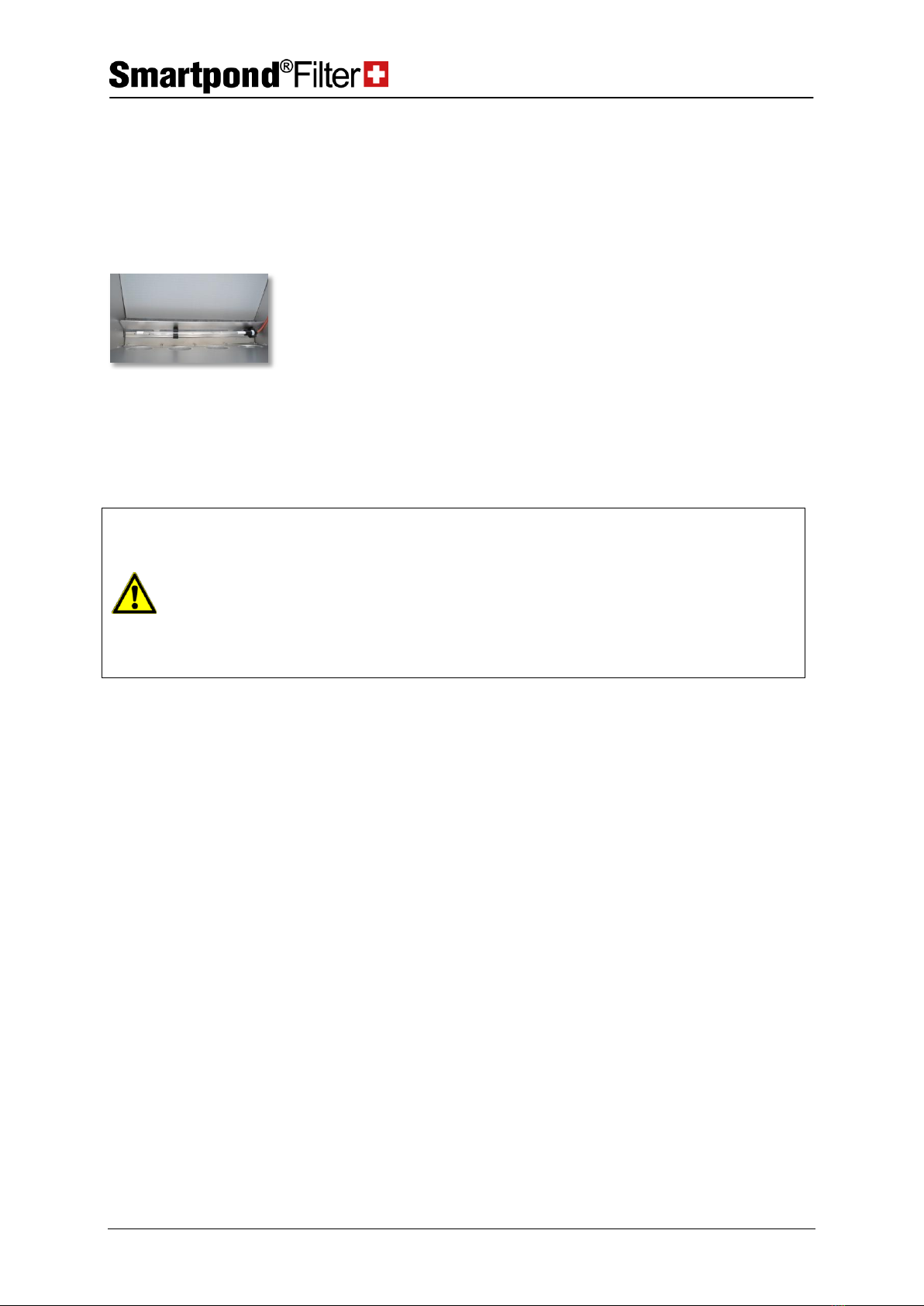

2.1.4 Control unit circuit board

On the control unit circuit board, several LEDs (H1-H6) are available for

control purposes. They are visible all the time through the closed

transparent cover of the control unit box:

Picture control LED’s

H1

24V

Supply voltage 24VDC

(must light up during operation)

H2

3.3V

Internal circuit board voltage 3.3VDC

(must light up during operation)

H3

Float gauge sensor

Lights green when the float gauge sensor (B1) is active.

H4

Pump

Lights green when the power socket output for ‘‘spraying pump’’ is

triggered/activated.

H5

Belt drive

Lights green when the output for belt drive is triggered.

H6

Error

Lights red when the belt drive motor overloads (after 5 attempts).

Reset error by pushing the manual control (push button T1 –page 5)

Model EBF

Application

Instruction manual EBF / EBF ECO page 8 of 19

11/2014

3Model EBF

3.1 Application

The Pumped version is ideal for koi pond and pond owners who have

installed a pump directly in their pond or in a collecting chamber and

pump the contaminated water into the filter. In this system the outlet of

the biological stage lies above the pond level. The water flows back into

the pond according to the principal of gravity.

The Gravity version is suitable for koi and pond owners who have

installed floor drains and/or float gauges in their pond. With this system,

the pond water flows directly through large pipes into the Smartpond®

filter by gravity. With a pump the cleaned water is again pumped back

into the pond.

3.2 Delivery form

The plants are delivered in completely assembled state.

The unused tank ducts can be sealed from inside with silicone and the

discs delivered alongside.

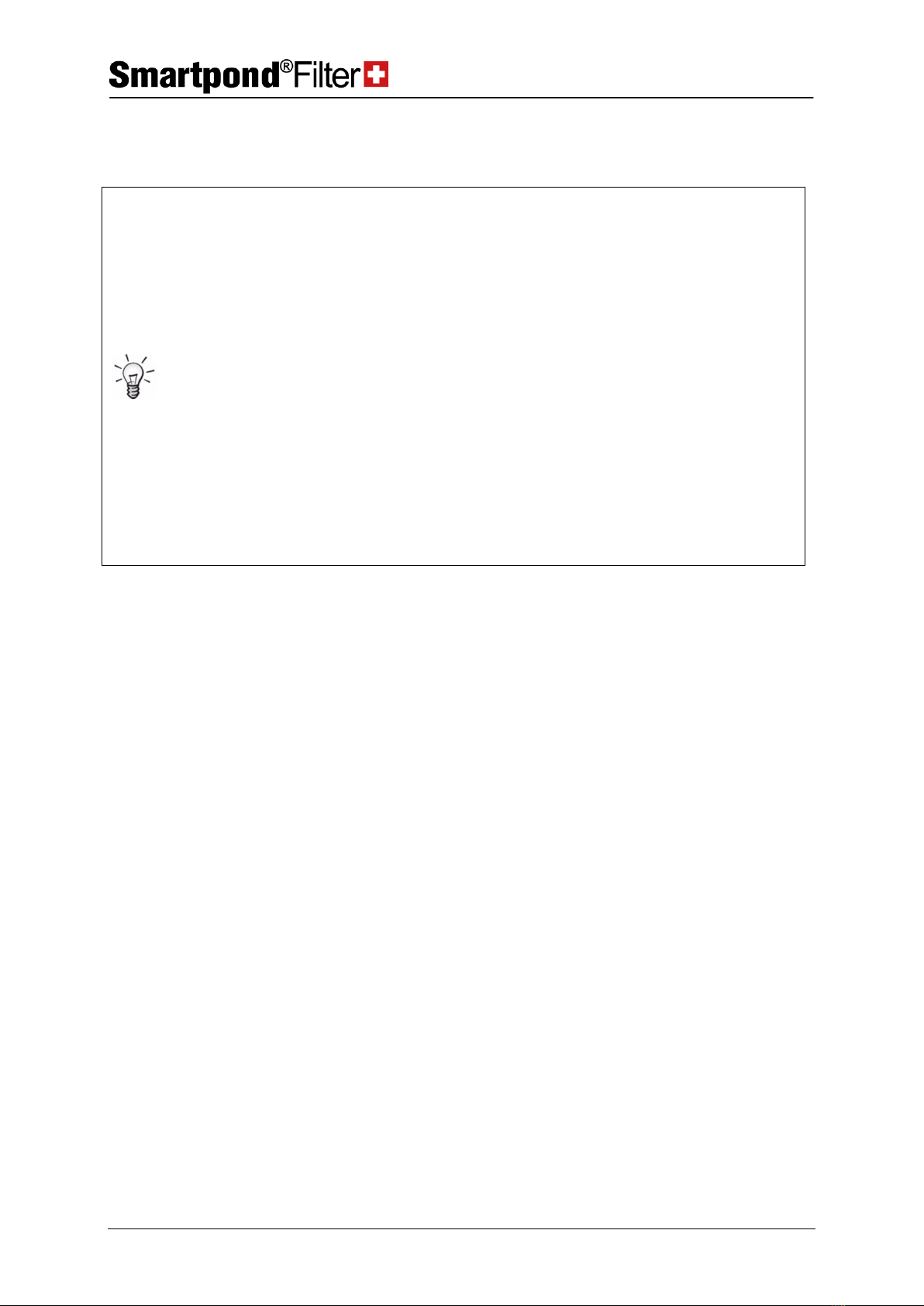

(see picture)

3.3 Installation

3.3.1 Mechanical installation

Instruction

The filter must be installed frost-free. If this is not done, no guarantee can

be claimed for damage cause by frost.

The filter must be positioned on a plain and solid foundation. Ideally, the

filter is placed on a thin Styrofoam /Styrodur layer. This would provide an

even surface and prevent scratches from appearing on the filter base.

Instruction

It must be assured that the backflow to the pond takes place through an

adequate number of pipes to prevent build-up of backwater in the filter.

Instruction

The upper edge of the filter is positioned 10 cm higher than the pond

water level. 10 cm is the minimum value and the filter shall not be

positioned lower than this.

In order to comply with this value, the pond shall have an overflow outlet.

If the filter is installed more than 10 cm above the water level in the

pond, the filtration efficiency will fall. Ideally, the maximum water level in

the pond shall be limited through an overflow outlet.

Filter inputs

The filters are equipped with welded pipe sockets for D110mm pipes.

Model EBF

Installation

Instruction manual EBF / EBF ECO page 9 of 19

11/2014

Every intake point to the filter shall be fitted with slide or ball valves.

For the G-Version or high pumping outputs, the water shall be distributed

in several inflow pipe sockets so that it can reach the filter quietly.

Filter outputs

The Smartpond® continuous belt filters are delivered together with

D 110mm tank screws for the return flow. Further a drill hole (or even a

second one depending on the model) is present for screw joints with D

75mm. The PVC screw joint for this is not provided in the delivery

package.

In the PVC tank screws, short pipe fittings shall be bonded onto so that

pipes having a sealing ring can easily be pushed onto. Like this

disassembly of the inlets is assured without having to saw off any pipes.

Instruction

It shall be assured in particular that the water feedback system to the

pond is large enough to prevent build-up of backwater in the filter.

In order to maintain a certain water level in the bio-stage for biological

organisms, the bio-stage outlets are turned upwards with a 90° elbow,

and with a T-joint, the pond is re-conected. The height relations of the T-

joint determine the water level in the bio-stage (see picture).

T-Drain pipe to the pond

(not included in the delivery

package)

The height from the

ground to centre of the T-

drain pipe shall be set to

approx. 40–45 cm (30-35cm

for EBF ECO).

Overflow pipe

In the filter, an overflow pipe shall also be installed with a height of up to

65 cm above ground level. This serves as overflow prevention in case if

the filter basket in the bio-stage is clogged with sludge. The safety

opening at the top shall be not covered with any filter basket or the like

but must rather remain completely open.

Model EBF

Installation

Instruction manual EBF / EBF ECO page 10 of 19

11/2014

Positioning of the pond

pumps

Feed pumps can be set up In the bio-stage or outside the filter ‘‘dryly’’.

In order to keep biological organisms away from the pumps, a slotted pipe

can also be delivered optionally.

Dirty water drain

The dirty water drain is present at the right side of the filter. Please take

this into consideration during the planning.

Dirty water drain with 110 mm elbow

Setting of the safety overflow

With the overflow plate mounted in the filter, emergency water supply can

be adjusted for the pumps and biological life.

Function

If the contaminated filter belt cannot be driven further for some reason,

the water level in the filter module will increase and the pond water will

rise above the overflow plate in the bio-pond.

Setting

The overflow slit shall be kept as wide as possible. The overflow edge of

the overflow plate is positioned around 1 cm above the water level in the

filter (before the flushing process begins) and tightly screwed. The factory

default setting is 13 cm as shown in the picture below.

Local settings

Commissioning

Instruction manual EBF / EBF ECO page 11 of 19

11/2014

3.3.2 Electrical installation

Warning

Before handling the filter, the power plug shall be drawn out of the main

power supply socket for safety reasons.

The filter is delivered in mounted and operational mode. The control unit

box must be protected from rain/water and moisture and hung up in frost-

free surroundings.

Warning

FI switch: With regard to electrical installation of the plant, it must be

assured that the power supply is passed through a residual-current circuit

breaker

The switch in the control unit box is designed for a total of 16 A of current.

Instruction

In order to guarantee the safety functions, the pond pumps and pressure

pump as well as the optional immersing UV-C shall be directly connected to

the control unit box.

3.4 Commissioning

After the filter has been properly positioned, all supply and return pipes

have been installed and ca. 40cm water has been allowed to enter, the

power cable can be connected with the mains.

4Local settings

Fuses for the power sockets in the control unit box

F2 spraying pump –T 8A

F3 UVC –T 1.25A

F4 pond pump –T 5A

Warning

Only use slow-blow fuses (5x20mm)!

Local settings

Running times

Instruction manual EBF / EBF ECO page 12 of 19

11/2014

4.1 Running times

The feed times etc are adjusted in the control unit box using three

potentiometers according to the conditions of the local pond area.

Warning

Before the control unit box is opened, the supply cable is disconnected

from the power socket!

3 Potentiometers

On the Smartpond® circuit board, there are three potentiometers with the

following designations:

P1 Left

P2 Centre

P3 Right

Delay of the pump

Waiting time

Running time

P1 P2 P3

Functioning of the control unit

Start of the cleaning

cycle

B1 (float gauge)

When the fault gauge sensor B1 is pressed, the cleaning cycle begins. The

spraying pump is triggered for this purpose (Output A2 = power socket for

spraying pump).

Delay of the pump

P1

After a fixed delay time of 1 sec, the time P1 begins (delay of the pump)

which can be adjusted between from 0.1 to 10 sec.

Default setting ex factory: 0.1 Sec. = minimum; left-hand limit stop

After this time lapses, the conveyor belt starts moving (Lead L2)

Running time of the

conveyor belt

P3

The conveyor belt runs for a specific running time (P3) which can be varied

between 2 and 20 sec.

Default setting ex factory: ca. 11 sec. = Mean (ca. 12:00)

End of the cleaning

cycle

After the P3 time period lapses, the conveyor belt stops to move. But the

spraying pump operates for a fixed programmed time of 1 sec longer so

that no dirt remains on the belt or reaches the clean bio-chamber.

Waiting time till the

next cycle possible

P2

After the spray nozzle stops, the delay time P2 (waiting time) begins, which

can be varied between 5 and 30 sec.

Default setting ex factory: 30 sec. =max; right-hand limit stop

After the waiting period has passed, a new cleaning cycle can begin (if the

float gauge sensor is activated).

Optional accessories

Float gauge

Instruction manual EBF / EBF ECO page 13 of 19

11/2014

4.2 Float gauge

The float gauge (B1) is firmly installed at the top in the filter module and

its height can easily be adjusted.

For the gravity system version of the plant, the float gauge (B1) is

positioned below in the bio-pond. By moving the support pipe, this can be

vertically displaced. In this way, the water level in the bio-pond is defined.

With a water level above the slotted overflow plate, the noise of the

water can be largely reduced.

Fault gauge

(B1) Fault gauge

(B2) - Drying/Overflow protection

G-Version S-Version

5Optional accessories

5.1 Drying/Overflow protection

For this option, a second fault gauge is also installed (B2).

For the Pumped version, the second fault gauge (B2- recognisable at the

external black floating body) is mounted at the top part of the filter

chamber which switches the pump off before the filter overflows

(overflow protection)!

If the water level falls below the level of the second float gauge (B2), the

pump and immersion UV-C will be switched off. In this way, the pump

and the biological life in the water will not dry up (dry-running

protection).

The UV-C is switched on 20 seconds after restarting regular operation.

Function

These protection options provide additional protection to your pond and

pump.

Pumping output

For pumping output above 40,000l/H, the option ‘‘overflow protection’’ is

Maintenance and servicing

Integrated immersing UV-C

Instruction manual EBF / EBF ECO page 14 of 19

11/2014

>40.000 l/h

highly recommended for all Pumped models!

If the overflow protection system has not been installed, the manufacturer

will reject any claims for damage arising through pumping out/dry of the

pond.

5.2 Integrated immersing UV-C

The Smartpond® immersing UV-C can directly integrated in the filter. For

this purpose, a UV-C belt protection plate shall be built in since otherwise,

the filter belt may be damaged by the UV-C rays.

Connection

The Smartpond® immersing UV-C is connected at the control unit box.

Option

The filter can optionally be equipped with a UV-C switch-off feature.

Through this, the immersing UV-C will automatically switch off on

removal of the protective cover.

Warning

If the additional option “UV-C disconnection’’ has not been selected and

the filter is accessible to third parties, the owner of the plant shall ensure

that adequate safety measures are in place on-site in order to rule out

the possibility of UV-C irradiation.

Never lay down the immersion UV-C on the filter belt. It shall only be

placed in the UV-C holder specifically designed for it. The material can get

damaged through UV-C exposure!

6Maintenance and servicing

6.1 Cleaning of filter belt

Depending on the degree of contamination, the throughput volume on

the filter belt may be reduced after some time or the rinsing water

consumption may be increased since a bio-film or lime deposit forms up

on the filter belt.

A narrow strip of dirt may be formed on the filter belt in the direction of

movement due to blocking of a belt spraying nozzle. In this case, the

nozzle has to be cleaned (see 6.5 Cleaning of belt spraying nozzle).

The filter belt can be sprayed and washed up with the following

detergents according to the manufacturer:

Here is an overview of the resistance of the polyester filter belt fabric to various detergents (details provided

by the manufacturer):

Maintenance and servicing

Cleaning of filter belt

Instruction manual EBF / EBF ECO page 15 of 19

11/2014

Detergent

Concentration

Resistance

Hydrochloric acid (HCl)

5 %

good

16 %

optimal

20 %

limited

> 35 %

not resistant

Citric acid (C6H8O7)

100 %

very good

Table vinegar

100 %

Very good (our

recommendation)

Hydrogen peroxide (H2O2)

3 %

Very good

Instruction

The selected detergent shall be applied and allowed to have effect for at

least 15 minutes. The filter belt should be as dry as possible.

The water level in the bio-pond should lie below the filter stage (filter

belt).

High-pressure cleaner

The belt can cleaned with high pressure (max. 120 bar) of cold water with

a distance of more than 15 cm, but without any guarantee.

Instruction

The use with a high-pressure cleaner is not guaranteed by the belt

manufacturer and can be carried out at own risk. However, we have

obtained some good results for it in extensive tests.

Maintenance and servicing

Replacement of the filter belt

Instruction manual EBF / EBF ECO page 16 of 19

11/2014

6.2 Replacement of the filter belt

The filter belt only needs to be replaced when it has been mechanically

damaged or possesses a defect caused by external influences.

Instruction

Draw out the power cable so that the belt does not run unintentionally!

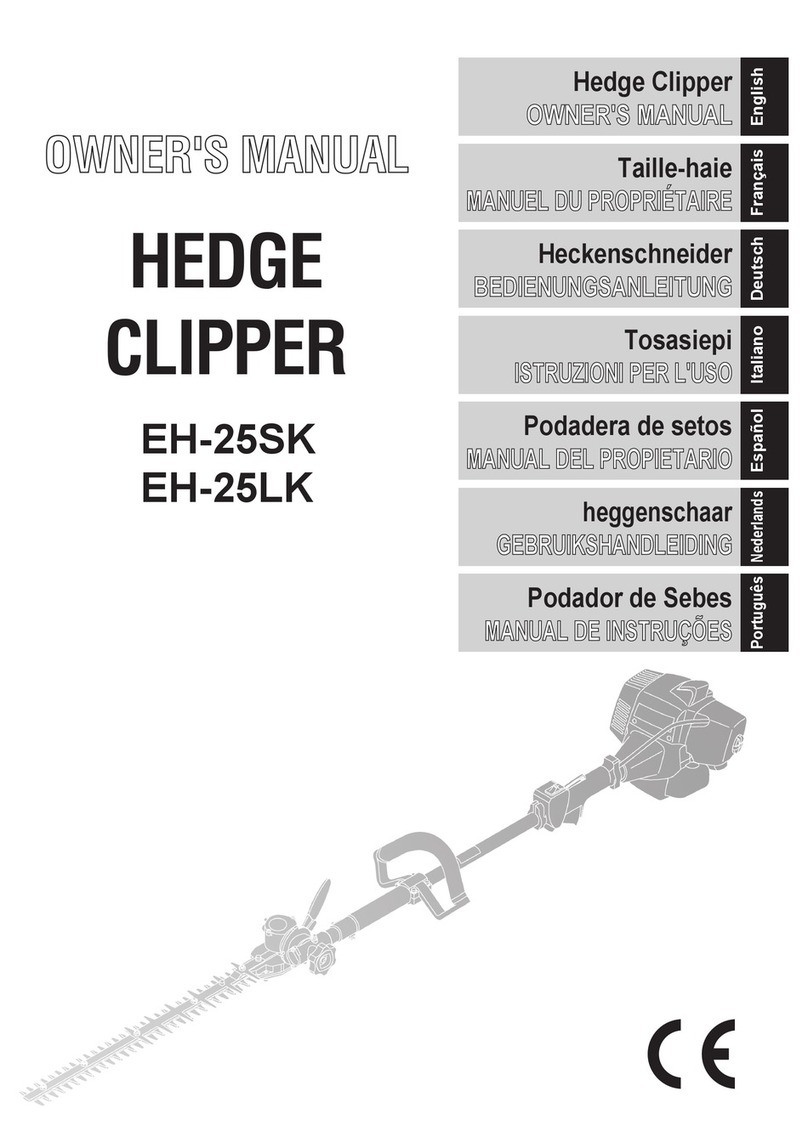

Insert the belt such that the tag (3- if present) does not get caught in (4,

see dotted arrow for direction of belt movement).

Connected belt

Position the blue quick-

release lock

Carry the belt forwards till the blue quick-release lock (2) reaches the

lateral opening (1). If there is no water on the belt, it can be positioned

accurately at the tag with the hand (2).

(1) Lateral opening

Remove the connecting

wire

Remove the connecting wire (4) of the belt from the side through the

lateral opening (1) (do not draw out the belt yet).

Move in a new belt

First clean the lock thoroughly and connect the quick-release lock side of

the old belt, on which the tag (2-if present) is found with the lock of the

new belt (see below ‘‘connecting the belts’’). Pull out evenly at the other

(open) side of the old belt till the end point of the new filter belt has

reached the opening (1). Like this the new belt will be easily guided

through. The connecting wire shall now be removed and the old belt can

then be separated from the new one.

Torn belt

If the belt is no longer connected for some reason, the new belt shall then

be ‘‘threaded up’’ manually.

Remove the belt

The no longer connected filter belt shall be removed so that the black

conveyor belt becomes visible.

Preparation

Attach a string or the like to the right and left side of the black conveyor

belt (e.g. through gluing or tying up). Control the belt feeder such that the

circular part at the top becomes visible/accessible once again

Threading up the filter

Attach the new filter belt to the threads and pull it carefully around the

(2) Blue quick-release lock

(4) Connecting wire

(3) Label

(5) Laufrichtung

Maintenance and servicing

Cleaning of the fine filter and pressure pump

Instruction manual EBF / EBF ECO page 17 of 19

11/2014

belt

black conveyer belt till it comes out at the top end. The strings can be

easily attached to the inserted connecting wire.

Connecting the belt

1. Position the start and end points of the belt in front of the opening

(1) at the side wall of the filter.

2. Insert the connecting wire to the belt through the lateral opening in

such a way that the blue teeth of the ends link together.

3. The angled piece of wire shall be inserted to the other side/loop (see

picture)

6.3 Cleaning of the fine filter and pressure pump

Filter basket

The rinse water for the filter belt is obtained from the bio-pond. The

pressure pump has a filter basket which can retain large wastes.

Fine filter

The fine filter retains all particles larger than 1/10mm. Through the

double safety offered, the spraying nozzles can hardly become blocked.

The fine filter (black Y-filter) has a cover cap at its end which can be

unscrewed for backwashing of the fine filter. After taking off the cover

manually begin the rinsing process in order to flush and clean the fine

filter. Protect yourself from splashes (e.g. through connection with a

hose). The complete sieve may also be removed and cleaned. The fine

filter should be examined after every 3 months.

6.4 Cleaning of the float gauge

It is advisable to check the float gauge after regular intervals of time and

to remove any dirt if necessary. For this purpose, the float gauge is drawn

out of the pipe together with its cap, rinsed with water and put back in

place again.

6.5 Cleaning of the belt spraying nozzle

Special anti-lime nozzles are used. The belt spraying nozzles are

positioned below the Plexiglas lid in front of the filter belt. You can check

the functioning of the flushing nozzles by slightly raising the Plexiglas lid.

Remove the spraying

nozzle

Screw out the blue spraying nozzle from the PVC pipe.

Clean the nozzle

Remove the accumulated dirt from the nozzle opening with a thin object

Replacement / Guarantee

Cleaning of the belt spraying nozzle

Instruction manual EBF / EBF ECO page 18 of 19

11/2014

(e.g. thin needle).

Insert the nozzle

When the nozzle is being inserted, it shall be made sure that the thread is

not overtightened.

Non-return valve

A non-return valve is present beside the manometer which prevents

dripping of water from the spraying nozzle when the water level is high in

the pond.

Water nozzle, Rinsing

channel

Another nozzle directed inwards facilitates the efficient transport of dirt

and contaminated water away from the system into the dirt outlet

channel.

Instruction

The opening of the nozzle is very delicate and it shall not be damaged!

The nozzles must be aligned to each other at a slightly slant angle so that

the ‘‘fan beam’’ overlaps and covers a large area (see picture).

Alignment / Angle of the flushing nozzles

7Replacement / Guarantee

Only original replacement parts of the firm AquaFil GmbH shall be used.

In case of improper installation, especially due to non-compliance with

the difference in the installation height of the S-Filter to the water level of

the pond, the manufacturer will not accept any claims for damage

resulting from it.

For defects which arise during and after the winter season, a guarantee

claim cannot be taken into consideration, if the plant has not been

adequately protected against temperatures lower than zero degrees.

The following wear parts are excluded from the guarantee:

Filter belt

Spraying nozzles

Fine filter insert

Replacement / Guarantee

Further instructions

Instruction manual EBF / EBF ECO page 19 of 19

11/2014

7.1 Further instructions

Instruction

The client is responsible for a safe installation of the G-versions on-site.

For pumping outputs above 40,000l/h, the installation of the option

‘‘Overflow protection’’ is mandatory. Without its installation, the

guarantee will be considered void.

The suction area of the pressure pumps must remain free in order to

avoid blockage or feeding of the pump through an air diffuser.

EBF 1200S

The float gauge shall not be positioned deeper than at its initial position

at the time of delivery.

The client would be considered responsible that the pond cannot be dried

out in case of a defect.

AquaFil GmbH draws attention to this danger and declines any liability in

the event of damage.

Table of contents

Other Smartpond Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

OCHIAI

OCHIAI EH-25SK owner's manual

Wolf Garten

Wolf Garten LI-ION POWER FINESSE 30 R Original operating instructions

juwel

juwel BIOSTAR PROTECT 2000 Assembly instructions

Zipper Mowers

Zipper Mowers ZI-RD300 user manual

ST. SpA

ST. SpA SPS 700 AE Operator's manual

Gardena

Gardena SR 1600 operating instructions