LFE**-TFP41

Installation and Maintenance Manual

Electromagnetic Digital Flow Switch

LFE

*

Series

Thank you for purchasing the LFE*Series Electromagnetic type Digital

Flow Switch.

Please read this manual carefully before operating the product and make

sure you understand its capabilities and limitations.

Please keep this manual in a safe place for future reference.

To obtain more detailed information about operating this product, please

refer to the SMC website ( URL http://www.smcworld.com) or contact SMC

directly.

1 Safety Instructions

These safety instruction are intended to prevent a hazardous situation

and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of

“Caution”,”Warning” or ”Danger”. They are all important notes for safety

and must be followed in addition to International standards(ISO/IEC),Japan

Industrial Standards(JIS) and other safety regulations.

Caution Indicates a hazard with a low level of risk, which if not

avoided, could result in minor or moderate injury.

Warning Indicates a hazard with a medium level of risk, which if

not avoided, could result in death or serious injury.

Danger Indicates a hazard with a high level of risk, which if not

avoided, will result in death or serious injury.

Operator

・This operation manual has been written for those who have knowledge

of machinery and apparatus that use pneumatic equipment and have full

knowledge of assembly, operation and maintenance of such equipment.

・Please read this operation manual carefully and understand it before

assembling, operating or providing maintenance to the product.

Warning

1. The compatibility of the product is the responsibility of the person

who designs the equipment or decides its specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided by

the person who designs the equipment or decides its specifications

based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will

be the responsibility of the person who has determined its compatibility

with the product.

This person should also continuously review all specifications of the

product referring to its latest catalog information, with a view to giving

due consideration to any possibility of equipment failure when configuring

the equipment.

2. Only personnel with appropriate training should operate machinery

and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment

including our products must be performed by an operator who is

appropriately trained and experienced.

3. Do not service or attempt to remove product and

machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should only

be performed after measures to prevent falling or runaway of the

driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures

as mentioned above are implemented and the power from any

appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent

unexpected operation and malfunction.

1 Safety Instructions (continued)

■Do not disassemble, modify (including changing the printed

circuit board) or repair.

An injury or failure can result.

■Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

■Do not operate in an atmosphere containing flammable or

explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

■Do not use with flammable or highly permeable fluids.

Fire, explosion, damage or corrosion can result.

■Do not use the product in a place where static electricity is a

problem.

Otherwise it can cause failure or malfunction of the system.

■If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

■The following instructions must be followed during maintenance:

•Turn off the power supply.

•Ensure the flow is shut off before performing maintenance.

Otherwise an injury can result.

Caution

■Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the product can

result.

■Do not touch the piping or its connected parts when the fluid is at

high temperature.

It may cause burns.

Ensure the piping cools sufficiently before touching.

■After maintenance is complete, perform appropriate functional

inspections and leak tests.

Stop operation if the equipment does not function properly or there is a

leakage of fluid.

When leaks occur from parts other than the piping, the product may be

faulty.

Cut off power supply and stop supplying fluid.

Do not apply fluid at leaking condition.

Safety cannot be assured in the case of unexpected malfunction.

2 Specifications

Refer to the product catalogue or SMC website ( URL

http://www.smcworld.com) to obtain more detailed information about the

product specifications.

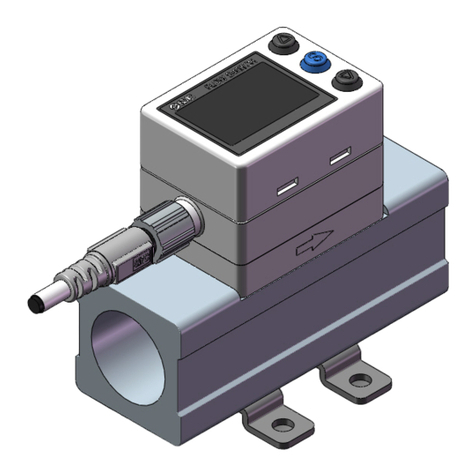

3 Summary of Product parts

3.1 Body

Item Description

Connector Connector for electrical connections.

Cable with M12 connector Cable to supply power and transmit output

signals.

Piping port Port to connect the fluid.

Bracket Mounting bracket used to install the

product.

Display

(With display only)

Displays the flow, settings and error codes.

(see below.)

3.2 Display (With display only)

Item Description

Main screen

(2-colour display)

Displays the flow, the status of setting mode and

error codes.

Sub screen

Displays the accumulated flow, set value,

peak/bottom value and line names. In

measurement mode, the set status is displayed.

Output display

(Indicator LED)

Displays the output status of OUT1 and OUT2.

When ON: Orange light is ON.

Unit display Displays the unit selected.

UP button Selects the mode and the sub screen display, and

increases the ON/OFF set value.

SET button Press this button to select mode and to confirm a

set value.

DOWN button Selects the mode and the sub screen display, and

decreases the ON/OFF set value.

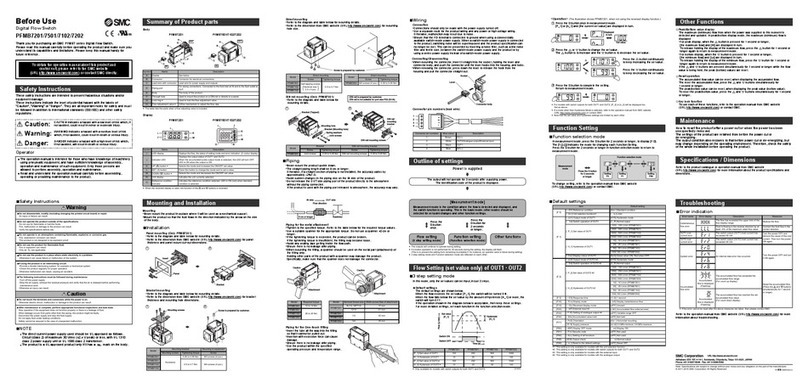

4 Mounting and Installation

Refer to the product catalogue or SMC website ( URL

http://www.smcworld.com) for more detailed information.

4.1 Mounting

•Never mount the product in a location where it will be used as a support.

•Mount the product so that the fluid flows in the direction indicated by the

arrow on the side of the body.

•Check the flow characteristics data for pressure loss and the straight inlet

pipe length effect on accuracy, to determine inlet piping requirements.

•Do not sharply reduce the piping size.

•The piping port and metal part of the body are grounded to DC (-)/ blue.

Note that a power supply with positive ground cannot be used.

4 Mounting and Installation (continued)

•When several sensors are mounted in parallel, do not mount them in the

area where installation is prohibited as shown below.

If the product is mounted in the area where installation is prohibited, the

accuracy will decrease.

4.2 Installation

•Use the product within the specified operating pressure and temperature

range.

•Proof pressure is 2 MPa. Proof pressure could vary according to the fluid

temperature. Check the characteristics data for applying pressure.

Bracket mounting

Mount the product (with bracket)

using the mounting screws (M4 x 4

pcs).

Bracket thickness is approx. 1.6mm.

Refer to the outline dimension

drawing for the bracket thickness

and mounting hole dimensions.

Direct mounting

Mount the product with the screws stated below.

Thread type Nominal thread size Tightening torque

Self tapping screws 3 0.32 ±0.03 Nm

Refer to the dimension drawing

for mounting hole dimensions.

When a self tapping screw is

used, it should not be re-used

several times.

4.3 Piping

When connecting piping to the product, a spanner should be used on

the metal piping attachment only.

Using a spanner on other parts may damage the product.

In particular, do not let the spanner come into contact with the M12

connector.

The connector can be easily damaged.

Width across flats of attachment

Port Width

3/8 24 mm

1/2 28 mm

3/4 35 mm

1 41 mm