PS1000-TF2Z054EN

Page 1 of 2

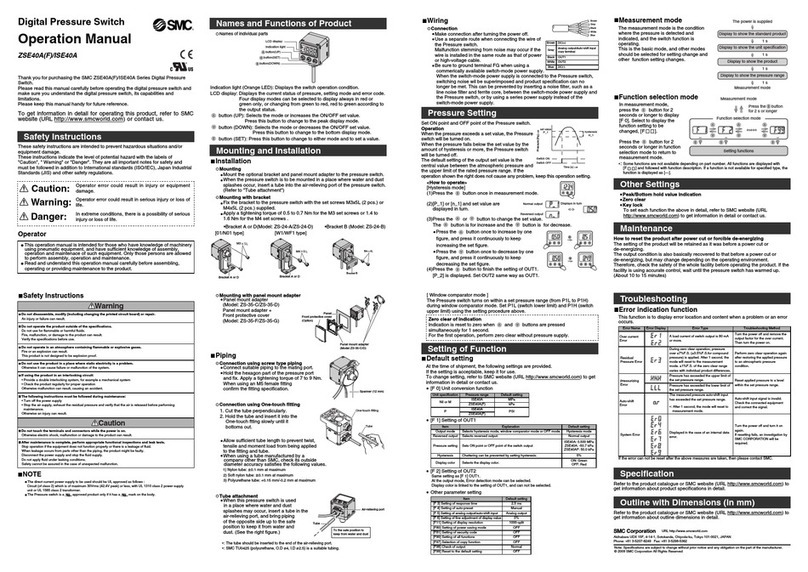

Instruction Manual

Air Checker: Electronic Pressure Switch

PS1000 / PS1100 / PS1200

The intended use of the compact pressure switch is to measure, monitor

and display pressure and provide an output signal.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Robots and robotic devices - Safety requirements for

industrial robots - Part 1: Robots.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

•This product is class A equipment intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted

or radiated disturbances.

•Refer to the operation manual or catalogue on the SMC website (URL:

https://www.smcworld.com) for more safety instructions.

2 Specifications

2.1 General specifications

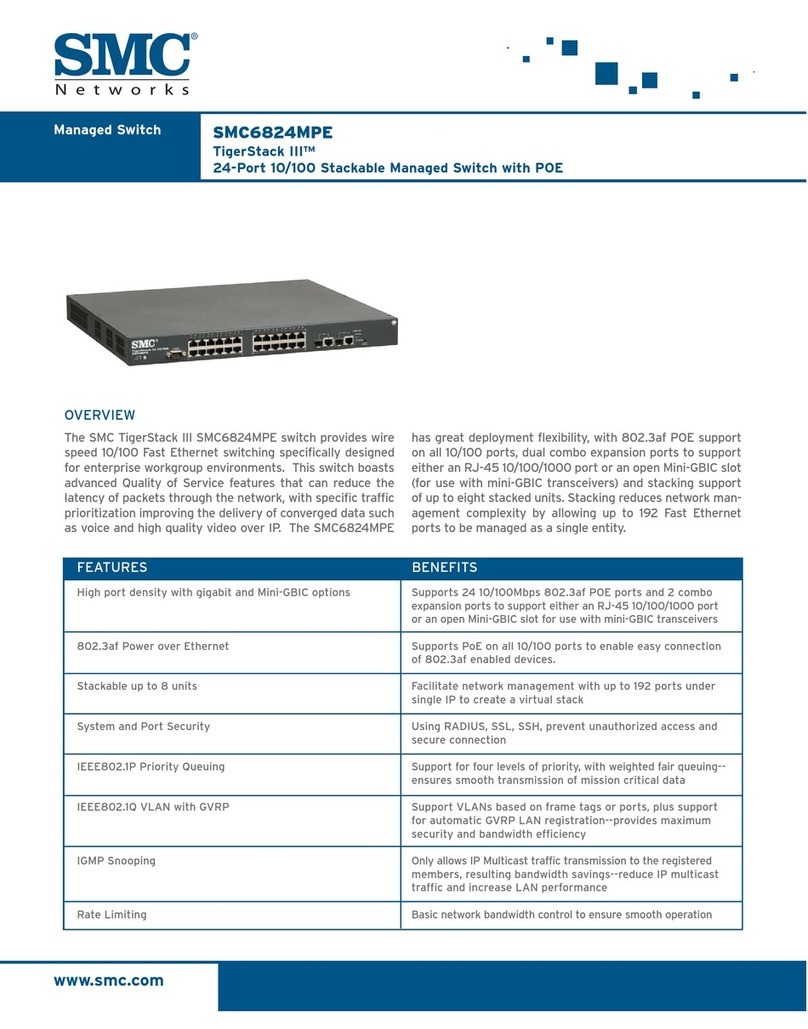

2.2 PS1000 / PS1100 switch specification

2.3 PS1200 switch specification

3 Installation

3.1 Installation Warning

Do not install the product unless the safety instructions have been read

and understood.

3.2 Piping

Caution

•Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

3.3 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact. Check the

product specifications.

•Do not mount in a location exposed to radiant heat.

3.4 Lubrication Caution

•SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

•If a lubricant is used in the system, use turbine oil Class 1 (no additive),

ISO VG32. Once lubricant is used in the system, lubrication must be

continued because the original lubricant applied during manufacturing

will be washed away.

4 Wiring

4.1 Wiring

•Connections should be made with the power supply turned OFF.

•Use a separate route for the product wiring and any power or high

voltage wiring. Otherwise, malfunction may result due to noise.

•Incorrect wiring may cause damage to the pressure switch, breakdown

and malfunction. Confirm the colour of the wires with the operation

manual before wiring.

•Wiring applying repeated bending and tensile stress to the lead wire

can break the circuit.

•The recommended bend radius of the lead wire is 6 times the outside

diameter of the sheath, or 33 times the outside diameter of the

insulation material, whichever is larger.

•Avoid defective insulation (crossed lines with other circuit, ground fault,

defective insulation between terminals, etc.) with the wiring.

Excessive current can flow through the pressure switch, which may

cause damage.

•If the pressure switch is turned on with no load connected to the switch,

over current will flow, causing the pressure switch to break instantly.

•The pressure switch has no reverse connection protection for the

brown (+) and blue (-) of the power supply line.

•Do not exceed the maximum allowable load (24 VDC,40mA) specified.

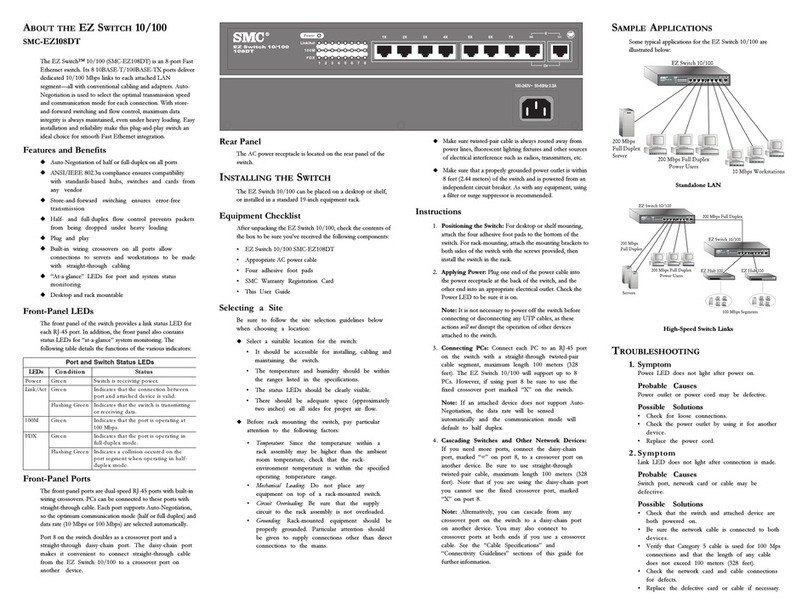

4.2 Circuit Diagram

4 Wiring (continued)

4.3 Wiring diagram

Example of connection to a PLC (sequence controller).

(Source Input type)

(Sink Input type)

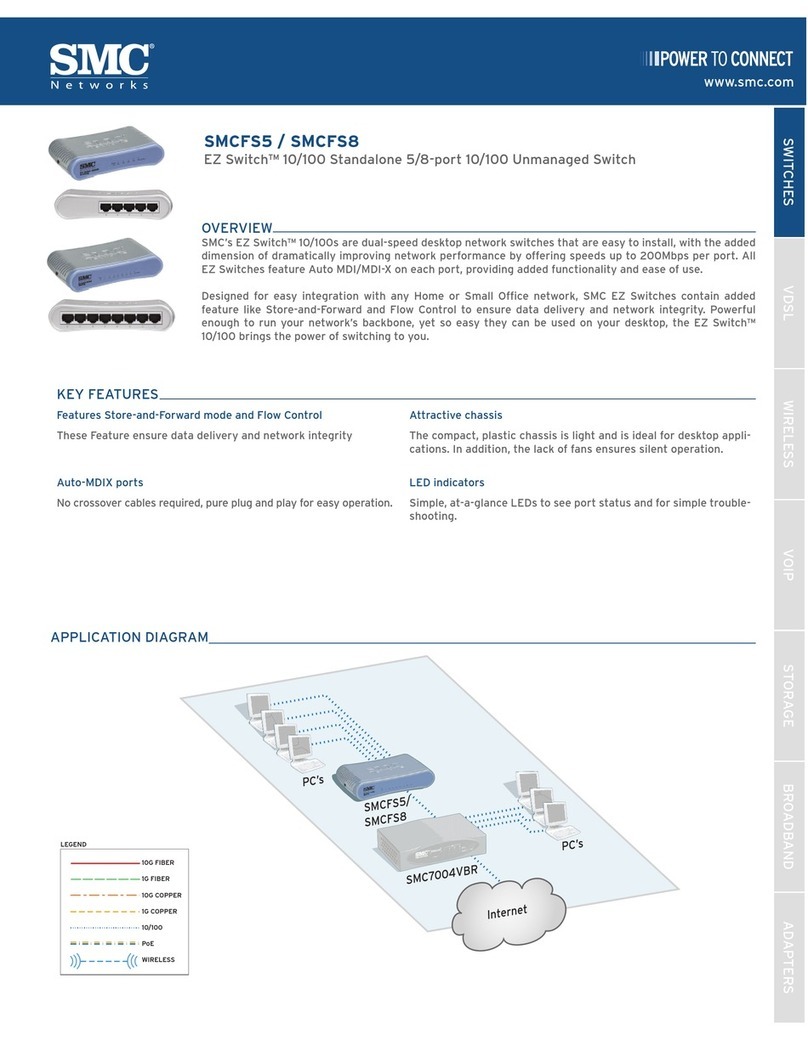

5 Setting

•Adjust the calibration adjustment to set the ON pressure.

•Rotate clockwise to increase the set pressure. For setting vacuum

pressure rotate anticlockwise.

•For setting, use a flat blade screwdriver suitable for a trimmer. Rotate

lightly to adjust.

•The rotation angle of the trimmer is 220°.

There is a stop provided to prevent the trimmer from rotating beyond

its limits. Rotation beyond the limits can damage the trimmer. Adjust

the trimmer gently within the rotation angle.

Caution

•Do not use a large screwdriver as this may damage the trimmer groove.

•Gently turn the trimmer and do not exceed the trimmer adjustment

range.

5.1 Hysteresis

Hysteresis is the pressure difference between the ON and OFF pressure.

The set pressure is the pressure selected to switch from OFF to ON.

6 How to Order

Refer to the operation manual or catalogue on the SMC website (URL:

https://www.smcworld.com) for How to order information.

Model No. PS1000 PS1100 PS1200

Switch output

Set pressure:

Pressure ≤ Set pressure: ON

1 MPa 500 kPa

Applicable fluids Air, non-corrosive gas, non-flammable gas

Indicator light Switch ON: Red LED turns ON

±3% F.S.

Repeatability ±1% F.S.

Hysteresis 4% F.S. or less

Load voltage

12 to 24 VDC ±10%,

ripple (p-p) 10% or less

Load current 5 to 40 mA

Leakage current 1 mA max.

Internal voltage drop 5 V max.

Operating

temperature range

0 to 60°C (no condensation)

Insulation resistance

2 MΩ or more at 500 VDC

(between live parts and case)

Withstand voltage

1000 VAC, 1 minute

(between live parts and case)

Port sizes R06 φ6 reducer

R07 φ1/4” reducer

Weight 5 g (excluding lead wire)

Enclosure rating IP40

Lead wire

Oil resistant vinyl cabtyre cable

2 cores, φ2.55, 3 m long

Conductor cross section 0.18 mm2

Sensor: Silicon, Body: PBT, O-ring: HNBR

the set pressure is reached

The switch turns ON at the

set pressure or below.

at the set pressure or