Series ZSE2/ISE2

Calibration Procedure

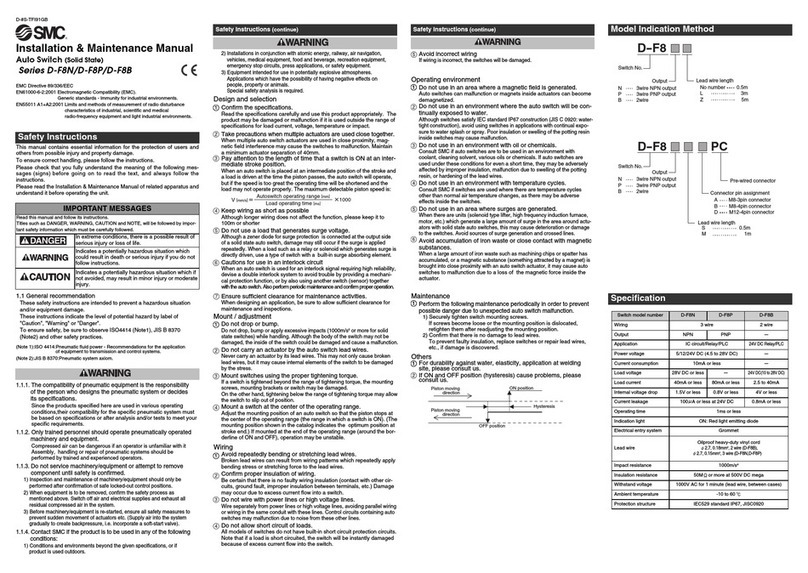

•Set the ON-pressure by the pressure setting

trimmer. Turning clockwise can set the high

pressure/high vacuum pressure.

Pressure

setting trimmer

Indicator light

SET

Set point

Supply pressure

Atmospheric

pressure

0

Unsteady

adsorption

Non adsorption

Steady adsorption

High vacuum

•Set the possible min. pressure for adsorption

confirmation. If setting the pressure lower

than that, switch becomes ON in case that

adsorption is not completely done. If setting

the pressure higher than that, switch does

not become ON even though it may absorb

workpieces.

Hysteresis

•Regarding the pressure setting

Observe the following precautions for setting

the vacuum pressure: Use your fingertips to

gently turn the screwdriver. Do not use a

screwdriver with a large grip or with a tip that

does not fit into the trimmer groove because

this could strip the groove.

Hysteresis is the pressure difference between

the ON and the OFF pressure of the output

signal. The set pressure is the pressure

selected to switch from OFF to ON condition.

Caution

Set point

Atmospheric

pressure 0

High vacuum

Hysteresis

ON

OFF

High

pressure

How to Use Connector

1. Attaching and detaching connectors

•

When assembling the connector to the switch

housing, push the connector straight onto the

pins until the lever locks into the housing slot.

•When removing the connector from the

switch housing, push the lever down to

unlock it from the slot and then withdraw the

connector straight off of the pin.

Lead wire

0.2 to 0.33 mm

2

Max. coating O.D.

ø1.7 mm

0.2 to 0.33 mm

2

Max. coating O.D.

ø1.7 mm

Socket

Connector

DC polarity indicator

Lever

Hook

Lever

DC polarity indicator

Connector

Socket

Lead wire

Hook

Pin

Slot

Housing

Lead wire

Socket

Covering retainer

Core wire crimping area

Hook Covering

Core wire

2. Crimping of lead wires and sockets

Strip 3.2 to 3.7 mm at the end of the lead

wires, insert the ends of core wires evenly into

the sockets, and then crimp with a crimping

tool. When this is done, take care that the

coverings of the lead wires do not enter the

core wire crimping area.

(Crimping tool: model no. DXT170-75-1)

Connector

Lead wire

Socket

Hook

3.

Attaching and detaching lead wires

with sockets

•Attaching

Insert the sockets into the square holes of

the connector (with +, 0, – indication), and

continue to push the sockets all the way in

until they lock by hooking into the seats in

the connector. (When they are pushed in

their hooks open and they are locked

automatically.) Then confirm that they are

locked by pulling lightly on the lead wires.

•Detaching

To detach a socket from a connector, pull out

the lead wire while pressing the socket’s

hook with a stick having a thin tip (about 1

mm). If the socket will be used again, first

spread the hook outward.

•Filter vessel

1. Do not use with thinner, carbon tetrachloride,

chloroform, acetate, aniline, cyclohexane,

trichloroethylene, sulfuric acid, lactic acid

and watermiscible cutting fluid (alkaline).

2. Operate it away from direct sunlight.

Caution

How to Replace Filter Element

Filter vessel

(Filter gasket part no.: ZX1-FG)

Filter element

(ZX1-FE)

Filter gasket

(ZX1-FG)

Gasket groove

If the filter element becomes clogged, leading

to a reduced adsorption force or delayed re-

sponse time, stop the operation and re-place

the element.

(Element part number ZX1-FE) Verify that the

filter gasket is placed properly in the gasket

groove before installing an element.

Filter vessel assembly (Filter

vessel + Filter element)

ZX1-FK-PC

12 to 24

VDC

Brown DC (+)

Black OUT1

Blue DC (−)

Main circuit

+

−

12 to 24

VDC

Brown DC (+)

Black OUT1

Blue DC (−)

+

−

Internal Circuits and Wiring Examples

-15

NPN (1 output)

-55

PNP (2 outputs)

Load

Main circuit

Load

854