SME 60 User manual

2

SME is an iconic brand founded in 1946 by audio legend Alastair

Robertson-Aikman in West Sussex, England. Today SME is

recognised as makers of the nest precision turntables

and

tonearms in the world. Entirely made in-house with state of

the art manufacturing processes, complemented by traditional

craftsmanship methods.

SME audio has evolved from 75 years of engineering excellence,

innovation and perfection delivering precise and pure audio

reproduction

.

Audio Perfection

MODEL 60

PRECISION TURNTABLE

INSTRUCTIONS

This is no ordinary turntable.

These instructions include unpacking, set up procedures and specications.

Please read carefully.

CAUTION: RISK OF ELECTRIC SHOCK DO NOT REMOVE POWER UNIT COVERS.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE THE POWER UNIT OR SPEED CONTROL UNIT

COVER. THERE ARE NO USER SERVICEABLE PARTS INSIDE. REFER ALL SERVICING TO QUALIFIED PERSONNEL.

• Please read this manual carefully and keep it in a safe place for future reference.

• TheventslotsintheSpeedControlUnitarefornecessaryvenlaon.Toensurereliableoperaonofthisapparatusandtoprotect

fromoverheangtheseventsmustneverbeblockedorcovered.

• Donotplaceawatercontainingvesselonthisapparatus,asthiscanresultinariskofreorelectricshock.Donotexposethis

apparatus to rain or place it near water.

• Ifthisapparatusaccidentallygetswet,unplugitandcontactanauthoriseddealerimmediately.

• Youcancleanthisapparatuswithadampclothwhennecessary,butbesuretounplugtheapparatusrst.Tocutothepower

source,unplugtheapparatusfromtheACwalloutlet.

• DonotoverloadACwalloutlets,powercablesoradaptorsbeyondtheircapacityasthiscanresultinreorelectricshock.

• Powercablesshouldberoutedsothattheyarenotlikelytobewalkedonorpinchedbyitemsplaceduponoragainstthem,paying

parcularaenontocablesattheplugend,adaptorsandthepointtheyexitfromtheappliance.

• BeforeconnecngtheACpowercabletothePowerUnit,makesurethevoltageofthePowerUnit,asmarkedontheidencaon

labelattherear,correspondstothelocalelectricitysupply.

• Neverinsertanythingmetallicintotheopenpartsofthisapparatus.

• OnlyaqualiedtechnicianshouldremovethePowerUnitorSpeedControlUnitcover.

• Besuretoholdtheplug,notthepowercable,whendisconnecngthisapparatusfromanelectricsocket.

• LocatethisapparatusnearaneasilyaccessibleACoutlet.

• If this apparatus does not operate normally, in parcular if there are any unusual sounds or smells, unplug it immediately

and consult an authorised dealer.

• UnplugthisapparatusfromtheACoutletbeforeanyservice.

IMPORTANT NOTICE:

ThepowercableonthisequipmentwhensuppliedforuseintheUK,isedwithamouldedplugincorporangafuse.Thevalueof

thefuseisindicatedonthepinfaceoftheplugandifitrequiredreplacingafuseapprovedtoBSI1362ofthesamerangmustbe

used.Neverusetheplugwiththefusecoveromiedifthecoverisdetachable.Iftheplugedisnotsuitableforthepowerpointsin

yourroomorifthepowercableisnotlongenoughtoreachthepowerpoint,youshouldobtainasuitablesafetyapprovedextension

lead or consult your dealer for assistance.

IMPORTANT:

Thewiresinthepowercablearecolouredinaccordancewiththefollowingcode:BLUE NEUTRAL, BROWN LIVE. As these colours may

notcorrespondtothecolouredmarkingsidenfyingtheterminalsinyourplug,proceedasfollows:ThewirecolouredBLUEmustbe

connectedtotheterminalmarkedwiththeleerNorcolouredBLUEorBLACK.ThewirecolouredBROWNmustbeconnectedtothe

terminalmarkedwiththeleerLorcolouredBROWNorRED.

WARNING:

DO NOT CONNECT EITHER WIRE TO THE EARTH TERMINAL, WHICH IS MARKED WITH THE LETTER (E) OR BY THE EARTH SYMBOL

OR COLOURED GREEN OR GREEN/YELLOW.

WEEE SYMBOL INFORMATION

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

(Applicable to the European Union and other European countries with separate collecon system).

Themarkingshownonthisproductoritsliterature,indicatesthatitshouldnotbedisposedwithotherhouseholdwastesatthe

endofitsworkinglife.Topreventpossibledamagetotheenvironmentorhumanhealthfromuncontrolledwastedisposal,please

separatethisfromothertypesofwastesandrecycleitresponsiblytopromotethesustainablere-useofmaterialresources.

Householdusersshouldcontacteithertheretailerwheretheypurchasedthisproductortheirlocalgovernmentoce,formore

detailedinformaonofwhereandhowtheycantakethisitemforenvironmentallysaferecycling.

Businessusersshouldcontacttheirsupplierandcheckthetermsandcondionsofthepurchasecontract.Thisproductshouldnot

bemixedwithothercommercialwastesfordisposal.

4

5

1. CONTENTS

Page TURNTABLE

6 Introducon

7 Overview

8 Weights&Dimensions

8 Drive System

8 SpeedRanges

9 PackingList

10 Idencaon-Turntable

12 Unpacking

13 SengUp-Turntable

15 PowerCableConnecons

16 Operaon-Turntable

17 Operaon-PlayingaRecord

17 Maintenance

18 TransitPrecauons

TONEARM

21 Introducon

22 Overview

23 GeneralArrangement

24 SetUp&Operaon

33 Guarantee

34 Appendix

6

2. INTRODUCTION

The Model 60 Precision Turntable

TheModel60Flagshipturntable,introduced60yearsaerSMEentered

the elite high end audio world is far superior than the highly credible

Model 30 which has been the reference precision turntable for over

3decades.

Thenewagshipisanenrelynewturntabledesignwithcleverengineering

andtechnologicaladvancement,butimportantlyretainingkeySMEaudio

engineeringprinciples.

The Model 60 specicaon includes: de-coupled feet with mulpoint

isolaon, an intelligent suspended suspension system with horizontal

and vercal control, hydraulically dampened main bearing, acouscally

treated main chassis, sub-chassis and plaer, sophiscated electronic

speed control with AC motor with remote (separate) power transformer.

In addion the legendary SME Series V tonearm has been extensively

sonically improved by use of a non-metallic tonearm tube made from

an advanced polymer resin material with high density and high rigidity

properesandimportantlyacouscallyinert.Withaloweecvemass

andsignicantlyreducedresonancesignaturetheSeriesVtonearmhas

beenredenedtotheSeriesVA(advanced).

TheModel60isthemosttechnicallyadvancedSMEturntableevermade

with extremely high build quality, close tolerance precision engineered

componentry, striking design and a range of non-painted uniquely

engineerednishes.

7

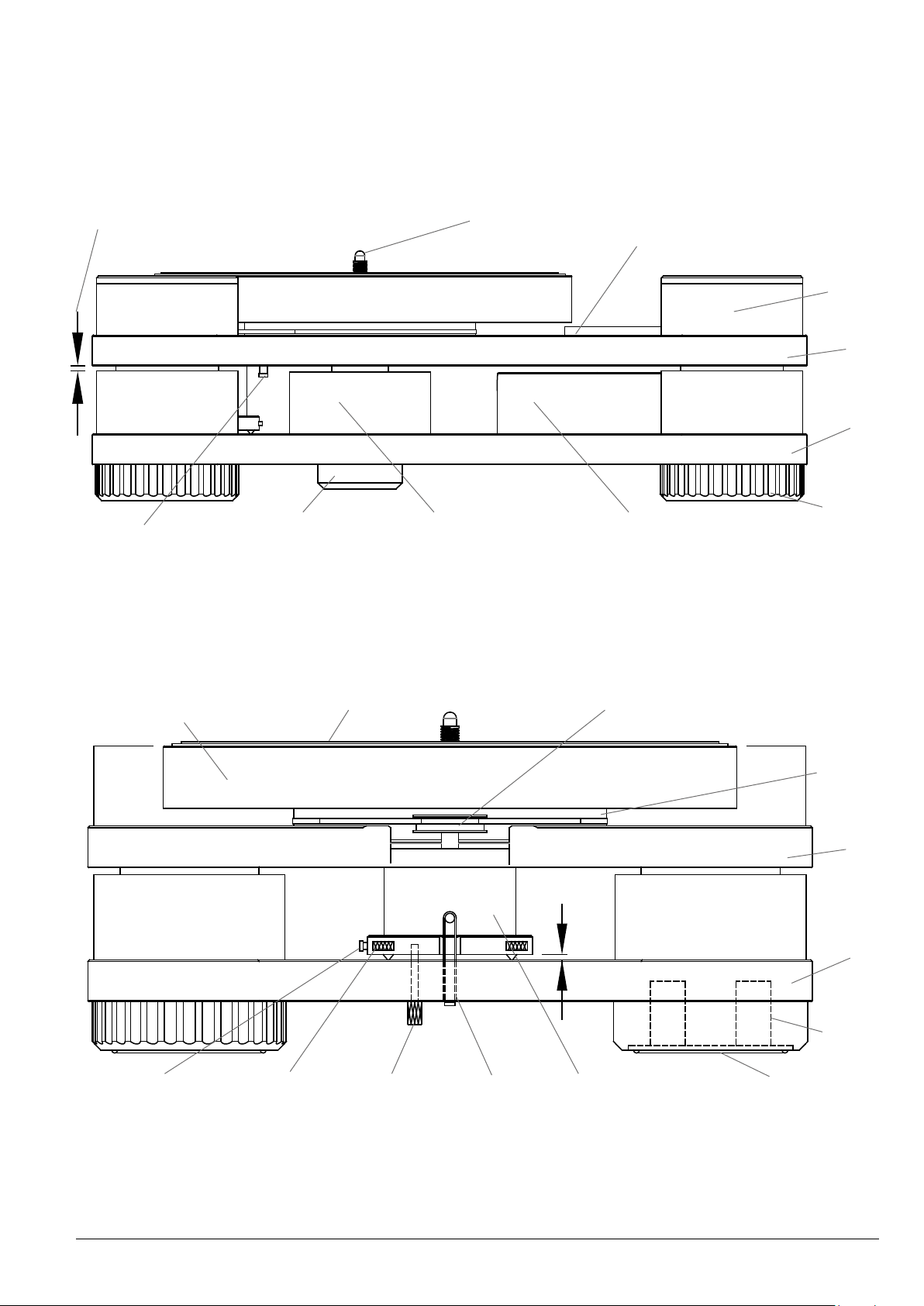

3. OVERVIEW

2

6 7

8

9

10

11

12

1

2

1 15

14

126 109 1143 7 85 13

3

5

4

1. SpeedControlUnit

2. PowerBuon

3. RotarySpeedControl

4. Air Vents

5. Plaer

6. RecordClamp

7. Tonearm

8. Power Unit

9. Suspension Column

10. SubChassis

11. MainChassis

12. AdjustableFoot

1. PowerUnit

2. Power Unit Output

3. VoltageIdentLabel

4. PowerON/OFFBuon

5. Mains Input AC Socket

6. LeRCAPhonoOutput

7. Phono Ground

8. RightRCAPhonoOutput

9. SerialNumberPlate

10. SpeedControlUnitInput

11. EarthPost-Turntable

12. PowerUnitInput

13. SpeedControlUnitOutput

14. AirVents

15. SpeedControlUnit

8

4. WEIGHTS & DIMENSIONS

WEIGHTS:

Turntable 48kg

SpeedControlUnit 2kg

PowerUnit 4.2kg

BoxedShippingWeight 86kg

DIMENSIONS:

Turntable

Height 212mm(topofclamp)

Width 557mm

Depth 417mm

Speed Control Unit

Height 87mm

Width 170mm

Depth 295mm

Power Unit

Height 83mm

Width 190mm

Depth 243mm

330mm

Spindle to Arm 215.35mm

5. DRIVE SYSTEM

The turntable is driven by a custom made bi-phase AC synchronous

motor.ThespeedcontrolunitusesadedicatedDSPenginetogenerate

two independent pure mathemacal sine waves which provide total

controloffrequency,phaserelaonshipandamplitude.Theseinturnare

matched(tuned) tothe motorforaccuracyto obtainthe bestpossible

performance. The output driver stage is a 2 channel, class AB Bi-polar

designwithlow distoronandrelaycoupleddirectlyto themotor. The

enredesignisimplementedusinghighqualitysurfacemounttechnology

onagoldplatedFR4PCB.

6. SPEED RANGE

Thespeedrangeis331

/3and45rpmwithindependentmemorysengsvia

a switched encoder.

9

7. PACKING LIST

Qty TURNTABLE

1 Model60ChassisAssembly

1 Plaer

1 StroboscopicDisc

1 SpeedControlUnit

1 PowerUnit

1 ConneconCable‘A’

1 ConneconCable‘B’

1 ACPowerCable

1 RecordClamp

1 RecordSpindleWasher

1 DriveBelt

1 SyringeofBearingSpindleOil

1 BearingSpindleOilFillerAdaptor

1 BearingSpindleOilFillerBoxSpanner

1 SyringeofTonearmDampingFluid

1 FingerLiwith2Washers

1 CartridgeScrews(StainlessSteelSet)

1 CartridgeScrews(AluminiumSet)

Qty TOOL KIT

1 CartridgeScrewdriver-FlatBlade

1 CartridgeScrewdriver-2mmHex

1 5mmSpanner(CartridgeScrews)

1 1/16A/FHexWrench

1 0.89mmHexWrench

1 2mmHexWrench

1 2.5mmHexWrench

1 3mmBall-endedHexHandle

1 4mmHexWrench

1 SuspensionAdjustmentKey(4mm)

4 SuspensionHeightGauges(5mm)

1 MotorHeightSengGauge(2mm)

1 Spirit/BubbleLevel

1 Alignment/HeightProtractor

1 MounngTemplate

1 VTAScrew

1 HTAKey

1 ProtractorSpindleBush

10

8. IDENTIFICATION TURNTABLE

Driven Pulley

Suspension

Column

Tonearm

Base

Chassis Transit

Screw (x4)

Pulley Transit

Screw (x4)

RCA Phono Connectors

Suspension Adjustment

4mm Hex Key

Motor

Pulley

Motor

PLAN VIEW

Figure 1

REAR VIEW

Figure 2

11

Motor Pulley

Spindle

Driven

Pulley

Suspension

Column

Sub-Chassis

Sub-Chassis

Main

Chassis

Main

Chassis

Feet

Isolators

Adjustable

Foot

Foot Pad Ring

Motor

Tonearm Wiring

Housing

Bearing

Spindle Base

Earth Post Dampening Bath

Height

Gauge

2mm

Height

Gauge

5mm

Motor

Counter

Balance Band

Motor

Transit

Screw

Motor Height

Adjuster (x3)

Motor Earth

Post

Tonearm

Base

SIDE VIEW L/H

Figure 4

SIDE VIEW R/H

Figure 3

12

9. UNPACKING

1. UnpackandcheckallitemsagainstthepackinglistinSecon7.

2. Having opened the packing case lid carefully li upwards the top

secon high density foam module which covers the turntable/

tonearmunit.DuetotheweightoftheModel60turntableitisbest

lied out of the caseby two people, one at each end andliing

from under the main chassis (boom of turntable) and not the

upper sub-chassis. The turntable should be sited on a substanal

tableorstrongaudiostandwhichmustbecapableofsupporngthe

turntableweightof48kg.

3. With the turntable sited li the le side of the turntable to gain

access to the motor transit screw which secures (clamps) the

motor to the main chassis. Remove the motor transit screw and the

an-fret packing strips and posion the turntable squarely and

centrally onto an audio stand. Ensure that the motor spikes are

securely inserted into the compliance cups.

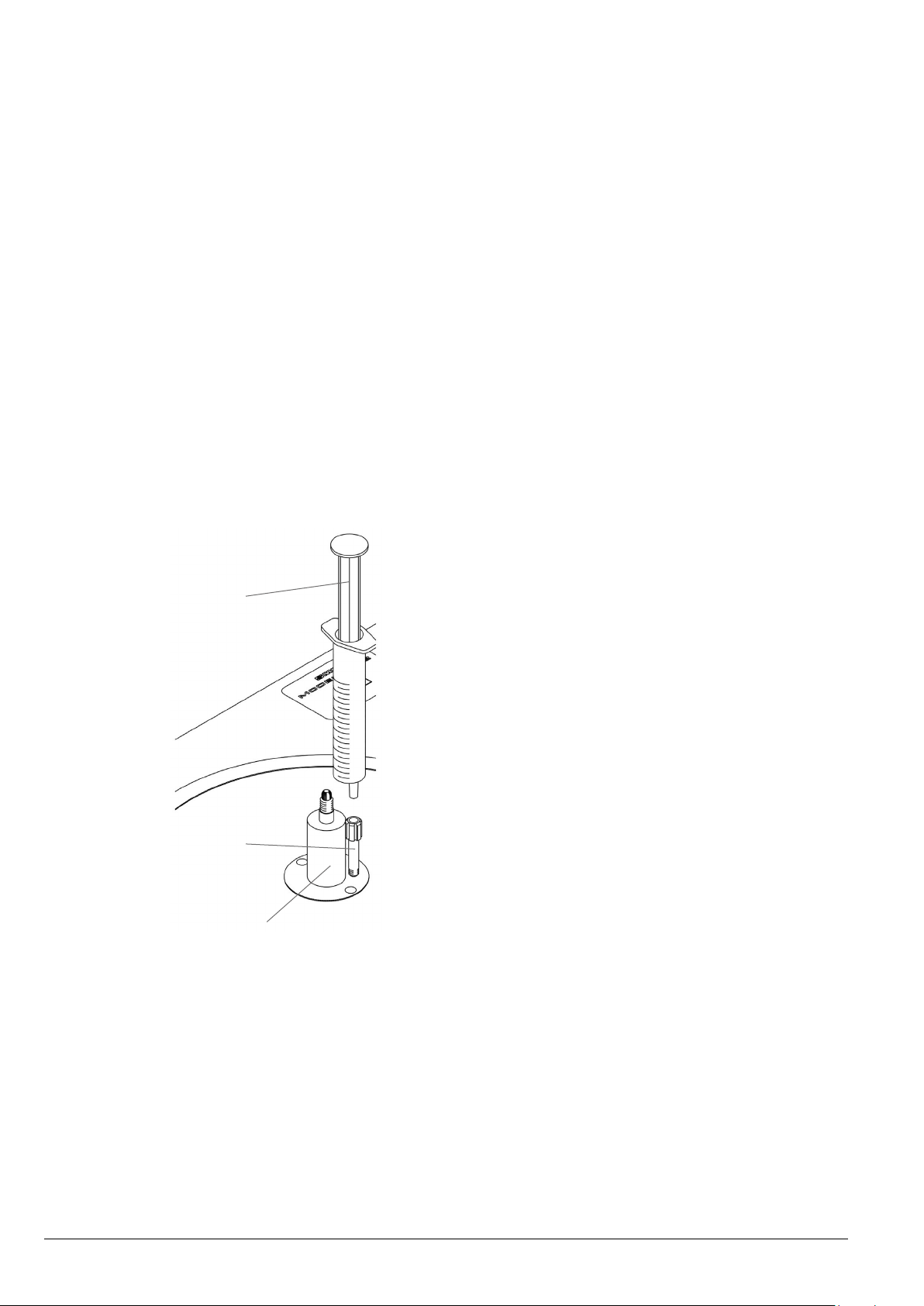

4. Theturntableisshippedwithonlya

smallquantyofoilin thebearing

housing and this should be lled

before seng up the turntable. A

measuredquantyofoilisprovided

in the syringe and needs to be

injectedintothebearinghousing.

5. Removethesyringefromitspacking

and insert the p into the oil ller

adaptor, which will be found

factory ed next to the spindle

(as illustrated).

6. Slowlyinjectthecompletequanty

of oil into the bearing housing

maintaining downward pressure

throughouttheoperaontoprevent

leakage. Remove the syringe and

disposeofitresponsibly.

7. Unscrew and remove the oil ller adaptor using the box spanner

foundinsidethetoolkit.Retaintheadaptorforpossiblefutureuse.

8. With the turntable removed and sited, proceed to remove all

ancillarycomponentsandaccessories locatedin thepackingcase

modulesbelowtheturntablepackingplaorm.

Oil Syringe

Oil Filler Adaptor

Spindle

13

10.

With the turntable unpacked and sited follow the turntable seng up

proceduresintheorderdetailedbelow:

1. Levelling the Turntable

Withtheuseofaspirit/bubblelevelensurethatthemainchassis(lower

chassis)islevelinthelateralandlongitudinalplanes.The4feetareheight

adjustableandcanbeusedtoachievealevelchassis.Whenadjusngthe

feet it is recommended to slightly li the chassis adjacent to the foot

beingadjusted.Thisaideseaseofrotaonofthefootandpreventsthe

footrubberpadbinding.

2. Levelling the Motor

a. Themotorismountedon3heightadjustmentscrews,thepointsof

whichsitincompliantcupsinthechassisbase.Fortransitpurposes

thesescrewshavebeenbackedoclearofthecompliantcups.

b. Raise the motor by adjusng the x3 height adjustment screws

(clockwise)toaheightsengof2mm,achievedbyuseofthesupplied

2mmheightgauge.Theheightgaugeisinsertedneareachadjustment

screwinturnbetweentheundersideofthemotorandthesurfaceof

thechassisbase.

c. The motor level can be checked by use of the spirit/bubble level

applied to the top surface of the motor pulley.

3. Chassis Unlocking

a. Fortransitthesub-chassis(upperchassis)islockeddownbyx4transit

screws (Secon 8 Figure 1). The transit screws should be turned

an-clockwisewiththesupplied4mmhexwrenchandremoved.The

sub-chassiswilllislowlyupwardsasthetransitscrewsareremoved.

b. Also for transit the main bearing is o-loaded by x4 pulley

transit screws. The transit screws are located in the driven pulley

(Secon8Figure1).Thesearecapvescrewsandshouldbeturned

an-clockwisewiththesupplied3mmhexhandlewrenchunlthey

stop.Ensurethehandlewrenchisfullyengagedtoavoiddamageto

the transit screw socket.

c. Withthesub-chassisunlockedcarefullyinsertthex4(5mm)suspension

height gauges between the underside of the sub-chassis and the

mid-secon of the suspension columns (Secon 8 Figure 3). With

use of the suspension adjustment key (4mm) insert the key into

the access hole on the top of each suspension column and adjust

the suspension height by turning the key clockwise to lower and

an-clockwise to raise. Adjust each column evenly unl the

sub-chassislightlycontactsall 4heightgaugesat thesameme to

ensurethesub-chassisisevenlysettoaxedheightof5mm.

14

11.

a. Placethedrivebeltoverthelargedrivenpulleyandstretchoverthe

motorpulley.Slowlyturnthedrivenpulleytoallowthedrivebeltto

takeupitsnaturalrunningposion.

b. Rotatethedrivenpulleybyhandtoensurethedrivebeltisposioned

correctlyandrotangfreely.

Removeandunpacktheplaerfromtheboomseconofthepacking

case.Placeitcarefullyandsquarelyovertheturntablespindleandlower

itgentlydownunlitrestsonthedrivenpulley,havingrstensuredthat

bothmangsurfacesareclean.

Thesuspensionheightisadjustedbyuseoftheheightadjustmentkey.

Carefullyengagethekeyintothetopcentreofeachsuspensioncolumn

andinsequenceturnan-clockwisetoraisethesuspensiontoaheight

sengof5mm(clockwisewilllowerthesuspension).Theheightsengis

checkedbycarefullyinsernga5mmheightgaugebetweentheunderside

of the sub-chassis and the mid-secon of each suspension column

(Secon8Figure3).

7. Power Unit & Speed Control Unit

Thepowerunitisconnectedtothespeedcontrolunitandturntableby

way of the connecon cables (Secon 12) with LEMO connectors. The

cablescannotbeconfusedastheycarryadierentnumberofpinswhich

arepurposelyconguredtoobservebothsafetyandmiss-idencaon.

ThecablesareidenedasAandB.

• ConneconCableA -PowerUnitOutputtoSpeedControlUnitInput

• ConneconCableB -SpeedControlUnitOutputtoTurntableInput

The AC mains power cable is connected to the power unit AC input.

A push ON/OFF switch is located on the rear of the power supply unit.

IMPORTANT

The mains voltage seng is indicated on the rear panel of the power unit.

Before ng the mains power cable check carefully that this matches your

mainsvoltage.

WARNING

Tomeetinternaonalsafetystandardsthepowersupplyunitisearthedthrough

theyellow/greenwireofthepowercableandparcularcaremustbetakento

ensurethatthisis connectedso astomaintaineecveearthing shouldthe

originalmainsplugbechanged.

TheModel60isequippedwithafactoryedSMESeriesVAtonearm.Under

no circumstancesaempttoremovethetonearmasitiswireddirectlytothe

RCA phono output sockets.

15

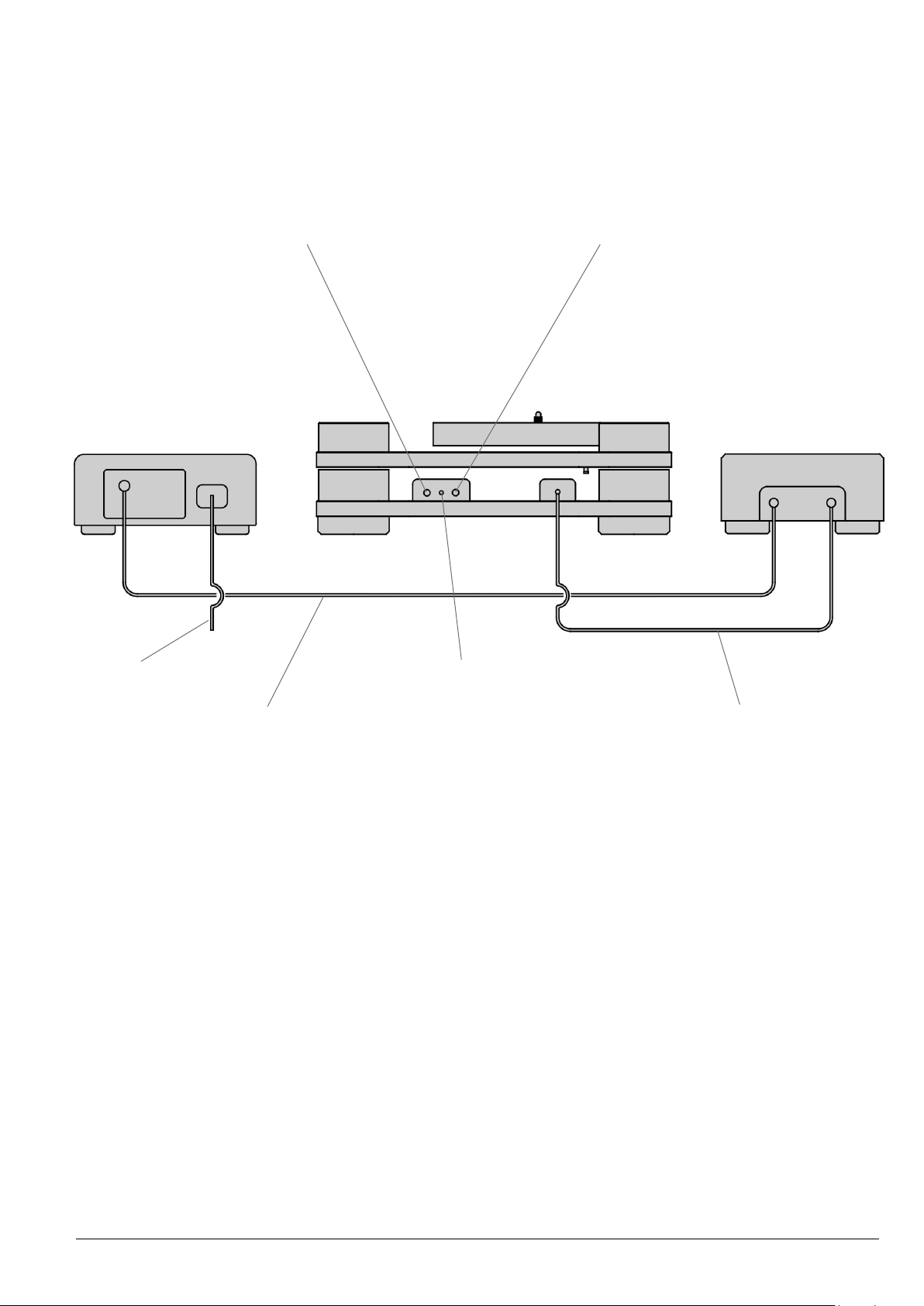

12. POWER CABLE CONNECTIONS

Right RCA Phono Output

AC Power Cable

Output

Output

Input

Input

Power Unit Speed Control Unit

Phono Ground

NOTE:

• Mains powerwhenconnecngcables.

16

13. OPERATION - Turntable

TheModel60precisionturntableispartlyrun-inbeforeleavingthefactory

butwill benetand improveaer a fewweeksof use.Do notworry if

iniallythebearingisnottotallysilent.Aslight‘swish’barelyaudibleat

verycloserangeinasilentroomwillquicklydisappearaeruseofthe

turntable.Ifyoushouldwishtocheckthespeedsengsandmakeyour

ownadjustmentstheprocedureisasfollows:

1. Mains Power:thepowerON/OFFbuonislocatedontherearof

the power unit. With power ON the last used speed indicator LED

lightwillilluminateonthespeedcontrolunitfascia.

2. Motor Power: pressing the power buon on the speed control

unitfasciawill start themotor.WithpowerOFF andpressingthe

rotarybuononthefasciathespeedsengsof331

/3and 45rpm will

cycleandbeindicatedbythespeedLED.Withthemotorrunning,

pressingthepowerbuonwillstopthemotor.

3. the stroboscopic disc installed on the plaer is

used to check speeds of 331

/3 and 45rpm. Use the strobe bands

appropriateforyourmainsACfrequency.Thediscshouldbeviewed

inauorescentorneonlight.Theappropriatebandwillsynchronise

and appear staonary when the speed is correct. Whilst forward

and reverse band movement will indicate fast or slow running

respecvely.Thisisbestobservedwiththecartridgeedandthe

tonearm in the raised posion and placed directly over the band

beingviewedasareferencepoint.

4. Speed Adjustment: with the motor running press and hold the

rotary buonfortwoseconds,the speed indicatorLEDwill begin

toash.Themotorisnowinspeedadjustmodeandthespeedcan

nowbeadjustedinconjunconwiththestroboscopicdisc.Turning

the rotary buon an-clockwise will reduce speed and clockwise

willincreasespeed.Themethodprovidesamicroneincremental

adjustment.Whenthespeedadjustmentiscompleteddepressand

release the rotary buon, the speed indicator LED light will stop

ashingandbecomeconstantandthespeedsengwillbestored

in the system memory for future use.

5. Repeatthisprocessforthe45rpmspeedrangeifrequired.

17

14. OPERATION - Playing a Record

Placetherecordspindlewasheronthespindlefollowedbytherecordand

clamp.Theclampshouldbescreweddownclockwiseenoughtodeect

therecordatintormcontactwiththeplaer.Withangerp,tapthe

recordin threeplaces equallyoveritssurfaceandwith alile pracce

it will soon become evident whether or not the record is touching the

plaer.Ifnot,somefurtherghteningoftheclampmaybenecessary.

15. MAINTENANCE

1. Therearenocricaladjustmentsorneedfor‘tweak’andonlyvery

lilemaintenanceisrequired.Cleanthedrivebeltoccasionallyby

drawing it through a piece of so ssue or linen moistened with

lighterfuel.Thesamematerialmaybeusedtocleantheperiphery

ofthemotorpulleyanddrivenpulley.Themainbearingislubricated

for life.

2. The sub-chassis (upper chassis) damping system automacally

seals when the sub-chassis is locked down and does not require

maintenance.

3. Replacethedrivebeltaer1000hoursuse.Areplacementbeltis

availabledirectlyfromSMELimited.

4. Thelifeofthesuspensionbandswilldependonclimaccondions.

If eventually they should stretch beyond further adjustment,

replacement suspension bands are available directly from SME

Limited.

5. Changing the suspension bands should only be conducted by

an experienced technician or at the supplying dealer. A technical

instruconprocesscanbeobtainedfromSMELimited.

6. Therearenouser-serviceablepartsinsidethePowerUnitorSpeed

Control Unit.

18

16. TRANSIT PRECAUTIONS

TheModel60canbesafelytransported.

SUBJECT TO THE FOLLOWING PRECAUTIONS:

Shortjourneysbycar:removetheplaer,disengagethedrivebeltfrom

themotorpulley,backothemotorheightadjustmentandretthemotor

transit screw. Lock down the sub-chassis suspension. Screw down the

fourdrivenpulleytransitscrewslightlyandevenly,justenoughtoprevent

thepulleyrotang.Theturntableitselfisbestplacedonaatoorofa

car boot/trunk. The plaer and other items can be carefully protected

and packed separately from the turntable. For all other transportaon

purposestheoriginalpackingcaseandmaterialsmustbeused.

INSTRUCTIONS

HIGH DENSITY TONEARM

This is no ordinary tonearm.

These instructions include set up procedures, adjustments and specications.

Please read carefully.

20

17. CONTENTS

Page

21 Introducon

22 Overview

23 GeneralArrangement

24 SetUp&Operaon

33 Guarantee

34 Appendix

Table of contents

Other SME Turntable manuals