3. This signal passes

through D10 (peak hold

diode), and is applied to the differential cir-

cuit consisting

of C7, R30, and R31. This dif-

ferential circuit servesto convert the tonearm

position signalinto a speed

signal.

o Peakhold diode

Sewes to prevent misoperation due to ec-

centricity in the recorddisc.

4. As the tonearm stylus moves into the record

disc lead-out groove, its movement becomes

faster, and when the potential at point A rises

above approxfmately 0.6V, Q8 comes ON,

dropping the potential of the collector side.

This senresas an end sensorsignal sending the

number 8 and 9 pin of IC1 L.

5. When the tonearm is UP, transistorQ6 andQ7

prevent transistor Q8 from turning ON.

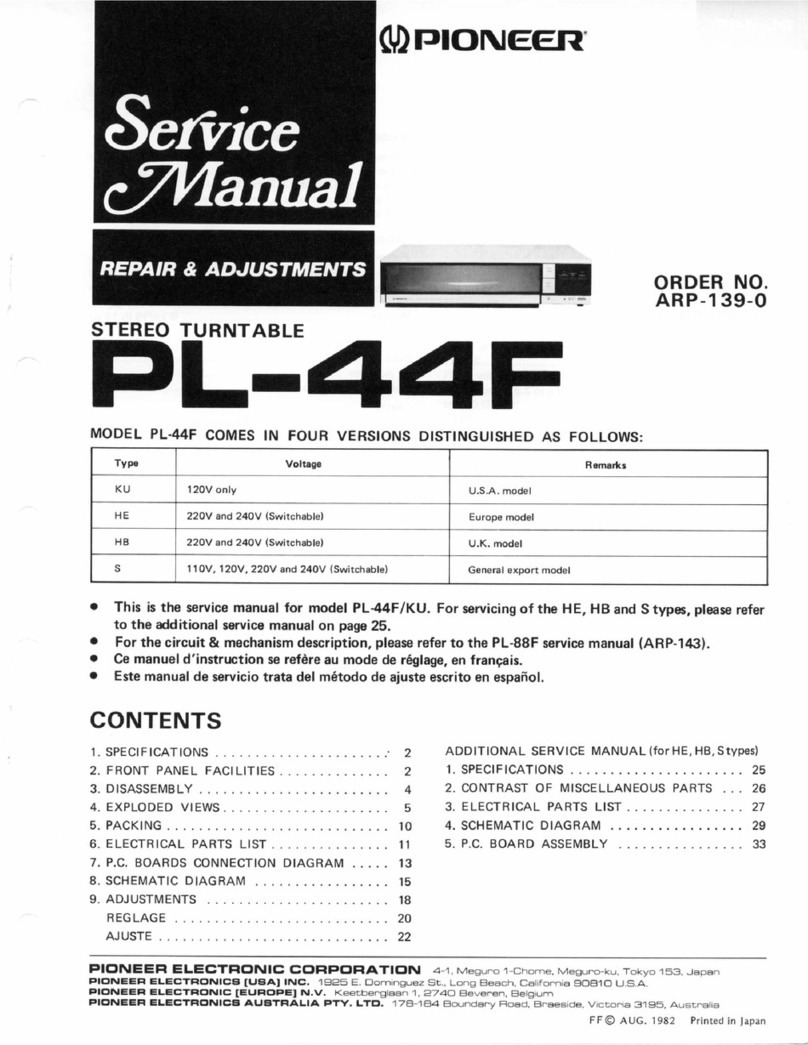

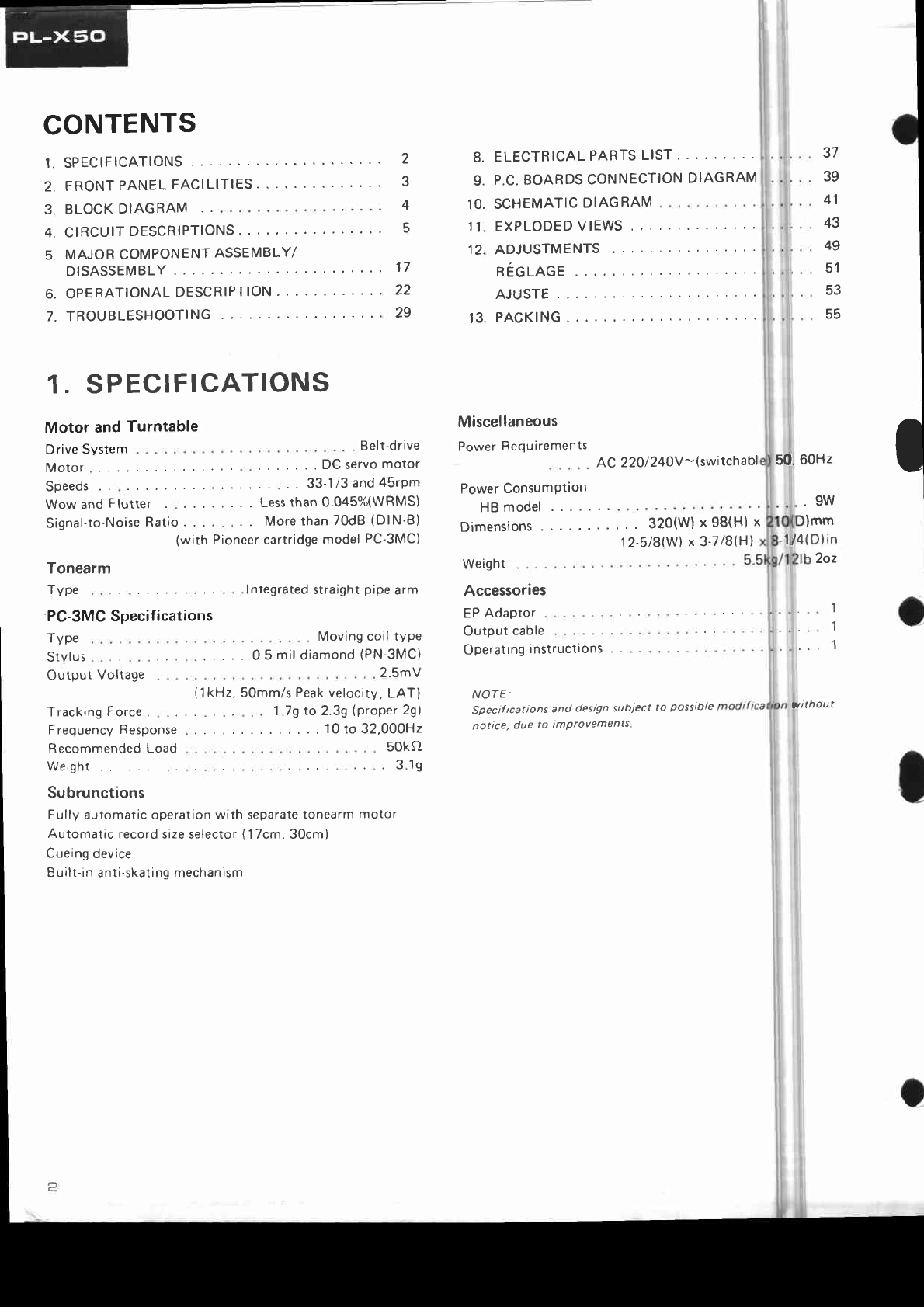

4.5 AUTO STOP

1. When the START/STOP button (switch 56)

is pressed

during record playback, the number

13 pin of.

IC2 goes

from L to H, and the num-

ber15pin goes

H.

2. Whenthe number 15 pin goes

H, the number 3

pin (number 8 pin) of IC3 also

goes

H, starting

the mechanism motor in the CW direction and

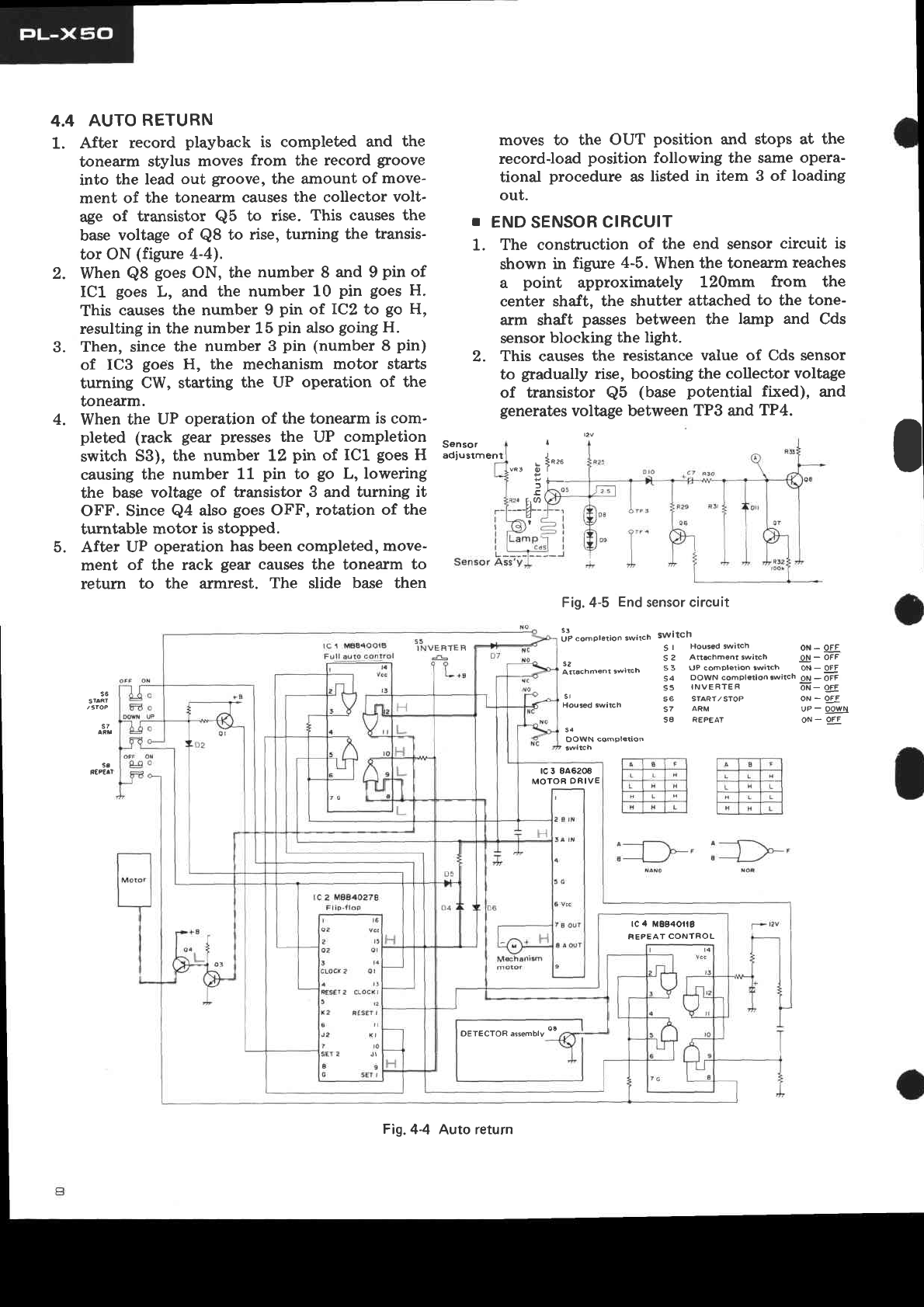

rcr ra8400tg

Full ruro control

940

arm returns to the armrest fing the opera-

enteringUP operations.

After UP operations are

tions listed in items 4 and

section,and the slide base

loadposition.

. ill "*o,",,o..*,tch twitch

3. . the tone-

e auto return

at the record-

Str)

in theUP

OFF

status,

r L. and the

mfter 1 pin of

mber 3 pin is

igtal input to

H, thereby

ber 2 pin

. the mecha-

turn CCW.

Pbut-

t{e ON posi-

15pin

pfn will go L

c$anging the

ber 2 pin

to L.

5!

INVERTER

it*n-.'r,*,..n it uP

on _ oFF

Irch ot _ oFF

rw,rch oil - oFF

Sl

OOWN complstioô

sirn ot _ oFF

oi - of,F

ot - oFF

uP - qg!-\

ON

_ OFF

rc 3 846206

MOTOR

DRIV€

âI

3

f_l

:

€

With the ARM button (

position and transistor Q1 in

the number 7 pin of IC2

number 2 pin is H, and the

IC1 is H. tn this status.the

held L no matter whether the

the number 2 pin of IC1 is

making it impossible for the

(number7 pin) of IC3 to go

nism motor therefore

At this point, when the ST

ton (switch 56) is switched

tion and the number 13 and

of IC2 goes

H, the number 1

turning transistor Ql ON

number 7 pin of IC2 to H,

to L, andthe number 1 pin

rc 2 M80aoa78

rc

4 H88401!8

REPEATCONT

Fig.

4-6 Autostop