SME 15 User manual

INSTRUCTIONS

MODEL 15

SME is an iconic brand founded in 1946 by audio legend Alastair

Robertson-Aikman in West Sussex, England. Today SME is

recognised as makers of the nest precision turntables

and

tonearms in the world. Entirely made in-house with state of

the art manufacturing processes, complemented by traditional

craftsmanship methods.

SME audio has evolved from 75 years of engineering excellence,

innovation and perfection delivering precise and pure audio

reproduction

.

Audio Perfection

INSTRUCTIONS

This is no ordinary turntable.

These instructions cover unpacking, set up, specications and operation.

Please read carefully.

MODEL 15

PRECISION TURNTABLE

CAUTION: RISK OF ELECTRIC SHOCK DO NOT REMOVE POWER UNIT COVERS.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE THE POWER UNIT OR SPEED CONTROL UNIT

COVER. THERE ARE NO USER SERVICEABLE PARTS INSIDE. REFER ALL SERVICING TO QUALIFIED PERSONNEL.

• Please read this manual carefully and keep it in a safe place for future reference.

• TheventslotsintheSpeedControlUnitarefornecessaryvenlaon.Toensurereliableoperaonofthisapparatusandtoprotect

fromoverheangtheseventsmustneverbeblockedorcovered.

• Donotplaceawatercontainingvesselonthisapparatus,asthiscanresultinariskofreorelectricshock.Donotexposethis

apparatus to rain or place it near water.

• Ifthisapparatusaccidentallygetswet,unplugitandcontactanauthoriseddealerimmediately.

• Youcancleanthisapparatuswithadampclothwhennecessary,butbesuretounplugtheapparatusrst.Tocutothepower

source,unplugtheapparatusfromtheACwalloutlet.

• DonotoverloadACwalloutlets,powercablesoradaptorsbeyondtheircapacityasthiscanresultinreorelectricshock.

• Powercablesshouldberoutedsothattheyarenotlikelytobewalkedonorpinchedbyitemsplaceduponoragainstthem,paying

parcularaenontocablesattheplugend,adaptorsandthepointtheyexitfromtheappliance.

• BeforeconnecngtheACpowercabletothePowerUnit,makesurethevoltageofthePowerUnit,asmarkedontheidencaon

labelattherear,correspondstothelocalelectricitysupply.

• Neverinsertanythingmetallicintotheopenpartsofthisapparatus.

• OnlyaqualiedtechnicianshouldremovethePowerUnitorSpeedControlUnitcover.

• Besuretoholdtheplug,notthepowercable,whendisconnecngthisapparatusfromanelectricsocket.

• LocatethisapparatusnearaneasilyaccessibleACoutlet.

• If this apparatus does not operate normally, in parcular if there are any unusual sounds or smells, unplug it immediately

and consult an authorised dealer.

• UnplugthisapparatusfromtheACoutletbeforeanyservice.

IMPORTANT NOTICE:

ThepowercableonthisequipmentwhensuppliedforuseintheUK,isedwithamouldedplugincorporangafuse.Thevalueof

thefuseisindicatedonthepinfaceoftheplugandifitrequiredreplacingafuseapprovedtoBSI1362ofthesamerangmustbe

used.Neverusetheplugwiththefusecoveromiedifthecoverisdetachable.Iftheplugedisnotsuitableforthepowerpointsin

yourroomorifthepowercableisnotlongenoughtoreachthepowerpoint,youshouldobtainasuitablesafetyapprovedextension

lead or consult your dealer for assistance.

IMPORTANT:

Thewiresinthepowercablearecolouredinaccordancewiththefollowingcode:BLUE NEUTRAL, BROWN LIVE. As these colours may

notcorrespondtothecolouredmarkingsidenfyingtheterminalsinyourplug,proceedasfollows:ThewirecolouredBLUEmustbe

connectedtotheterminalmarkedwiththeleerNorcolouredBLUEorBLACK.ThewirecolouredBROWNmustbeconnectedtothe

terminalmarkedwiththeleerLorcolouredBROWNorRED.

WARNING:

DO NOT CONNECT EITHER WIRE TO THE EARTH TERMINAL, WHICH IS MARKED WITH THE LETTER (E) OR BY THE EARTH SYMBOL

OR COLOURED GREEN OR GREEN/YELLOW.

WEEE SYMBOL INFORMATION

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

(Applicable to the European Union and other European countries with separate collecon system).

Themarkingshownonthisproductoritsliterature,indicatesthatitshouldnotbedisposedwithotherhouseholdwastesatthe

endofitsworkinglife.Topreventpossibledamagetotheenvironmentorhumanhealthfromuncontrolledwastedisposal,please

separatethisfromothertypesofwastesandrecycleitresponsiblytopromotethesustainablere-useofmaterialresources.

Householdusersshouldcontacteithertheretailerwheretheypurchasedthisproductortheirlocalgovernmentoce,formore

detailedinformaonofwhereandhowtheycantakethisitemforenvironmentallysaferecycling.

Businessusersshouldcontacttheirsupplierandcheckthetermsandcondionsofthepurchasecontract.Thisproductshouldnot

bemixedwithothercommercialwastesfordisposal.

4

5

1. CONTENTS

Page

6 Introducon

7 Dimensions&Weights

7 Drive System

7 SpeedRange

8 PackingList

9 PartsIdencaon-Turntable

11 Unpacking

13 SengUp-Turntable

15 SengUp-Tonearm

16 PowerCableConnecons

17 Operaon-Turntable

18 Operaon-PlayingaRecord

18 Operaon-Tonearm

19 Maintenance

20 TransitPrecauons

21 Guarantee

22 Appendix

6

2. INTRODUCTION

The SME Model 15 precision turntable is built to exacng engineering

standards providing reliability and freedom from crical adjustments.

Buildintegrity,sophiscatedelectronicsandvibraonfreemovingparts

allowthefullcapabiliesofanysoundtobefullyexplored.

7

3. DIMENSIONS & WEIGHTS

Turntable mm (inch)

Width 452(17.80)

Depth 361(14.21)

Height(topoftonearm) 175(6.88)

Speed Control Unit

Width 150(5.90)

Depth 295(11.61)

Height 85(3.34)

Power Unit

Height 83(3.26)

Width 190(7.48)

Depth 243(9.56)

330(12.99)

Weight kg (Ib)

Turntable 18.73(41.29)

PowerUnit 4.04(8.90)

SpeedControlUnit 2.52(5.55)

Shipping 29.1(64.15)

4. DRIVE SYSTEM

The turntable is driven by a custom made bi-phase AC synchronous

motor.ThespeedcontrolunitusesadedicatedDSPenginetogenerate

two independent pure mathemacal sine waves which provide total

controloffrequency,phaserelaonshipandamplitude.Theseinturnare

matched (tuned) to the motor for accuracy to obtain the best possible

performance. The output driver stage is a 2 channel, class AB Bi-polar

designwith lowdistoronandrelaycoupleddirectlytothe motor.The

enredesignisimplementedusinghighqualitysurfacemounttechnology

onagoldplatedFR4PCB.

5. SPEED RANGE

Thespeedrangeis331

/3and45rpmwithindependentmemorysengsvia

a switched encoder.

8

6. PACKING LIST

Qty Descripon 3

1 Model15Turntable..............Tonearm..............

1 SpeedControlUnit

1 PowerUnit–100V 115V 230V

1 PowerCable–UK EU USA

1 LEMOPowerCables

1 DriveBelt

1 SyringeofBearingOil

1 Plaer

1 StroboscopicDisc

1 OilFillerAdaptor(ed)

1 OilFillerBoxSpanner

1 RecordClamp

1 RecordSpindleWasher

1 SuspensionHeightSengGauge

1 StylusGuard

4 M3x12CapScrews(ed)

1 3mmHexHandleWrench

1 4mmHexWrench

1 TonearmToolKit

1 GuaranteeCard

1 TonearmInstruconManual

1 Model15InstruconManual

9

7.

Upper Gallery

Cover Driven Pulley Drive Belt

Turntable

Spindle

Record

Spindle

Washer

Plaer M3x12

Cap Screws

Suspension

Bands

Lower Gallery

Cover

Sub-Chassis

Motor

AdjustableFeet

(x3) Motor

Transit

Screw

Dampening

Bath

Insert

Stylus

Guard

Centralising

Band

Rubber

Insert Pad

Stainless

Steel Ball

Main

Chassis

Height

Seng

Gauage

Column

Base

Motor

Pulley

Pulley Transit

Screws(x4)

SuspensionAdjustment

Point-3mmHexWrench

Suspension Transit Screws

(x2)

TonearmMounngPlate

JackingScrews

10

7.

2

3

4567

9

10

11

12

5

6

8

1

23

1

4

1. SpeedControlUnit

2. PowerBuon

3. RotarySpeedControl

4. Air Vents

5. Plaer

6. RecordClamp

7. Tonearm

8. Headshell

9. Stylus Guard

10. SubChassis

11. MainChassis

12. AdjustableFoot

1. SpeedControlUnitInput

2. LeRCAPhonoOutput

3. EarthPost-Turntable

4. RightRCAPhonoOutput

5. Motor

6. EarthPost-Motor

11

8. UNPACKING

1. UnpackandcheckallitemsagainstthepackinglistonPage8.

2. Theturntableshouldbeplacedonasubstanaltableorstrongaudio

stand,thisshouldbeinitsnalposionforsengup,asmovement

aerthisprocedureisbestavoided.

3. The adjustable feet allow for two methods of interface with the

mounngsurface.

a)Asreceivedonrubberinsertpadssetintotheundersideofthe

feet.

b)Stainlesssteelballsalsosetintotheundersideofthefeet.

WARNING:

Method (b) is not suitable for delicate surfaces as indentaon

damagemaybecaused.

4. Ifhardmounngtheturntableonthestainlesssteelballsispreferred,

proceed as follows:

a)Posionthebasesothatoneofthesupporngfeetoverhangs

thetablebyabout10cms,unscrewandremovethatfoot.

b)Removetherubberpadfromthefootbypushingoutthroughthe

smallholeontheuppersideofthefootusingthelongerlegof

the2mmhexwrench.

c)Replace the supporng foot and repeat the procedure for the

other two feet.

5. Lithemotorsideoftheturntableandremovethemotortransit

screwfromtheundersideofthemainchassis(immediatelybelow

themotor).Removethetwopackingstripsfrombeneaththemotor

andrelocatethethreemotorbasepostsintotherubbercompliance

cups.

6. The turntable is packed with only a small quanty of oil in the

bearing housing and this should now be lled. A metered charge

(syringe)ofbearingoilisprovided.

12

8. UNPACKING

7. Removethesyringefromitspackagingandinsertthesyringepinto

theoillleradaptor,whichwillbefoundalreadyedtonearthe

spindle(asillustrated).

8. Slowlyinjectthecompletequantyofoilintothebearinghousing

maintaining downward pressure throughout the operaon to

preventleakage.

9. Removethesyringeanddisposeofitresponsibly.

10. Unscrew and remove the oil ller adaptor using the box spanner

tool.Retaintheadaptorforpossiblefutureuse.

Oil Syringe

Oil Filler Adaptor

Spindle

13

9.

1. Levelling

Withtheuseofaspirit/bubblelevelensurethatthemainchassis(lower

chassis)islevelinthelateralandlongitudinalplanes.The3feetareheight

adjustableandcanbeusedtoachievealevelchassis.Whenadjusngthe

feet it is recommended to slightly li the chassis adjacent to the foot

beingadjusted.Thisaideseaseofrotaonofthefootandpreventsthe

footrubberpadbinding.

2. Transit Locks

Fortransitthesuspensionislocked(secured)bytwoscrews;theseare

accessiblethroughholesinthedrivenpulley.Thetransitscrewsshouldbe

turnedan-clockwisewiththesupplied4mmhexwrenchandremoved.

Themainbearingiso-loadedbyfourpulleytransitscrews.Theseare

capveand shouldbe turnedan-clockwisewith the3mm ball-ended

hexwrenchunltheystop.Ensurethewrenchisfullyengagedtoavoid

damagetothetransitscrewsocket(seepage9,transitscrews).

3. Drive Belt

Placethedrivebeltoverthelargedrivenpulleydownasfarasthepulley

ange, ensuring that it is free from twists and stretch over the motor

pulley. The pulleys will be out of alignment without the weight of the

plaersorotaonmustnottakeplaceunltheplaerhasbeened.

Unpacktheplaerandplaceitcarefullyandsquarelyovertheturntable

spindleloweringitgentlydownunlitrestsonthedrivenpulley,having

rst ensured that both mang surfaces are clean. Rotate the plaer

slowlybyhandtoposionthebeltonthepulleys.

WARNING:

The unique damping material (isodamp) installed on the plaer top

surfacehasbeendiamondturnedandscrolledforinmatecontactwith

therecord.Avoidhandlingtheisodampmaterialandtreatitlikeavinyl

recordasitcouldbeeasilydamaged.

5. Suspension

The sub-chassis suspension system is set to the operang height by

way of inserng the 3mm hex wrench into the centre hole of each

uppergallerycoverandrotangclockwisetoraisethesub-chassis.The

operang height is correct when a 3.5mm clearance (gap) is achieved

betweenthesub-chassisandcolumnbaseasindicatedonpage9.The

3.5mmclearanceismeasuredbyuseoftheheightsenggauge.An-

clockwiserotaonofthe3mmhexwrenchwilllowerthesub-chassis.

Aer seng the suspension height hold the sub-chassis fully down

and then release it. Check and re-adjust as needed, nong that new

suspensionbandstakealilewhiletoseledown.

Asinglebandarrangedhorizontallybeneaththesub-chassiscentralises

thesub-chassisagainsttheopposingpullofthedrivebelt.

14

9.

Ifitisdesiredtoincreasesub-chassisisolaonbecauseofunusuallyclose

proximitytothespeakerstherecommendedsuspensionheightclearance

of 3.5mm can be reduced to 2mm. This lowers the spindle/bearing

housingdeeperintothedampeningbathandsubsequentlyincreasesthe

dampeningacon.

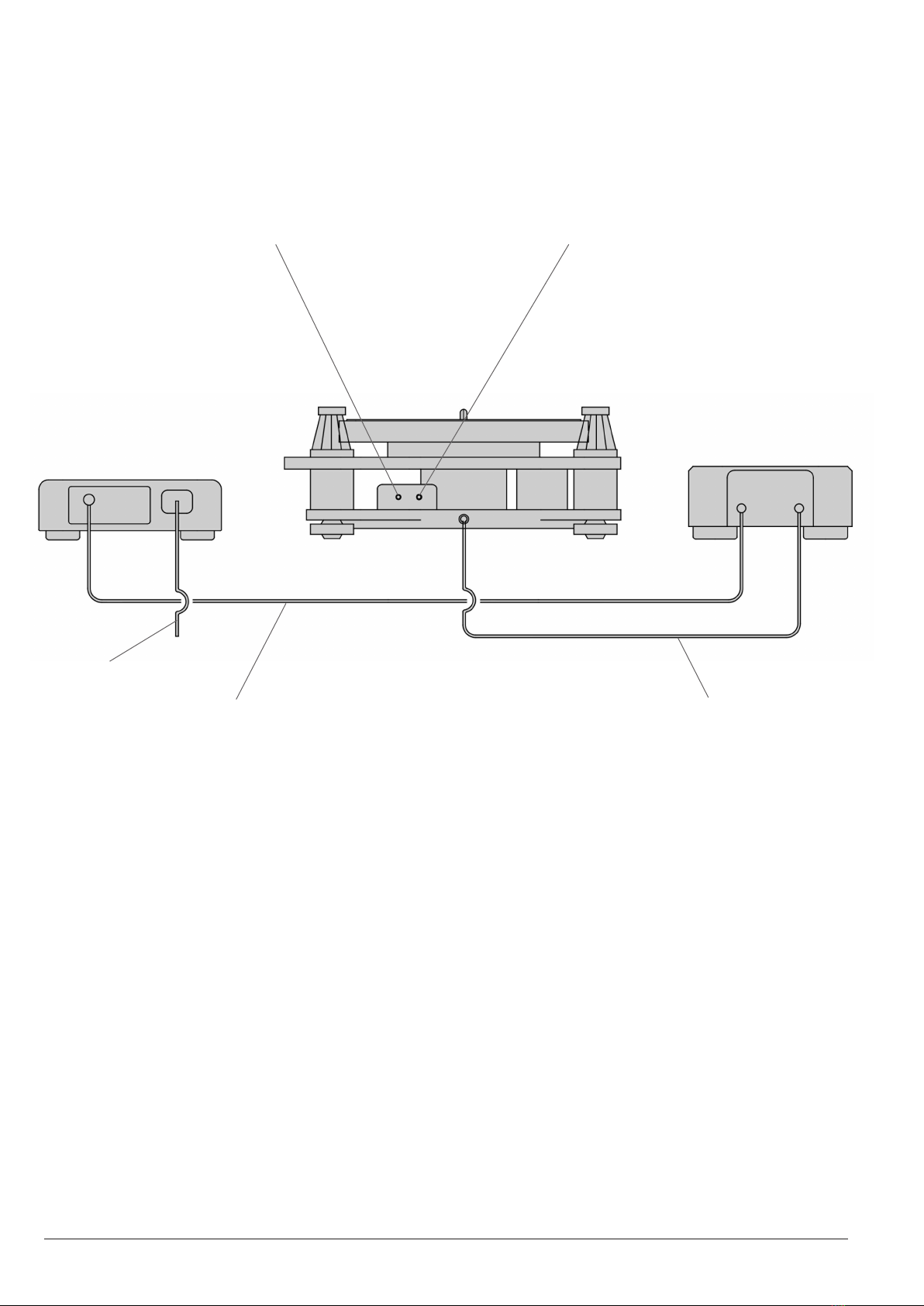

6. Power Unit & Speed Control Unit

Thepowerunitisconnectedtothespeedcontrolunitandturntableby

wayofthe conneconcables(Secon16)withLEMO connectors. The

cablescannotbeconfusedastheycarryadierentnumberofpinswhich

arepurposelyconguredtoobservebothsafetyandmiss-idencaon.

ThecablesareidenedasAandB.

1. ConneconCableA-PowerUnitOutputtoSpeedControlUnitInput

2. ConneconCableB-SpeedControlUnitOutputtoTurntableInput

The AC mains power cable is connected to the power unit AC input.

A push ON/OFF switch is located on the rear of the power supply unit.

IMPORTANT

Themainsvoltagesengisindicatedontherearpanelofthepowerunit.

Beforengthe mainspowercable checkcarefullythatthismatches

yourmainsvoltage.

15

10. SETTING UP - TONEARM

The Model 15 is equipped with a mounng base for SME tonearms,

Model309,SeriesIVandSeriesV.

The tonearm manual provides installaon, set up and operaon

informaon, including cartridge installaon. Before ng the tonearm

ensure that the four socket cap screws holding the tonearm mounng

plate tothesub-chassisareght.Thetonearmshould nowbesecured

tothemounngplateusingthefourM3x12mmcapscrews.Rotatethe

output socket on the underside of the tonearm and connect to the audio

cableextendingfromthemainchassis.

The tonearm mounng plate is ed with jacking screws to facilitate

removalfromthesub-chassis.Theyshouldbeturnedclockwise,alternately

insmallincrementsunltheplatecanbeliedo.The2mmhexwrench

is provided for this purpose.

16

11. POWER CABLE CONNECTIONS

Right RCA Phono Output

AC Power Cable

Output

Output

Input

Power Unit Speed Control Unit

NOTE:

Mains power whenconnecnganddisconnecngCablesAandB.

17

12. OPERATION - TURNTABLE

TheModel15precisionturntableispartlyrun-inbeforeleavingthefactory

but will benet and improve aer a few weeks of use. Do not worry if

iniallythebearingisnottotallysilent.Aslight‘swish’barelyaudibleat

verycloserangeinasilentroomwillquicklydisappearaeruseofthe

turntable.Ifyoushouldwishtocheckthespeedsengsandmakeyour

ownadjustmentstheprocedureisasfollows:

1. Mains Power:thepowerON/OFFbuonislocatedontherearof

the power unit. With power ON the last used speed indicator LED

lightwillilluminateonthespeedcontrolunitfascia.

2. Motor Power: pressing the power buon on the speed control

unitfasciawillstartthemotor.With powerOFF and pressingthe

rotarybuononthefasciathespeedsengsof331

/3and 45rpm will

cycleandbeindicatedbythespeedLED.Withthemotorrunning,

pressingthepowerbuonwillstopthemotor.

3. the stroboscopic disc installed on the plaer is

used to check speeds of 331

/3 and 45rpm. Use the strobe bands

appropriateforyourmainsACfrequency.Thediscshouldbeviewed

inauorescentorneonlight.Theappropriatebandwillsynchronise

and appear staonary when the speed is correct. Whilst forward

and reverse band movement will indicate fast or slow running

respecvely.Thisisbestobservedwiththecartridgeedandthe

tonearm in the raised posion and placed directly over the band

beingviewedasareferencepoint.

4. Speed Adjustment: with the motor running press and hold the

rotarybuonfortwoseconds,thespeedindicatorLEDwillbegin

toash.Themotorisnowinspeedadjustmodeandthespeedcan

nowbeadjustedinconjunconwiththestroboscopicdisc.Turning

the rotary buon an-clockwise will reduce speed and clockwise

willincreasespeed.Themethodprovidesamicroneincremental

adjustment.Whenthespeedadjustmentiscompleteddepressand

release the rotary buon, the speed indicator LED light will stop

ashingandbecomeconstantandthespeedsengwillbestored

in the system memory for future use.

5. Repeatthisprocessforthe45rpmspeedrangeifrequired.

18

13. OPERATION - PLAYING A RECORD

Placetherecordspindlewasheronthespindlefollowedbytherecordand

clamp.Theclampshouldbescreweddownclockwiseenoughtodeect

therecordatintormcontactwiththeplaer.Withangerp,tapthe

recordin threeplacesequally overitssurfaceand witha lile pracce

it will soon become evident whether or not the record is touching the

plaer.Ifnot,somefurtherghteningoftheclampmaybenecessary.

14. OPERATION - TONEARM

1. Withthecontrolleverintheraisedposionmovethetonearmout

ofthearmrestandposionthetonearmsothatthestylusisover

theselectedrecordgroove.

2. Tolowerthestylusontotherecordmovethecontrolleverforward

unlitisjustpasttopdeadcentre.Thiswillsettheloweringcontrol

inmoon,atwhichpointitwilltakeoverthemovementofthelever,

givingasmoothcontrolleddescent.

Note:Forthecorrectdescentmethe controlmustbe operated

exactly as above. The speed will be increased considerably if the

lever is pushed down instead of being allowed to fall of its own

accord.

3. To raise the stylus from the record slowly move the control lever

backtoitsoriginalposion.Whenthetonearmisnotinuseitshould

alwaysbereturnedtothearmrestforsafety.

19

15. MAINTENANCE

1. Therearenocricaladjustmentsorneedfor‘tweak’andonlyvery

lilemaintenance.Cleanthedrivebelt occasionallybydrawing it

throughapieceofsossueorlinenmoistenedwithlighterfuel.

Thesamematerialmaybeusedtocleantheperipheryofthemotor

and driven pulleys.

2. Thesuspensiondampeningbathisautomacallysealedwhenthe

sub-chassisislockeddownanddoesnotrequiremaintenance.

3. Replacethedrivebeltaer1000hoursuse.Areplacementbeltis

availablefromSME.

4. Thelifeofthesuspensionbandswilldependonclimaccondions.

If eventually they should stretch beyond further adjustment,

replacementsareavailablefromSME.

5. Changingthesuspensionbandsissimple.Unscrewandremovethe

uppergallerycoverfromthetopofthesuspensioncolumnandli

othelowergallerycover.Removetheoldband(s)andaachthe

newband(s)ontotheanchorstuds.Replacethecoversandre-check

thesuspensionheightwiththeheightsenggauge.

6. The motor retaining and centralising bands will last indenitely.

Howevershouldtheyrequirereplacingrefertotheillustraonon

page9.

7. There are no user-serviceable parts inside the speed control unit

or power unit. A safety fuse is located below the mains socket,

its replacement should only be undertaken by qualied service

personnel.

20

16. TRANSIT PRECAUTIONS

TheModel15canbesafelytransported,

SUBJECT ABSOLUTELY TO THE FOLLOWING PRECAUTIONS:

Shortjourneysbycar:removetheplaer,disengagethedrivebeltfrom

themotorpulley,andreplacethetwopackingstripsbeneaththemotor

and secure with the motor transit screw. Lock down the suspension. Screw

downthefourdrivenpulleytransitscrewsnotmorethanoneturn,just

enoughtopreventthepulleyrotangfreely.Theturntableitselfisbest

placedontheoorofthecarinfrontofthepassengerseat.Theplaer

and other items can be stowed elsewhere provided they are carefully

protected.Forallothertransportaonpurposestheoriginalpackingcase

andmaterialsmustbeused.

This manual suits for next models

1

Table of contents

Other SME Turntable manuals