SME Diamond MK2 Synergy User manual

INSTRUCTIONS

SME is an iconic brand founded in 1946 by audio legend Alastair

Robertson-Aikman in West Sussex, England. Today SME is

recognised as makers of the nest precision turntables

and

tonearms in the world. Entirely made in-house with state of

the art manufacturing processes, complemented by traditional

craftsmanship methods.

SME audio has evolved from 75 years of engineering excellence,

innovation and perfection delivering precise and pure audio

reproduction

.

Audio Perfection

INSTRUCTIONS

This is no ordinary turntable.

These instructions include unpacking, set up, specications and operation.

Please read carefully.

PRECISION TURNTABLE

Warning! Important Safety Instrucons

CAUTION: RISK OF ELECTRIC SHOCK DO NOT REMOVE POWER UNIT COVERS.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE THE POWER UNIT OR SPEED CONTROL UNIT

COVER. THERE ARE NO USER SERVICEABLE PARTS INSIDE. REFER ALL SERVICING TO QUALIFIED PERSONNEL.

• Please read this manual carefully and keep it in a safe place for future reference.

• TheventslotsintheSpeedControlUnitarefornecessaryvenlaon.Toensurereliableoperaonofthisapparatusandtoprotect

fromoverheangtheseventsmustneverbeblockedorcovered.

• Donotplaceawatercontainingvesselonthisapparatus,asthiscanresultinariskofreorelectricshock.Donotexposethis

apparatus to rain or place it near water.

• Ifthisapparatusaccidentallygetswet,unplugitandcontactanauthoriseddealerimmediately.

• Youcancleanthisapparatuswithadampclothwhennecessary,butbesuretounplugtheapparatusrst.Tocutothepower

source,unplugtheapparatusfromtheACwalloutlet.

• DonotoverloadACwalloutlets,powercablesoradaptorsbeyondtheircapacityasthiscanresultinreorelectricshock.

• Powercablesshouldberoutedsothattheyarenotlikelytobewalkedonorpinchedbyitemsplaceduponoragainstthem,paying

parcularaenontocablesattheplugend,adaptorsandthepointtheyexitfromtheappliance.

• BeforeconnecngtheACpowercabletothePowerUnit,makesurethevoltageofthePowerUnit,asmarkedontheidencaon

labelattherear,correspondstothelocalelectricitysupply.

• Neverinsertanythingmetallicintotheopenpartsofthisapparatus.

• OnlyaqualiedtechnicianshouldremovethePowerUnitorSpeedControlUnitcover.

• Besuretoholdtheplug,notthepowercable,whendisconnecngthisapparatusfromanelectricsocket.

• LocatethisapparatusnearaneasilyaccessibleACoutlet.

• If this apparatus does not operate normally, in parcular if there are any unusual sounds or smells, unplug it immediately

and consult an authorised dealer.

• UnplugthisapparatusfromtheACoutletbeforeanyservice.

IMPORTANT NOTICE:

ThepowercableonthisequipmentwhensuppliedforuseintheUK,isedwithamouldedplugincorporangafuse.Thevalueof

thefuseisindicatedonthepinfaceoftheplugandifitrequiredreplacingafuseapprovedtoBSI1362ofthesamerangmustbe

used.Neverusetheplugwiththefusecoveromiedifthecoverisdetachable.Iftheplugedisnotsuitableforthepowerpointsin

yourroomorifthepowercableisnotlongenoughtoreachthepowerpoint,youshouldobtainasuitablesafetyapprovedextension

lead or consult your dealer for assistance.

IMPORTANT:

Thewiresinthepowercablearecolouredinaccordancewiththefollowingcode:BLUE NEUTRAL, BROWN LIVE. As these colours may

notcorrespondtothecolouredmarkingsidenfyingtheterminalsinyourplug,proceedasfollows:ThewirecolouredBLUEmustbe

connectedtotheterminalmarkedwiththeleerNorcolouredBLUEorBLACK.ThewirecolouredBROWNmustbeconnectedtothe

terminalmarkedwiththeleerLorcolouredBROWNorRED.

WARNING:

DO NOT CONNECT EITHER WIRE TO THE EARTH TERMINAL, WHICH IS MARKED WITH THE LETTER (E) OR BY THE EARTH SYMBOL

OR COLOURED GREEN OR GREEN/YELLOW.

WEEE SYMBOL INFORMATION

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

(Applicable to the European Union and other European countries with separate collecon system).

Themarkingshownonthisproductoritsliterature,indicatesthatitshouldnotbedisposedwithotherhouseholdwastesatthe

endofitsworkinglife.Topreventpossibledamagetotheenvironmentorhumanhealthfromuncontrolledwastedisposal,please

separatethisfromothertypesofwastesandrecycleitresponsiblytopromotethesustainablere-useofmaterialresources.

Householdusersshouldcontacteithertheretailerwheretheypurchasedthisproductortheirlocalgovernmentoce,formore

detailedinformaonofwhereandhowtheycantakethisitemforenvironmentallysaferecycling.

Businessusersshouldcontacttheirsupplierandcheckthetermsandcondionsofthepurchasecontract.Thisproductshouldnot

bemixedwithothercommercialwastesfordisposal.

4

5

1. CONTENTS

Page

6 Introducon

7 Dimensions&Weights

7 Drive System

7 SpeedRange

8 PackingList

9 PartsIdencaon-Turntable

10 Unpacking

11 SengUp -Turntable

13 Cartridge

14 PowerCableConnecons

15 Operaon-Turntable

16 Operaon-PlayingaRecord

16 Operaon-Tonearm

16 Maintenance

17 TransitPrecauons

17 Guarantee

18 Appendix

6

2. INTRODUCTION

Synergyisauniqueprecisionengineeredintegratedturntableofnewdesign

combined with the highly acclaimed SME Series IV tonearm, Ortofon’s

‘exclusiveseries’MCWindfeldTimovingcoilcartridgeandanexclusivephono

stagebyNAGRA,coupledwithmonocrystalsilverwirebyCrystalCable,all

factoryconguredrequiringminimaluserset-up.

Compact, sleek, modern and built to exacng engineering standards

providing reliabilityand freedomfromcricaladjustments.Build integrity,

sophiscated electronics and vibraon free moving parts allow the full

capabilies of any sound system to be fully explored, above all Synergy

deliversanextraordinaryvinyllisteningexperience.

7

3. DIMENSIONS & WEIGHTS

Turntable mm (inch)

Width 370(14.57)

Depth 350(13.80)

Height(topoftonearm) 178(7.0)

PlaerDiameter 304(11.97)

SpindletoArm 215.35(8.48)

Speed Control Unit

Width 170(6.70)

Depth 305(12.0)

Height 68(2.68)

Power Unit

Height 83(3.26)

Width 190(7.48)

Depth 243(9.56)

Plaer 303(11.92)

Weight kg (Ib)

Turntable 19.59(43.18)

PowerUnit 4.04(8.90)

SpeedControlUnit 2.88(6.34)

Shipping 32.0(70.54)

4. DRIVE SYSTEM

The turntable is driven by a custom made bi-phase AC synchronous

motor.ThespeedcontrolunitusesadedicatedDSPenginetogenerate

two independent pure mathemacal sine waves which provide total

controloffrequency,phaserelaonshipandamplitude.Theseinturnare

matched (tuned) to the motor for accuracy to obtain the best possible

performance. The output driver stage is a 2 channel, class AB Bi-polar

designwith lowdistoronandrelaycoupleddirectlytothemotor.The

enredesignisimplementedusinghighqualitysurfacemounttechnology

onagoldplatedFR4PCB.

6. SPEED RANGE

Thespeedrangeis331

/3and45rpmwithindependentmemorysengsvia

a switched encoder.

8

7. PACKING LIST

Qty Descripon 3

1 SynergyTurntable..............Tonearm..............

1 SpeedControlUnit

1 PowerUnit–100V 115V 230V

1 PowerCable–UK EU USA

1 LEMOConneconCables

1 NagraPowerUnit–100V 115V 230V

1 NagraPowerCable–UK EU USA

1 NagraLowVoltageCable

1 OrtofonCartridge(ed)

1 DriveBelt

1 Plaer

1 StroboscopicDisc

1 OilFillerAdaptor(ed)

1 OilFillerBoxSpanner

1 SyringeofBearingOil

1 StylusGuard

1 RecordSpindleWasher

1 RecordClamp

1 TonearmToolKit

1 3mmHexHandle

1 4mmHexWrench

1 VelcroStrap

1 GuaranteeCard

1 TonearmInstruconManual

1 SynergyInstruconManual

9

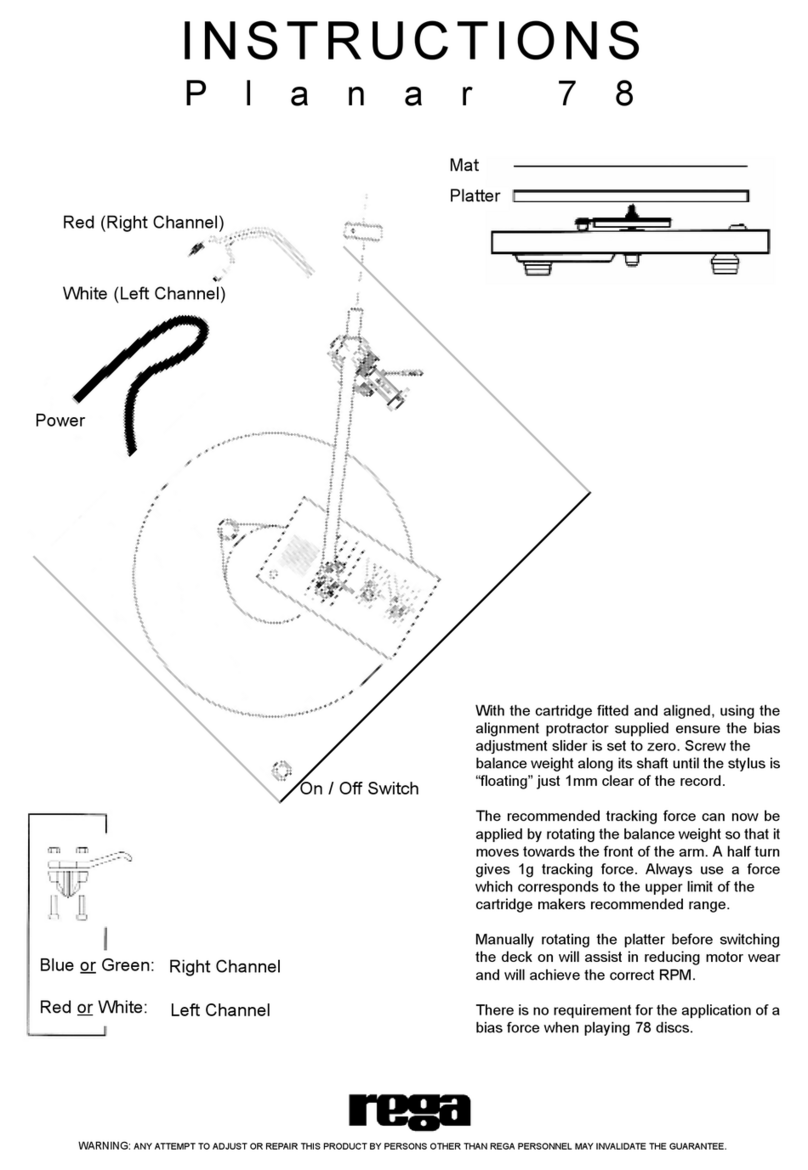

3

4

6

5

2

1

1. SpeedControlUnit

2. PowerBuon

3. RotarySpeedControl

4. Air Vents

5. Plaer

6. RecordClamp

7. Tonearm

8. Headshell

9. Stylus Guard

10. SubChassis

11. MainChassis

12. AdjustableFoot

1. NagraPhonoStageInput

2. RightRCAPhonoOutput

3. LeRCAPhonoOutput

4. Speed Control Unit Input

5. EarthPost-Turntable

6. Motor&EarthPost

12

3

4

5

6

8. PARTS IDENTIFICATION - TURNTABLE 7

8

10

11

9

12

10

9. UNPACKING

1. UnpackandcheckallitemsagainstthepackinglistinSecon7.

2. Havingopenedthepackingboxcarefullyliupwardsthetopsecon

highdensityfoammodulewhichcoverstheturntable/tonearmunit.

Lioutthe turntableliing fromunder themainchassis (boom

ofturntable).Theturntableshouldbesitedonasubstanaltable

or strong audio stand which must be capable of supporng the

turntableweight.

3. With the turntable sited li the le side of the turntable to gain

access to the motor transit screw which secures (clamps) the

motor to the main chassis. Remove the motor transit screw and

posiontheturntablesquarelyandcentrallyontoanaudiostand.

Ensure that the motor base posts are securely inserted into the

compliance cups.

4. The turntable is shipped with only a small quanty of oil in the

bearing housing and this should be lled before seng up the

turntable.Ameasuredquantyofoilis

providedinthesyringeandneedstobe

injectedintothebearinghousing.

5. Removethesyringefromitspacking

and insert the p into the oil ller

adaptor, which will be found

factoryednexttothespindle(as

illustrated).

6. Slowlyinjectthecompletequanty

of oil into the bearing housing

maintaining downward pressure

throughouttheoperaontoprevent

leakage. Remove the syringe and

disposeofitresponsibly

7. Unscrew and remove the oil ller

adaptor using the box spanner

found inside the tool kit. Retain the

adaptorforpossiblefutureuse.

Oil Syringe

Oil Filler Adaptor

Spindle

11

10. SETTING UP - TURNTABLE

1. Levelling

Withtheuseofaspirit/bubblelevelensurethatthemainchassis(lower

chassis)islevelinthelateralandlongitudinalplanes.The4feetareheight

adjustableandcanbeusedtoachievealevelchassis.Whenadjusngthe

feet it is recommended to slightly li the chassis adjacent to the foot

beingadjusted.Thisaideseaseofrotaonofthefootandpreventsthe

footrubberpadbinding.

2. Transit Locks

Fortransitthesuspensionislocked(secured)bytwoscrews;theseare

accessiblethroughholesinthedrivenpulley.Thetransitscrewsshouldbe

turnedan-clockwisewiththesupplied4mmhexwrenchandremoved.

3. Drive Belt

1. Placethedrivebeltoverthelargedrivenpulleyandstretchoverthe

motorpulley.Slowlyturnthedrivenpulleytoallowthedrivebeltto

takeupitsnaturalrunningposion.

2. Rotatethedrivenpulleybyhandtoensurethedrivebeltisposioned

correctlyandrotangfreely.

4. Plaer

Unpacktheplaerandplaceitcarefullyandsquarelyovertheturntable

spindleloweringitgentlydownunlitrestsonthedrivenpulley,having

rstensuredthatbothmangsurfacesareclean.

WARNING

The unique damping material (isodamp) installed on the plaer top surface

hasbeendiamond turnedandscrolledforinmatecontactwiththe record.

Avoidhandlingtheisodampmaterialandtreatitlikeavinylrecordasitcould

beeasilydamaged.

12

10. SETTING UP - TURNTABLE (connued)

6. Power Unit & Speed Control Unit

Thepowerunitisconnectedtothespeedcontrolunitandturntableby

wayofthe conneconcables(Secon12) withLEMOconnectors.The

cablescannotbeconfusedastheycarryadierentnumberofpinswhich

arepurposelyconguredtoobservebothsafetyandmiss-idencaon.

ThecablesareidenedasAandB.

1. ConneconCableA-PowerUnitOutputtoSpeedControlUnitInput

2. ConneconCableB-SpeedControlUnitOutputtoTurntableInput

The AC mains power cable is connected to the power unit AC input.

A push ON/OFF switch is located on the rear of the power supply unit.

IMPORTANT

The mains voltage seng is indicated on the rear panel of the power unit.

Before ng the mains power cable check carefully that this matches your

mainsvoltage.

7. Phono Stage Power Unit

ConnecttheNagrapowerunitlowvoltageoutputcableintotheturntable

chassisconnectorattherearoftheturntable

.

8. Tonearm Set Up

Synergy is equipped with a factory ed SME tonearm. Refer to the

tonearminstruconmanualforsetupprocedures.

13

11. CARTRIDGE

Thetonearmandcartridgearefactoryinstalledandsetup.Itisadvisedthat

postshippingtransitadigitalstyluspressuregaugeisusedtocheckthatthe

styluspressurehasremainedatthefactorysengof2.3grams.

Should the cartridge need to be replaced, observe the following guideline

points and refer to the tonearm manual.

1. Before removal and installaon of the cartridge, ensure that its stylus

guardisinposionasaprecauonagainstaccidentaldamage.

2. TheSiltechsilvercartridgeleadshave1mmdiameterreceptaclesforthe

headshellandstandard1.25mmforthecartridge.Thelaermayrequire

adjustmentwithpointednosepliersorascrewdriverbladeforasnugt

onnon-standardterminals.Conneconstothecartridgemustneverbe

madebydirectsoldering.

3. Thecartridgeleadcolourcodingisasfollows:

Red-RightChannel

Green-RightChannelGround

White-LeChannel

Blue-LeChannelGround

4

. Replacement Siltech silver cartridge leads can be obtained direct

from SME.

Blue

White

Green

Red

14

12. POWER CABLE CONNECTIONS

Le RCA Phono OutputRight RCA Phono Output

AC Power Cable Nagra Phono Stage Input

Connecon Cable ‘A’ Connecon Cable ‘B’

Output

Output

Input

Power Unit Speed Control Unit

NOTE:

Mains power must be owhenconnecnganddisconnecngCablesAandB.

15

13. OPERATION - TURNTABLE

YourSynergyprecisionturntableispartlyrun-inbeforeleavingthefactory

but will benet and improve aer a few weeks of use. Do not worry if

iniallythebearingisnottotallysilent.Aslight‘swish’barelyaudibleat

verycloserangeinasilentroomwillquicklydisappearaeruseofthe

turntable.Ifyoushouldwishtocheckthespeedsengsandmakeyour

ownadjustmentstheprocedureisasfollows:

1. Mains Power:thepowerON/OFFbuonislocatedontherearof

the power unit. With power ON the last used speed indicator LED

lightwillilluminateonthespeedcontrolunitfascia.

2. Motor Power: pressing the power buon on the speed control

unitfasciawillstartthe motor.WithpowerOFF andpressingthe

rotarybuononthefasciathespeedsengsof331

/3and 45rpm will

cycleandbeindicatedbythespeedLED.Withthemotorrunning,

pressingthepowerbuonwillstopthemotor.

3. Speed Tesng: the stroboscopic disc installed on the plaer is

used to check speeds of 331

/3 and 45rpm. Use the strobe bands

appropriateforyourmainsACfrequency.Thediscshouldbeviewed

inauorescentorneonlight.Theappropriatebandwillsynchronise

and appear staonary when the speed is correct. Whilst forward

and reverse band movement will indicate fast or slow running

respecvely.Thisisbestobservedwiththecartridgeedandthe

tonearm in the raised posion and placed directly over the band

beingviewedasareferencepoint.

4. Speed Adjustment: with the motor running press and hold the

rotarybuonfortwoseconds,the speedindicatorLED willbegin

toash.Themotorisnowinspeedadjustmodeandthespeedcan

nowbeadjustedinconjunconwiththestroboscopicdisc.Turning

the rotary buon an-clockwise will reduce speed and clockwise

willincreasespeed.Themethodprovidesamicroneincremental

adjustment.Whenthespeedadjustmentiscompleteddepressand

release the rotary buon, the speed indicator LED light will stop

ashingandbecomeconstantandthespeedsengwillbestored

in the system memory for future use.

5. Repeatthisprocessforthe45rpmspeedrangeifrequired.

16

14. OPERATION - PLAYING A RECORD

Placetherecordspindlewasheronthespindlefollowedbytherecord

andclamp.Theclampshouldbescreweddownclockwiseenough

todeecttherecordatintormcontactwiththeplaer.Witha

ngerp,taptherecordinthreeplacesequallyoveritssurfaceand

withalilepracceitwillsoonbecomeevidentwhetherornotthe

recordistouchingtheplaer.Ifnot,somefurtherghteningofthe

clampmaybenecessary.

15. OPERATION - TONEARM

1. Withthecontrolleverintheraisedposionmovethetonearmout

ofthearmrestandposionthetonearmsothatthestylusisover

theselectedrecordgroove.

2. Tolowerthestylusontotherecordmovethecontrolleverforward

unlitisjustpasttopdeadcentre.Thiswillsettheloweringcontrol

inmoon,atwhichpointitwilltakeoverthemovementofthelever,

givingasmoothcontrolleddescent.

Note:Forthe correct descentmethe controlmust beoperated

exactly as above. The speed will be increased considerably if the

lever is pushed down instead of being allowed to fall of its own

accord.

3. To raise the stylus from the record slowly move the control lever

backtoitsoriginalposion.Whenthetonearmisnotinuseitshould

alwaysbereturnedtothearmrestforsafety.

16. MAINTENANCE - TURNTABLE

1. Therearenocricaladjustmentsorneedfor‘tweak’andonlyvery

lilemaintenanceisrequired.Cleanthedrivebeltoccasionallyby

drawing it through a piece of so ssue or linen moistened with

lighterfuel.Thesamematerialmaybeusedtocleantheperiphery

ofthemotorpulleyanddrivenpulley.Themainbearingislubricated

for life.

2. Replacethedrivebeltaer1000hoursuse.Areplacementbeltis

availabledirectlyfromSME.

3. Therearenouser-serviceablepartsinsidethepowerunitandspeed

control unit.

17

17. TRANSIT PRECAUTIONS

Synergycanbesafelytransported,

SUBJECT TO THE FOLLOWING PRECAUTIONS:

Shortjourneysbycar:removetheplaer,disengagethedrivebeltfrom

the motor pulley and replace the transit screw. The plaer and other

itemscanbestowedseparatelyprovidedtheyarecarefullyprotected.For

allothertransportaonpurposestheoriginalpackingcaseandmaterials

mustbeused.

18. GUARANTEE

Your SME Synergy turntable is guaranteed against faulty material and

workmanship.Thenominalperiodoftheguaranteeis24monthsbutis

liberallyinterpretedatSME’sdiscreonsubjecttothefollowingcondions

beingobserved:

1. AnymaerarisingmustintherstinstancebereportedtoSMEat

theaddressappearingbelow.

2. Do not return the turntable or any part thereof to SME unless

requested to do so.

3. SMEwillnotacceptliabilityforanyitemsunltheyreachthefactory

safely.

4. Any parts found to be faulty will be replaced free of charge.

5. Returntransportandinsurancecostswillbecharged.

6. Theguaranteeexpresslyexcludes:

(a)Cartridge/Styluswearandtear.

(b)Damagebyanycause.

(c)Conngentandthirdpartyliability.

(d)Personalinjury.

7. No alteraon or variaon of the guarantee will be recognised

bySME.

8. Theguaranteeisnottransferable.

SME LIMITED · MILL ROAD · STEYNING · WEST SUSSEX ·BN443GY· ENGLAND

T:+44(0)1903814321· E: [email protected] · W: www.sme.ltd.uk

18

19. APPENDIX

Wehope theseinstruconshavemadethe installaonofyourSynergy

precisionturntablestraighorward.Careforitasbetsitsneconstrucon.

Donotinvertit.Donotapplyoilorotherlubricantexceptasdirected.Do

notaempttotakeittopiecesorinterferewithanyofthescrewsexcept

asdirectedintheinstrucons.Todosowillinvalidatetheguaranteeand

mayincurcostlyrepairs.Keepyourturntablecleanbydusngitregularly

withdueregardforthesafetyofthecartridgeandstylus.Fingermarks

may be removed from the nished surfaces with a linen handkerchief

moistened with warm soapy water. Do not use any kind of spirit or solvent

cleaner.

Intheunlikelyeventofaproblemconcerningoperaonorservice,always

contactthesupplyingdealerorSMELimitedstangtheexactnatureof

theproblemandtheserialnumberwhichwillbefoundontherearofthe

main chassis.

EC DECLARATION OF CONFORMITY

The SME Synergy Turntable has been manufactured to conform with the protecon

requirementsoftheECCouncilDirecve89/336/EECrelangtoEMCbyapplicaonof

thefollowingstandards:

BSEN61000-6-3:2007+A1:2011EmissionsStandard.

BS EN 61000-6-1:2007 Immunity Standard and also the requirements of the EC low

voltagedirecverelangtoelectricalsafetybyapplicaonofthefollowingstandard:

BSEN62368-1:2014InternaonalSafetyStandard.

ForthepurposesoftesngtheSMESynergyTurntablewasusedwiththehighquality

interconnects supplied as standard equipment. Compliance with the above standards

mayonly bemadeifthe unitisinstalledas perthisinstruconmanualandusing the

correctcables.

SME Limited · Mill Road · Steyning · West Sussex · BN44 3GY · England

PrintedinSteyningEngland

19

SME LIMITED •STEYNING •WEST SUSSEX •ENGLAND

Table of contents

Other SME Turntable manuals

Popular Turntable manuals by other brands

ZEN

ZEN Neeon 2 manual

auna

auna TBA-928 manual

Gold Note

Gold Note Vasari Series user manual

Audio Technica

Audio Technica AT-LP60XBTa user manual

Pro-Ject Audio Systems

Pro-Ject Audio Systems Pro-Ject RPM 5 SuperPack Instructions for use

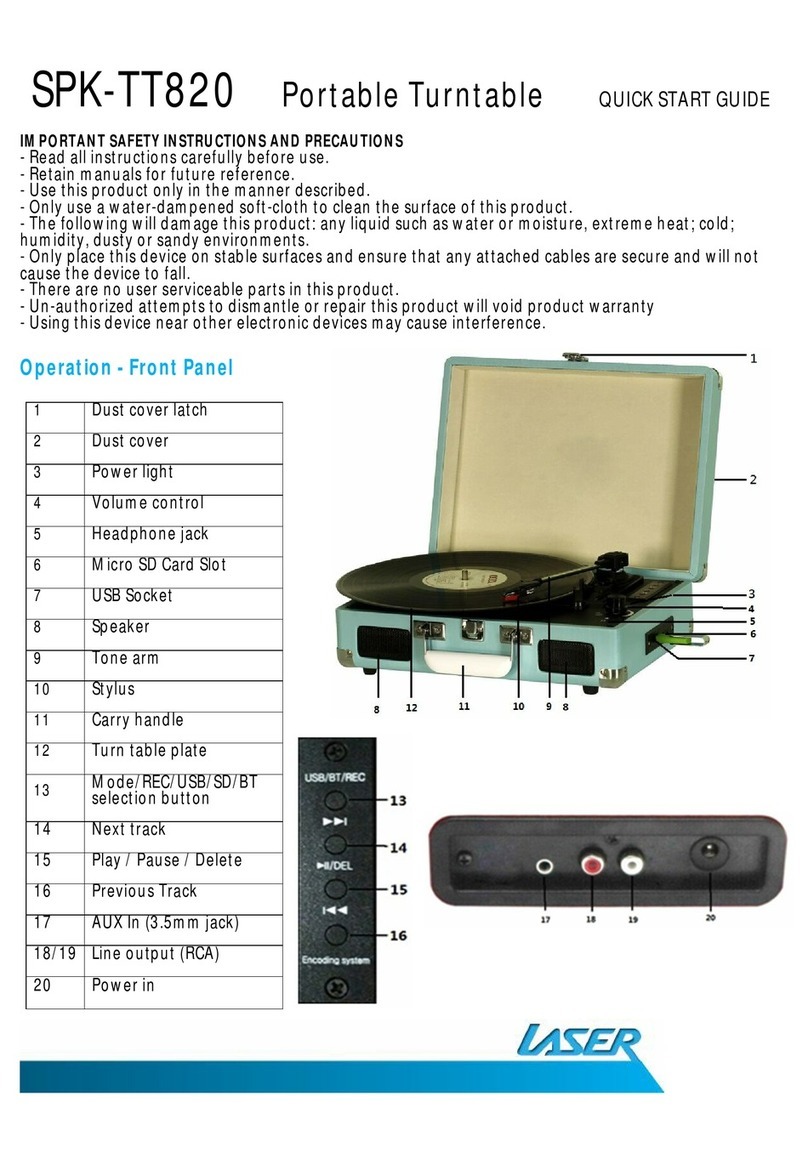

Laser Corporation Pty

Laser Corporation Pty SPK-TT820 quick start guide