SME Model 6 User manual

INTEGRATED PRECISION TURNTABLE

OWNERS MANUAL

CLASSIC

Instructions

This is no ordinary turntable.

These instrucons include unpacking, set up procedures and specicaons.

Please read carefully.

INTEGRATED PRECISION TURNTABLE

CLASSIC

Warning! Important Safety Instrucons

CAUTION: RISK OF ELECTRIC SHOCK DO NOT REMOVE POWER UNIT COVER.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE THE SPEED CONTROL UNIT (POWER UNIT)

COVER. THERE ARE NO USER SERVICEABLE PARTS INSIDE. REFER ALL SERVICING TO QUALIFIED PERSONNEL.

• Please read this manual carefully and keep it in a safe place for future reference.

• The vent slots in the underside of the Speed Control Unit are for necessary venlaon. To ensure reliable operaon of this apparatus

and to protect from overheang these vents must never be blocked or covered.

• Do not place a water containing vessel on this apparatus, as this can result in a risk of re or electric shock. Do not expose this apparatus

to rain or place it near water.

• If this apparatus accidentally gets wet, unplug it and contact an authorised dealer immediately.

• You can clean this apparatus with a damp cloth when necessary, but be sure to unplug the apparatus rst. To cut o the power source,

unplug the apparatus from the AC wall outlet.

• Do not overload AC wall outlets, power cables or adaptors beyond their capacity as this can result in re or electric shock.

• Power cables should be routed so that they are not likely to be walked on or pinched by items placed upon or against them, paying

parcular aenon to cables at the plug end, adaptors and the point they exit from the appliance.

• Before connecng the AC power cable to the Speed Control Unit, make sure the voltage of the Power Unit, as marked on the idencaon

label at the rear, corresponds to the local electricity supply.

• Never insert anything metallic into the open parts of this apparatus.

• Only a qualied technician should remove the Speed Control Unit cover.

• Be sure to hold the plug, not the power cable, when disconnecng this apparatus from an electric socket.

• Locate this apparatus near an easily accessible AC outlet.

• If this apparatus does not operate normally, in parcular if there are any unusual sounds or smells, unplug it immediately and consult

an authorised dealer.

• Unplug this apparatus from the AC outlet before any service.

1

IMPORTANT NOTICE:

The power cable on this equipment when supplied for use in the UK, is ed with a moulded plug incorporang a fuse. The value of the

fuse is indicated on the pin face of the plug and if it required replacing a fuse approved to BSI 1362 of the same rang must be used. Never

use the plug with the fuse cover omied if the cover is detachable. If the plug ed is not suitable for the power points in your room or if

the power cable is not long enough to reach the power point, you should obtain a suitable safety approved extension lead or consult your

dealer for assistance.

IMPORTANT:

The wires in the power cable are coloured in accordance with the following code: BLUE NEUTRAL, BROWN LIVE. As these colours may not

correspond to the coloured markings idenfying the terminals in your plug, proceed as follows: The wire coloured BLUE must be connected

to the terminal marked with the leer N or coloured BLUE or BLACK. The wire coloured BROWN must be connected to the terminal marked

with the leer L or coloured BROWN or RED.

WARNING:

DO NOT CONNECT EITHER WIRE TO THE EARTH TERMINAL, WHICH IS MARKED WITH THE LETTER (E) OR BY THE EARTH SYMBOL OR

COLOURED GREEN OR GREEN/YELLOW.

WEEE SYMBOL INFORMATION

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

(Applicable to the European Union and other European countries with separate collecon system).

The marking shown on this product or its literature, indicates that it should not be disposed with other household wastes at the

end of its working life. To prevent possible damage to the environment or human health from uncontrolled waste disposal, please

separate this from other types of wastes and recycle it responsibly to promote the sustainable re-use of material resources.

Household users should contact either the retailer where they purchased this product or their local government oce,

for more detailed informaon of where and how they can take this item for environmentally safe recycling.

Business users should contact their supplier and check the terms and condions of the purchase contract.

This product should not be mixed with other commercial wastes for disposal.

2

Introducon

SME is an iconic brand founded in 1946 by audio legend Alastair Robertson-Aikman in

West Sussex, England. Today SME is recognised as makers of the nest precision turntables

and tonearms in the world. Enrely made in-house by state of the art manufacturing

processes, complemented by tradional crasmanship methods. SME audio has evolved

from 75 years of engineering excellence, innovaon and perfecon delivering precise and

pure audio reproducon.

The Model 6 Classic is a precision turntable with a CNC machined chassis made from

a unique polymer high density resin material which provides high mass and superb

resonance absorpon. The chassis is complemented by a specialist isolaon system

incorporated into the self-levelling feet. The main bearing, spindle and drive pulleys

are precision made to the same exact standards as all SME high-end turntables. Speed

control is a highly sophiscated bi phase, frequency and amplitude, DSP based sine wave

generator, with a dedicated discrete power amplier to drive the motor. It generates

two pure sine waves which drive twin coils present inside a custom made AC motor. The

frequency (speed) is user adjustable in approximately 0.0133 Hz steps allowing a very

accurate musical pitch to be set.

The Model 6 Classic is equipped with the highly credible SME M2-9R tonearm which is

of meculous build quality. Primary features include lightweight stainless steel tonearm

tube, detachable aluminium headshell with double draw pins for extra rigidity and azimuth

adjustment, thumbwheel vercal tracking adjustment, tungsten balance weight(s) and

high quality ball race bearings in all planes. The M2-9R tonearm is designed to suit a wide

range of cartridges up to 38 grams and with a direct plug-in head up to 46 grams.

Design and engineering excellence built by audio enthusiasts for audio enthusiasts.

3

Contents

1 Weights & Dimensions

2 Packing List

3 Parts Idencaon

4 Unpacking

5 Seng Up

6 Operaon – Speed Control

7 Operaon – Turntable

8 Tonearm

9 Maintenance

10 Guarantee

4

1. Weights & Dimensions (mm)

Turntable

Width: 420

Depth: 320

Height: 128

Plaer Diameter: 300

Spindle to Arm: 215.4

Net Weight: 9.1kg

Speed Control Unit

Width: 220

Depth: 200

Height: 85

Net Weight: 2.05kg

Power Consumpon: Idle 5W - Max 10W

5

2. Packing List

Qty Descripon 3

1 Model 6 Serial No □

1 M2-9R Tonearm □

1 Control Unit – 100V □ 115V □ 230V □ □

1 Power Cable – UK □ EU □ USA □ □

1 Plaer □

1 Stroboscopic Disc □

1 Record Clamp □

1 Spindle Washer □

1 Drive Belt □

1 Velcro Strap □

1 Balance Weight □

1 Accessory Weight □

1 Detachable Headshell □

1 Cartridge Screw Set □

1 Bias Weight □

1 Bias Guide □

1 2mm Hex Wrench □

1 0.89mm Hex Wrench □

1 Alignment Protractor □

1 Owner’s Manual □

6

2

5

6

11

10

9

12

7

1

3

4

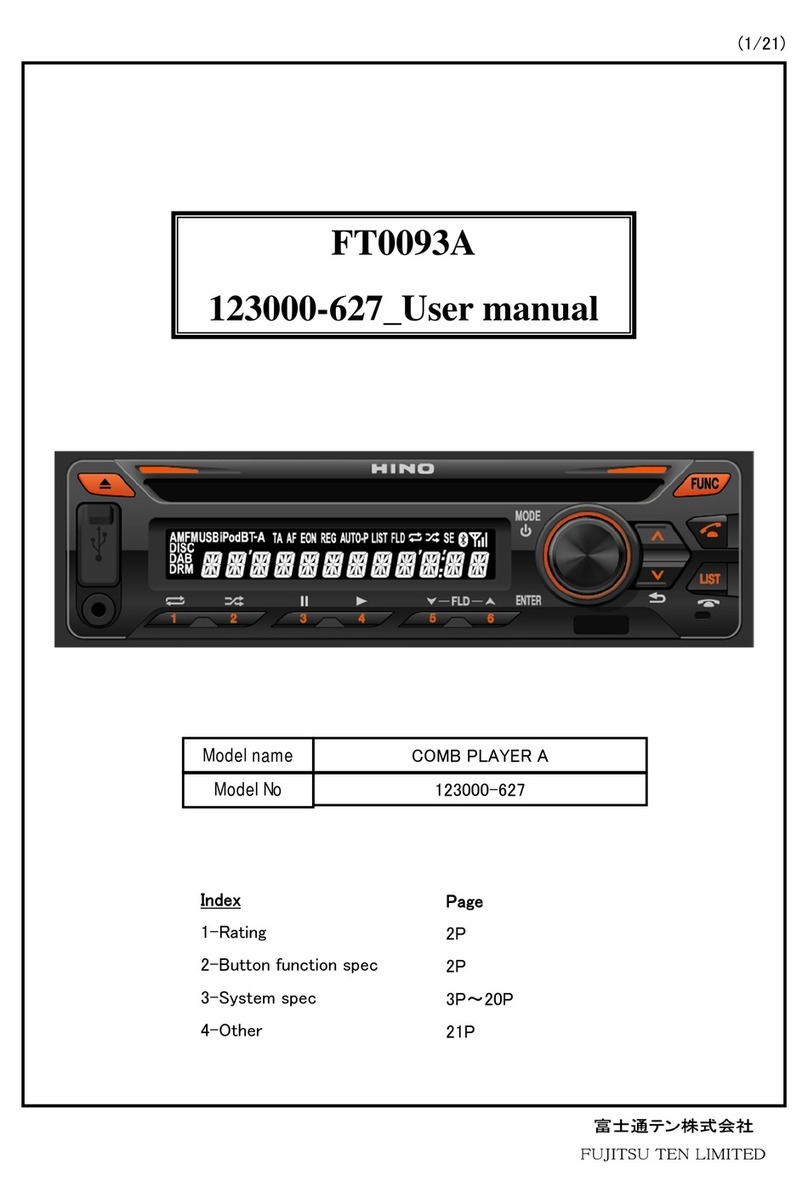

1. Speed Control Unit

2. Power ON/OFF Buon

3. Rotary Speed Control

4. Plaer

5. Bias Weight

6. Bias Guide

7. An-Skate Lever

8. Balance Weight

9. Tonearm

10. Finger Li

11. Headshell

12. Wayrod/Rider Weight

3. Parts Idencaon

7

8

8

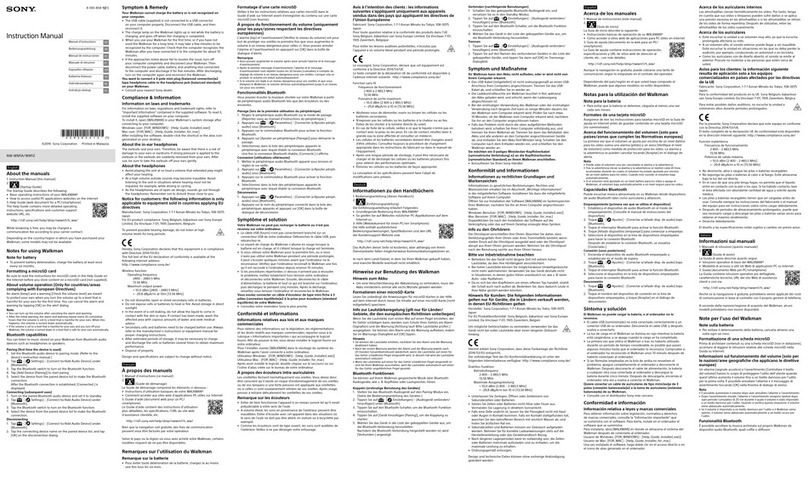

Power Cable & Phono Connectors

Idencaon

Low Voltage

Power Cable 24V

Phono Output

Sockets

Power

ON / OFF

Earth Point

AC Power

Cable Socket

Low Voltage Input

Socket 24V

9

5. Seng Up

1. With the turntable sited, follow the set

up instrucons in the order detailed.

2. Drive belt installaon: place the belt

over the driven pulley, pressing it down

as far as the lower ange and ensuring

free from twists and stretch the belt

over the motor pulley. Rotate the

driven pulley slowly by hand to posion

the belt on the pulleys.

3. Plaer tment: ensure the upper face

of the driven pulley and the underside

of the plaer mang surfaces are

clean, place the plaer squarely over

the turntable spindle lowering it gently

unl it rests on the driven pulley.

4. Speed control unit: t the mains power

cable (check carefully that this matches

your mains power voltage). The mains

voltage seng is indicated on the back

panel.

4. Unpacking

1. Unpack and check all items against the

packing list in Secon 2. In the very

unlikely event that anything is missing

your dealer should be noed at once.

2. The design of the turntable allows it

to be used on any substanal table or

similar piece of furniture in the absence

of a dedicated audio equipment stand.

WARNING! To meet internaonal

safety standards the control unit is

earthed through the yellow/green

wire of the power cable and parcular

care must be taken to ensure that

this is connected in order to maintain

eecve earthing.

5. Low voltage connecon cable: connect

the speed control unit to the turntable

by inserng the cable plug into the

24v input socket at the rear of the

turntable.

6. Timeout: if in adjustment mode and

no adjustments have been made for 20

seconds the new sengs will be saved

and the system will exit adjust mode

and resume running normally.

7. Cancel/Abort Adjustment: with the

motor running and the system in

adjustment mode, if the power buon

is pressed, the motor will stop and any

adjustments that have been made will

be discarded and not saved.

7. Operaon – Turntable

1. Turn on mains power at rear of the speed

control unit (push ON/OFF switch).

2. Place record spindle washer on spindle

followed by the record.

3. Fit record clamp by holding main body

of the clamp and turn locking knob

gently about 1⁄4 turn.

4. Select required speed by pressing the

rotary control buon on speed control

unit unl 33 or 45 is indicated.

5. Press power buon.

6. You are now ready to play your record.

10

appear staonary when the speed is

correct. Whilst forward and reverse

band movement will indicate fast or

slow running respecvely. This is best

observed with the cartridge ed and

the tonearm in the raised posion and

placed directly over the band being

viewed as a reference point.

4. Speed Adjustment: with the motor

running press and hold the rotary buon

for two seconds, the speed indicator

LED will begin to ash. The motor is now

in speed adjust mode and the speed

can now be adjusted in conjuncon

with the stroboscopic disc. Turning the

rotary buon an-clockwise will reduce

speed and clockwise will increase

speed. The method provides a microne

incremental adjustment. When the

speed adjustment is completed depress

and release the rotary buon, the speed

indicator LED light will stop ashing and

become constant and the speed seng

will be stored in the system memory for

future use.

5. Repeat this process for the 45rpm speed

range if required.

The Model 6 precision turntable is

extensively run-in and it’s speeds set before

leaving the factory. If you should wish to

check the speed sengs and make your own

adjustments, the procedure is as follows:

1. Mains Power: the power ON/OFF

buon is located on the rear of the

speed control (power unit). With power

ON the last used speed indicator LED

light will illuminate on the speed control

unit fascia.

2. Motor Power: pressing the power

buon on the speed control unit fascia

will start the motor. With power OFF and

pressing the rotary buon on the fascia

the speed sengs of 33 and 45rpm will

cycle and be indicated by the speed LED.

With the motor running, pressing the

power buon will stop the motor.

3. Speed Tesng: the stroboscopic disc

installed on the plaer is used to check

speeds of 33 and 45rpm. Use the strobe

bands appropriate for your mains AC

frequency. The disc should be viewed

in a uorescent or neon light. The

appropriate band will synchronise and

6. Operaon – Speed Control

11

Note:

Tonearm images for references only, mounng base plate prole may vary.

For your convenience the headshell is supplied detached from the tonearm ready for tment of your cartridge.

Cartridge not supplied – images of cartridge used for illustraon purposes only.

8. Tonearm

• General Arrangements

• Dimensions

• Specicaons

• Fing Balance & Bias Weights

• Fing Headshell & Cartridge

• Tonearm Set Up & Adjustment

12

General Arrangement

13

Dimensions (mm)

A – Pivot to Stylus 233.20

B – Pivot to Turntable Centre 215.40

C – Cartridge Fixing Centres 12.70

D – Oset Angle (degrees) 23.63˚

E – Linear Oset 93.47

F – Overhang 17.80

G – Height above Mounng Surface (Max) 87.00

Height above Mounng Surface (Min) 63.00

H – Mounng Surface to Underside of Headshell (Max) 67.40

Mounng Surface to Underside of Headshell (Min) 43.40

J – Depth below Mounng Surface 46.00

K – Balance Weight Radial Clearance 79.00

Specicaons (g/mm)

Eecve Mass (g) 9.50

Cartridge Balance Range

Headshell: Up to (g) 38.0

Plug-heads: Up to (g) 46.0

Vercal Tracking Force (g) 5.0

Maximum Tracking Error (degree/mm) 0.013

Null Points: Inner (mm radii) 66.04

Outer (mm radii) 120.9

Silver Litz Internal Wiring

RCA Phono – Gold Plated Connectors

14

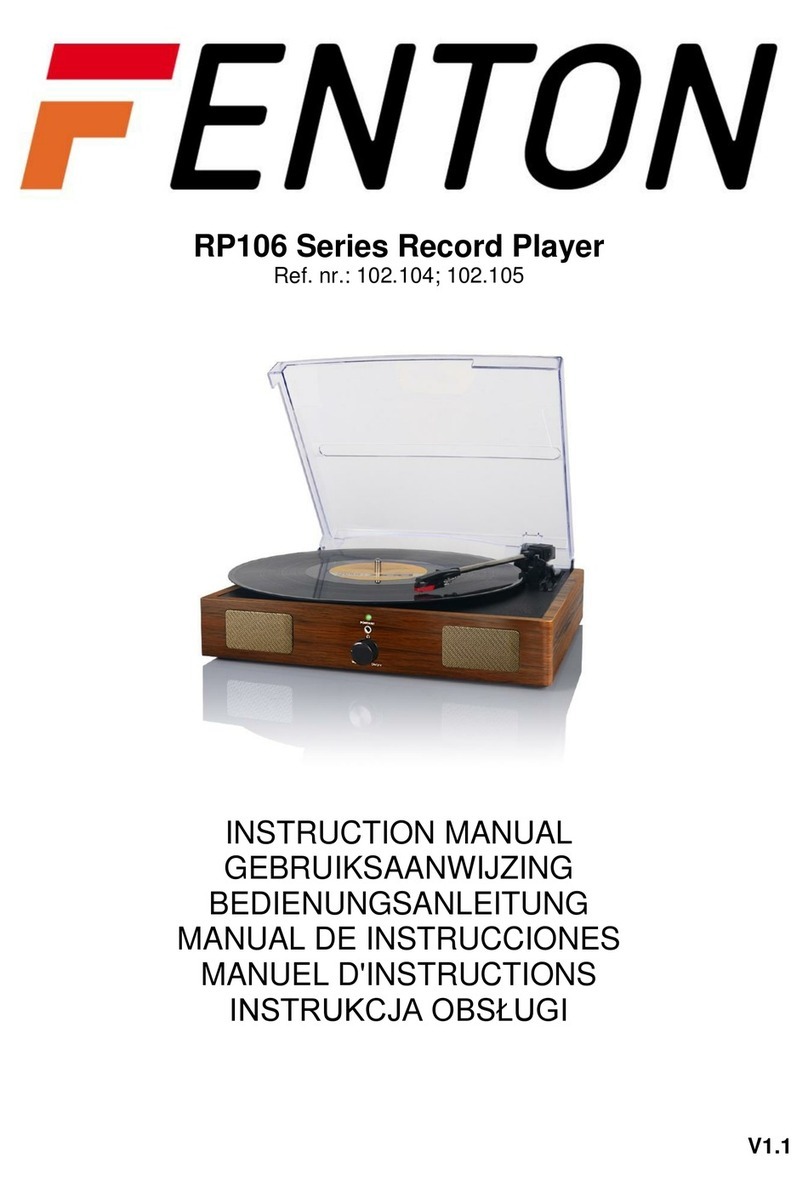

Anti

-Skate Guide

Accessory Balance Weight

Balance Weight

Anti

-Skate Weight

Anti

-Skate Lever

Arm Lift

M3 Button Head Mounting Screw

& Arm Mounting Washer

Bedplate

Shield Can

Armrest Catch

Armrest

Tonearm

Azimuth Locking Screw

underside tonearm at this point

Arm Socket Nut

Detachable Headshell

Ground Terminal

Control Lever

Base Clamp Nut & Washer

VTA Thumbwheel

Wayrod/Rider Weight

Pillar Clamp Screw

Tonearm Idencaon

Fing Balance & Bias Weights

The tonearm balance and bias weights are packed separately for safety in transit. Carefully screw the balance weight onto the threaded

stud on the rear of the tonearm, the dial should face forward towards the headshell.

Fing of the bias weight is described in the following set up pages.

15

Before ng the cartridge see that the

stylus guard (not illustrated) is in posion

as a precauon against accidental damage.

Cartridge leads may require adjustment for

a snug t. This can be achieved by use of

pointed nose pliers to close connectors or

with a narrow screwdriver blade to splay

(open) connectors. Connecons must

never be made by direct soldering.

The coding is as follows:

Red – Right Channel Signal

Green – Right Channel Ground

White – Le Channel Signal

Blue – Le Channel Ground

Most cartridges have their own screws.

One pair #3-48 UNC x 11mm with nuts

and washers are provided, other lengths

are available from SME.

Examine the top of the cartridge. It is

important that it presents a good at face

to the underside of the headshell. Before

nal ghtening check that the cartridge is

lying parallel to the reference edge of the

headshell, as shown.

Tighten the xing screws securely using a

screwdriver, which must be a good t in

the screw slots to avoid damage. Hold the

nut if necessary to prevent rotaon.

The screws are non-magnec. Damage

can be caused if a screw is snatched by

magnec aracon whilst being oered

up to the cartridge. For the same reason

do not lay down tools nearby.

Fing Headshell & Cartridge

16

WHITE

BLUE

GREEN

RED

WHITE

BLUE

GREEN

RED

WHITE

BLUE

GREEN

RED

Cartridge Lead Replacement

Replacement cartridge leads can be

obtained directly from SME.

They should be ed according to the

colour coding shown looking onto the

headshell from the front.

Fing Headshell

Insert the headshell into the arm socket

and press rmly inwards unl the draw

pins contact the thread of the socket nut.

Maintaining pressure, turn the socket nut

an-clockwise viewed from the front to

draw the headshell home. It should be

ghtened rmly but not to the point of

strain.

Removing Headshell

Removal is the reverse of ng. Holding

the headshell rmly to prevent rotaon

turn the socket nut, clockwise when

viewed from the front, unl the headshell

is completely released.

Take care to avoid damaging the cartridge

during this operaon.

17

Longitudinal Balance

With only the main balance weight ed,

cartridges up to 16g may be balanced.

However by removing the balance weight

end cap and coupling the accessory balance

weight (as illustrated) cartridges up to 38g,

mounted in the headshell or plug in heads

up to 46g can be catered for.

Slide the wayrod/rider weight into the

rearmost zero posion and balance the

tonearm by rotang the balance weight in

the required direcon.

Remove the accessory balance weight,

when needed, by unscrewing an-clockwise

from the balance weight. Replace the

balance weight end cap.

Adjust unl the tonearm (with the cartridge ed) is either level or slightly low at the

front end.

Tonearm Set Up & Adjustment

18

For safety the lever of the lowering control

should now be moved into the raised

posion.

VTF is set aer longitudinal balancing has

been completed.

It is applied by moving the complete

wayrod assembly forward as indicated.

The assembly is calibrated to provide a

maximum of 5.0g VTF in 1.0g increments

between the indent posions.

Posion shown is the seng for 3.0g VTF.

Half gram sengs are indicated by the

shallow grooves alternang with the

indent posions.

Vercal Tracking Force (VTF) Adjustment

Other manuals for Model 6

1

Table of contents

Other SME Turntable manuals