Summary

1 PRECAUTIONS FOR SAFETY AND USE .......................................................................................................................2

1.1 Trademark ........................................................................................................................................................2

1.2 Name and address of manufacturer or d str butor ..........................................................................................2

1.3 Declarat on of conform ty to product standards ..............................................................................................2

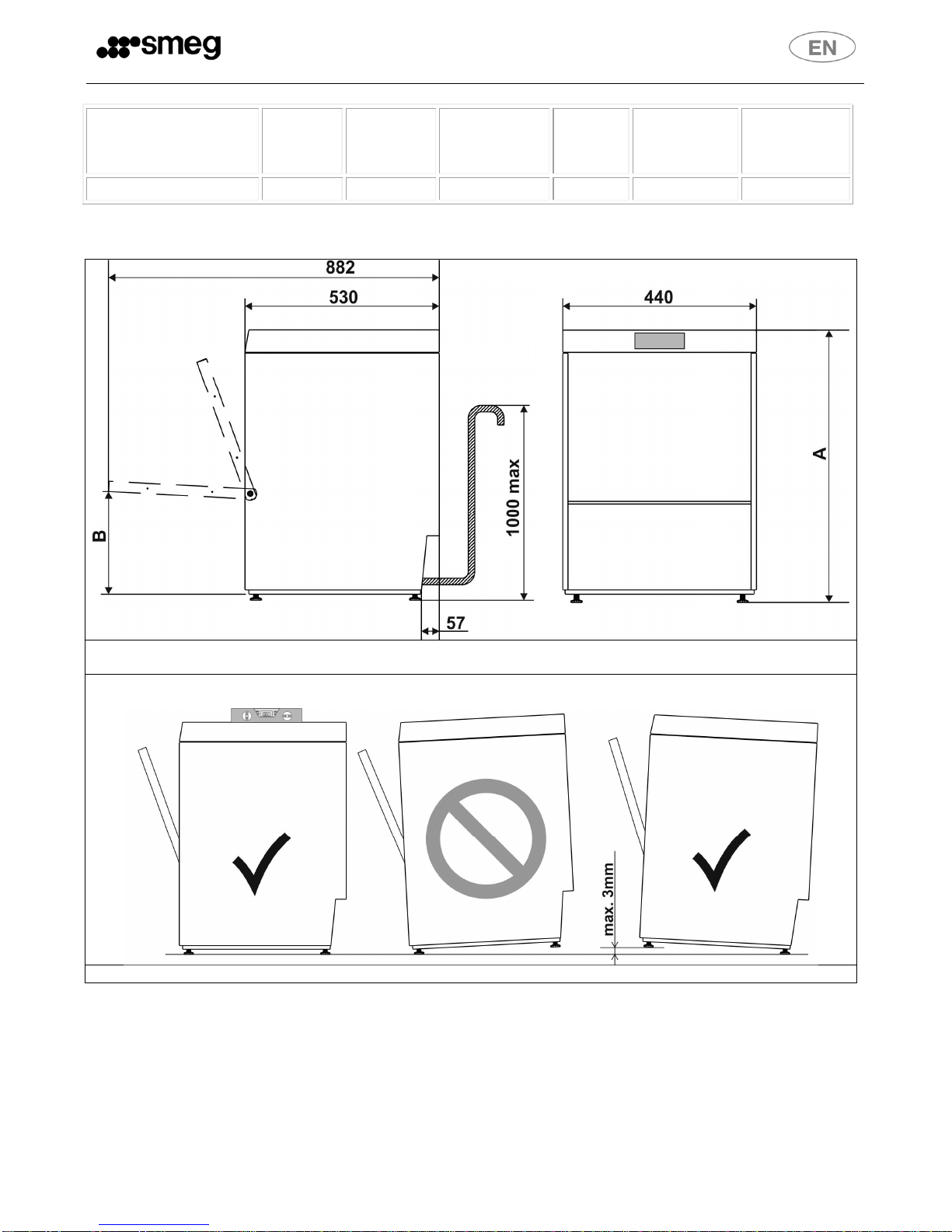

2 TECHNICAL DATA ......................................................................................................................................................3

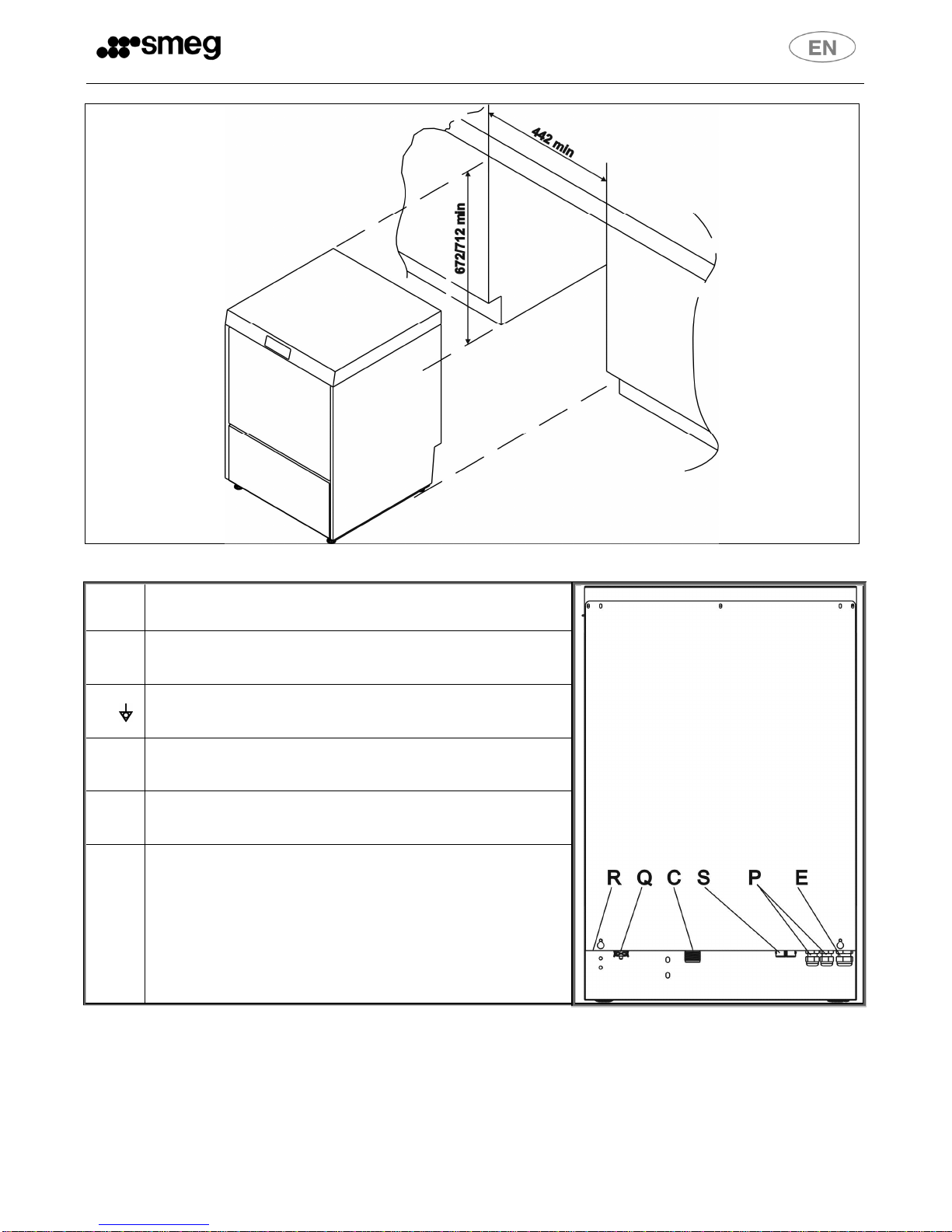

3 INSTALLATION AND POSITIONING ............................................................................................................................6

4 INSTRUCTIONS FOR TECHNICAL STAFF .....................................................................................................................6

4.1 Plumb ng hookup ..............................................................................................................................................6

4.2 Electr cal connect on ........................................................................................................................................7

5 FIRST START-UP ........................................................................................................................................................7

5.1 Us ng the water softener (on models w th th s feature only) ..........................................................................8

6 SET-UP (Author sed techn cal staff only) ..................................................................................................................9

6.1 Contents of d splay ........................................................................................................................................ 10

6.2 Note on d splay of temperatures .................................................................................................................. 10

6.3 Parameter programm ng procedure (setup) ................................................................................................. 10

6.4 Mod f able parameters .................................................................................................................................. 11

6.5 Adjust ng detergent and r nse a d d spens ng (only ava lable on certa n models) ........................................ 11

6.5.1 R nse a d – Grams/l ter dosage (depends on model)- The d splay reads “ri” ....................................... 11

6.5.2 Detergent - Grams/l ter dosage (depends on model) - The d splay reads “dE” .................................... 11

6.6 Start ng the per stalt c pumps n manual mode – rap d f ll ng of detergent and r nse a d c rcu t ................ 12

6.7 Adjust ng the regenerat on frequency (models w th softener only) ............................................................. 12

6.8 Ma ns water hardness sett ng table .............................................................................................................. 12

6.9 Extra r nse opt on (long r nse). - D splay reads “E.r” ..................................................................................... 12

6.10 "Clean water cycle" opt on - D splay reads “CL” ........................................................................................... 13

6.11 “Thermostop” opt on - D splay reads “tS” .................................................................................................... 13

6.12 Fast/eco start ng opt on - D splay reads “F”................................................................................................. 13

7 MALFUNCTIONS SHOWN ON THE DISPLAY (FOR THE TECHNICIAN) ..................................................................... 13

8 INSTRUCTIONS FOR THE USER ............................................................................................................................... 15

8.1 Control panel ................................................................................................................................................. 15

8.2 Before wash ng .............................................................................................................................................. 16

8.3 F rst use each day (tank and bo ler empty) ................................................................................................... 17

8.4 Choos ng the program ................................................................................................................................... 18

8.5 Chang ng the program ................................................................................................................................... 18

9 MAINTENANCE AND CLEANING............................................................................................................................. 20