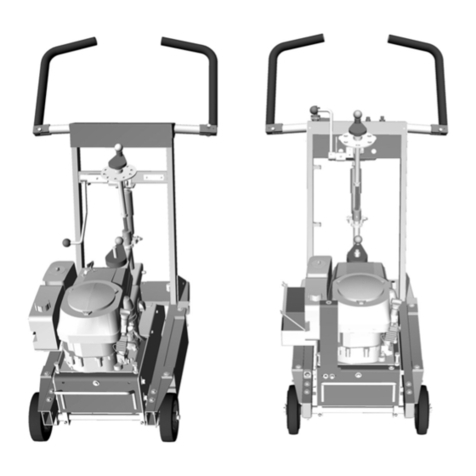

Smith FS351 Series User manual

®

FS351 PCD Drum Assembly

Table of Contents

Component Identication............................................................................. page 3

Drum Assembly ............................................................................................ page 4

First Endcap Installation ................................................................ page 4

Plate Installation ............................................................................ page 4

Second Endcap Installation........................................................... page 5

Drum Installation .......................................................................................... page 6

Sideplate Removal......................................................................... page 6

Options for Handling/Lifting Drum................................................. page 7

First Hex Alignment ....................................................................... page 7

Second Hex Alignment.................................................................. page 8

Final Drum Assembly Onto Shaft .................................................. page 9

Sideplate Installation ..................................................................... page 9

SMITH Warranty ........................................................................................... page 10

2

WARNINGS

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to

a general warning and the hazard symbols refer to procedure-specic risks. When these symbols appear in the body of this manual or on warning

labels, refer back to these Warnings. Product-specic hazard symbols and warnings not covered in this section may appear throughout the body

of this manual where applicable.

DUST AND DEBRIS HAZARD

Grinding concrete and other surfaces with this equipment can create dust that contains hazardous substances. Grinding can also create ying

debris.

To reduce the risk of serious injury:

• Control the dust to meet all applicable workplace regulations.

• Wear protective eye wear and a properly t-tested and government approved respirator suitable for the dust conditions.

• Use equipment only in a well-ventilated area.

• Grinding equipment must be used only by trained personnel who understand the applicable work-place regulations.

ENTANGLEMENT AND MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate ngers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Before checking, moving, or servicing equipment, disable power. For gas/propane units, disconnect negative (-) battery cable. For electric units,

unplug power cord.

BURN HAZARD

Cutters and engine can become very hot during operation. To avoid severe burns, do not touch hot equipment. Wait until equipment has cooled

completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you

from serious injury, including eye injury, inhalation of dust or chemicals, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear.

• Protective shoes.

• Gloves.

• Hearing protection.

• Properly t-tested and government approved respirator suitable for the dust conditions.

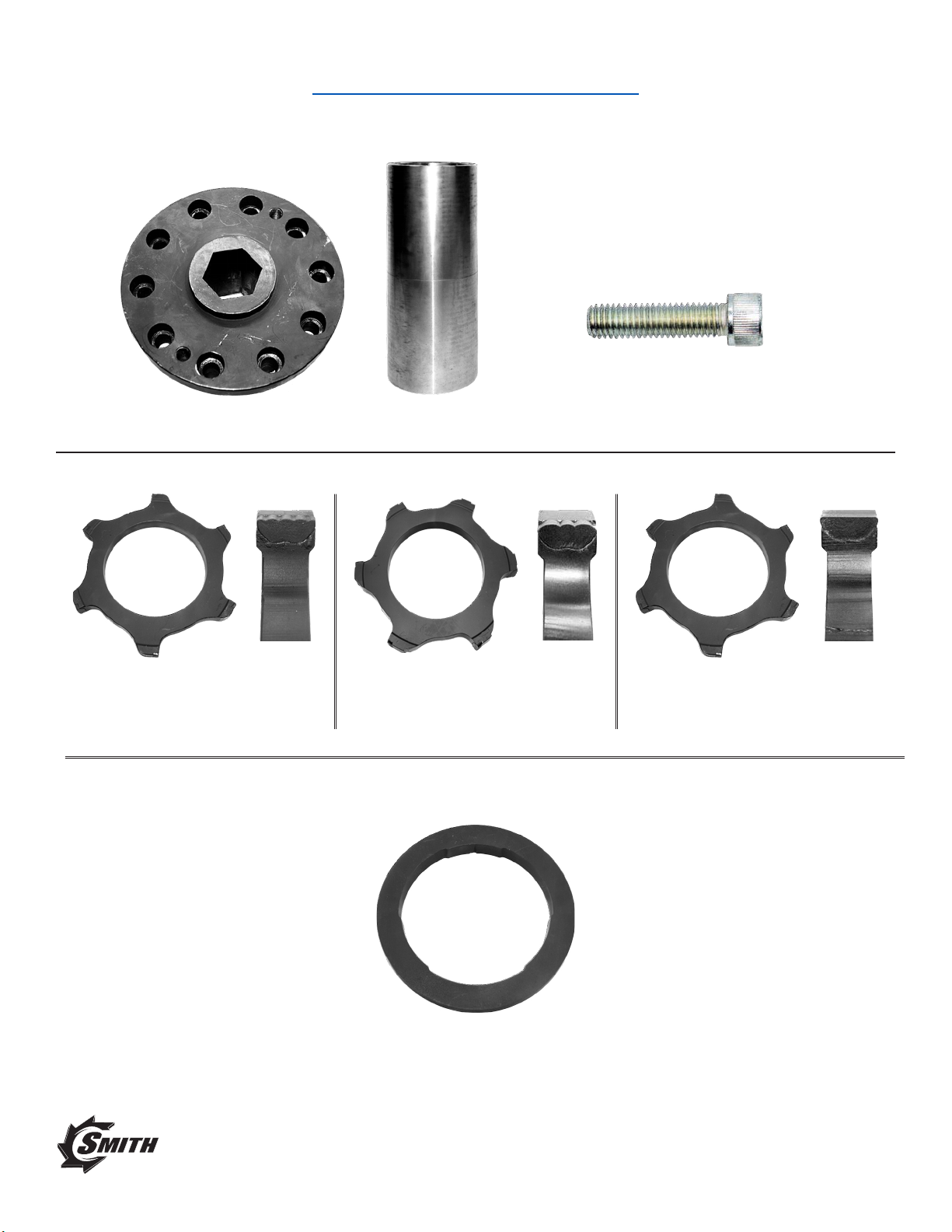

Component Identification

END CAP (QTY: 2) MANDREL (QTY: 1)

SOCKET HEAD BOLT – 3/8” ALLEN KEY

(HEX BIT) (QTY: 20)

PLATE – NANO-WAVE 10” OD

(QTY: 22 PLATES OR SPACERS)

SPACER – (USE AS A SUBSTITUTE FOR OTHER PLATES)

PLATE – ROUND 10” OD

(QTY: 22 PLATES OR SPACERS)

PLATE – FLAT 10” OD

(QTY: 22 PLATES OR SPACERS)

3

A GRACO COMPANY

™

4

Drum Assembly

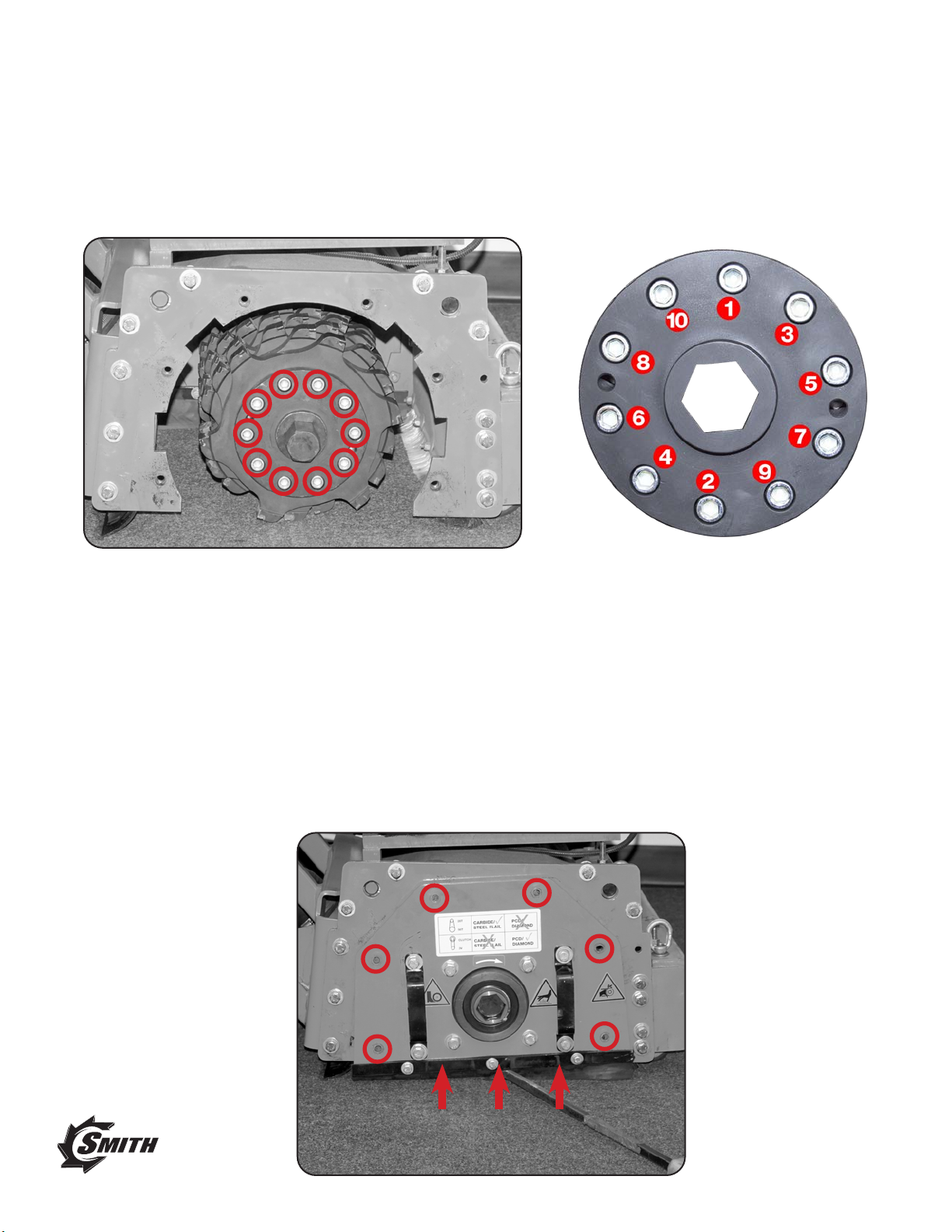

First End Endcap Installation

• Place the endcap onto one end of the mandrel – ensure holes are aligned. Cleaning and light

polishing of surfaces may be required for proper t.

• Clean and apply blue threadlocker to the 10 hex head bolts, then insert each through the endcap

threading into the mandrel and hand-tighten in a star sequence (see below). Torque to 65 ft-lbs

(requires 3/8” hex bit socket).

Plate Installation

• Place mandrel on endcap end

• Ensure outside of mandrel and each plate are cleaned – light polishing of plate inside bore may

be required

• Gently align plate with mandrel (plate should be level and concentric force should not be re-

quired) remove plate and re-clean (do not use force, do not hammer, do not lubricate), then plate

should slip onto mandrel.

5

Plate Installation (cont’d)

• Place mandrel on endcap end.

• Ensure outside of mandrel and each plate are cleaned. A light polishing of plate inside bore may

be required.

• Gently align plate with mandrel (plate should be level and concentric force should not be re-

quired) remove plate and re-clean (do not use force, do not hammer, do not lubricate), then plate

should slip onto mandrel.

• Once plate is on mandrel, gently rotate the plate until it reaches the end cap.

Second Endcap Installation

• Insert the end cap onto the mandrel and insert two (2) hex cap bolts through the endcap into

the mandrel, then hand tighten. End cap installation for now is only for handling and moving the

drum. Final assembly of end cap will be after drum installation.

• One by one, slide each plate onto the mandrel ensuring all PCDs face the same direction. For

best performance, rotate each individual plate so that each blade is staggered.

Be sure to put all of the PCD plates facing the same direction,

otherwise severe damage to drum will occur.

Failure to properly assemble will result in voiding of warranty.

A GRACO COMPANY

™

6

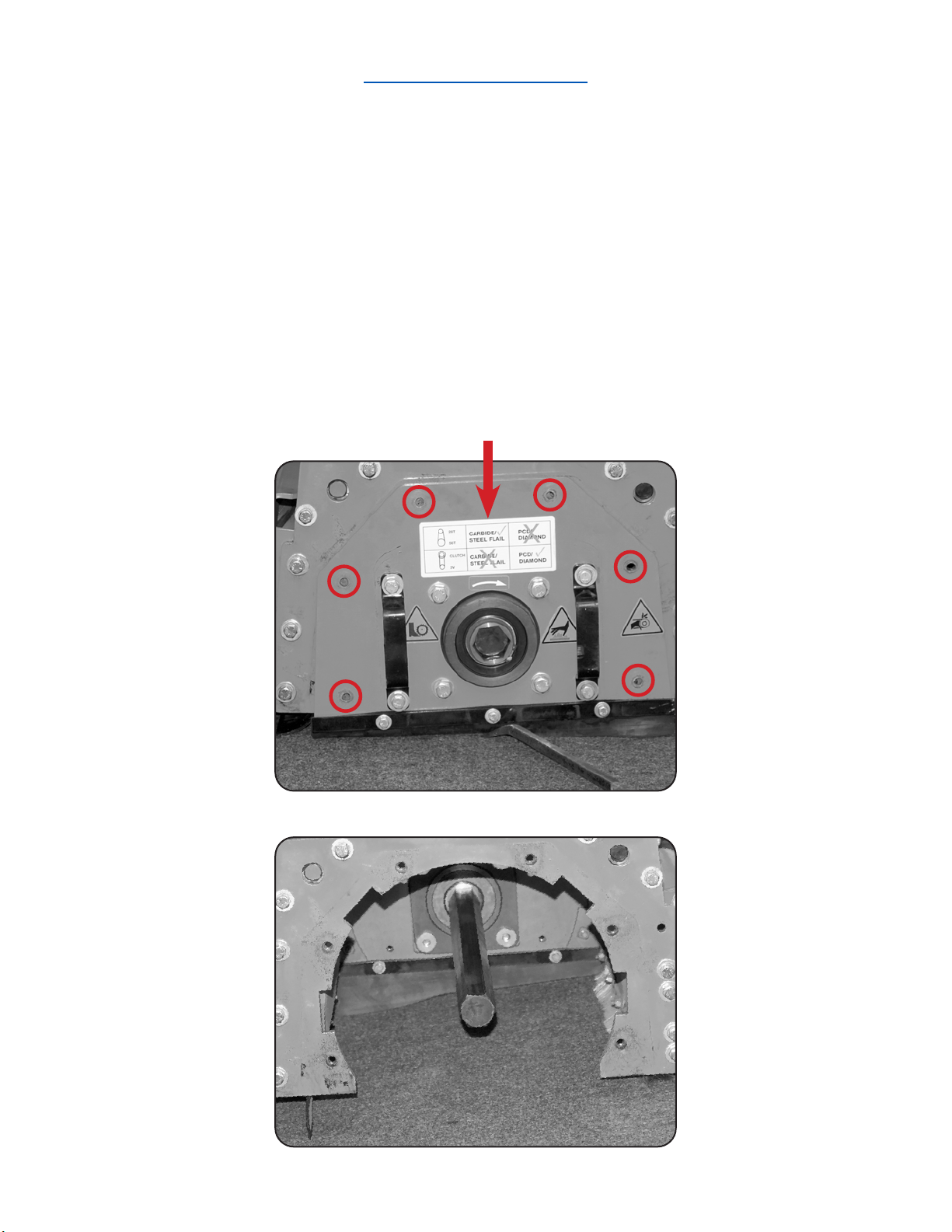

Drum Installation

Sideplate Removal

• Remove the six (6) bolts and washers using a 9/16” socket – do not impact.

• Ensure the correct high-speed or clutch kit is installed.

• Remove side plate using handles, or gently pry.

• Remove existing drum and spacers if installed.

• Inspect shaft for any rounding or deformation.

7

Options For Handling and Lifting the Drum (Weighs up to 250lbs)

• Using the control box, or manually adjusting the actuator, simply raise and lower the machine

rather than the drum.

• Using lifting straps with an overhead crane, forklift, engine lift or other device to lift and move the

drum.

• Using a lift strap, use manpower to lift drum while additional person controls the drum.

• Using a skid plate or sheet of metal on the ground may allow you to drag or slide the drum.

First Hex Alignment

• Place drum on ground in front of hex shaft – look into main housing to see hex, then level hex

with drum

• Look through the hex at the other end of the drum, check hex level and alignment

• Lower and raise until hex is level, and rotate shaft until aligned with hex

• Slide drum straight onto hex shaft. Once aligned, there should be little resistance except

the weight of the drum. The drum will stop 3/4 of the way through. Do not force the shaft into

the drum.

37

A GRACO COMPANY

™

8

Second Hex Alignment

• Remove all of the bolts. Place two bolts into the endcap only (do not thread into the mandrel).

The mandrel and endcap should be able to rotate independently.

• Using a light source, peek into the hex bushing of the end cap and eyeball alignment with shaft.

• Lower or raise the machine as necessary.

• Rotate endcap using pry bar as shown below.

• Once the endcap hex is aligned with the shaft hex, the drum can be pushed onto the shaft.

37

9

Final Drum Assembly Onto Shaft

• Clean and apply blue threadlocker to the ten (10) hex head bolts, then insert each through the

endcap threading into the mandrel. Hand-tighten in a star sequence (see below).

Torque to 65 ft-lbs (requires 3/8” hex bit socket).

Side Plate Installation

• Align hex shaft with sideplate bearing

• Using the handles, lift the sideplate into the main housing – the square notches must align.

NOTE: the weight of the drum can cause the shaft to sag and not align.

a) Raise/lower the machine using the actuator to level the shaft and allow the sideplate on

b) Using a pry bar, pry the sideplate off the oor into the housing

• Insert side plate bolts, tighten using a 9/16” socket. Torque to 40 ft-lbs, do not impact.

A GRACO COMPANY

™

SMITH Standard Warranty

SMITH warrants all equipment referenced in this document which is manufactured by SMITH and bearing its name to be

free from defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of

any special, extended, or limited warranty published by SMITH, SMITH will, for a period of twelve months from the date

of sale, repair or replace any part of the equipment determined by SMITH to be defective. This warranty applies only

when the equipment is installed, operated and maintained in accordance with SMITH’s written recommendations.

This warranty does not cover, and SMITH shall not be liable for general wear and tear, or any malfunction, damage or

wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence,

accident, tampering, or substitution of non-SMITH component parts. Nor shall SMITH be liable for malfunction, damage

or wear caused by the incompatibility of SMITH equipment with structures, accessories, equipment or materials not sup-

plied by SMITH, or the improper design, manufacture, installation, operation or maintenance of structures, accessories,

equipment or materials not supplied by SMITH.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized SMITH

distributor for verication of the claimed defect. If the claimed defect is veried, SMITH will repair or replace free of

charge any defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection

of the equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable charge,

which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PUR-

POSE.

SMITH’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer

agrees that no other remedy (including, but not limited to, incidental or consequential damages for lost prots, lost sales,

injury to person or property, or any other incidental or consequential loss) shall be available. Any action for breach of

warranty must be brought within two (2) years of the date of sale.

SMITH MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS

SOLD BUT NOT MANUFACTURED BY SMITH. These items sold, but not manufactured by SMITH (such as electric

motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. SMITH will provide purchaser with

reasonable assistance in making any claim for breach of these warranties.

In no event will SMITH be liable for indirect, incidental, special or consequential damages resulting from SMITH supply-

ing equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether

due to a breach of contract, breach of warranty, the negligence of SMITH, or otherwise.

For SMITH Canadian Customers

The Parties acknowledge that they have required that the present document, as well as all documents, notices and

legal proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up

in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que

tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de ou en rapport, directement ou

indirectement, avec les procédures concernées.

For the latest information about SMITH products, visit smithmfg.com.

TO PLACE AN ORDER, call 1-800-653-9311 for your SMITH sales representative.

All written and visual data contained in this document reects the latest product information available at the time of

publication. SMITH reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A7832

SMITH SURFACE-PREP SOLUTIONS • 2504 NW 19 ST • POMPANO BEACH, FL • USA

Copyright 2022, SMITH Manufacturing. www.smithmfg.com

Revision A, April 2022

Other manuals for FS351 Series

1

Table of contents

Other Smith Construction Equipment manuals