IMT 28562 User manual

99903701:24562/28562INSTALLATION:20131211 PARTS-1

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

641-923-3711

MANUAL PART NUMBER: 99903701

Model 24562/28562 Crane

INSTALLATION MANUAL

Iowa Mold Tooling Co., Inc. is an Oshkosh Truck Corporation company.

99903701:24562/28562INSTALLATION:20131211 PARTS-2

In addition to the information presented in this manual,

read and understand the IMT Crane Operator's Safety

Manual before operating or performing any maintenance

on your crane.

REVISIONS LIST

DATE LOCATION DESCRIPTION OF CHANGE

20050421 NEW MANUAL RELEASE

20070227

20131211 ALL PAGES ADDED 28562

COVERUPDATED OWNERSHIPSTATEMENT

PARTS-3

READ ALL INSTRUCTIONS PRIOR

TO STARTING INSTALLATION!

MATERIALS REQUIRED

•Mounting Kit (IMT # 95719252)

•Torque wrench capable of measuring from 220

to 885 ft-lb

•Grinder

•Cut-off wheel

•Band / chop saw

•Square

•Level

•Paint marker

•Welder

•Drill (for 1/2” and 5/8" drill bits)

•Sockets sized for 30 mm and 33 mm

(1-13/16" and 2")

•Shim stock (see instructions)

•Hammer

•Feeler gage

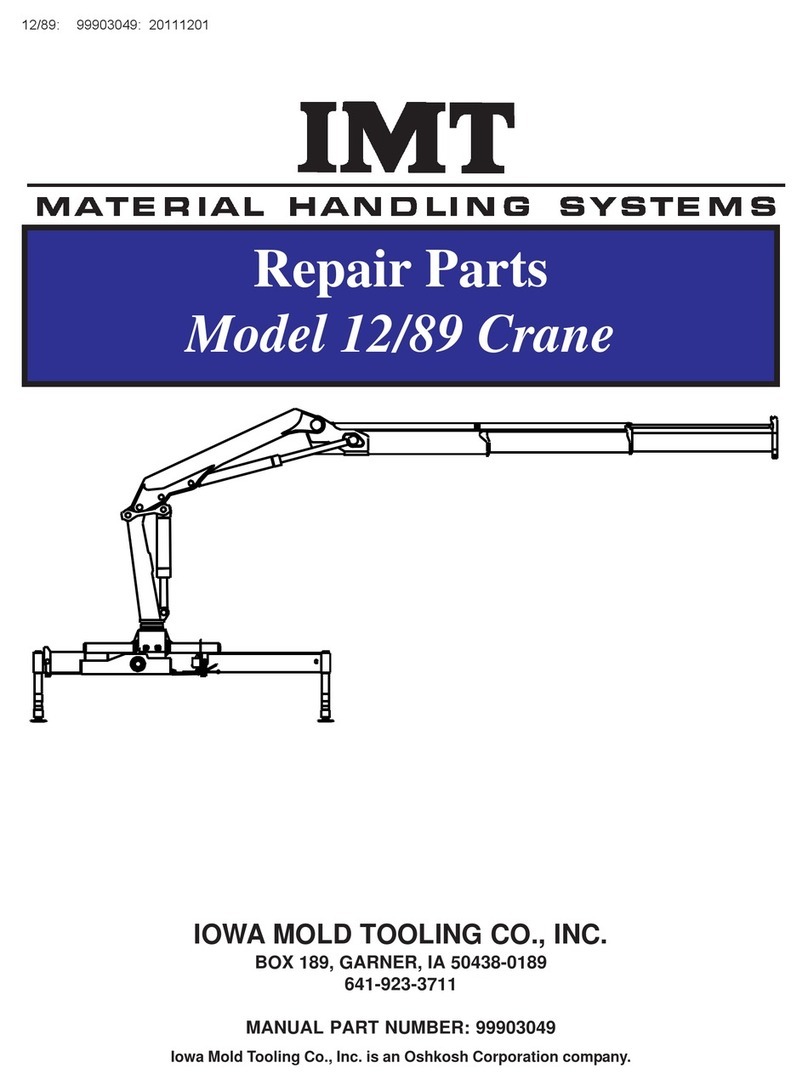

The instructions provided here for an IMT 24562 crane

apply to a mount similar to the one shown in Figure 1,

a “behind the cab mount”. This guide references a

Sterling chassis and assumes no interferences with

the crane.

NOTE

ALL APPLICABLE LEGAL HEIGHT,

LENGTH, WIDTH AND WEIGHT LIMITS ARE THE

RESPONSIBILITY OF THE INSTALLER.

Figure 1: Behind the cab crane mount

INSTALLATION STEPS

The installation procedure is broken into eight steps.

Read the procedure prior to starting work, and follow

the steps in order.

Step I. Truck Chassis Preparation

Check for fit

Check for shims

Step II. Riser Construction

Match truck frame dimensions

Shear plate on each corner

Step III. Crane Preparation

Check and fix pockets if necessary

Step IV. Crush Tube Installation

Install for a force fit

Step V. Crane Tie Rod Installation

Confirm clearances

Tighten either M30 or M33 size tie rod to the

proper torque value

Step VI. Gusset Stop Block Installation

Ensure proper fit

Weld additional stop blocks after crane is tied

down

Step VII. Final Tie Down Process

Install frame to riser bolts

Crush tube retainers

Step VIII. Marker System

Marker (Paint) system

Unique Crane Applications: Units mounted on non-

Sterling chassis may require unique handling.

Consult IMT if the unit is not compatible with these

instructions.

99903701:24562/28562INSTALLATION:20131211

PARTS-4

STEP I. TRUCK CHASSIS PREPARATION

Inspect chassis for adequate space to mount the

crane.These instructions and parts were developed

for a chassis which has no interferences (no cross

member issues, frame bolts or other equipment in the

way). The instructions are formatted using a Sterling

chassis. Other chassis types may vary significantly.

If a double frame is used, check the truck frame for

gaps in between the frame channels . Shim any truck

frame flange gaps using shim stock as necessary to

fill gaps:

i. If gap is less than 1/16", do nothing as gap

will be absorbed when tie rods are tightened.

ii. If gap is between 1/16" and 1/4”, shim.

iii.If gap is greater than 1/4”, consult IMT.

The shims are installed in relation to the crush tube

and crane tie down bolt areas. The pieces should be

about 3-1/2 inches long and about 2-1/2 inches wide

and of the thickness necessary to fill the gap. Steel

stock of 1/8, 3/16 and 1/4” in thickness is the most

commonly used. The IMT kit does not include the

shim stock since only a small percentage of the

trucks need to have the shims installed. See figure 2

for additional detail on shim locations.

Ensure no cross members will interfere with the crush

tubes and retaining bracket. Also check to assure

the tie rods will clear any frame bolts.

STEP II. RISER CONSTRUCTION

Construct the riser for the crane from 3/8" thick tube

and plate. Take special care to match the width of

the tube to the truck frame flange width. For

example, if the frame flange is 4-inches wide, the tube

should be 4-inches wide. The height of the riser tube

should be kept to 4 inches. If a 6-inch riser is used,

an internal stiffener in the tube is required.

Ensure the tubes extend beyond the width of the

crane base by at least 1/2” (more space is needed on

the compensated side to allow for stop block

installation). The width of the riser should be flush

with the outside of the truck frame. Constructing the

riser in this manner aids in the installation of the

crane by making sure no interferences exist.

Incorporate shear plates on each corner to ensure the

riser does not move on the truck frame. Ensure the

shear plates do not cause an interference with the tie

rods. Welding end caps on the tubes stiffens the

sides and prevents water from entering the tube. See

figure 3.

After the riser is constructed, mount the crane and

stop blocks to the riser (instruction steps III through

VI) prior to bolting the riser to the truck frame.

Figure 2: Areas which may require shims

Figure 3: Crane riser example

FRONT OF CRANE

INSTALL SHIMS

AS NECESSARY

BETWEEN FRAMERAILS

(TOP AND/OR BOTTOM

OF FRAME.)

END CAP

99903701:24562/28562INSTALLATION:20131211

PARTS-5

STEP III. CRANE PREPARATION

Measure the tie rod pockets on the stabilizer side of

the crane, as shown in figure 4. Use a square and a

level to make sure the pockets are level and true to 1/

16". Some grinding may be necessary to ensure the

pockets are flat.

DO NOT GRIND THE WELD ON THE CRANE

POCKET!

Measure the stabilizer side crane tie rod pockets and

make sure the stop blocks will fit. The stop block

part was designed to fit the largest gap of the tie rod

pocket so it is normal to have the part milled down to

accomplish a slight forced fit. The rear stop blocks

(P/N 60128955) are welded to the riser. Make sure the

crane fits flat on the riser and is not suspended on a

weld.

Bevel the rear top washer plate (60128019) on the

long edge on one side. Place the ground corner near

crane base for tie rod pocket weld clearance as

shown in Figure 5. Otherwise the washer plate can

sit on a weld which will cause an uneven condition as

shown in Figure 6.

Figure 5: Beveled edge on washer plate

Figure 6: Avoid excess weld

WITH THE SQUARE FLAT

AGAINST THE FRONT OF

THE FORMED PLATE,

CHECK THE GAP BETWEEN

THE SQUARE BLADE AND

MOUNT WITH A FEELER

GAUGE AND RECORD.

Figure 4: Pocket check

MAY NEED TO

BEVEL EDGE OF

WASHER PLATE TO

ALLOW PROPER

SEATING.

EXCESS WELD AT THIS

JOINT WILL PREVENT

WASHER PLATE FROM

SITTING FLAT AND

WILL CAUSE TIE ROD

TO BE SUBJECTED

TO SIDE LOADS.

TIE ROD POCKET

99903701:24562/28562INSTALLATION:20131211

PARTS-6

STEP IV. CRUSH TUBE INSTALLATION

Cut crush tube weldment (52719230) to length. Force

fit into truck frame rail (use hammer if necessary).

Custom fit each corner of the mount. If the crush tube

causes installation interference, consult IMT.

Weld retaining “L” (angle) bracket (P/N 60128035)

onto the tube. After the crane is tightened down, drill

a hole for 1/2” diameter bolt to secure the retaining

bracket as close to the frame centerline as possible.

See Figure 7 for details.

STEP V. CRANE TIE ROD INSTALLATION

Fit up the parts to center the clamp plates and make

sure the tie rods will be parallel and perpendicular to

1/8" on the truck. Once the parts are in place, check

for clearance between the tie rods, truck frame, and

riser (nominal 1/4" clearance).

Front of Crane (tilting compensator- nearest cab)

Center tie rods on the truck frame.

Tighten to 680 ft-lb ± 65 ft-lb for M30 (P/N 71411440

and P/N 71411441). Tighten tie rod nuts in

increments to ensure clamp plate and washer plates

are parallel, and both tie rods have the same load.

Use a second nut as a jam nut on both ends of the tie

rod.

Rear of Crane (farthest from cab)

Center tie rods on the truck frame.

Tighten to 850-880 ft-lb for M33 (P/N 71411439).

Tighten tie rod nuts in increments to ensure clamp

plate and washer plates are parallel, and both tie rods

have the same load. Use a second nut as a jam nut

on both ends of the tie rod.

The top washer plates are tack welded to the crane

pocket. The rear washer plates must be ground on

one edge to allow the plate to fit up next to the crane

base. Otherwise the washer plate can sit on a weld

which will cause an uneven condition.

NOTES:

1) DRIVE THE NUT ONTO THE TIE ROD FROM

THE BOTTOM TO AVOID TOP MOUNT

INTERFERENCE.

2) MAKE SURE THE SOCKET HAS ENOUGH

DEPTH TO ALLOW TWO FULL THREADS

BEYOND THE JAM NUT.

TOP

WASHER

PLATE

TIE

ROD

BOTTOM

CLAMP

PLATE

CRUSH

PLATE

(NOT

SHOWN)

TACK

WELD

LOCATIONS

Figure 7: Crush tube weldment and bracket

Crush Tube

Weldment

Figure 8: Part locations

99903701:24562/28562INSTALLATION:20131211

PARTS-7

STEP VI. GUSSET STOP BLOCK INSTALLATION

The gusset stop blocks (P/N 60128954) are welded to

the crane only. The gusset stop blocks prevent the

crane from twisting on the truck frame. On the rear

side of the crane, the gusset stop block must be

welded to the reinforced area, not the area where the

surface steps down.

Figure 9: Stop block views

STEP VII. FINAL TIE DOWN PROCESS

Drill the holes in the truck frame and bolt on the riser

after the crane tie rods have been tightened. This

requires four 5/8" diameter bolts, grade 5 to grade 8,

on each shear plate.

Drill holes for the crush tube retainers and install bolts

to hold them in place after the crane tie rods have

been tightened. Bolt to frame with 1/2” diameter bolt,

grade 5 to grade 8. See Step IV and refer to Figure 7

for additional information.

Follow the chassis manufacturer’s requirements for

hole locations, etc.

REAR STOP

BLOCK (60128955)

(INSIDE POCKET)

GUSSET STOP

BLOCK (60128954)

99903701:24562/28562INSTALLATION:20131211

PARTS-8

STEP VIII. MARKER SYSTEM

Using a paint marker, mark the nuts and rod after the tie rods are tightened so that a visual mechanism exists to

verify the rods were tightened correctly and to help aid in future visual inspections.

Also mark the clamp plate and the frame to use as a visual aid in inspecting for clamp plate movement on the truck

frame. Paint marks across the frame (Figure 10) and both sides of the clamp plate (Figure 11). If the clamp plate

has moved in any direction relative to the truck frame during use, the marks will no longer line up. This system has

measurement resolution to approximately 1/8" and provides a baseline for future comparison. If the marks degrade

or wear away, please repaint them.

While conducting the crane inspection, monitor the clamp plates for movement. If the clamp plates have moved, the

entire mount should be inspected. Possible corrective action may be necessary- consult IMT for assistance.

Figure 10: Mark painted across the frame and clamp

plate near the center of the truck frame

Figure 11: Marks painted on both sides of clamp

plates

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

MANUAL PART NUMBER: 99903701

99903701:24562/28562INSTALLATION:20131211

This manual suits for next models

1

Table of contents

Other IMT Construction Equipment manuals