Smiths Silmat Test Socket Quick guide

Copyright© 2016 | Version 1.0

Silmat®Test Socket

Assembly & Maintenance Instructions

Test Socket with SC4 or SC5 Contact Set

Recommended Tools

►

Socket drawings for components’ terminology and appropriate stack up sequence.

►

Allen wrench or screwdriver appropriate for socket mounting screws.

►

Straight edge tool or flat-tip tweezers for easing contacts on/off the guide pins.

►

Fiberglass brush or stiff wire brush for cleaning and removing oxides from Contact Set

and PCB.

►

Soft animal hair brush or Post-it® Note with light adhesive for gently removing debris and

contaminants from Silmat®.

►

Compressed air for blowing debris off Contact Set, Silmat® and PCB.

smithsinterconnect.com

Copyright© 2016 | Version 1.0

Assembly, Removal & Storage

Assembly of Contacts to Socket

►

Install/Remove the Contact Set:

►

Note keying orientation patterns, tooling holes and/or side with gold plated mounting

arms.

►

Blow off both sides with compressed air prior to assembly to remove any debris.

►

Install Contact Set on the back side of the socket body, orienting the side with the gold

plated mounting arms and contact tips towards the socket body and DUT.

►

Gently press one of the Contact Set's tooling holes over a corresponding guide pin.

►

Do the same for the next tooling hole and guide pin.

►

Gently manipulate any remaining tooling holes onto their corresponding guide pins (if

applicable).

►

When all tooling holes are on the guide pins, use a flat tip tweezers to ease the

Contact Set further down onto the pins, alternating sides until the Contact Set is

seated against the socket.

►

Work carefully to avoid enlarging or deforming the Contact Set tooling holes.

►

Work the opposite direction to remove the Contact Set, carefully easing it off the guide

pins. Do not use a sharp instrument or grab one corner and pull it off the guide pins

because it can cause damage to the Contact Set tooling holes.

►

Install / Remove the Silmat®:

►

Note keying orientation patterns and/or tooling holes.

►

Blow off both sides with compressed air prior to assembly to remove any debris.

►

Important: Do not touch, rub, brush or clean the Silmat®columns.

►

Install Silmat® so one side touches the Contact Set and the other side faces the PCB.

►

Gently press one of the tooling holes over a first corresponding guide pin.

►

Do the same for the next tooling hole and guide pin.

►

Gently manipulate any remaining tooling holes onto their corresponding guide pins

(if applicable).

►

When all tooling holes are on the guide pins, use flat tip tweezers to ease the Silmat®

further down onto the pins, alternating sides until the Silmat® is seated against the

Contact Set.

►

Work carefully to avoid enlarging or deforming the Silmat® tooling holes.

►

Work the opposite direction to remove the Silmat®, carefully easing it off the guide

pins. Do not use a sharp instrument or grab one corner and pull it off the guide pins

because it can cause damage to the Silmat® tooling holes.

►

If the same Silmat® is removed and then reinstalled on a socket, the Silmat® should

remain in the same orientation with the same side facing the Contact Set. Installing

either the Contact Set or the Silmat® upside down may impact performance.

smithsinterconnect.com

Copyright© 2016 | Version 1.0

Assembly of Socket to PCB:

►

Assure that the test site PCB pads and immediately surrounding surfaces are clean, dry and

free of contaminants or any other residues. If necessary, clean the PCB pads with a brush

and blow with compressed air.

►

Place the socket’s alignment pins into the corresponding holes in the PCB.

►

Secure the socket to the PCB and stiffener (if applicable) using the mounting screws or

fasteners. Assure that the socket is firmly seated and coplanar with the PCB.

Removal & Storage:

►

Remove the socket body from the PCB and store with the contacts attached in the protective

packaging provided. Do not allow multiple sockets to rub against each other.

►

If the contacts are separated from the socket body, always keep them contained and

protected. This will keep them from being touched or damaged and prevent the accumulation

of dust and debris.

►

It is recommended to leave the socket assembled to the PCB whenever possible to keep the

contacts clean and free of contamination. Only remove the contacts when extra cleaning is

required or when the contacts need to be replaced.

►

While the socket assembly remains attached to the PCB, it is recommended to store it

without a DUT in the socket so the contacts remain unactuated during that time, which will

help extend the life.

Handling & Cleaning

Contact Set:

►

Always handle by the outside edges and avoid touching the top and bottom of the contacts.

►

Use compressed air to blow dust and debris from the top and bottom of the contacts prior to

use and assembly.

►

It is recommended to leave the contacts assembled on the socket as long as possible.

However, if cleaning is necessary after a number of actuations to remove difficult

contaminants or solder residue, remove the contacts from the socket, taking note of the

orientation with the Silmat®, and clean both sides (tips and tails) of the Contact Set with a

fiberglass or bristle brush. Isopropyl alcohol may also be used to clean the Contact Set.

►

Important: Cleaning using brushes and isopropyl alcohol is for the Contact Set only and

should never be used on the Silmat®. If cleaning chemicals are used on the Contact Set,

it must be completely dry prior to installing the Silmat®.

smithsinterconnect.com

Copyright© 2016 | Version 1.0

►

When using a brush to clean the Contact Set,

always brush in a sweeping motion across

the contacts in one direction and then do the

same in the perpendicular direction. Always

brush both the top and bottom of the Contact

Set and blow off any debris with compressed

air prior to use and assembly.

►

Important: Be sure no debris is picked

up by the Silmat®material.

Silmat®:

►

Always handle by the outside edges and avoid touching the top and bottom of the conductive

columns which should have protruding “buttons” of conductive particles.

►

Important: Do not touch or rub the conductive columns or the buttons

could be damaged.

►

Never use a stiff/wire brush on the Silmat®.

►

Never use any alcohol or cleaning chemicals on the Silmat®. If the Contact Set or PCB is

cleaned with chemicals, always be sure they are completely dry prior to touching the Silmat®.

►

Use compressed air to blow dust and debris from the top and bottom of the contacts prior to

use and assembly.

►

If there is debris that cannot be removed by air, use a soft animal hair brush or a Post-it® Note

with light adhesive to gently remove any remaining debris. It may also be helpful to use a

microscope and tweezers to remove some contaminants.

►

Note: Some loose particles from the Silmat®conductive columns are common and do not

impact functionality. If there is excessive particle dispersion, please contact Smiths

Connectors.

Possible Issues & Troubleshooting

Debris and/or Obstructions:

Signals may be impacted by various types of

debris or obstructions (hair, fibers, etc). These

should be removed by compressed air if

possible. If necessary, the Contact Set may be

cleaned or brushed. However, the Silmat®

should never be cleaned or brushed and only air

should be used or careful manual removal of

contaminants.

Note: Some amount of loose particles on

the Silmat®is normal and won’t impact functionality.

smithsinterconnect.com

Copyright© 2016 | Version 1.0

Solder Residue and Oxide Migration:

The amount of transfer may vary by the type of device or solder and may build up on the Contact

Set tips over high numbers of device insertions causing an increase in contact resistance. The

Contact Set tips may be cleaned with a brush to remove residue and oxides.

Note: Since the Silmat® does not touch the device leads, it should not accumulate solder residue and

should not need to be cleaned.

Over / Under Actuation:

This may cause poor or inconsistent test results and possibly impact contact life.

It is important to stay within the recommended compression operating range. It is also important

to eliminate any PCB flex or deflection to maintain coplanar actuation of the contacts.

DUT Mis-Registration:

Over or under-sized devices compared to nominal specs may cause mis-registration with the

contacts and impact test results. It could also cause mis-insertions and non-coplanar actuation

which could damage the contacts. Assure devices are within design tolerances.

DUT Misplacement:

Device mis-insertions can cause non-coplanar actuation and potentially damage the contacts.

The DUT should be inserted appropriately into the socket and actuated in a coplanar manner.

smithsinterconnect.com

Table of contents

Popular Accessories manuals by other brands

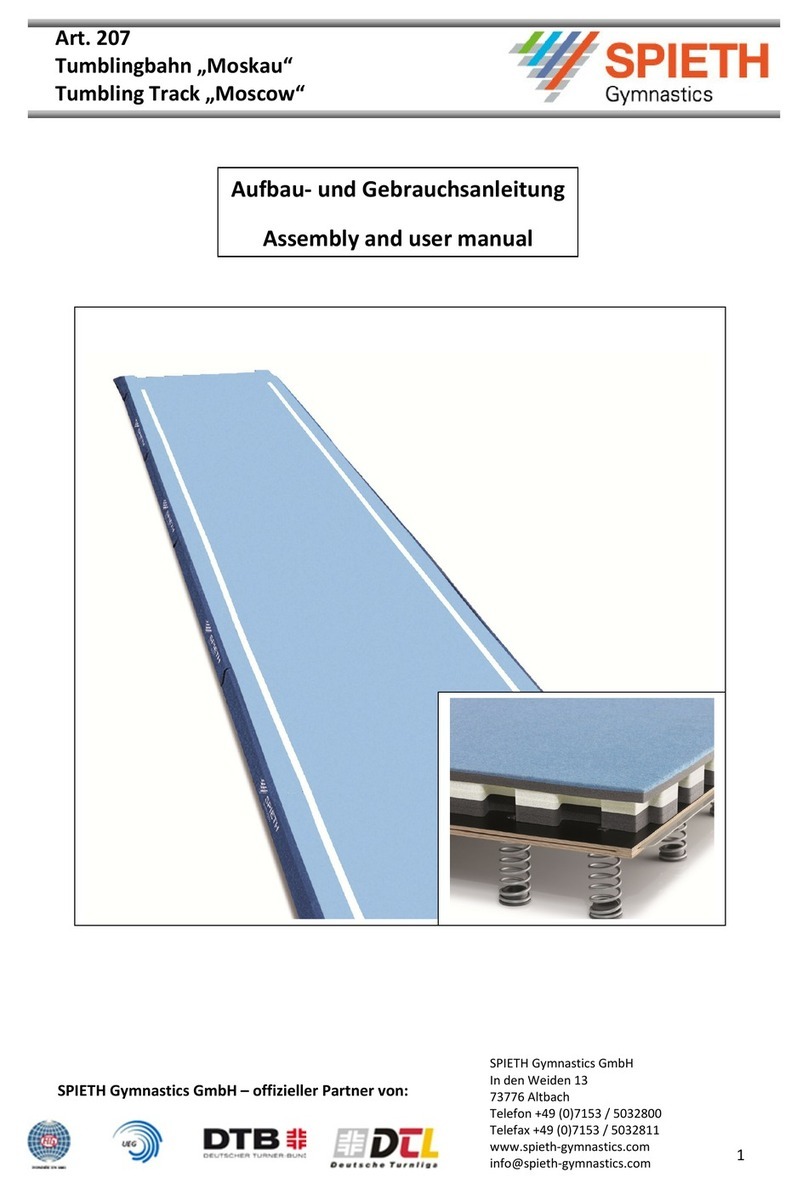

SPIETH Gymnastics

SPIETH Gymnastics Moscow Assembly and user's manual

elobau

elobau 470 EFR 2D1 2K quick start guide

Connection

Connection Tubes Assembly instructions

SUZHOU SYNTA

SUZHOU SYNTA Synscan Tour instruction manual

Rokinon

Rokinon IOLS-C instruction manual

NATURE & DECOUVERTES

NATURE & DECOUVERTES 15225540 manual