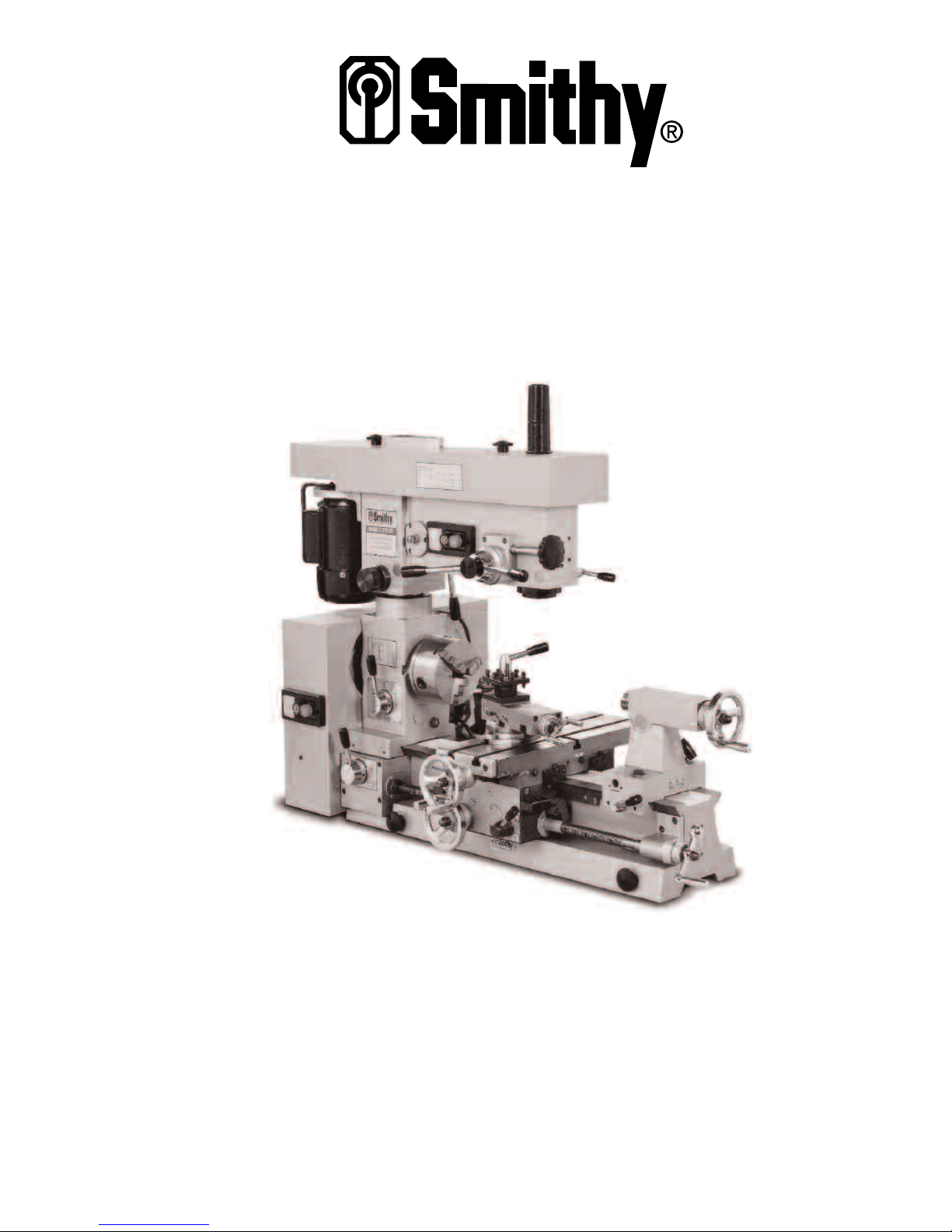

Smithy MIDAS MI-1220 LTD User manual

MIDAS 1220 & 1230 LTD

Combination Lathe - Mill - Drill

OPERATOR’S MANUAL

Updated Feb. 2019

170 Aprill Dr., Ann Arbor, MI, USA 48103

1-800-476-4849

www.smithy.com

© 2019 Smithy - All rights reserved (Revision 1).

170 Aprill Dr., Ann Arbor, Michigan, USA 48103

Toll Free Hotline: 1-800-476-4849

International: 734-913-6700

All images shown are from Midas 1220 LTD machine.

All rights reserved. No part of this manual may be reproduced or transmitted in any form by

any means, electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of Smithy Co. For information on getting permission for

While every precaution has been taken in the preparation of this manual, Smithy Co. shall not

have any liability to any person or entity with respect to any loss or damage caused or

alleged to be caused directly or indirectly by the instructions contained in this manual. Please

see section on warranty and safety precautions before operating the machine.

Printed and bound in the United States of America.

Table of Contents

Chapter 1: Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Chapter 2: Safety

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Chapter 3: Caring For Your Machine

Caring for you machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Chapter 4: Basic Parts of the MI-1220 LTD

Basic Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Chapter 5: Uncrating and Setting Up the MI-1220 LTD

Moving the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Uncrating and Positioning the machine . . . . . . . . . . . . . . . . . . . . . .5-1

Millhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Three Jaw Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Cleaning and Lubricating the MI-1220 LTD . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Ways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Millhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Headstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Oiling the Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Oiling the Compound Angle Toolpost . . . . . . . . . . . . . . . . . .5-5

Oiling the Apron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Oiling the Leadscrew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Oiling the Tailstock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Oiling the Mill/Drill Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Adjusting Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Mill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Lathe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Adjusting Gibs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Reducing Backlash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Running in the MI-1220 LTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Millhead Run in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Lathe Run in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Setting Lathe and Mill Speeds for the MI-1220 LTD . . . . . . . . . . .5-10

Chapter 6: Turning

Turing Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Gear Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Chapter 7: Metal Theory

Tool Sharpness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Chapter 8: Grinding Cutter Bits for Lathe Tools

High Speed Steel Cutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

Materials Other than Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Bits for Turning and Machining Brass . . . . . . . . . . . . . . . . . . . . . . . .8-3

Special Chip Craters and Chipbreakers . . . . . . . . . . . . . . . . . . . . . . .8-4

Using a Center Gauge to Check V-Thread Forms . . . . . . . . . . . . . .8-4

Acme or Other Special Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Carbide-Tipped Cutters and Cutter Forms . . . . . . . . . . . . . . . . . . . . .8-5

Chapter 9: Setting Up Lathe Tools

Cutting Tool Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Turning Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Threading Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Cutoff, Thread Cutting and Facing Tools . . . . . . . . . . . . . . . . . . . . . .9-3

Boring and Inside Threading Tools . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Chapter 10: Setting Up with Centers, Collets and Chucks

Centering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Mounting Work between Centers . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Using a Clamp Dog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Using Faceplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Setting Up Work on Mandrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Steady Rest and Follow Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Steady Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Follow Rest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

Setting Up Work in a Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

Mounting Work in a Four-Jaw Independent

Lathe Chuck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

Mouting Work in a Three-Jaw Universal Chuck . . . . . . .10-9

Toolpost Grinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

Chapter 11: Lathe Turning

Rough Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Finish Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Turning to Shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Machining Square Corners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

Finishing and Polishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

Taper Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

Chapter 12: Lathe Facing and Knurling

Facing Across the Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Knurling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

Chapter 13: Cutting Off or Parting with a Lathe

Cutting Off or Parting with a Lathe . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

Chapter 14: Lathe Drilling and Boring

Lathe Drlling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

Reaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

Boring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-2

Cutting Internal Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

Cutting Special Form Internal Threads . . . . . . . . . . . . . . . . . . . . . .14-4

Chapter 15: Changing Gears on Your MI-1220 LTD

Changing Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-1

Chapter 16: Cutting Threads on Your MI-1220 LTD

Threading Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-1

Cutting Right Hand Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-3

Using the Threading Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-4

Cutting Multiple Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-5

What Not To Do When Cutting Threads . . . . . . . . . . . . . . . . . . . . .16-5

Finishing Off a Threaded End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-5

Cutting Threads on a Taper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-5

This manual suits for next models

1

Table of contents