4.2 Testing/ Test plan

4.2.1 Pump EX5 230V/50Hz

Optical test

Test:

Check if all tubes are connected properly, no fluid is escaped (see 3.3 Fluid circuit).

Solution:

If there are tubes disconnected reconnect them. Is fluid escaped somewhere, have a closer look to the

tubes and fittings maybe there is one leaking. Change the leaking one. Maybe the heat exchanger is

clogged, see test plan for the HE 2400 Heat Exchanger. If there is no fluid escaped or tube

disconnected go on testing.

Function test

Check each pump separately.

Test:

Check if the pump starts working after entering P99, is it ratteling with a 50Hz rhythm? That’s ok. Is it

priming the fluid? Disconnect the pressure pipe (part number 59020) from the HE and check if there is

fluid coming out of it.

Solution:

If there is no sound or no fluid coming out of the disconnected tube, supply the pump directly with 230

VAC. If it’s not working, it is dead. If it’s working, it’s necessary to check the power supply from the

PCB. If the pump is working properly test the HE 2400 Heat Exchanger.

Power supply test

Test:

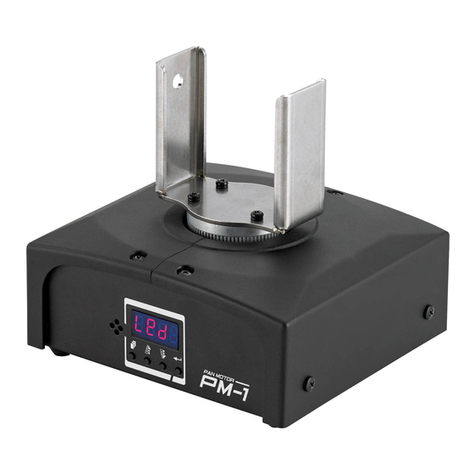

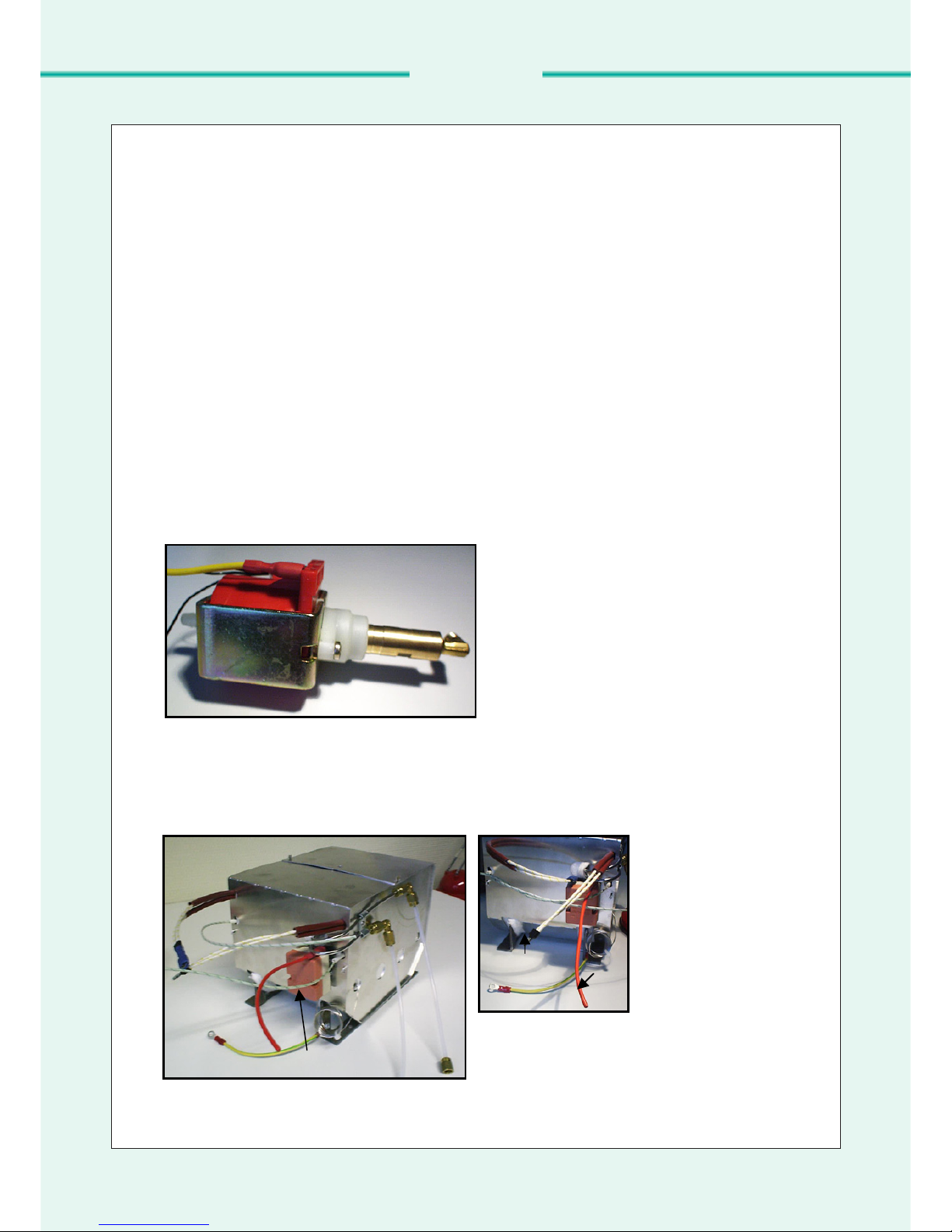

Check if there is power at pin X1:1/2 resp. at the power connection at the pump (see picture 2.1)

between the yellow and the black cable. At P99 you can measure about 170VAC.

Solution:

If there is no power check the PCB ENTERPRISE TC4 for function. If there is power and the pump

does work test the HE 2400 Heat Exchanger.

4.2.2 HE 2400 Heat Exchanger

Faults shown in display

Test:

Check the display for faults (E1-E4)

Solution:

Errors displayed:

E-1: Thermocouple A broken or not connected

E-2: Thermocouple B broken or not connected

E-3: Both thermocouples broken or not connected

E-4: Board to hot

For the errors E-1 to E-3 reconnect the thermocouples or change the heat exchanger. For E-4 switch

ENTERPRISE TC4 off and wait till the unit is cooled down.

Function test

Test:

Check if the heat exchanger is heating up (don’t touch it directly, it’s getting really hot, just nearby). If

the pumps are both working properly check if there is less or no fog.

Solution:

If the HE remains cold, measure the resistance of the heater: ENTERPRISE TC4 ca. 20Ω. If the

resistance is much higher, the device needs to be changed.