Snap Fresh BBT-KP526 User manual

Before reading, unfold the page containing the illustrations and familiarize yourself with

all functions of the device.

MADE IN CHINA

Ningbo Babytec Technology Co.,Ltd

Rm. 2802, Block A, Hebang Bldg., No.933 N.

Tiantong Rd. , Ningbo, China

www.snapfreshtools.com

User Manual

Read all safety rules and instructi ons carefully before operating this tool.

info@ s napfr es htools .com

+1(737) 471- 0443

CORDLESS ROTARY TOOL

BBT-KP526

8

910

13 14

15 16 17 18 19 20

22 23 25 26 2721

11

12

54

3

67

12

24

1 ■

Contents

Introduction ...................................................... ... . . ... ...

...................................................... ... ... ... . ... ....

...................................................... ... ... . . ... .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . .....

........................ ... ..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................................... ... . ... ...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... ... ... . . . . .

............................................................

.............................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

......................................................... .

............................................................

..................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

..................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

..............................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . ..

........................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .... . . ....

2

Intended use 2

Features 2-3

Package contents 3

Technical details 3

General Power Tool Safety Warnings 3

1. Work area safety 3

2. Electrical safety 3-4

3. Personal safety 4

4. Power tool use and care 4-5

5. Use and handling of the cordless electrical power tool 5

6. Service 5

Safety instructions for all applications 5-7

Additional safety instructions for all applications 7-8

Supplementary safety instructions for grinding and abrasive cutting 8

Supplementary safety instructions for working with wire brushes 9

Safety guidelines for battery chargers 9-10

Use 10

Charging the battery pack 10-11

Checking the battery charge level 11

Changing/inserting the tool/collet chuck 11

Switching on and off/setting speed range 11

Notes on working with materials/tools/speed range 11-14

Additional description for accessories/attachments 14-16

Maintenance and Cleaning 19

Disposal 19

Warranty 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .... . . ... . . .... . . ........... . . . . .... . . . ..

Additional safety warnings 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . .

Operating Instructions 17-18

■ 2

Introduction

CORDLESS PRECISION

ROTARY TOOL BBT-KP526

Terminology

Intended use

Warnings used

As used in this instruction manual in general

and with regard to safety information, safety

information and safety messages and warn-

ings in particular, the following words have

the following means:

NOTICE indicates information considered

important, but not hazard related (e. g.

messages related to property damage).

A “Tip” identifies additional information that

will assist you in using the device.

This cordless rotary tool is intended for drill-

ing, milling, engraving, polishing, cleaning,

grinding, cutting of materials such as wood,

metal, plastics, ceramics and stone in dry

rooms using the corresponding attachments

(as supplied). Any other usage of or modific-

ation to the appliance is deemed to be impro-

per and carries a significant risk of accidents.

The manufacturer accepts no responsibility

for damage(s) attributable to misuse. This

appliance is not intended for commercial use.

Congratulations on the purchase of your new

appliance. You have selected a high-quality

product. The operating instructions are part

of this product. They contain important infor-

mation about safety, usage and disposal.

Before using the product, please familiarise

yourself with all operating and safety instru-

ctions. Use the product only as described

and for the range of applications specified.

Please also pass these operating

instructions on to any future owner.

The following types of warning are used in

these operating instructions:

DANGER indicates a hazardous situation

that/ which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation

that, if not avoided, could result in death or

serious injury.

CAUTION indicates a hazardous situation

that, if not avoided, could result in minor or

moderate injury.

►

►

►

►

■

This word is understood to be permissive.

May:

Shall:

Should:

■

This word is understood to be mandatory.

■

This word is understood to be advisory.

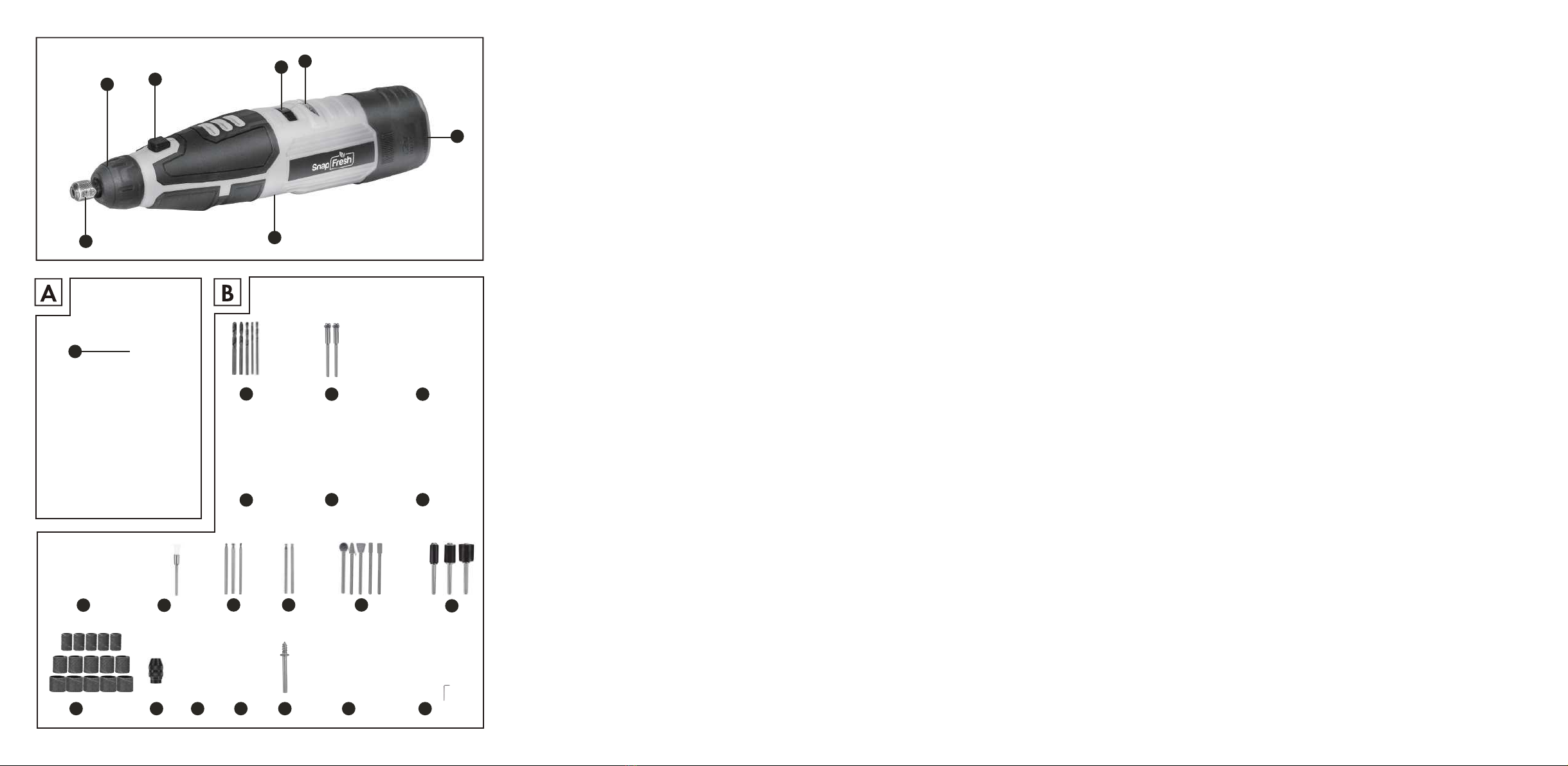

Features

Cordless precision rotary tool:

Variable speed dial

Battery LED

ON/OFF switch

Charging socket

Collet nut

Nose cap

Shaft lock

Battery charger (See Fig. A):

Charger

Accessories (See Fig. B):

5 HSS drill bits

2 mandrels as tool holders

4+4 felt polishing wheels

8 grinding discs

1 coppered steel wire brush

16 cutting discs

3 collet chuck(1/16", 3/32", 1/8")

DANGER

WARNING

CAUTION

NOTICE

TIP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1 hour

Attachments (See Fig. B):

2 nylon brush

3 milling cutters

2 engraving bits

3 ■

Package contents

1 cordless precision rotary tool

1 battery charger

1 accessories set (79 pieces)

1 plastic case

1 operating manual

Technical details

Model BBT-KP526:

Rated voltage: 12 V (DC)

Rated idle speed: n 5000–28000 rpm

Max. disc ø: max.

Chuck clamping

range: max.

ø 1/8 (3

ø 31/32 (25mm)

.2 mm)

Capacity: 1500 mAh

Battery (integrated): LITHIUM-ION

Cells: 3

Battery charger XZ1350-1500:

Primary (input):

Rated voltage: 100-240 V~, 50/60 Hz

(AC)

Rated power

consumption: 0.8 A

Secondary (output):

Rated voltage: 12 V (DC)

Rated current: 1 .5 A

Charging time: approx.

Polarity:

General Power Tool Safety

warnings

WARNING!

►Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may

result in electric shock, fire and/

or serious injury.

Save all warnings and instructions for

future reference.

The term "power tool" in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

a)

b)

c)

a)

b)

.

1. Work area safety

2. Electrical safety

16

17

18

5 grinding bits

3 sanding drum mandrels

15 grit sanding bands

19

20

21

1 keyless chuck

1 combination spanner

1 grinding wheels

22

23

24

1 screw mandrel

25

1 cutting/drilling guide

26

1 flex shaft

27

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tools in explo-

sive atmospheres, such as in the

presence of flammable liquids, gases

or dust. Power tools create sparks which

may ignite the dust or fumes.

Keep pets, children and bystanders

away while operating a power tool.

Distractions can cause you to lose control.

Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmo-

dified plugs and matching outlets will

reduce risk of electric shock.

Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or grounded.

a)

c)

d)

f)

g)

a)

b)

e)

f) 4. Power tool use and care

3. Personal safety

■ 4

b) Use personal protective equip-

ment. Always wear eye protection.

Protective equipment such as

c)

d)

e)

Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on

the switch or energising power tools that

have the switch on invites accidents.

Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in

personal injury.

Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

Dress properly. Do not wear loose cloth-

ing or jewellery. Keep your hair, clothing

and gloves away from moving parts.

Loose clothes, jewellery or long hair can

be caught in moving parts.

If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of dust collection

can reduce dust-related hazards.

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was

designed.

Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjust-

ments, changing accessories, or stor-

ing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tools operation. If dama-

ged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

Stay alert, watch what you are doing

and use common sense when operat-

ing a power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication. A moment

of inattention while operating power tools

may result in serious personal injury

dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

5. Use and handling of the cordless

electrical power tool

Safety instructions for all

applications

5 ■

6. Service

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and

tool bits, etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation. a)

a) Charge a rechargeable battery unit

using only the charger recommended

by the manufacturer. Chargers are often

designed for a particular type of recharge-

able battery unit. There is the danger of

fire if other types of rechargeable battery

units are used.

b) Only the rechargeable battery units

supplied are to be used with an

electrical power tool. The use of other

rechargeable battery units may lead to the

danger of injury or fire.

c) When they are not being used, store re-

chargeable battery units away from

paper clips, coins, keys, nails, screws

or other small metal objects that could

cause the contacts to be bridged.

Short-circuiting the contacts of a recharge-

able battery unit may result in heat damage

or fire.

d) Fluids may leak out of rechargeable

battery units if they are misused. If this

happens, avoid contact with the fluid. If

contact occurs, flush the affected area with

water. Seek additional medical help if any

of the fluid gets into your eyes. Escaping

battery fluid may cause skin irritation or

burns.

CAUTION! RISK OF EXPLOSION!

Never charge non-rechargeable

batteries!

Protect the rechargeable battery

from heat, for example from

continuous exposure to sunlight,

fire, water and moisture. There is

a risk of explosion.

Have your power tool serviced by a quali-

fied repair person using only identical

replacement parts. This will ensure that

the safety of the power tool is maintained.

This power tool is intended for use as

a grinder, sandpaper sander, wire brush,

polisher, milling machine and abrasive

cutting appliance. Please follow all safety

instructions, instructions, diagrams and

data that you receive with the appliance.

If you do not observe the following instruc-

tions, this can lead to electrical shock, fire

and/or serious injuries.

b)

a)

General safety instructions for grinding, san-

dpaper sanding, working with wire brushes,

polishing, milling and abrasive cutting:

Wear personal protective equipment.

Depending on the application, ensure

that you use full face protection, eye

protection or goggles. If required, use a

dust mask, ear protectors, protective

gloves or special apron to protect you

from grindings and material particles.

Protected your eyes from flying debris

that may be created during certain app-

lications. Dust or filter masks must be

used to filter any dust created by the app-

lication. If you are exposed to loud noise

for any length of time, you may suffer

hearing loss.

■ 6

Do not use any accessories that have

not been provided or recommended

by the manufacturer for this power

tool. Just because you can attach the

accessories to your power tool, does not

ensure they are safe to use.

The permissible speed of the accessory

tool used must be at least as high as

the maximum speed specified for the

power tool. Accessories that rotate faster

than the permissible rate can break and

throw pieces into the air.

The external diameter and thickness of

the accessory tool used must comply

with the dimensions of the power tool.

Incorrectly dimensioned accessory tools

cannot be sufficiently shielded or controlled.

d)

Grinding discs, sanding drums or other

accessories must match the grinding

spindle or collet chuck of your power

tool exactly. Accessory tools which do

not fit precisely into the take-up of the

power tool will rotate unevenly, vibrate

severely and can lead to a loss of control.

e)

Discs, grinding cylinders, cutting tools

or other accessories mounted on a

mandrel must be completely inserted

in the collet or chuck. Any "protrusion"

or exposed parts of the mandrel between

the grinding tool and the collet or chuck

must be kept to a minimum. If the mandrel

is not sufficiently tightened or the grinding

tool protrudes too far, the tool could come

loose and been thrown out at high speed.

f)

Never use damaged accessory tools.

Before each use, check accessory tools

such as grinding discs for chips or cracks,

sanding drums for cracks, wearing or ex-

cessive wear and tear and wire brushes

for loose or broken wires. If the power tool

or the accessory tool in use is dropped,

check to see if it is damaged or use an

undamaged accessory tool. When you

have checked and inserted the accessory

tool, ensure that you and any other people

in the vicinity remain outside of the range

of the rotating accessory tool and allow

the tool to rotate at maximum speed for

one minute. Damaged accessory tools

usually break during this test period.

j)

g)

h)

c) Ensure that other people remain at a

safe distance to your workspace.

Anyone who enters the workspace must

wear personal protective equipment.

Fragments of the workpiece or broken

accessory tools can fly off and cause

injury – even outside the immediate

working area.

i)

Never put the power tool down until the

accessory tool has come to a complete

standstill. The rotating accessory tool can

come into contact with the surface and

cause you to lose control of the power tool.

n)

Hold the power tool only by the insulated

gripping surfaces when performing an

operation where the accessory tool may

contact hidden wiring or its own cord.

Contact with a live cable can also make

metal parts of the appliance live and could

result in an electric shock.

k) Always hold the power tool firmly. When

running up to full speed, the torque of the

motor can cause the power tool to twist.

l) If possible, use clamps to hold the work-

piece in position. Never hold a small work-

piece in one hand and the power tool in

the other while you are using it. By clamp-

ing small workpieces, you keep both

hands free for better control of the power

tool. When cutting round workpieces such

as dowels, rods or pipes, be aware that

these can roll away and this can cause

the tool to jam and be thrown towards you.

m)Hold the power cord away from any

rotating accessories. If you lose control

of the appliance, the cord may get cut or

caught and your hand or arm could get

caught in the rotating accessory tool.

Additional safety instructions

for all applications

7 ■

Kickback is a sudden reaction caused when

a rotating accessory tool, e.g. grinding disc,

abrasive band, wire brush, etc., catches or

jams. Catching or jamming leads to an abrupt

stop of the rotating accessory tool. If this

happens, an uncontrolled power tool will turn

rapidly against the direction of rotation of the

accessory tool.

a)

When changing accessory tools or

changing settings, tighten the collet

nut, the chuck or other fixing elements

tightly. Loose fixing elements can shift

unexpectedly and lead to loss of control;

unfixed, rotating components will fly off

violently.

o)

p) Do not leave the power tool running

whilst carrying it. Accidental contact

between your clothing and the rotating

accessory tool could lead to physical

injury.

q)

r)

Clean the ventilation slits of your

power tool regularly. The engine fan

draws dust into the housing and a strong

accumulation of metal dust can cause

electrical hazards

Do not use the power tool in the

vicinity of flammable materials. Sparks

can ignite such materials.

Do not use any accessory tools which

require liquid coolant. The use of water

or other liquid coolants may lead to electric

shock.

Do not touch the bit or collet after use.

After use the bit and collet are too hot to

be touched by bare hands.

u)

t)

s)

Kickback and corresponding safety

instructions

Do not alter or misuse tool. Any altera-

tion or modification is a misuse and may

result in serious personal injury. This

product is not intended for use as a dental

drill, in human or veterinary medical

applications. Serious injury may result.

A kickback is caused by incorrect use or

misuse of the power tool. This can be

avoided by taking proper precautions as

given below.

Hold the power tool firmly in both

hands and position your body and

arms so they can absorb the force of

a kickback. By taking adequate precau-

tions, the operator can stay in control of

the kickback forces.

b) Take special care when working around

corners, sharp edges, etc. Avoid allowing

the accessory tool to bounce back from

the workpiece or jam in the workpiece.

The rotating accessory tool is more likely

to jam in corners or sharp edges or if it

rebounds off them. This can cause a loss

of control or kickback.

c) Do not use toothed saw blades. Such

accessories often cause a kickback or

loss of control over the power tool.

d) Always move the accessory tool in the

same direction in the material in which

the cutting edge leaves the material (in

other words, the same direction in

which the dust is thrown out). Guiding

the power tool in the wrong direction will

cause the cutting edge of the accessory

tool to jump out of the workpiece which

can lead to the accessory tool being pulled

in this direction.

If, for example, a grinding disc catches or

jams, the edge of the grinding disc that is

projecting into the workpiece can get caught

and break off the grinding disc or cause a

kickback. The grinding disc can then fly in

the direction of the operator or away from

him, depending on the direction of rotation

of the disc at the blockage. This can also

break grinding discs.

Supplementary safety instructions

for grinding and abrasive cutting

Supplementary safety instructions

for working with wire brushes

■ 8

Special safety instructions for grinding

and abrasive cutting

Special safety instructions for working

with wire brushes:

e)

a)

Always fix the workpiece when using

rotary files, cutting discs, high-speed

milling tools or hard-metal tools. Even

a minimal tilting in the groove can cause

these tools to jam and lead to a kickback.

When the cutting disc jams, it usually

breaks. When a rotary file, high-speed

milling tool or hard-metal milling tool jams,

the accessory tool can jump out of the

groove and lead to loss of control of the

power tool.

Use only the grinding accessories

approved for your power tool and only

for the recommended applications.

Example: Never grind with the side

surface of a cutting disc. Cutting discs are

designed to remove material with the

edge of the disc. Any lateral application

of force on these grinding tools can lead

to breakage.

b) Use only undamaged mandrels of the

correct size and length and without

undercut on the shoulder for conical

and straight pencil grinders. Using an

appropriate mandrel reduces the risk of

breakages.

c) Avoid cutting disc jams or excessive

contact pressure. Do not make any ex-

cessively deep cuts. Overloading the

cutting disc increases the stress and

likelihood of tilting or jamming and thus

the possibility of kickback or breakage of

the grinding tool.

d) Avoid putting your hand in the area in

front of or behind the rotating cutting

disc. When you move the cutting disc

away from your hand, it is possible, in the

event of a kickback, that the power tool

along with the rotating disc could be

thrown out directly towards you.

e) If the cutting disc jams or you stop

working, switch the tool off and hold

it steady until the disc has completely

stopped turning. Never attempt to pull

a rotating cutting disc out of a cut. This

could lead to kickback. Identify and

remove the cause of the jam.

f) Do not restart the cutting operation in

the workpiece. Let the wheel reach full

speed and carefully re-enter the cut. The

wheel may bind, walk up or kickback if

the power tool is restarted in the

workpiece.

g) Support panels or large workpieces to

reduce the risk of the cutting disc

jamming and causing a kickback. Large

workpieces can bend under their own

weight. The workpiece must be supported

on both sides, namely in the vicinity of the

cut, and also at the edge.

h) Be particularly careful when making

"pocket cuts" into existing walls or

other obscured areas. The inserted

cutting disc may cut into gas or water

pipes, electrical wiring or other objects

that can cause kickback.

a) Be aware that the brush can lose wire

bristles even during normal operation.

Do not overstress the wires by applying

excessive pressure to the brush. The wire

bristles can easily penetrate light clothing

and/or skin.

b) Allow the brush to run at working

speed for at least one minute before

applying it to the workpiece. Ensure

that no one is standing in front of or in line

with the brush during this time. Loose

pieces of wire could fly off during the

run-in period.

Safety guidelines for battery

chargers

■

9 ■

WARNING

a)

b)

c)

c)

d)

Aim the rotating steel brush away from

yourself. When working with these brush-

es, small particles and minute pieces of

wire can fly off at great speed and pierce

skin.

GFCI and personal protection devices

like electrician’s rubber gloves and

footwear will further enhance your

personal safety.

Do not use AC only rated tools with a

DC power supply. While the tool may

appear to work, the electrical components

of the AC rated tool are likely to fail and

create a hazard to the operator.

Keep handles dry, clean and free from

oil and grease. Slippery hands cannot

safely control the power tool.

Develop a periodic maintenance

schedule for your tool. When cleaning

a tool be careful not to disassemble any

portion of the tool since internal wires may

be misplaced or pinched or safety guard

return springs may be improperly mounted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause cancer, birth defects or

other reproductive harm. Some examples

of these chemicals are:

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designedto filter out microscopic particles.

This appliance may be used by

children aged 8 years and above and

by persons with limited physical,

sensory or mental capabilities or lack

of experience and knowledge, provided

that they are under supervision or have

been told how to use the appliance

safely and are aware of the potential

risks. Do not allow children to use the

appliance as a plaything. Cleaning and

user maintenance tasks may not be carried

out by children unless they are supervised.

■

■

■

■

■

■

To avoid potential risks, damaged mains

cables should be replaced by the manu-

facturer, their customer service depart-

ment or a similarly qualified person.

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Additional safety warnings

This manual contains instructions for

battery charger model BBT-KP526. Do

not substitute with any other charger.

Before using charger, read all instruc-

tions and cautionary markings on

battery charger.

Charge only SnapFresh rotary tool

BBT-KP526.

Charge battery in temperatures above

+32 degrees F (0 degrees C) and below

+113 degrees F (45 degrees C). Store

tool in locations where temperatures will

not exceed 120 degrees F (49 degrees C).

This is important to prevent serious

damage to the battery cells.

Do not recharge battery in damp or wet

environment. Do not expose charger to

rain or snow. Water entering battery charger

may result in electric shock or fire.

FCC Caution

WARNING!

■

Use

■

■

■

■

■

■

■

■

Charging the battery pack

NOTICE

►A new battery pack or a battery pack

which has not been used for a long time

will need to be charged before first use/

reuse. It will reach its full capacity after

3–5 charge cycles. The charging

process lasts around 60 minutes.

Insert the battery charger plug into the

charging socket on the appliance and

then plug the mains plug into a mains

socket. Once the battery is fully charged,

the battery LED lights up RED/

ORANGE/ GREEN.

■ 10

■

Keep the Charging socket clean by

blowing compressed air. Contamination

may result in electric shock or fire.

The charger is suitable for indoor

use only.

Do not operate the appliance with a

damaged cable, power cable or power

plug. A damaged power cable poses a

threat of fatal electric shock.

Never use the appliance for other purposes

and only original parts/accessories. Using

attachments or accessory tools other than

those recommended in the operating

instructions can lead to a risk of injury.

The manufacturer is not responsible for radio

interference caused by unauthorized

modifications to this equipment. Such

modifications could void the user’s authority

to operate the equipment.

8

CAUTION!

►Do not use the tool while charging

because it will harm the battery.

4

2

■First unplug the charger from the mains

power socket and then the charger plug

from the charging socket on the

appliance.

8

8

4

Battery leakage may occur under extre-

me usage or temperature conditions.

Avoid contact with skin and eyes. The

battery liquid is caustic and could cause

chemical burns to tissues. If liquid comes

in contact with skin, wash quickly with soap

and water. If the liquid contacts your eyes,

flush them with water for a minimum of 10

minutes and seek medical attention.

Place tool on flat nonflammable surfac-

es and away from flammable materials

when recharging the battery. Carpeting

and other heat insulating surfaces block

proper air circulation which may cause

overheating of the charger and the battery.

If smoke or melting of the charger or tool is

observed, unplug the charger immediately

and do not use the tool or charger. Contact

customer service immediately.

Make sure cord is located so that it will

not be stepped on, tripped over, or

otherwise subjected to damage or

stress. Damaged plug and cord may result

in electric shock or fire.

Disconnect the charger by pulling the

plug rather than the cord. Do not operate

charger with damaged cord or plug; have

them replaced immediately. Damaged plug

or cord may result in electric shock or fire.

Do not disassemble charger or operate

the charger if it has received a sharp

blow, been dropped or otherwise

damaged in anyway. Incorrect reassembly

or damage may result in electric shock or

fire. Before each use, check the battery

charger, cable and plug. If damage is

detected, do not use the battery charger.

Never open the charger yourself, Incorrect

reassembly may result in electric shock or

fire.

Do not use attachments not recommend-

ed or sold by SnapFresh. Using attach-

ments not recommended may result in

electric shock or fire.

4

■

■

■

■

■

■

■

CAUTION!

►

Checking the battery charge level

Never recharge a battery pack again

immediately after charging. There is a

risk that the battery pack will become

overcharged.

CAUTION!

►Do not press the shaft lock button

while the rotary tool is running.

If the appliance is switched on, the status/

remaining charge will be shown on the

battery LED as follows:

RED / ORANGE / GREEN = maximum

charge

RED / ORANGE = medium charge

RED = low charge – charge the battery

Changing/inserting the tool/collet

chuck

Press the shaft lock and hold it down

Turn the collet nut until the lock clicks

into place

Undo the collet nut from the thread

using the combination spanner.

Remove any tool which is inserted.

First push the intended tool through the

collet nut before inserting it into the

appropriate collet chuck for the tool shaft.

■

■

Press the shaft lock and hold it down.

Push the collet chuck into the thread

insert and screw the collet nut tight

with the combination spanner .

NOTICE

►Use the screwdriver side of the

combination spanner to undo and

tighten the screw on the mandrel .

Switching on and off/setting speed

range

Switching on/setting the speed range:

Set the ON/OFF switch to the position

between "I".

Set the variable speed dial to a position

between “1” and “MAX”.

Switching off:

Set the ON/OFF switch to the "O"

position.

Notes on working with materials/tools

/speed range

■Determine the rotational speed range for

working on zinc, zinc alloys, aluminium,

copper and lead by trying it out on test

pieces.

■Use the cutting wheels for working on

the steel and iron at maximum speed or

speed "6".

■Use a low rotational speed for work on

plastics and materials with a low melting

point.

■Use a high rotational speed for working on

wood.

■Carry out cleaning, polishing and buffing

work in the medium speed range.

The following are recommendations only

and not binding. When carrying out

practical work, carry out your own tests

to see which tool and which settings are

ideal for the material you are working on.

The best way to determine the correct speed

for work on any material is to practice for a

few minutes on a piece of scrap.

You can quickly learn that a slower or faster

speed is more effective just by observing

what happens as you make a pass or two at

different speeds. When working with plastic,

for example, start at a slow rate of speed and

increase the speed until you observe that the

plastic is melting at the point of contact. Then

reduce the speed slightly to get the optimum

working speed.

11 ■

7

7

3

3

1

7

5

5

5

5

23

23

10

15

15

2

14

■ 12

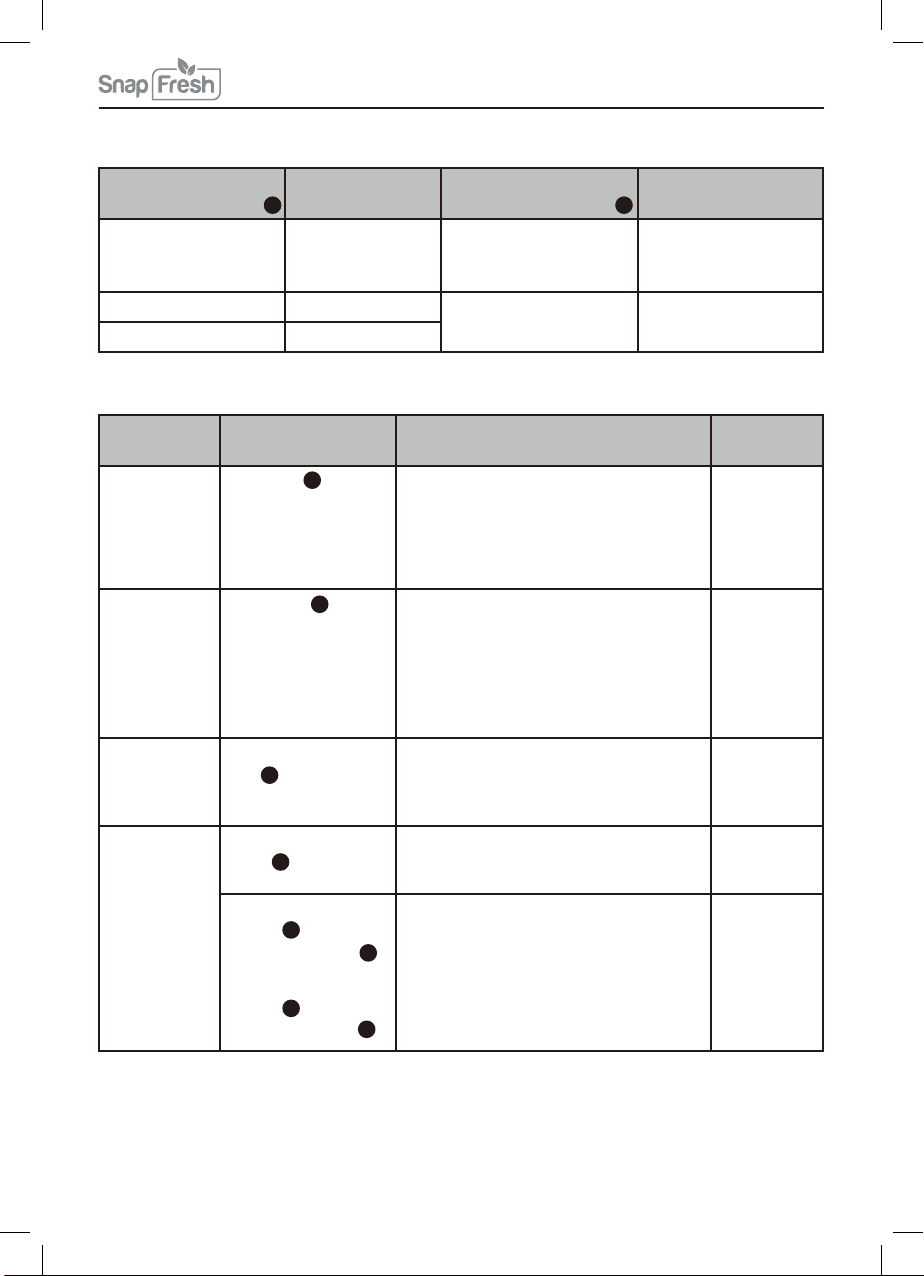

Setting a suitable rotational speed:

Number on the

variable speed dial

1–3 6

Max

4–5

Material being

worked

Material being

worked

Application examples/selecting a suitable tool:

Function Accessories Use Protrusion

(min–max) in

Drilling HSS drills

Plastics and

materials with a

low melting point

Hardwood

Steel

Stone, ceramics

Soft wood, metal

Drilling on wood or plastic

3/64"(1.4mm),

1/16"(1.6mm),

5/64"(2.0mm),

3/32"(2.4mm),

1/8'(3.0mm)

Are made for intricate work on wood carvings,

e.g. creating recesses, hollows, forms, grooves

or slits. They should not be used on steel and

other hard materials but are good on wood,

plastic.

3/32" shank.

3/32" shank.

Carve intricate details, etch metal, glass,

stoneware, terracotta.

3/32" shank.

Use for metal cleaning or rust removal.

3/32" shank.

Felt polishing wheel used for polishing plastics,

metals, jewelry and small parts. Polishing

points make a very smooth surface, but a high

luster is obtained using felt and polishing

compound. For best results polishing

accessories should be used at speeds not

greater than Speed 5.

0.7–0.98 in,

using the

smallest drill,

the protrusion

is 0.39 in

Milling Milling bits 0.7–0.98 in

1

9

17

Number on the

variable speed dial 1

5

0.7–0.98 in

0.35–0.59 in

0.47–0.7 in

Carving/

Engraving

Diamond carving

bits

Coppered steel wire

brush

Thinner felt polishing

wheels

(use with mandrel )

Thicker felt polishing

wheels

(use with mandrel )

CAUTION!

18

13

10

11

11

25

Polishing,

rust removal

Exert only

slight pressure

when applying

the tool to the

workpiece.

13 ■

0.35–0.59 in

0.47–0.7 in

0.39 in

0.47–0.7 in

Synthetic brushes The nylon wire brushes are good for general

purpose cleaning. These are excellent

cleaning tools on silverware, jewelry and

antiques. The two shapes make it possible

to get into tight corners and other difficult

places.

3/32" shank.

Aluminum Oxide Grinding Wheel/Stones

(Pink/brown) These are made of aluminum

oxide and cover virtually every possible kind

of grinding application on metal. Use them

for sharpening lawn mower blades,

screwdriver tips, knives, scissors and other

cutting tools. Use to remove flash from metal

castings, deburring any metal after cutting,

smoothing welded joints and removing rust.

These grinding stones can be resharped

with a dressing stone. 3/32" or 1/8" shank.

These thin discs are used for slicing,

cutting off and similar operations on

metal, plastic and wood. Use them

for cutting off frozen bolt heads and

nuts, or to reslot a screw head which

has become so damaged that the

screwdriver won’t work in it. Fine for

cutting small rods, small tubing,

cable.

Warning: Do not grind with the side

of a cut off wheel. Abrasive cut-off

wheels are intended for peripheral

grinding, side forces applied to these

wheels may cause them to shatter.

3/32" shank.

Cleaning

Gringding/

sharpening

Cutting

16

Grinding wheels

(use with mandrel )

12

10

10

Grinding bits 19 24

Cutting discs

(use with mandrel )

14

Silicon Carbide Grinding Wheel/Stones

(gray/green) Tougher than aluminum oxide

points, these are made especially for use on

hard materials such as glass and ceramics.

Typical uses might be the removal of stilt

marks and excess glaze on ceramics.

Engraving or grinding on glass.

3/32" shank.

■ 14

Additional instructions for accessories/attachments

■Note that the maximum diameter of the

grinding assembly, and of grinding cones

and pencil grinders with a thread insert,

may not exceed 2.16 in (55 mm) and the

maximum diameter for sandpaper sanding

accessories may not exceed 3.14 in

(80mm).

■Store the accessories in the original box

or store the accessory components

somewhere else to protect them from

damage.

■Store the accessories somewhere dry and

not in the vicinity of aggressive media.

NOTICE

►The max. permissible length of a mandrel

is 1.29 in (33 mm).

0.47–0.7 inSanding Band in S, M and L sizes are made

to fit mandrels . They can be used for

small sanding job, suah as model making,

or furniture finishing. The tiny drum which fits

into the rotary tool and makes it possible to

shape wood, sand inside curves and other

difficult places, and other sanding jobs. You

replace the sanding bands on the drum as

they become worn and lose their grit. They

are used most effectively as a finishing

sander after heavier surface sanding and

material removal is completed. They work

effectively on wood, glass, metal and plastics.

Suggested speed: don't exceed Speed 5.

1/8" shank

Mandrels as tool holders Collet chucks

This is a mandrel with a small screw at its tip, and

is used with cutting wheels , grinding discs

and thinner polishing wheels .

3/32" shank.

Collet chuck(1/16"):

Use with HSS drill bits 3/64"(1.4mm), 1/16"(1.6mm)

Collet chuck(3/32"):

Use with HSS drill bits 5/64"(2.0mm), 3/32"(2.4mm),

and accessories

Collet chuck(1/8"):

Use with HSS drill 1/8'(3.0mm),

and accessories

Sanding 15 Grit sanding

bands 21

10

10 13 16

20 24 25

17 18 19

15

11

1214

(use with drum

mandrels )

20

20

15 ■

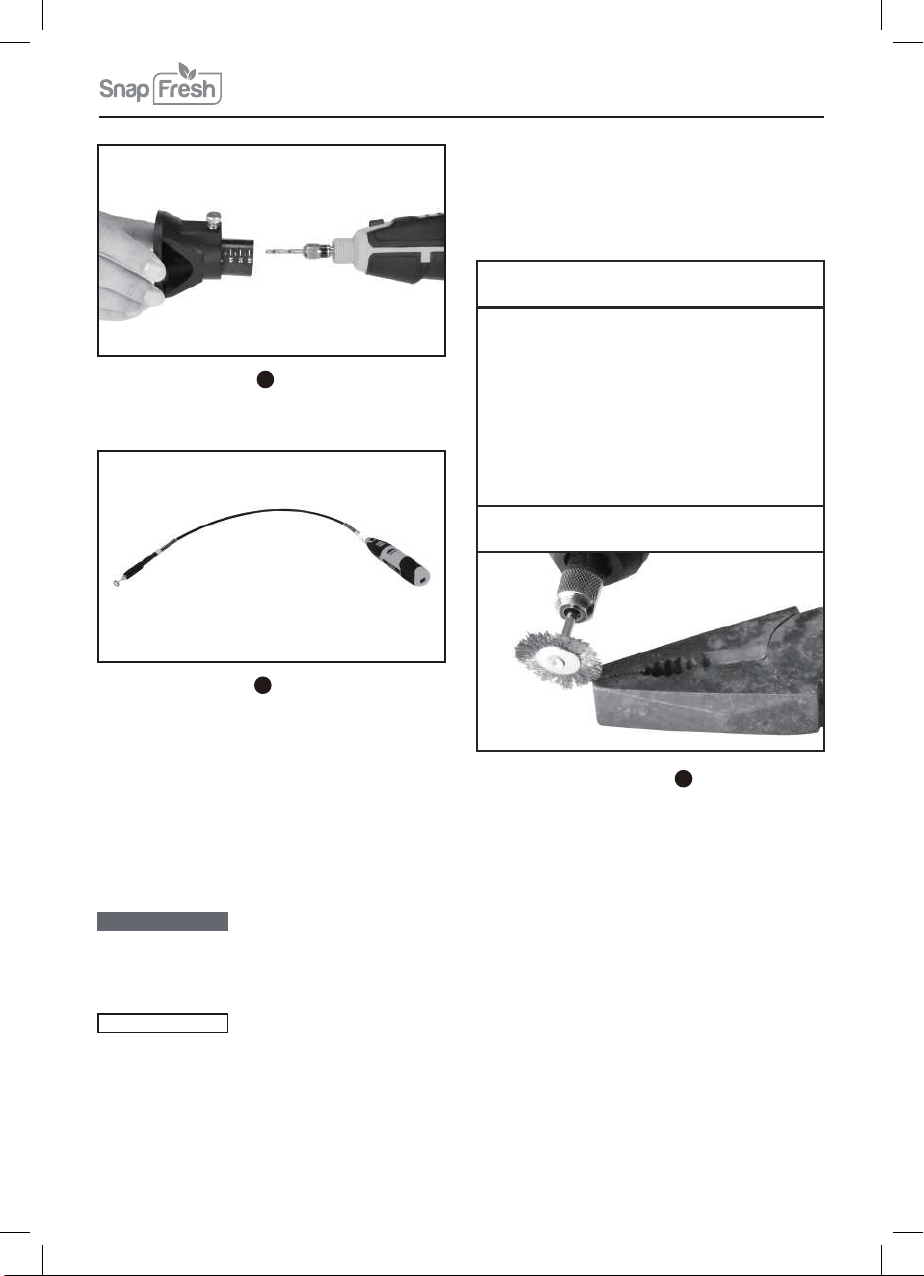

Sanding drum mandrels

Keyless chuck

Use with sanding band

To replace a band on the Drum Sander, loosen the

screw without removing it to contract the drum then

slide the old band off. Slide the new sanding band

on and then expand the drum by tightening the

screw once again.

Ideal for 1/32” (0.8mm) to 1/8” (3.2mm)

This chuck allows you to quickly and easily change

accessories on rotary tools without changing

collets. Accepts accessories with 1/32” - 1/8” shank.

Insert and securely tighten the shank of the

accessory well within the jaws of the chuck.

But we suggest to use 1/16" chuck for 3/64"(1.4mm),

1/16"(1.6mm) drill bit

20

21

22

Combination spanner

Screw mandrel

After changing the bits or making any adjustments,

make sure the collet nut, chuck or any other

adjustment devices are securely tightened.

Use spanner to tighten!

Loose adjustment devices can unexpectedly shift,

causing loss of control, loose rotating components

will be violently thrown.

This is a screw mandrel used with the thicker felt

wheels of the felt polishing wheel .

Thread the thicker wheels on to the screw carefully.

The felt wheel must thread down straight on the

screw Mandrel, and be turned all the way to the

collar.

23

25

11

WARNING

Before each use, check to make certain that all

components are assembled to accessory shank and

that the drum is sufficiently expanded to secure the

band during use. If sanding band is loose on the

drum during operation it may fly off and strike you or

bystanders.

■ 16

Cutting/drilling guide

Flex shaft length 43"

Depth adjustment quickly sets correct cutting/drilling

depth up to 3/4"

Pre-installed with a 1/8"(3.2mm) collet chuck, also

will fit other collet chucks for SnapFresh rotary tool.

Ergonomic pen design makes easy, comfortable

carving, sanding and polishing. It can used with

polishing kits, drill bits, wire brushes, cut off wheels,

grinding wheels, sanding bands and more working

in tight spaces, ideal for engraving and jewelry

making the 43" Flexible Shaft rotary tool simplifies

working in cramped spaces and allows the user more

freedom while working on DIY projects.

26

27

Coppered steel wire brush

If excessive pressures are used, the wires will

be overstressed, resulting in a wiping action;

and if this is continued, the life of the brush will

be shortened due to wire fatigue.

13

TIP

It may cause heat or shock depending on the speed

or the degree of bending, the higher rotating speed

with higher degree of bending may burn the cover.

Do not use the flexible shaft for a long time, stop

the tool and let it cool down every 5-10 minutes;

NOTICE

a)

b)

c)

Try to keep it straight while working as possible

as you can and don't bend it too much;

Suggested speed: don't exceed Speed 3;

d) For best performance and long life, be sure to

apply a greasing lubricant to the inner flex shaft

parts as needed. Like all tools proper care and

attention will extend the longevity of the tool.

Overall length: 43 inches

a)

b)

Remember, the tips of a wire brush do the work.

Operate the brush with the lightest pressure so

only the tips of the wire come in contact with the

work.

INCORRECT:

Excessive pressure can cause wire breakage.

CORRECT:

Wire tips doing the work.

17 ■

Operating Instructions

SnapFresh rotary tool BBT-KP526

Thank you for purchasing the SnapFresh

rotary tool BBT-KP526.

It has a wide speed range including a high

performance motor that allows the tool to

maintain its speed under load. The design

of the tool also contains plenty of soft grip

so the tool can be held comfortably in many

positions. The quick collet lock mechanism

makes locking the output shaft easier for

changing accessories.

Rotary Tool Introduction

The rotary tool has a small, powerful

electric motor, is comfortable in the hand,

and is made to accept a large variety of

accessories including abrasive wheels, drill

bits, wire brushes, polishers, engraving

cutters, router bits, cutting wheels and

attachments.

Getting the most out of your rotary tool is

a matter of learning how to let this speed

work for you. To learn about more uses and

the versatility of accessories and attachmen-

ts refer to this Owner's Manual.

Using the rotary tool

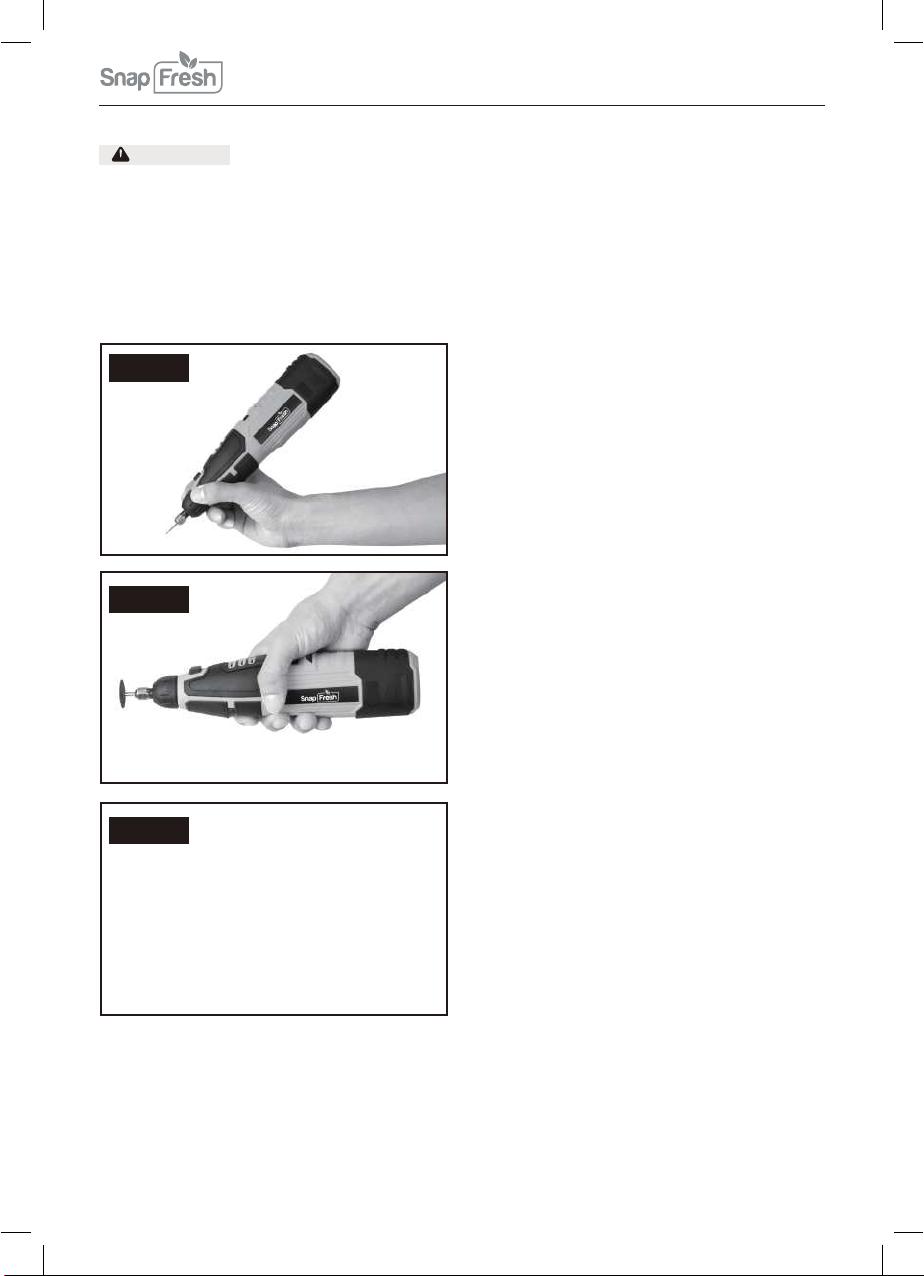

Always hold the tool

away from your face.

Accessories can be

damaged during

handling, and can fly

apart as they come

up to speed. This is not common, but it does

happen.

Wear eye protection

WARNING

TIP

The rotary tool operates at speeds up to

28,000 revolutions per minute, it's almost 10

times faster than the electric drill. The electric

drill is a low-speed, high torque tool; the

Rotary Tool is just the opposite – a high-

speed, low torque tool, so excessive pressure

will make the rotating stop. You don’t apply

much pressure to the tool, but simply hold

and guide it.

The speed enables it to do jobs low speed

tools cannot do, such as cutting hardened

steel, engraving glass, etc.

a)

b)

c)

d) Do not press the shaft lock button while

the rotary tool is running.

If you exert excessive pressure, the

fitted tool can break and/or the work-

piece could be damaged, also if the

rotating stopped by excessive pressure,

the protection system may be triggered,

resulting in shut down. If it happened,

the Battery LED lights will turn off, you

need to restart the tool. Then you can

continue to use the tool, but exert

lighter pressure. You will achieve

optimum working results by moving the

tool over the workpiece at a steady speed.

Increasing the pressure on the tool is not

the answer when it is not performing as

you think it should. Perhaps you should be

using a different accessory, and perhaps

an adjustment in speed would solve the

problem. Leaning on the tool does not help.

When carrying out cutting work, hold the

appliance firmly with both hands.

Observe the data and the information in

the table to prevent the end of the spindle

from touching the perforated base of the

grinding tool.

7

Always Wear Eye Protection

■ 18

CAUTION

For best control in close work, grip the rotary

tool like a pencil between your thumb and

forefinger (Figure A).

Whenever you hold the tool, be careful

not to cover the air vents with your hand.

This blocks the air flow and causes the

motor to overheat.

Usually, it is best to make a series of passes

with the tool rather than attempt to do all the

work in one pass. To make a cut, for example,

pass the tool back and forth over the work,

Cut a little material on each pass until you

reach the desired depth. For most work, the

gentle touch is best. With it, you have the

best control, are less likely to make errors,

and will get the most efficient work out of the

accessory.

The “Golf Grip” method of holding the tool

can be used for more aggressive operations

such as grinding a flat surface or using cutoff

wheels (Figure B and Figure C).

Practice on scrap materials first to see how

the rotary tool's high speed action performs.

Keep in mind that the work is done by the

speed of the tool and by the accessory in the

collet. You should not lean on or push the

tool during use.

Instead, lower the spinning accessory lightly

to the work and allow it to touch the point at

which you want cutting (or sanding or etching,

etc.) to begin. Concentrate on guiding the

tool over the work using very little pressure

from your hand. Allow the accessory to do

the work.

Figure A

Figure B

Figure C

Table of contents

Other Snap Fresh Power Tools manuals

Popular Power Tools manuals by other brands

Henry Tools

Henry Tools 46 ARA General safety and maintenance manual

Far Tools

Far Tools DPC 35E Original manual translation

Far Tools

Far Tools SN36 Original manual translation

Delta

Delta ShopMaster CL180JS instruction manual

Beveltools

Beveltools Bevel Mite EBI-06 Premium Quick start manual

Power Fist

Power Fist CETL 3072101 user manual