INTRODUCTION

This manual was written for shop technicians (car lift operators) and maintenance technicians. Before operating these car lifts, please

read these instructions completely. This manual gives helpful information about:

•Safety of people;

•Safety of the car lift;

•Safety of lifted car.

This manual is considered to be a permanent part of the lift and must be kept in an easily accessible place so that the operator can find

it and refer to it .A particularly careful reading of chapter “3” on safety is recommended.

All versions of “GLP99SM-GLP99SM/P” have been designed and built as required by:

EUROPEAN RECOMMENDATIONS: EEC 98/37/CEE, 73/23/CEE, 93/68/CEE, 89/336/CEE.

EUROPEAN RULES: EN 291/1992, EN 292/1992, EN 294, EN349, EN1050, EN 60204-1, EN 300683, EN 55022B.

Only skilled and previously authorized technicians should be allowed to carry out transport, assembling, setting, maintenance, overhaul,

moving, dismantling operations, etc. concerning the lift. The manufacturer is not responsible for possible damage to people, vehicles

and objects in the case that said operations are carried out by unauthorized personnel or the lift improperly used.

Read these instructions completely before operating the lift.

The lift must only be used for vehicles up to the specified capacity. Any inproper use of this lift is strictly forbidden

Disconnect the lift from the main electric supply before any extraordinary maintenance operation.

Lift installation must be carried out as specified by these instructions.

The manufacturer is not liable for possible damage resulting from failure to follow the instruction supplied with this car lift.

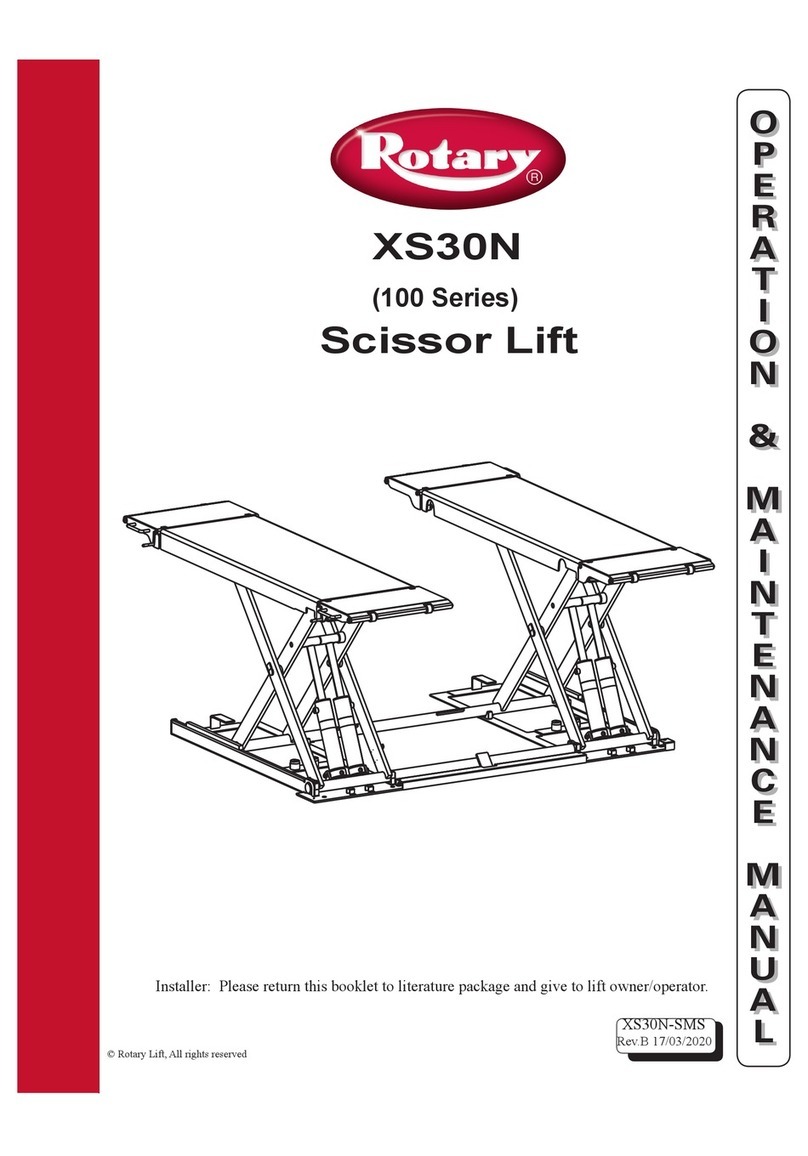

PACKING

Standard versions of the car lift are pre-assembled and equipped as follows:

2 x bases and platforms (p1-p2) placed on top of each other and sealed with pallet.

1 x control box.

1 x cardboard box equipped with hydraulic connections, rubber pads.

1 x set of lifting/lowering ramps.