Snap-on Equipment Epic EELR132AJK User manual

ADJUSTABLE

AIR-HYDRAULIC

SLIDING JACKBEAM

6000 lbs.

“EPIC” SERIES

6500 Millcreek Drive, Mississauga, Ontario, L5N 2W6

Tel: (905) 826-8600

Fax: (905) 826-7800 MAY 2012 REV. - 6-2461

SAVE ALL INSTRUCTIONS

READ ALL INSTRUCTIONS

THOROUGHLY BEFORE

INSTALLING, OPERATING,

SERVICING, OR

MAINTAINING THE LIFT.

INSTALLATION AND OPERATION MANUAL

2 of 11

JACKING BEAM INSTALLATION AND OPERATION MANUAL

The jacking beam should only be used with lifts installed on level concrete floors conforming to

the installation instructions for the lift. Consult lift installation instructions for concrete

thickness and strength requirements. Ensure clearance around and above lift conforms to

installation instructions for the lift.

ATTENTION! This lift is intended for indoor installation only. It is prohibited to

install this product outdoors. Operating environment temperature range should be

41 – 104 °F (5 – 40 °C). Failure to adhere will result in decertification, loss of

warranty, and possible damage to the equipment.

Installation of lifts shall be performed in accordance with ANSO/ALI ALIS, Safety

Requirements for Installation and Service of Automotive Lifts

For additional safety instructions regarding lifting, lift types, warning labels, preparing to lift,

vehicle spotting, vehicle lifting, maintaining load stability, emergency procedures, vehicle

lowering, lift limitations, lift maintenance, good shop practices, installation, operator training and

owner/employer responsibilities, please refer to “Lifting It Right” (ALI/SM) and “Safety Tips”

(ALI/ST).

For additional instruction on general requirements for lift operation, please refer to “Automotive

Lift-Safety Requirements For Operation, Inspection and Maintenance” (ANSI/ALI ALOIM).

3 of 11

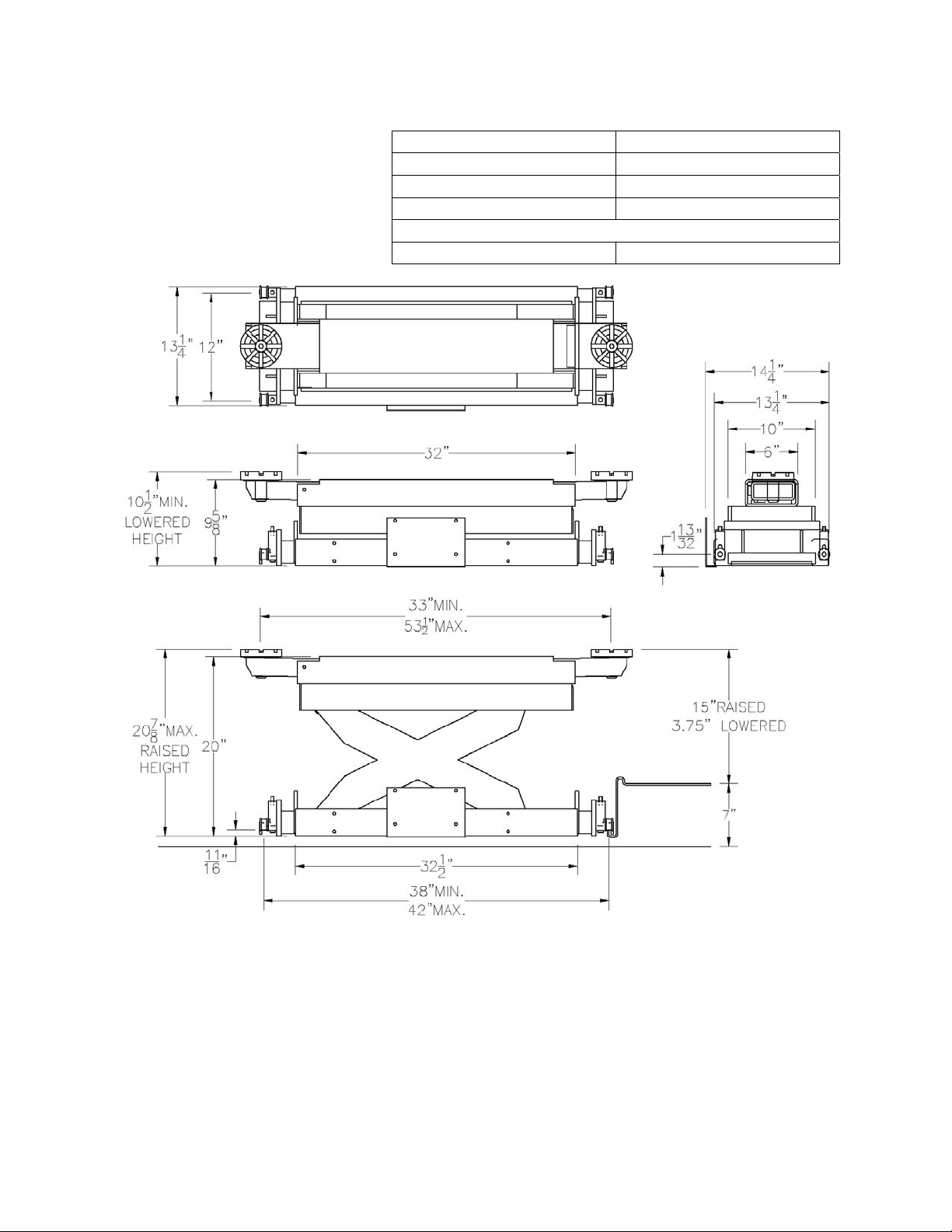

Specifications

Maximum Capacity: 6000 lbs 2722 kg

Width Rail to Rail: 38” to 42” 965 mm to 1067 mm

Down Position Height: 10-1/2” 267 mm

Maximum Raised Height: 20-7/8” 530 mm

Power Requirements: 90 – 120 psi Shop Air

Shipping Weight: 329 lbs 149 kg

Figure 1- Jacking beam plan and elevation views

4 of 11

Contents

The jacking beam is fully assembled and packaged to protect it from any damage that may occur

during shipping. Included are the following components:

- Jacking beam assembly

- Jacking beam keeper kit

Installation

1. Position the jacking beam on the lift so that the rollers rest on the rails on the inside edges of

the runways. The pump side of the jacking beam should face outwards.

2. Bolt on the keeper brackets using the supplied hardware in the keeper kit.

3. The jacking beam must be connected to the air supply in order to operate. Install the ¼” NPT

90° elbow from the keeper kit on to the pump.

4. Attach the recoil hose to the ¼” NPT 90° elbow.

5. Attach the other end of the recoil hose to the air fitting on the side of the lift runway.

NOTE: Keep the air source clean and make certain that an air filter/oiler is used to keep

dirt out of the air motor. Failure to provide clean air may void manufacturers warranty.

5 of 11

Positioning of Jacking Beam on Lift

1. The jack must be positioned on the lift correctly prior to usage.

2. Pull out each adapter from the sides of the Jacking Beam and place lift so that the center of

the rollers is on the jack beam rails.

3. To ensure that the Jacking Beam is centered between the decks, the adapters must be equally

spaced on both side of the base. Tighten stop screws.

NOTE: DO NOT EXTEND ADAPTERS MORE THAN 3” FROM BASE. SAFETY

STOP SCREWS ARE PROVIDED.

Positioning of Vehicle on Jacking Beam

1. The vehicle must be positioned correctly on the lift prior to raising the vehicle with the

jacking beam.

LIFTING AN IMPROPERLY POSITIONED VEHICLE WITH THE JACK

BEAM INCREASES THE POSSIBILITY OF ONE DECK LEADING OR

LAGGING THE OTHER DECK.

NOTE: USE ONLY THE SAME LIFTING PADS ON BOTH ARMS.

2. Move the jacking beam to the desired pickup area and connect the air line (if not permanently

connected).

NOTE: EASE OF POSITIONING WHILE JACKING BEAM IS NOT UNDER LOAD

IS DUE TO THE TRACK ROLLER ASSEMBLIES. THE ROLLER ASSEMBLIES

ARE SPRING LOOADED TO CARRY THE WEIGHT OF THE JACK ONLY. WHEN

THE JACKING BEAM IS UNDER LOAD THE JACK RESTS ON ITS STRUCTURE

AND CANNOT BE MOVED.

3. With the jacking beam positioned at the desired working location, select the proper lifting

pads. Insert the lifting pads into the arms.

NOTE: LIFT VEHICLE AT MANUFACTURER’S RECOMMENDED PICKUP

POINTS ONLY. PLEASE REFER TO “LIFTING IT RIGHT” (ALI/SM).

4. With the vehicle’s center of gravity equally spaced between the decks, the jacking beam can

be used to lift the vehicle. Select lifting points that are the same distance from the centerline

of the vehicle, i.e. position the jack beam pads so that they make contact at the same point on

each side of the vehicle.

6 of 11

Raising the Jack Beam

1. Press the up button and hold until jacking beam is at full working height and the automatic

safety is in place. Lower the jack beam onto the safety (Note: there are two safety stops to

allow multiple working heights).

NOTE: NEVER WORK ON A VEHICLE UNLESS THE SAFETY LOCK IS

ENGAGED AND THE JACKING BEAM CANNOT BE LOWERED.

Lowering the Jack Beam

1. To lower the jacking beam, first raise the jack up off the mechanical safety lock and release

the safety lock using the safety release lever.

NOTE: THE SAFETY LEVER MUST BE MANUALLY HELD IN THE RELEASED

POSITION.

2. Press the control handle to release pressure allowing the jacking beam to lower to its full

down position.

3. Never operate a jacking beam that is not in proper working order or in a manner not

recommended by the vehicle or jacking beam manufacturer.

ALWAYS ENSURE THAT THE MECHANICAL SAFETY IS ENGAGED WHENEVER

A VEHICLE IS SUPPORTED BY THE JACKING BEAM.

Recommended Maintenance

1. Inspect the jacking beam on a daily basis to ensure the jacking beam is in proper working

condition.

2. Make certain that the automatic safety drops into place when the jacking beam is raised and

that it will release when held in the down position during lowering.

3. Check the hydraulic fluid when jacking beam is in the lowered position by removing the

filler breather cap.

4. Keep the air source clean and make certain that an air filter is used to keep dirt out of the air

motor.

5. Keep the entire jacking beam as clean as possible at all times.

6. To maintain a clean shop air supply, (oil, lube, filter and regulator) should always be in good

working order in conjunction with the use of an oiler/separator.

7 of 11

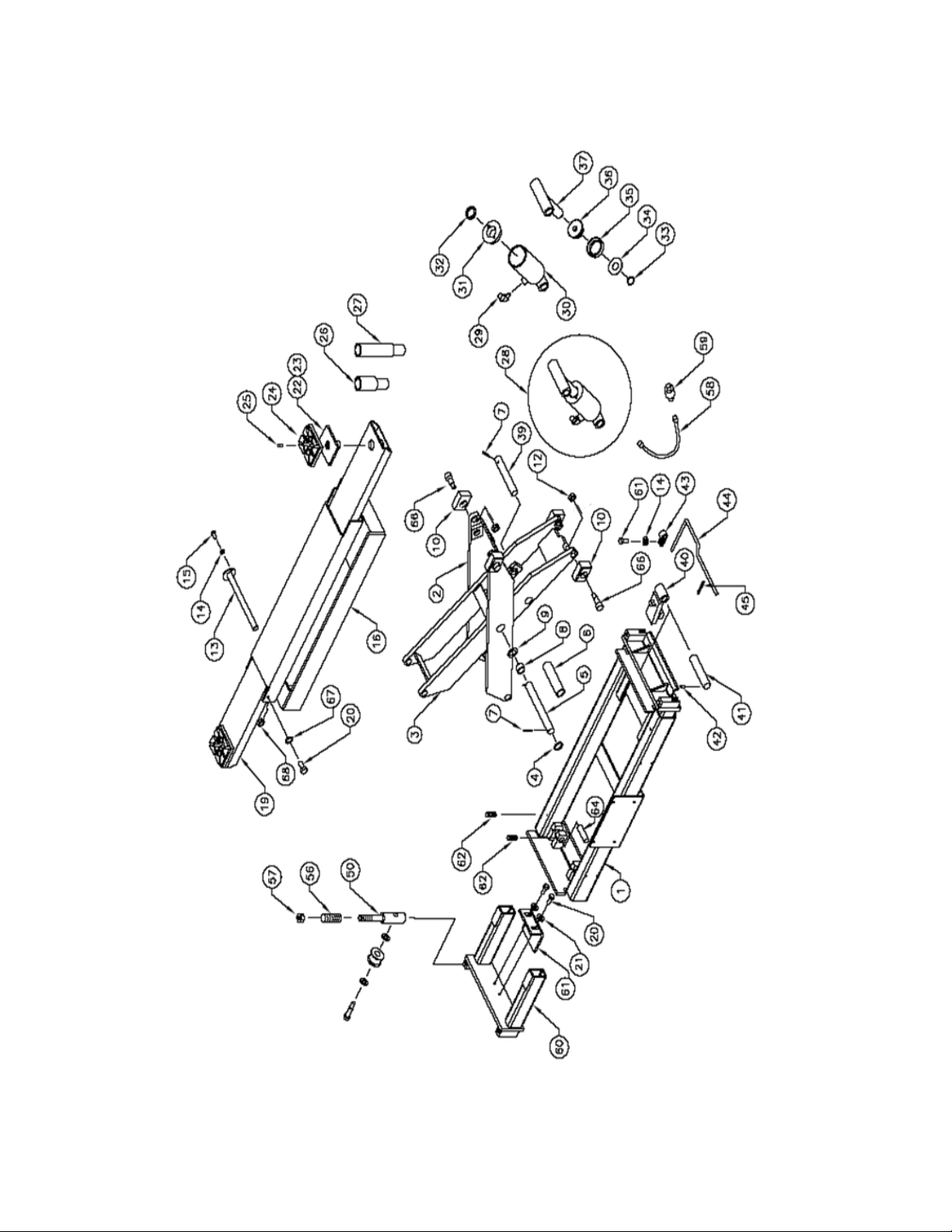

JACKING BEAM ASSEMBLY 6000 LBS.

*LIFT NOT EXACTLY AS SHOWN.

8 of 11

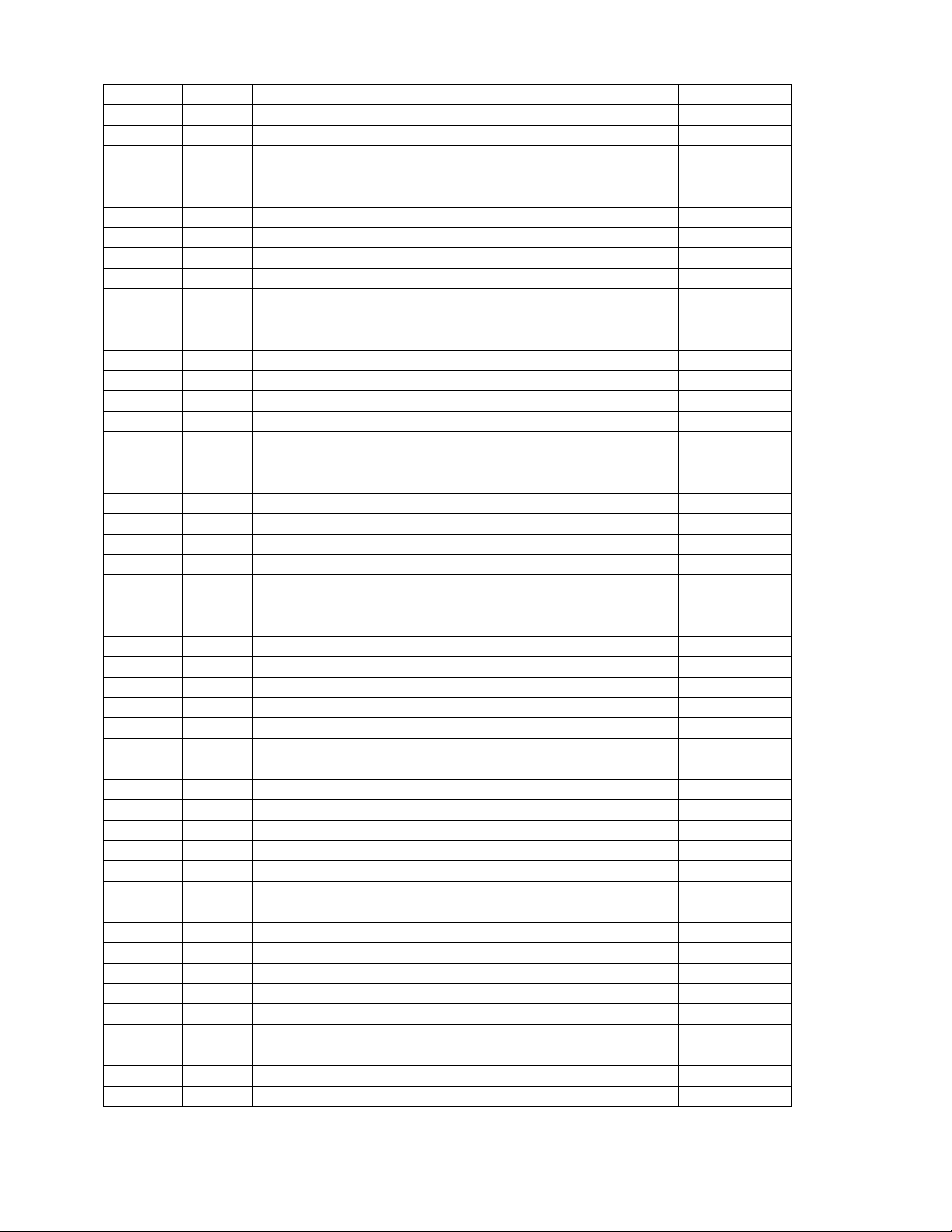

ITEM QTY. DESCRIPTION PART #

1 1 BASE FRAME WELDMENT 3-1111

2 1 OUTER SCISSOR WELDMENT 3-0824

3 1 INNER SCISSOR WELDMENT 3-0825

4 1 WASHER, 1 1/32” ID 6-0807

5 1 SCISSOR CENTER SHAFT 1-2270

6 1 CENTER PIPE SPACER 1-0575

7 4 SPRING PI, 3/16” X 2” LG 6-0146

8 4 BUSHING 6-2320

9 2 WASHER 6-0807

10 4 PLASTIC GLIDE BLOCK 1-3764

12 4 NYLON LOCKNUT, ½-13UNC 6-1553

13 1 UPPER SCISSOR PIN 1-1999

14 2 LOCKWASHER, ¼” ID 6-0056

15 1 SET SCREW ¼-20 X 1 1/2 6-0438

16 1 TOP WELDMENT 3-1112

19 2 LIFTING ARM WELDMENT 2-1572

20 4 HEX HD BOLT, 3/8”-NC X ¾” LG 6-0030

21 6 LOCKWASHER, 3/8” ID 6-0058

22 2 STACK PAD ASSEMBLY COMPLETE 1-3278

23 2 STACK PAD WELDMENT 2-2514

24 2 RUBBER PAD 3-0872

25 2 ALLEN HD FLAT SCREW ¼” – 20 X ¾”LG. 6-1086

26 2 STACK PAD ADAPTER, 3” 1-3280

27 2 STACK PAD ADAPTER, 6” 2-1580

28 1 CYLINDER ASSEMBLY COMPLETE 3-0474

* 1 CYLINDER ASSEMBLY (ALTERNATE) 3-1069

29 1 VELOCITY FUSE 1-1726

* 1 FLOW CONTROL (ALTERNATE) 6-3861

* 1 ADAPTER, 3/8” JIC F – ¼” JIC M (ALTERNATE) 6-0974

30 1 CYLINDER TUBE WELDMENT 2-0911

31 1 GLAND 1-1152

32 1 ROD WIPER 6-0653

33 1 SNAP RING 6-0581*

34 1 KEEPER WASHER 1-1148*

35 1 SEAL AND WEAR RING 6-2915*

36 1 PISTON 1-1150

37 1 PISTON ROD WELDMENT 2-0913

38 1 OUTSIDE CYLINDER SHAFT 1-1158

39 1 INSIDE CYLINDER SHAFT 1-1163

40 1 SAFETY STOP WELDMENT 2-1577

41 1 SAFETY PIN 1-0561

42 2 SET SCREW, ¼”-NC X ¾” LG 6-0438

43 2 SAFETY LEVER CLAMP 6-3959

44 1 SAFETY LEVER ARM 1-3202

45 1 ROLL PIN 6-0146

* 1 SAFETY LEVER ASSEMBLY 1-3203

50 4 ROLLER ASSEMBLY COMPLETE 2-0259

56 4 SPRING 6-0081

57 4 NYLON LOCKNUT, 3/8”-NC 6-0042

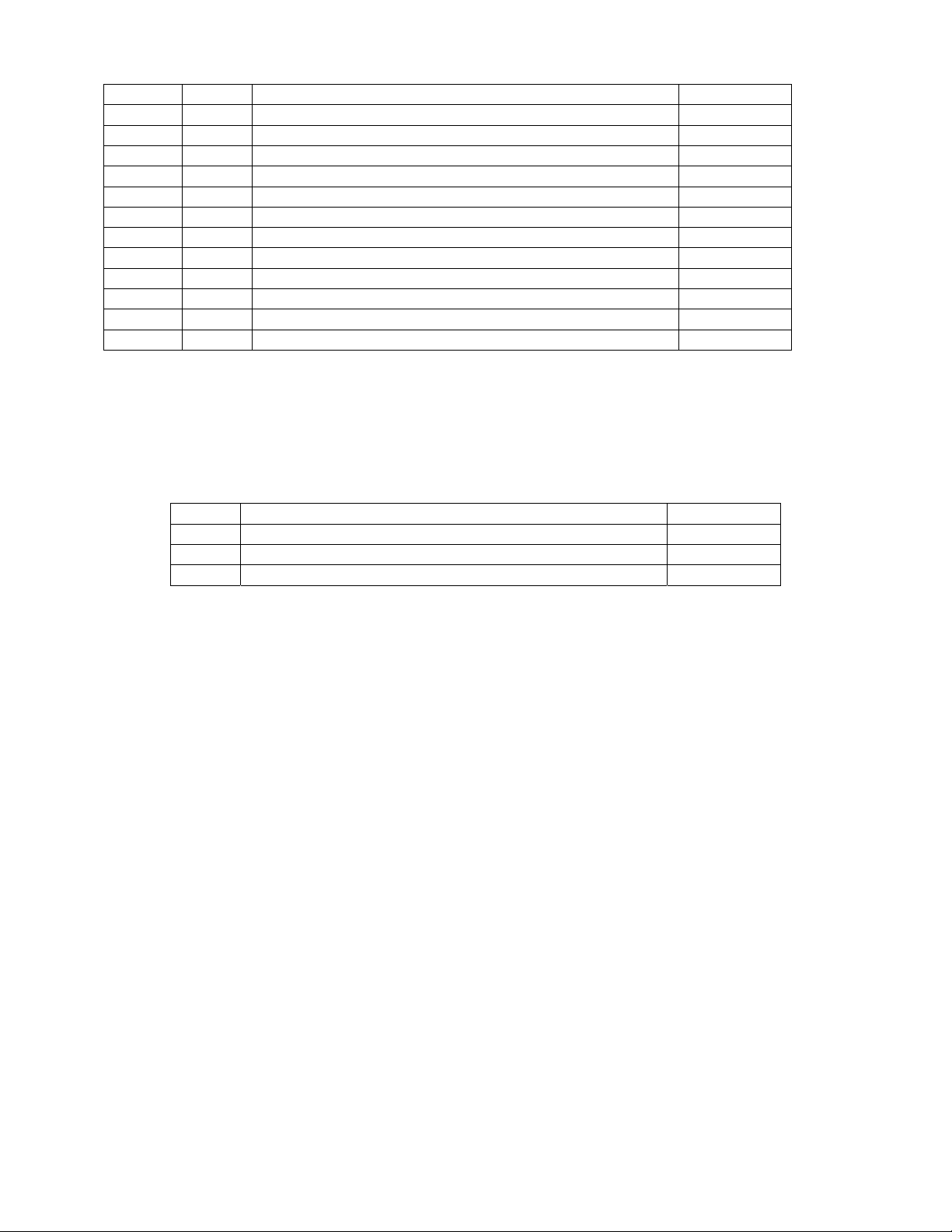

9 of 11

ITEM QTY. DESCRIPTION PART #

58 1 HYDRAULIC HOSE 1-0765

59 1 ADAPTER, 3/8”NPT-M x 3/8”JIC-M 6-0011

60 2 ROLLER ADAPTER 3-0841

61 2 BUTTON HD SCREW, ¼” X ¾” LG 6-2565

62 4 SET SCREW ¼”-20UNC x ½” LG 6-0438

63 2 KEEPER BRACKET 1-2381

64 2 LOWER SCISSOR PIN 1-2361

66 4 SHOULDER BOLT, 5/8” X 1-14”LG 6-3958

67 2 FLATWASHER 6-0062

68 2 NUT 6-3369

NOTE 1 AIR/HYDRAULIC PUMP COMPLETE 6-1428

NOTE 1 SCISSOR ASSEMBLY COMPLETE 3-0826

•PLEASE NOTE ALTERNATE CYLINDER ASSEMBLY MUST BE USED WITH

ITEMS LABELLED WITH (*).

•THE FOLLOWING PARTS ARE FOR (-L) MODELS, REAR, LEFT SIDE AIR

CONNECTION (IF REQUIRED)

QTY. DESCRIPTION PART #

2 STREET TEE 6-0015

2 ¼”NPT TO 3/8” PLOYTUBE 6-0710

1 ½” TUBE CLAMP 6-0536

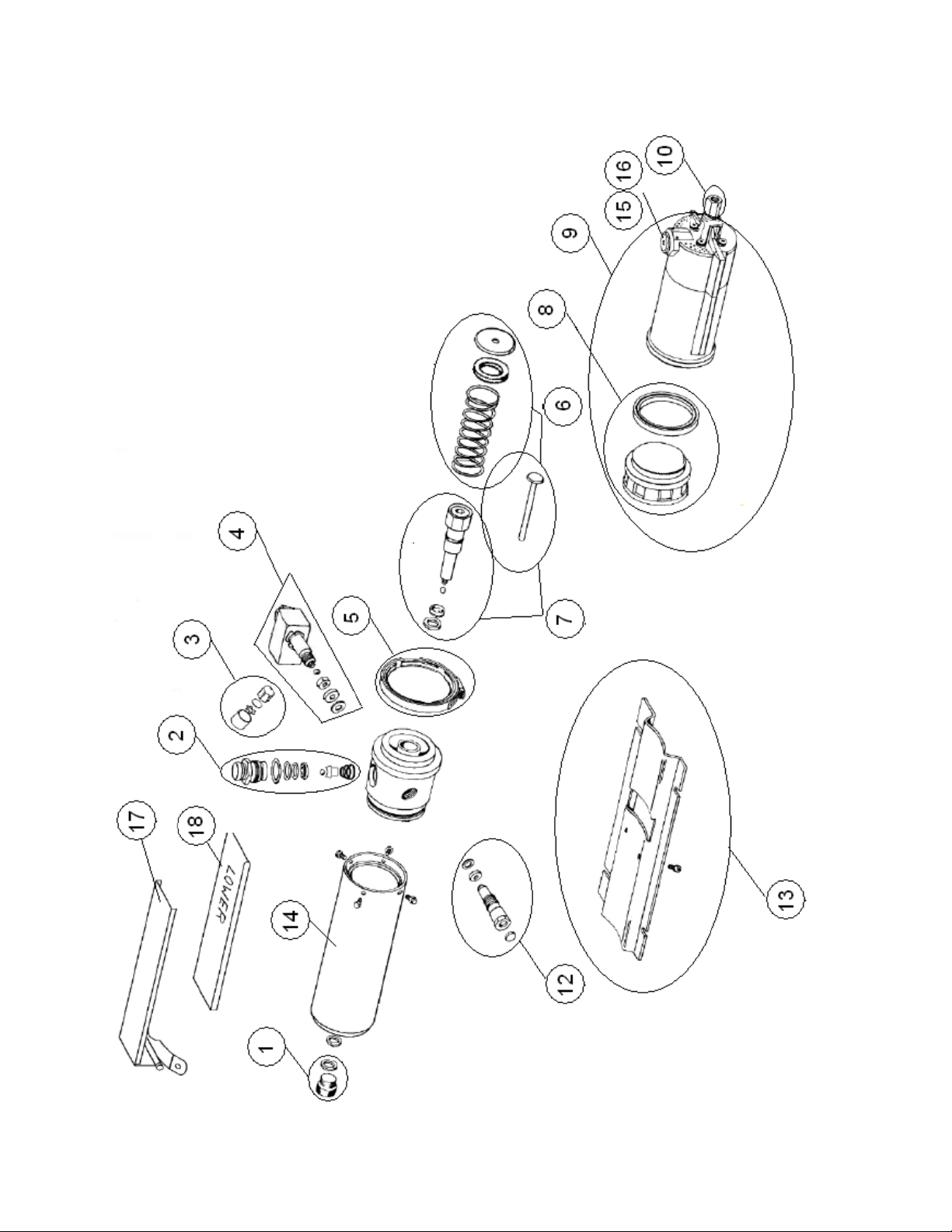

AIR / HY

D

10 of 11

D

RAULIC

PUMP

**

11 of 11

ITEM QTY. DESCRIPTION PART #

1 1 RESEVOIR CAP ASSEMBLY 6-3348

2 1 RELEASE GUIDE ASSEMBLY 6-3349

3 1 FLOW RESTRICTOR ASSEMBLY 6-3350

4 1 COUPLER ASSEMBLY 6-3351

5 1 COUPLING V-RETAINER 6-3352

6 1 PLUNGER & SPRING KIT 6-3353

7 1 HYDRAULIC CYLINDER ASSEMBLY 6-3354

8 1 AIR PISTON ASSEMBLY 6-3355

9 1 AIR MOTOR ASSEMBLY 6-3356

10 1 COUPLER KIT 6-3357

12 1 RELIEF VALVE ASSEMBLY 6-3359

13 1 BASE 6-3360

14 1 RESERVOIR 6-3361

15 1 POPPET GUIDE ASSEMBLY 6-3365

16 1 BOOT 6-3368

17 1 HANDLE 6-3366

18 1 RUBBER SLEEVE 6-3367

** Plunger is included in both kits 6-3353 and 6-3354.

This manual suits for next models

2

Table of contents