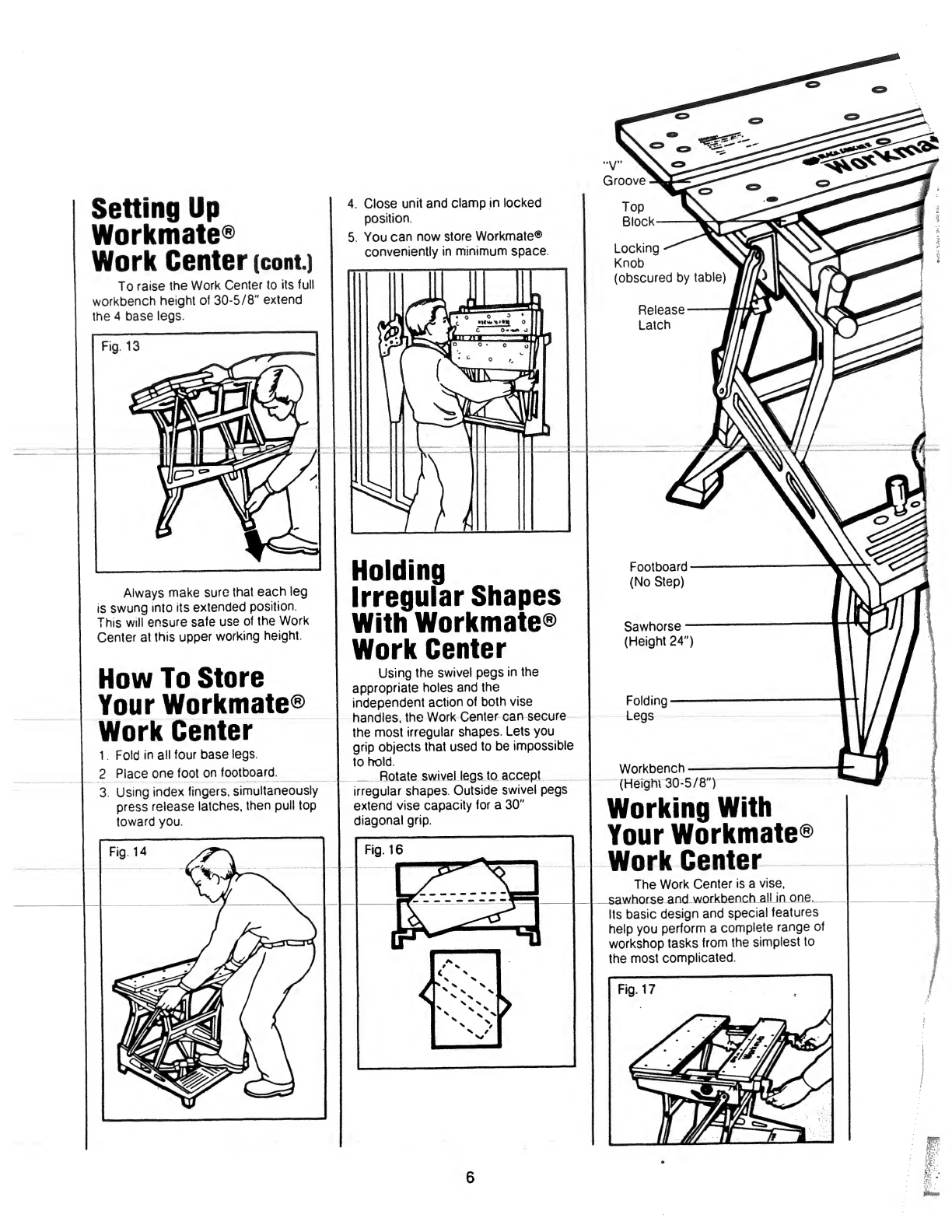

Black & Decker Workmate 79-041 User manual

Other Black & Decker Tools Storage manuals

Black & Decker

Black & Decker Workmate 425 TYPE 5 User manual

Black & Decker

Black & Decker Workmate 225 Type 6 User manual

Black & Decker

Black & Decker Workmate 79-041 User manual

Black & Decker

Black & Decker Workmate 200 User manual

Black & Decker

Black & Decker BDST98376BKAEV User manual

Black & Decker

Black & Decker WorkMate 125 User manual

Black & Decker

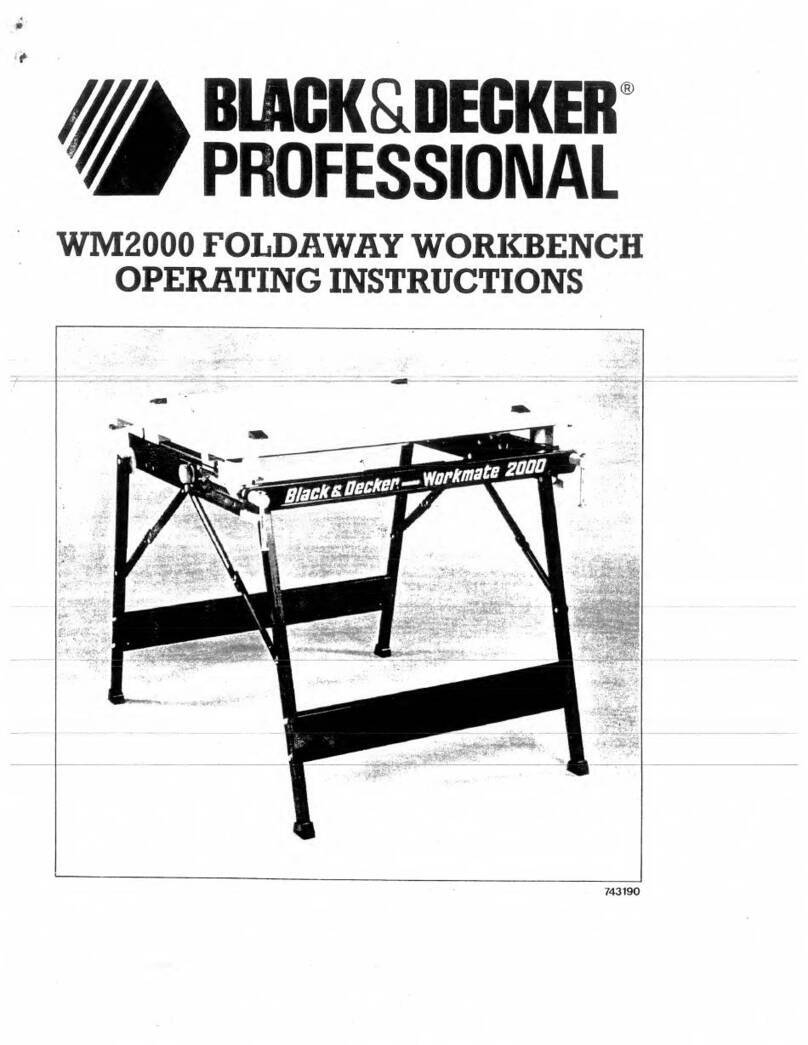

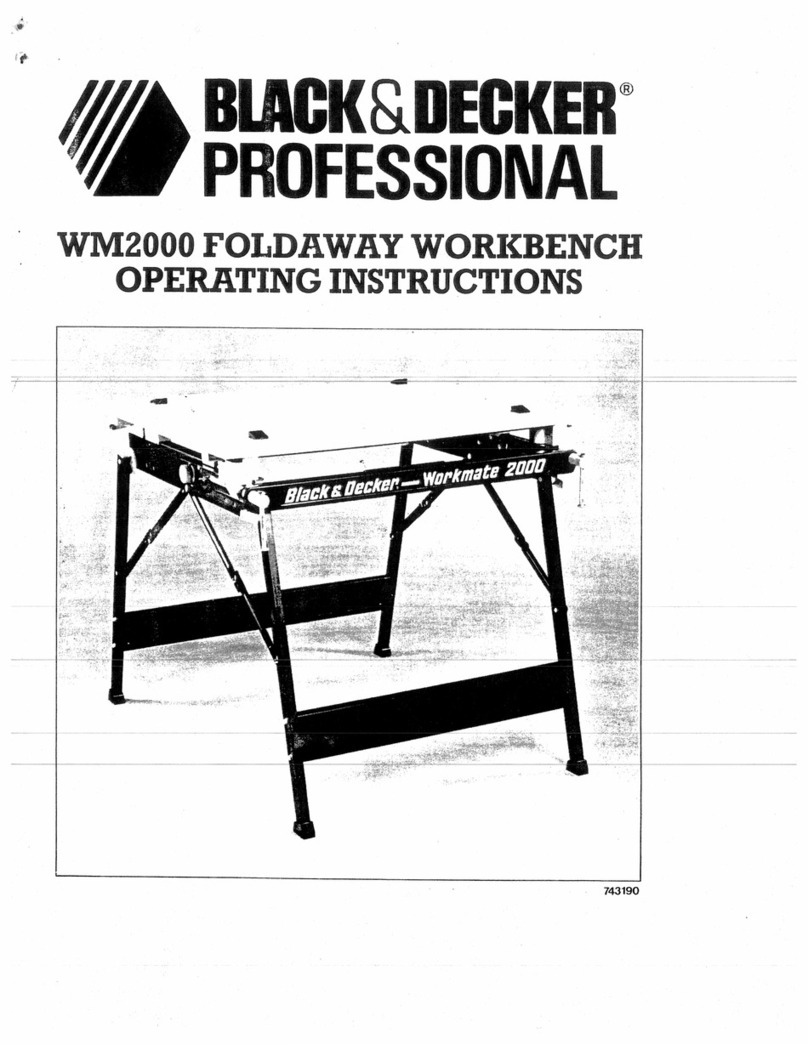

Black & Decker WM2000 User manual

Black & Decker

Black & Decker WM2000 User manual

Black & Decker

Black & Decker Workmate 225 Type 6 User manual

Black & Decker

Black & Decker WM535 User manual

Black & Decker

Black & Decker Workmate 425 TYPE 5 User manual

Black & Decker

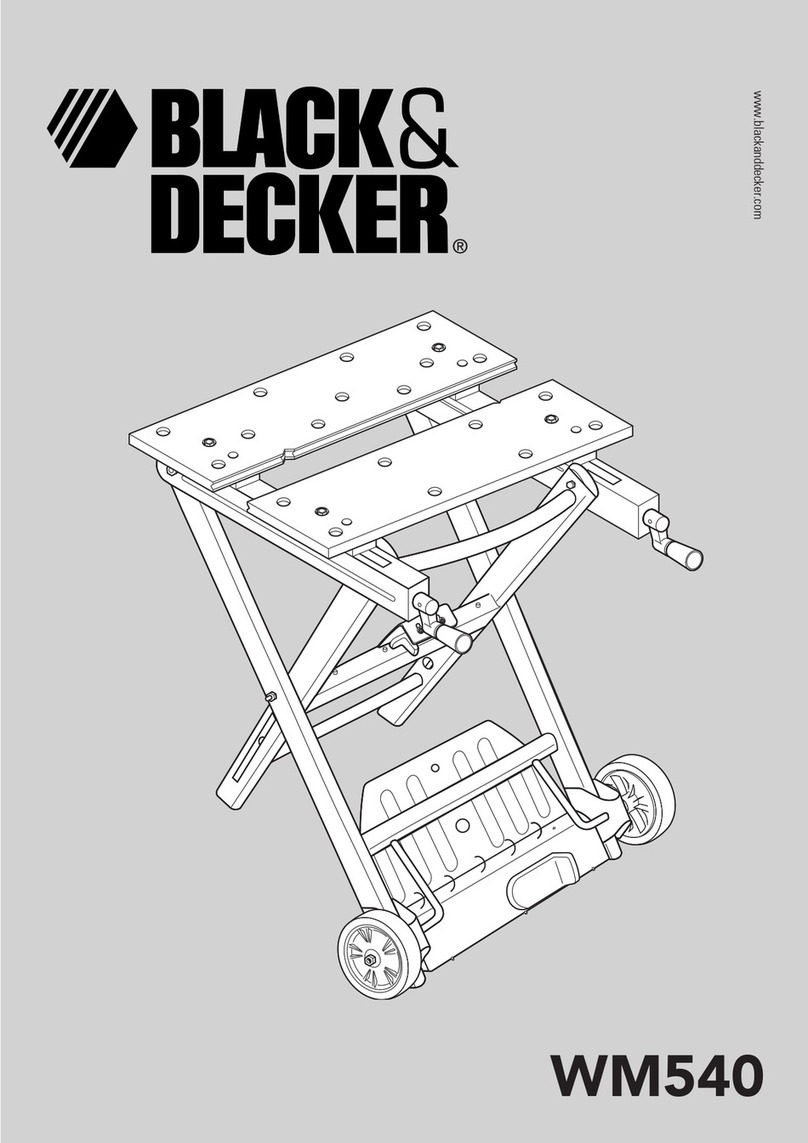

Black & Decker WM540 User manual

Black & Decker

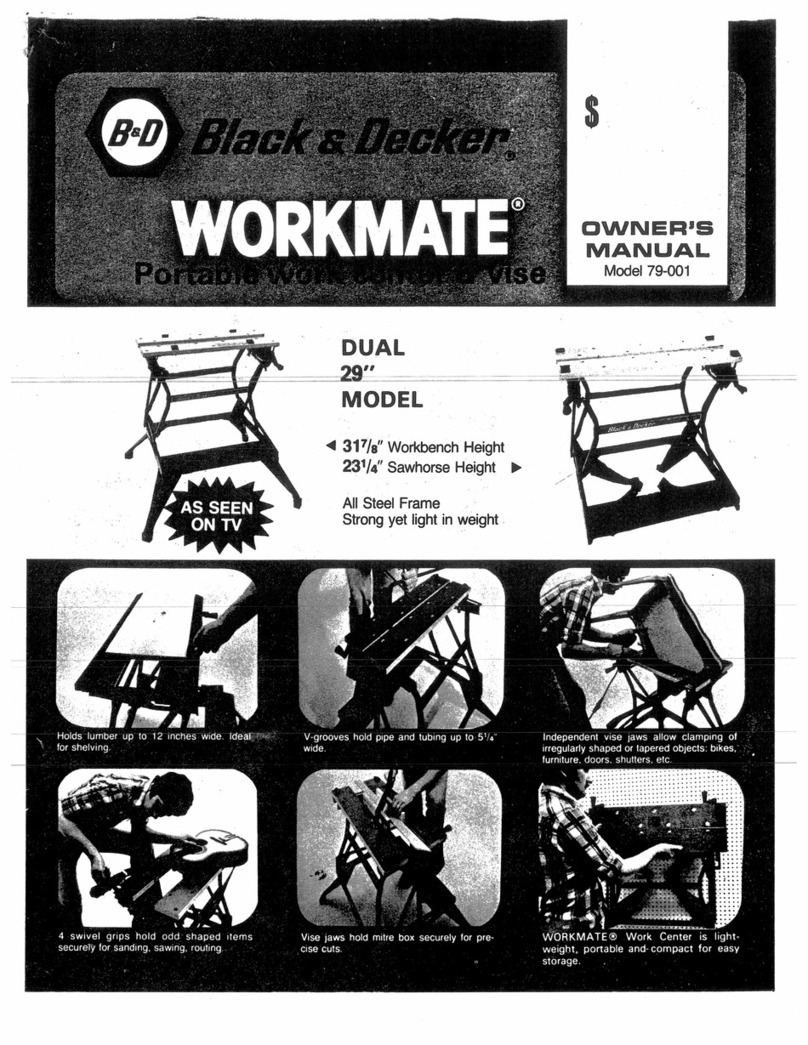

Black & Decker WORKMATE 79-001 User manual

Black & Decker

Black & Decker WorkMate 125 User manual

Black & Decker

Black & Decker BEZ100 User manual

Black & Decker

Black & Decker WM835 User manual

Black & Decker

Black & Decker Workmate 79-020 User manual

Popular Tools Storage manuals by other brands

Ryobi

Ryobi RWB03 Original instructions

Husky

Husky H27CH5TR4BGK Use and care guide

Scheppach

Scheppach ts 2100 Translation from original manual

DIVERSIFIED WOODCRAFTS

DIVERSIFIED WOODCRAFTS SHAIN GSB-6024 Assembly instruction

Cassese

Cassese CS200 CART user & parts manual

Cornwell Tools

Cornwell Tools CTB360AKBK Assembly instructions

Kendall Howard

Kendall Howard ESDW-9630-1000 owner's manual

Lista

Lista Align Instructions for assembly

Workzone

Workzone 99609 Assembly instructions

Stanley

Stanley STST83800-1 instruction manual

Homak

Homak PROFESSIONAL Series Owner's manual & operating instructions

Perel

Perel ROLLER SHUTTER STORAGE CABINET Assembly instructions