SNBC BTP-L580 User manual

USER’S MANUAL

Label Printer

BTP-L580

Shandong New Beiyang Information Technology Co., Ltd.

BTP-L580 User’s Manual

1

Declarations

Information in this document is subject to change without notice.

SHANDONG NEW BEIYANG INFORMATION TECHNOLOGY CO.,

LTD. (hereinafter referred to as “SNBC”) reserves the right to

improve products as new technology, components, software, and

firmware become available. If users need further data about this

product or have any doubt about safety issues that might arise from

using it, please feel free to contact SNBC or your local agents.

Copyright

No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose

without the express written permission of SNBC.

Copyright © 2011 by SNBC

Printed in China

Version 1.0

Trademarks

Our registered trademarks are

Warnings and Cautions in this manual

Warning: Items shall be strictly followed to avoid

damages to body and equipment.

Caution: Items with important information and prompts

for operating the printer.

BTP-L580 User’s Manual

2

The control system of SNBC has been approved of

the following certification:

ISO9001 quality control system certification

ISO14001 environmental control system certification

OHSAS18001 profession health safety control system

certification

IECQ QC080000 hazardous material process control system

certification

BTP-L580 User’s Manual

3

General Safety Instruction

Before installing and using the printer, please read the following

items carefully:

1. Safety Instructions

Caution: Do not touch the cutter of the printer.

Heating: The print head is at a high temperature during

printing or just after operation. Do not touch it

and its peripherals for reasons of safety.

Warning: The print head is an ESD-sensitive device. To

avoid damage, do not touch either its printing

parts or connecting parts.

2. Caution

1) Install the printer on a flat and stable surface.

2) Reserve adequate space around the printer so that convenient

operation and maintenance can be performed.

3) Keep the printer away from water source, direct sunlight, strong

light and heat.

4) Do not use or store the printer in a place exposed to heat or fire,

moisture or other pollution.

5) Do not place the printer in a place exposed to vibration or impact.

6) No dew condensation is allowed to the printer. In case of such

condensation, do not turn on the power until it has completely

gone away.

7) Connect the power cord to an appropriate grounding outlet.

Avoid sharing a single electrical outlet with large power motors

BTP-L580 User’s Manual

4

and other devices that may cause the fluctuation in voltage.

8) Disconnect the power cord if the printer is idle for a long time.

9) Do not spill water or other electric substances (like metal) on the

printer. If this happens, turn off the power immediately.

10) Do not allow the printer to start printing when there is no

recording paper installed, otherwise the print head and platen

roller will be damaged.

11) To ensure quality print and normal lifetime, use recommended or

good quality paper.

12) Shut down the printer when connecting or disconnecting

interface connectors to avoid damage to the control board.

13) Set the print darkness to a lower grade as long as the print

quality is acceptable. This will help to keep the Printhead

durable.

14) The printer should only be disassembled or repaired by a

technician, who is certified by SNBC.

15) Keep this manual safe and at hand for reference purpose.

BTP-L580 User’s Manual

1

Content

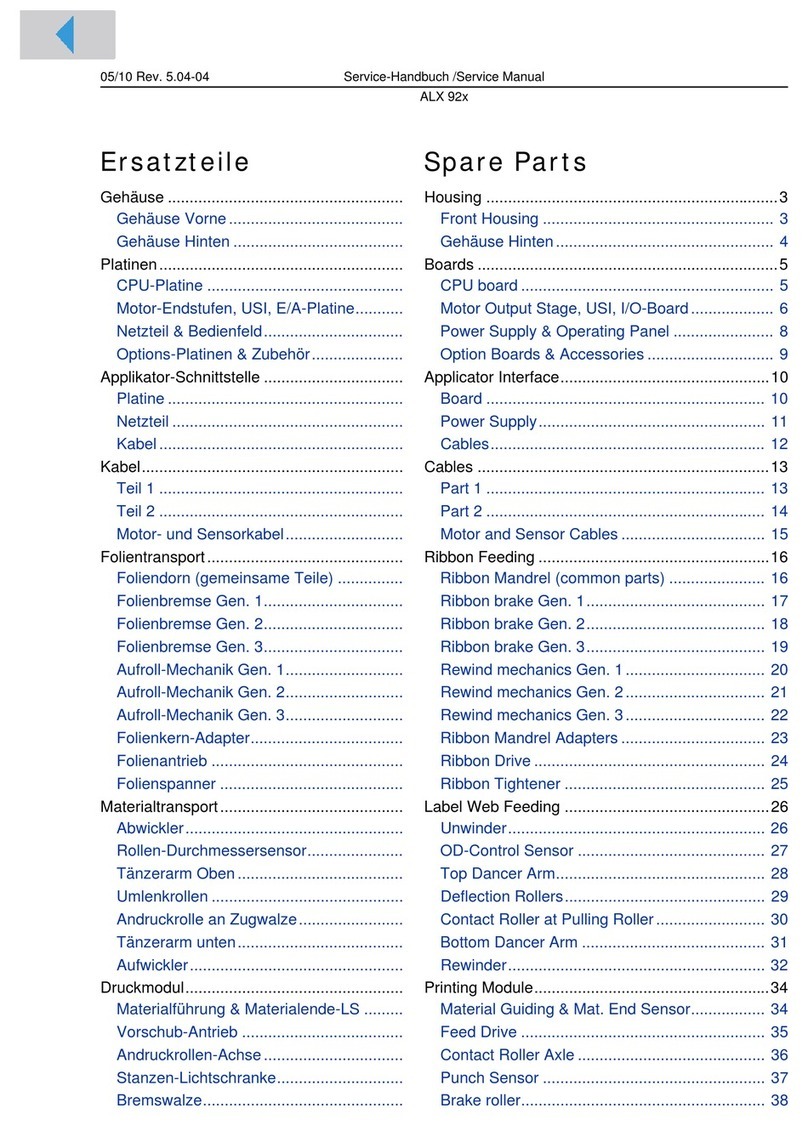

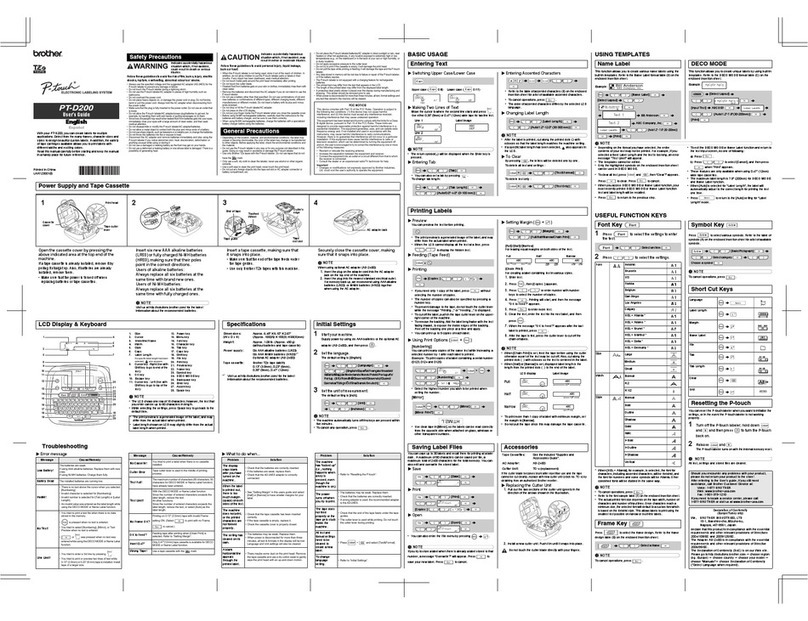

1 INTRODUCTION...........................................................................1

1.1 Outline ....................................................................................1

1.2 Main Features.........................................................................1

2 MAIN SPECIFICATION.................................................................2

2.1 Technical Specification............................................................2

2.2 Cutter Specification.................................................................3

2.3 Paper Specification.................................................................3

2.3.1 Thermal Label Paper Parameter......................................3

2.4 Print and tear off position........................................................5

2.4.1 Print position ....................................................................5

2.4.2 Tear off position................................................................6

3 OUTLINE AND PARTS.................................................................7

3.1 Outline and Parts....................................................................7

3.2 Error LED and Buzzers.........................................................10

4 INSTALLATION...........................................................................12

4.1 Unpacking.............................................................................12

4.2 Printer installation .................................................................12

4.3 Connecting the Power Adapter.............................................13

4.4 Connecting interface cable ...................................................14

4.5 Connecting the Cash Drawer................................................14

4.6 Paper roll loading..................................................................15

4.6.1 Confirm the paper type...................................................15

BTP-L580 User’s Manual

2

4.6.2 Load/replace a paper roll................................................15

4.7 Switching on and printing a self-test page ............................16

4.7.1 Switching on the printer..................................................16

4.7.2 Printing a self-test page..................................................16

5 PRINTER ROUTINE MAINTENANCE........................................18

5.1 Cleaning the platen...............................................................18

5.2 Cleaning the label sensors....................................................18

5.3 Clearing of a paper jam.........................................................19

6 INTERFACE SIGNAL .................................................................20

6.1 Parallel interface...................................................................20

6.2 Serial interface......................................................................21

6.3 USB interface........................................................................22

6.4 Ethernet interface .................................................................22

6.5 WLAN interface.....................................................................23

6.6 Signal definition of power connector.....................................24

6.7 Signal definition of cash drawer interface .............................24

7 TROUBLESHOOTING................................................................26

7.1 Printer doesn’t work..............................................................26

7.2 Alarm LED and buzzer sound...............................................26

7.3 Problems with printing ..........................................................26

7.4 Cutter resetting.....................................................................27

APPENDIX: FEED BUTTON CONFIGURATION ..........................28

BTP-L580 User’s Manual

1

1 Introduction

1.1 Outline

BTP-L580 thermal label printer has high performance. It can be used

for real-time label printing like for retail, storage, logistics, pharmacy,

etc.

This product can be connected to other equipment via Serial,

Parallel, USB, Ethernet or WLAN interfaces. The printer is supplied

with a user-friendly label creation software for use under

WINDOWS2000/XP/Server 2003/WIN7/Server 2008/VISTA.

1.2 Main Features

1) Low noise

2) 150mm/s high-speed printing

3) Easy paper loading

4) Easy operation and maintenance

5) Three different paper width

6) Auto paper cutting

7) Cash drawer control connector

8) Choice from several interfaces (“daughter boards”)

BTP-L580 User’s Manual

2

2 Main Specification

2.1 Technical Specification

Item Parameter

Print Method Direct Thermal

Resolution 203DPI

Print Speed 150mm/s (Max.)

Print Width 80mm (Max.)

Memory RAM: 2MB FLASH: 2MB

Interface

Optional Parallel(IEEE1248), Serial

(RS232C/RS485), USB, Ethernet, WLAN

Cash drawer 1~2 drives

Barcode Supported

1D:UPC-A, UPC-E, EAN8, EAN13,

CODABAR, CODE39, ITF,

CODE128,CODE93,

2D:PDF417,QR,MaxiCode

Fonts

ASCII Font A: 12×24; Font B:9×17;

Simplified Chinese(GB2312 or GB18030),

Korean, Japanese, Traditional Chinese

selected

Character Enlarge 1-6 times

Character Rotation Rotate (0°, 90°, 180°, 270°)

Image process

Bitmap download: download 8 bitmaps at

most; buffer size is 12 KB

Direct bitmap print: support bitmap mode and

can execute quick bitmap print

Paper type Label paper,continuous paper

Label sensor Optical sensor

Paper near end sensor Optical sensor

Top cover position sensor Microswitch

Print head temperature

sensor

Thermistor

Power supply AC 220V±10%, 50~60HZ

Printer head lifetime 100KM

Operation condition 5℃~45℃, 20%~90% RH (40℃)

Storage condition -40℃~55℃, 20%~93%RH (40℃)

Dimensions 147 (W) × 205 (D) × 147 (H) mm

BTP-L580 User’s Manual

3

2.2 Cutter Specification

Item parameter Note

Cutter type Slide cutter

Cutting time 600ms The time that one cut

takes

Cutting interval 2s 30 times/min. (Max.)

Paper type

0.05-0.07mm

Liner paper

Operation voltage

24VDC

Max. static curren

1.2A

24VDC

Cutter lifetime

Only liner paper:

1,500,000 cuts.

The cutter should cut

only the liner and not cut

the liner together with the

label paper, otherwise it

will negatively affect the

lifetime of the cutter

Full or partial cuts

Full cut: cut off the label completely;

Partial cut: little connection left in middle. When in partial

cut mode, it is not allowed to retract paper, otherwise the

not completely cut paper may cause paper jam.

2.3 Paper Specification

2.3.1 Thermal Label Paper Parameter

Appearance:

BTP-L580 User’s Manual

4

Paper transmittance

Label: transmittance <18%; Base Liner: transmittance >47%

Paper supply method: paper roll

Paper width: 82.5±0.5mm, 80±0.5mm, 57.5±0.5mm

Label Length:30mm~120mm

Paper thickness and stickiness requirements

Thermal senstive layer: outside

Paper roll specifications

OD (Max): Φ100 mm

ID (Min): Φ25mm

Caution:

Please use qualified paper, otherwise may affect printing

quality and TPH lifetime.

The paper should not be pasted to the core.

BTP-L580 User’s Manual

5

If the paper is contaminated by a chemical or oil, it may

discolor or lose heat sensitivity at the polluted spot.

Do not rub the paper surface strongly against hard objects,

otherwise printout may unclear.

When the temperature goes up to 70 degrees centigrade,

paper will discolor.

Don’t use or store paper under high temperature, high

humidity and strong light conditions.

2.4 Print and tear off position

2.4.1 Print position

BTP-L580 User’s Manual

6

2.4.2 Tear off position

In normal printing mode, tear off position should be:

L1: about 30mm

In paper exit mode, tear off position should be:

BTP-L580 User’s Manual

7

3 Outline and Parts

3.1 Outline and Parts

1 – Paper-near-end sensor lever

(only for receipt printing)

2 - Paper sensor

3 - Platen roller

4 - Middle cover

5 - Bottom cover

6 - Power switch

7 - Paper guide

8 - Top cover

9 - Cover spanner

10 - Print head

11 - Paper roller

12 - Spindle for label roll

13 – AC inlet

14 – Communicate interface

15 – Cash drawer kick-out

16 – Power LED

17 – Error LED

18 – Paper exit LED

19 – FEED button

BTP-L580 User’s Manual

8

Functions of parts:

a) Spindle for label roll

It is highly recommended to use the spindle for the label roll in

order to reduce resistance and to ensure printing quality.

b) Paper guide

Removing the paper guide or putting it in a different slot will

allow the printer to use following paper width: 82.5 ± 0.5mm,

80.5 ± 0.5 mm, 57.5 ± 0.5 mm.

c) Power switch

To turn the power of the printer on or off: “O” power is turned off.

“—” power is turned on.

d) Feed button

By switching on the printer while pressing the FEED button,

the printer will print a MAIN MENU. By press different times

of the button, user can select to print self-test page or do

paper checkout as shown in figure below:

MAIN MENU BTP-L580

Select a submenu

:

Exit -

〉

1

Print Self Test -

〉

2

Calibration -

〉

3

Select Print Mode -

〉

4

Enter code, then hold Button Down

at least 1 second to validate

BTP-L580 User’s Manual

9

Printer will quit standby status after pressing the FEED

button for a short time and a long time.

Printer will print self-test paper after pressing the FEED

button for two short times and a long time.

Printer will carry out paper checkout after pressing the

FEED button for three short times and a long time.

Printer will enter into Select Print Mode after pressing FEED

button for four short times and a long time. If selected

BTP-R580, then printer enters into a continuous paper

mode, if selected BTP-L580, then printer enters into a label

paper mode.

In normal status, every time the FEED button got pressed,

the printer will feed a label.

In error status, the printer will have no activity when the

FEED button is pressed.

e) Power indicator

This indicates power status (ON/OFF).

f) Error indicator

This indicates some error status. In normal status, ERROR LED

is always off. In some error status (Cover Open, Cutter Error,

Print head overheated, Input voltage is abnormal), ERROR LED

will flash.

g) Paper end LED

This indicates paper status. In normal status the PAPER LED is

always off. When the paper status changes (paper end or paper

near end) the PAPER LED flashes.

BTP-L580 User’s Manual

10

Notices:

The paper guide is an indispensable part of the printer and

should be kept with the printer.

The function of the paper-near-end sensor is not used when

printing labels. For printing receipts the paper-near-end sensor

will be operational.

3.2 Error LED and Buzzers

1) Error LED

Led Status Description

Power Indicator (Green)

(POWER) On Printer is powered on

Off Printer is powered off

Error Indicator (Red)

(ERROR) Off

Printer is in normal status

(except paper end or paper

near end)

Flash Printer is in error status

Paper Indicator (Red)

(PAPER)

On Printer Paper is normal

Flash Macro definition is running

Off Printer is in normal status

2) Description of LED and Error Status

Error information ERROR LED

PAPER

LED

Buzzer

Print head is

overheating

Six times Off Long-Short-Long

Input voltage is

abnormal Five times Off Short-Short-Long

Cutter Error Four times Off Long-Short-Long

Cover Is Open Three times Off Short-Long-Short

Paper End Twice On Short-Short-Short

Finding label error or

verify failed Flashing

continuously Off

BTP-L580 User’s Manual

11

Caution:

The temperature of the print-head is detected by means of a

thermistor sensor. If the temperature of the print head

becomes higher than 65°C, the protection circuit of the printer

will force the printer to stop printing.

BTP-L580 User’s Manual

12

4 Installation

4.1 Unpacking

Check whether all items, that are listed on the packing list are

present and in a good condition. If any items are damaged or

missing, please contact your dealer.

4.2 Printer installation

1) The printer should be installed on a flat and stable horizontal

surface.

2) The printers should be away from any water source.

3) Do not place the printer on a surface exposed to vibration or risk

from impact.

4) Ensure that the printers can be grounded safely.

5) During operation and maintenance of the printer there should be

sufficient space around the printer in accordance with the

dimensions as shown in Fig. 4.2-1.

Fig. 4.2-1

BTP-L580 User’s Manual

13

4.3 Connecting the Power Adapter

1) Ensure that the printer power is turned off.

2)Insert the power cord into the power socket on the backside of the

printer.

3)Secure the power cable cord to the printer with a clip as shown in

Fig. 4.3-1.

Fig. 4.3-1

Caution:

If the printer is not in use for a long period, disconnect the

power cord from the wall outlet for safety.

Table of contents

Other SNBC Label Maker manuals