Snelflight chinook Instructions for use

1

INTRODUCTION

Congratulations on purchasing your Snelflight Chinook helicopter. The

model is the smallest twin rotor model helicopter produced, yet it has a

realistic appearance and sound during flight.

Our unique and patented Electrocyclic control system gives the model an

unmatched combination of performance and mechanical simplicity. Since

it is mains powered it can fly continuously and, best of all, it comes ready to

fly, right out of the box.

The only setting up needed is the adjustment of your transmitter's settings,

where required. Although not strictly a beginner's model, the Snelflight

Chinook is surprisingly rugged and easy to fly. However we strongly

suggest that you take the time to read this manual carefully before your

first flight, as the aircraft behaves a little differently from other model

helicopters.

IMPORTANT NOTICE

This product is not a toy. It is an engineered model which

although light in weight is capable of causing damage or injury

if operated irresponsibly, primarily due to contact with the six

thrust propellers. Avoid flying close to people or pets.

It may start up violently if the instructions contained in this

manual are not followed, or if a fault occurs. To be sure of

avoiding damage or injury always hold the aircraft firmly by

grasping the sides of the rear rotor tower (keeping clear of the

propellers) when switching on the mains power.

The motors become hot in use; to avoid injury do not touch

until cool.

Unplug from the mains supply when not in use. Do not use in

the wet.

2

CONTENTS

1. Introduction

2. Packing List

3. Transmitter Requirement

4. Handling the Model

5. Transmitter Set-Up

6. Preparing for Flight

7. Your First Flight

8. Principles of Operation

9. Maintenance

10. Specifications

2. PACKING LIST

This Manual:

The Helicopter:

Power Adapter (with

detachable cord):

Signal Lead:

Decals:

Transmitter (if supplied):

Pencil:

Please read it carefully before flying the

model.

It comes with its thin command line already

attached.

This converts power from the wall into 36V

d.c. to power the model.

This is used to connect the model to a

suitable R/C transmitter. It is suitable for JR

transmitters, as well as the transmitter sup-

plied with the model (if applicable). Leads for

other transmitter types are available from

Snelflight.

For you to customise your model.

Handset to control the model. It requires 8

AA batteries.

For applying graphite lubricant to the rotor

brush slip-rings.

3. TRANSMITTER REQUIREMENT

Unless you purchased your model with transmitter included, you will need

your own transmitter to fly the Chinook helicopter. The model is designed

to operate with the following types:

FUTABA JR HITEC MULTIPLEX

3

Some Sanwa transmitters will also work, but please note that the newer

types with 5-pin trainer socket are not at present supported. The

transmitter you use will need to meet the following minimum features:

Minimum transmitter specification

zFour control channels with two twin-axis joysticks.

zFitted with a trainer (buddy box) socket, using PPM (pulse

position modulation) signalling.

zReversing switches on at least the first four channels.

Since the transmitter connects to the model by wire, frequency and

transmission type (AM or FM) do not matter.

The signal lead included with the model is suitable for JR transmitters only.

Please see your dealer or contact Snelflight to obtain leads for the other

types.

4. HANDLING THE MODEL

The Chinook should be held by the rotor centres, grasping them from

above by the green printed circuit discs immediately below the hubs (Photo

1). Alternatively, it can be held by firmly grasping the sides of the rear rotor

tower (Photo 2). On no account should it be picked up by the body.

Carefully lift the helicopter out of the box and place it on the floor.

Uncoil the command line, guiding it away from the model rearwards,

ensuring that it doesn't get hung up on the wheel axles.

Photos 1 and 2: How to hold the Model

1 2

4

5. TRANSMITTER SET-UP

If you are using the transmitter included with the model, it will have been

preset ready for use and you may skip this section. If you are using your

own transmitter, you should follow these steps carefully.

a) Switch your transmitter into training (buddy box) mode: In this mode, your

transmitter will send a signal to the trainer socket, but will not transmit from the

antenna. This greatly extends transmitter battery life, and eliminates interfer-

ence problems. On some radios, training mode is selected simply by inserting

the training plug into the socket. JR transmitters typically work this way. If this

is the case, the main power switch must be left in the OFF position. On other

units the power switch must be set to ON, but the crystal should be removed to

prevent radio transmission.

b) Signal Mode Selection: The Chinook requires PPM signalling, so if your

transmitter offers PCM as well, it must be switched to PPM. Most inexpensive

non-computer radios are PPM only, so this setting is not necessary. PCM-only

transmitters cannot be used, but these are fortunately very rare.

c) Servo Reverse Switches: These should be set according to the table below:

d) Servo Travel: If your transmitter has adjustable servo travels (endpoint

adjustments), set the first four channels to 100% in both directions of throw.

Exponential joystick response can be selected if you wish.

e) Channel Centres: If your transmitter has channel centre adjustments, these

should be set to zero (centred) on the first four channels. The external trim tabs

should also be centred.

f) Mixing Functions: If your transmitter has mixing functions such as Throttle to

Rudder mixing, these should be switched off, or set to zero.

g) Throttle Curve: If your transmitter has a throttle curve feature, it should be set

up to give a full range, linear throttle response. Make sure that the Throttle Hold

switch is turned off. Some transmitters have an Aeroplane mode, in which

these functions are omitted. It is usually easier to use this mode with the

Chinook.

1 2 3 4

Futaba

Hitec

JR

Multiplex

Normal

Normal

Reversed

Reversed

Normal

Reversed

Reversed

Reversed

Normal

Reversed

Reversed

Reversed

Normal

Normal

Reversed

Reversed

Channel >>

5

6. PREPARING FOR FLIGHT

Before flying the model, you should carry out the following procedure:

a) Stand the helicopter on the floor, facing away from you. Feed the command

line rearwards, ensuring that it doesn't catch on the wheel axles.

b) Connect the power adapter to the wall, and plug its 2.1mm output jack into the

matching socket at the bottom end of the command line. The helicopter's white

searchlight should illuminate, under the nose. You should now wait about 3

seconds before touching the aircraft, to allow the onboard heading-lock gyro to

self-calibrate.

c) Connect the signal cord to the transmitter and switch on (if necessary). Ensure

that the throttle stick is set to minimum.

d) Now connect the other end of the signal cord to the matching phono socket on

the command line. WHILST DOING THIS, HOLD THE AIRCRAFT FIRMLY BY

THE SIDES OF THE REAR ROTOR TOWER (PHOTO 2) IN CASE IT STARTS

SUDDENLY. KEEP CLEAR OF THE PROPELLERS!

e) During the next two seconds, the helicopter will configure itself to the type of

transmitter being used. The correct channel order will be set (this varies

between brands), and each control's zero position will be set to match the state

of the relevant channel. It is important not to move the joysticks during this

process.

f) If all is well, the helicopter's red & green navigation lights will start to blink. If

they don't, please read the suggestions in the panel below.

After maintenance, a crash or a heavy landing, please check the following:

g) Check that the aircraft canopy is properly seated below each rotor.

h) Inspect the motors to ensure they are properly seated in their plastic brackets.

If the navigation lights don't start to blink: Something is wrong. The

problem will usually be caused by one of the following:

1) No signal from transmitter: Ensure that the lead is properly connected at each end,

and that the power switch is in the required position (Section 5a).

2) Transmitter in PCM mode: The transmitter must be set to PPM mode.

3) Throttle not at zero: To prevent accidents, the helicopter won't start if the throttle

stick is above minimum. This will be the case if the reverse switch is set incorrectly

(see table in Section 5). On computer radios, incorrect setting of throttle travel or the

throttle curve can also cause this problem. The throttle needs to be set to give a

linear, +/-100% output, as on a basic transmitter.

4) Wrong type of transmitter: Please see Section 3 for supported brands.

6

7. YOUR FIRST FLIGHT

If you are new to helicopters, we recommend that you gain experience on a

single rotor trainer such as the HoverflyHoverfly before flying the Chinook. Although

quite easy to fly, the Chinook is not intended for beginners. Experienced

pilots should read this section, since the Chinook behaves slightly

differently from other models.

For your first flights, choose a room with as much unobstructed space as

possible. Do not attempt to fly outdoors. Place the helicopter on the floor in

the centre of the available flying area, facing away from you. Position

yourself about a metre behind it. After a final check to ensure that the

command line will not snag on either wheel axle, begin to advance the

throttle (collective) gradually, allowing the rotors time to rev-up as you do

so. The motors will not all start simultaneously (please see the next section

for an explanation of why this is so), and as a result the helicopter will

shake slightly (just like the real thing!) whilst revving up. Keep raising the

throttle until the aircraft starts to seem light on its wheels; at this point the

throttle will be at roughly mid-stick. It should not take less than 5

seconds to reach this stage. Please note that it is crucial to give the

rotors time to speed up prior to take-off.

Once revved-up and ready, advance the throttle smartly for a decisive

lift-off. This is the easiest way to begin the first few flights. Once in the air

you will find that the aircraft is docile, with good heading-hold. Controls

should be made smoothly and early, since twin-rotor helicopters respond

more slowly than single-rotor types.

Very occasionally, you may wish to make small adjustments to aircraft trim

during flight, using the transmitter trim controls. If you do so, please be sure

to return the trims to centre before connecting the transmitter next time,

otherwise the helicopter will self-calibrate to the new trim settings, treating

these as the centre positions. You will then need to add even more trim to

restore correct flight. Most trim issues can be resolved without use of the

transmitter trims and this is preferable: Please see the Maintenance

section.

8. PRINCIPLES OF OPERATION

The Chinook generates the lift necessary for flight by means of the six

small, rapidly spinning rotor-tip propellers. The rotors themselves do not

provide any lift. The outboard positioning of the motors gives each rotor a

large moment of inertia, thereby imparting a high degree of gyroscopic

7

stability to the aircraft. At the same time, the rapid movement of the motors

through the air keeps them comparatively cool during operation.

Cyclic control is provided by varying the speeds of the motors as they

move around their circular path. For example, to provide a left-hand roll

force, the motors slow down as they enter the left-hand semicircle, and

speed up as they enter the right hand semicircle. This patented control

method requires no actuation servos and few moving parts, resulting in an

extremely small, lightweight and mechanically simple aircraft.

Uniquely, both the aircraft's rotors turn in the same direction. This is

possible because the rotors are driven by their on-board motors, rather

than by an engine mounted within the fuselage. There are therefore no

torque reactions produced. Furthermore the rotors have no mechanism for

tilting independently of each another; their gyroscopic behaviours are

therefore combined. If the rotors turned in opposite directions these

behaviours would cancel each other out, making the aircraft very unstable.

Owing to the large combined gyroscopic reaction from the two rotors, the

helicopter's attitude control inputs get shifted a full 90 degrees clockwise

during actuation. To make the aircraft pitch (forwards or backwards), a roll

force must be applied. This is done by operating the two rotors' roll cyclics

in unison. To make the aircraft roll, a pitch force must be applied. This is

done by changing the front and rear collective controls in opposition, i.e.

the overall lift of one rotor is increased while that of the other is reduced.

To make the aircraft yaw, the two rotors' roll cyclics are operated in

opposition. The two gyroscopic reactions try to pitch the aircraft in both

directions at once and as a result, the aircraft as a whole doesn't tilt.

Instead, the front rolls one way and the back rolls the other way! This

causes the fuselage to twist along its length; the airframe is designed to

allow this. In the twisted state, the two ends of the aircraft are pulled

sideways in opposite directions, resulting in a yaw motion.

Although there are no torque reactions from driving the rotors, bearing

friction does tend to turn the fuselage in a clockwise direction. To prevent

this, a continuous anticlockwise yaw input is required. This is provided by

the cyclic controls as described above, and is the reason why the aircraft's

propellers start at different instants as the throttle is raised from minimum.

8

9. MAINTENANCE

A. DISASSEMBLY

1) Remove the rotors. To remove a rotor:

a) Unplug the power cord from the command line.

b) Pull the black plastic dome off the shaft.

c) Carefully lift the rotor off, taking care not to bend the brushes on the underside

of the hub. Don't mix up the two rotors!

2) Lift off the helicopter body, carefully easing it over the slip-ring panels at

the base of each rotor shaft. The interior parts will now be fully revealed.

3) To remove the electronic circuit board, first unplug the two connectors.

Next, detach the board by cutting through the double-sided foam adhesive

along the top edge, using a sharp knife. The foam can then be peeled off.

B. REASSEMBLY

Reassembly is the reverse of disassembly. Please note the following:

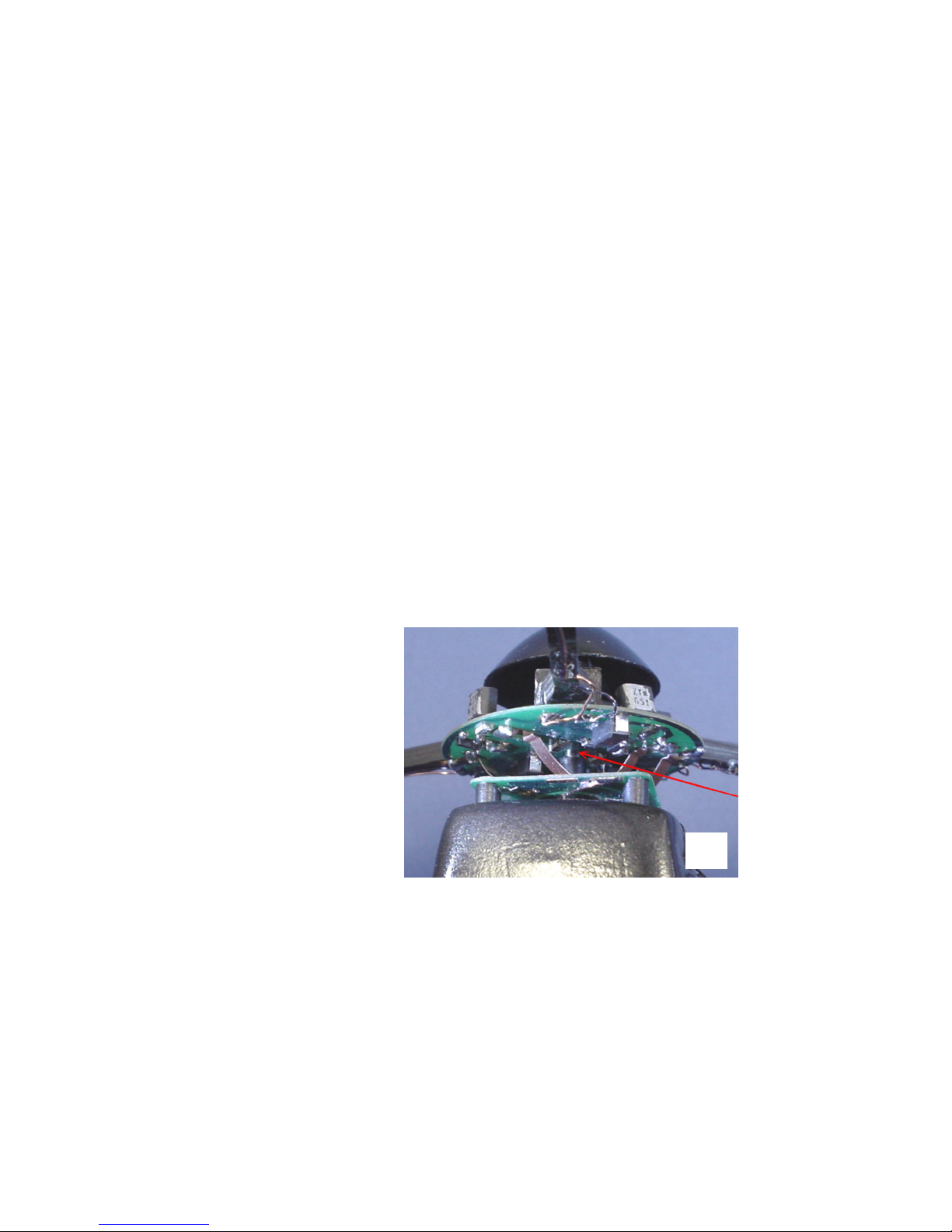

a) When replacing the

body, take care to

position the navigation

lights.

b) When replacing each

black plastic dome, it

should push the rotor

down against spring

pressure from the

brushes. The correct

position is reached when

there is about 0.5mm of

clear shaft visible below

the circuit board disc

(Photo 3)

C: SLIP-RING LUBRICATION

Each rotor receives power to drive its motors via a system of slip-rings

etched onto a small circuit board at the base of the shaft. Brushes on the

rotor hub run on the slip-rings, and from time to time they need lubrication.

This is done by applying graphite (a good electrically conductive lubricant)

using an ordinary pencil. Please note the following:

Photo 3: Rotor Clearance

3

0.5mm

clearance

9

a) Always disconnect the power before lubrication.

b) The path of the brush contacts on each slip-ring can be clearly seen (Photo 4).

Apply graphite sparingly to these areas.

c) Take great care to avoid getting

graphite between the slip rings, as

it will create a short circuit.

Remove any that does get in the

cracks, using a cotton tip

dampened with alcohol or nail

polish remover. An eraser is also

quite effective!

d) Apply graphite very sparingly to

the innermost slip-ring.

e) Lubrication should be carried out

after every 3-4 hours of flight, or if

brush running noise increases

(spin the rotor by hand and listen).

D. AIRCRAFT TRIM

When the control signal is connected to the Chinook, the aircraft

automatically configures itself to suit the particular transmitter being used.

This process includes precise adjustment of electrical control trims, making

further trimming of the aircraft unnecessary most of the time. There are two

exceptions when it becomes necessary to make manual adjustments:

1) Yaw Trim: In order to prevent rotor bearing friction from causing an

unwanted yaw movement, the helicopter has a continuous anticlockwise

bias built into its yaw control electronics. This is generally successful in

producing a "neutral" yaw trim, but the electonics are unable to completely

compensate for variations in bearing friction caused by wear, and by

changes in atmospheric temperature and humidity. If the aircraft has a

tendency to drift either clockwise or anticlockwise, this can often be cured

by taking steps to alter the bearing friction deliberately:

a) If the aircraft is drifting clockwise (right-hand yaw), then there is too much

bearing friction. Friction can be reduced by lubricating the slip-rings, or

lubricating the rotor bearings with a tiny amount of light oil. Increasing the rotor

clearance (up to 1mm, see Photo 3) by lifting the black dome slightly, will also

reduce friction.

b) If the aircraft is drifting anticlockwise, then there is too little bearing friction.

This is rare. However friction can be increased if necessary by reducing the

rotor clearance.

Photo 4: Slip-ring Lubrication

4

10

2) Roll Trim: Owing to the large combined gyroscopic reaction from the

two rotors, the helicopter is very sensitive to any difference in lift between

the two rotors. Some difference is inevitable due to motor and propeller

performance tolerances, and if uncorrected it will give rise to a roll trim

error. Correction is done simply by adding a small weight to either the front

or the back of the aircraft body. The weight needed will generally be under

two grams, and a small ball of Blu-Tack is ideal. A new Chinook will often

have this correction applied during factory testing:- the weight will be just

inside the body at either the front or rear end of the underbelly opening.

This weight may need to be modified after propeller replacement, or if the

two rotors are interchanged. In the latter instance it is usually enough just to

transfer the weight from one end of the aircraft to the other.

1) If the aircraft rolls to the left: It is tail heavy. Add weight to the front, or

remove it from the back.

2) If the aircraft rolls to the right: It is nose heavy. Add weight to the back, or

remove it from the front.

E. PROPELLER REMOVAL AND RE-FITTING

The propellers are a tight push-fit onto the motor shafts. To remove, the

motor should be grasped at the sides between thumb and forefingers, so as

to clamp the armature, preventing it from turning. The propeller can then

be twisted back and forth whilst pulling in order to remove it. Re-fitting is

done in much the same way, taking care to offer the propeller up to the

motor shaft as squarely as

possible. Take extra care when

fitting a new propeller, to hold the

motor armature very firmly,

otherwise the downward force of

fitting can dislodge the lower motor

bearing, damaging the motor's

plastic back-plate (Photo 5).

Propellers are grouped for thrust, because it

is important that they perform equally. The

packaging carries a thrust group letter, and all

three propellers fitted to a rotor should match. Photo 5: Propeller Removal/Refitting

5

11

For spares please

contact your supplier,

or apply direct to

Snelflight at:-

Snelflight Ltd

Churchill House

57 Jubilee Road

Waterlooville

Hants

PO7 7RF

Tel:- 023 92 258999

Fax:- 023 92 251333

Email

Web

www.snelflight.co.uk

Aircraft weight

Rotor diameter

Rotor speed at hover

Tip propeller speed at hover

Power consumption at hover

Aircraft supply voltage

Signalling system

156 grams

284mm measured to motor shafts

250rpm

22,000 rpm

70W

36V

4-channel PPM, 1.52ms centre

10. SPECIFICATIONS

Approximate ratings

12

Table of contents

Other Snelflight Toy manuals

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions