Page 3 MODEL: 3465

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................................................................................ 2

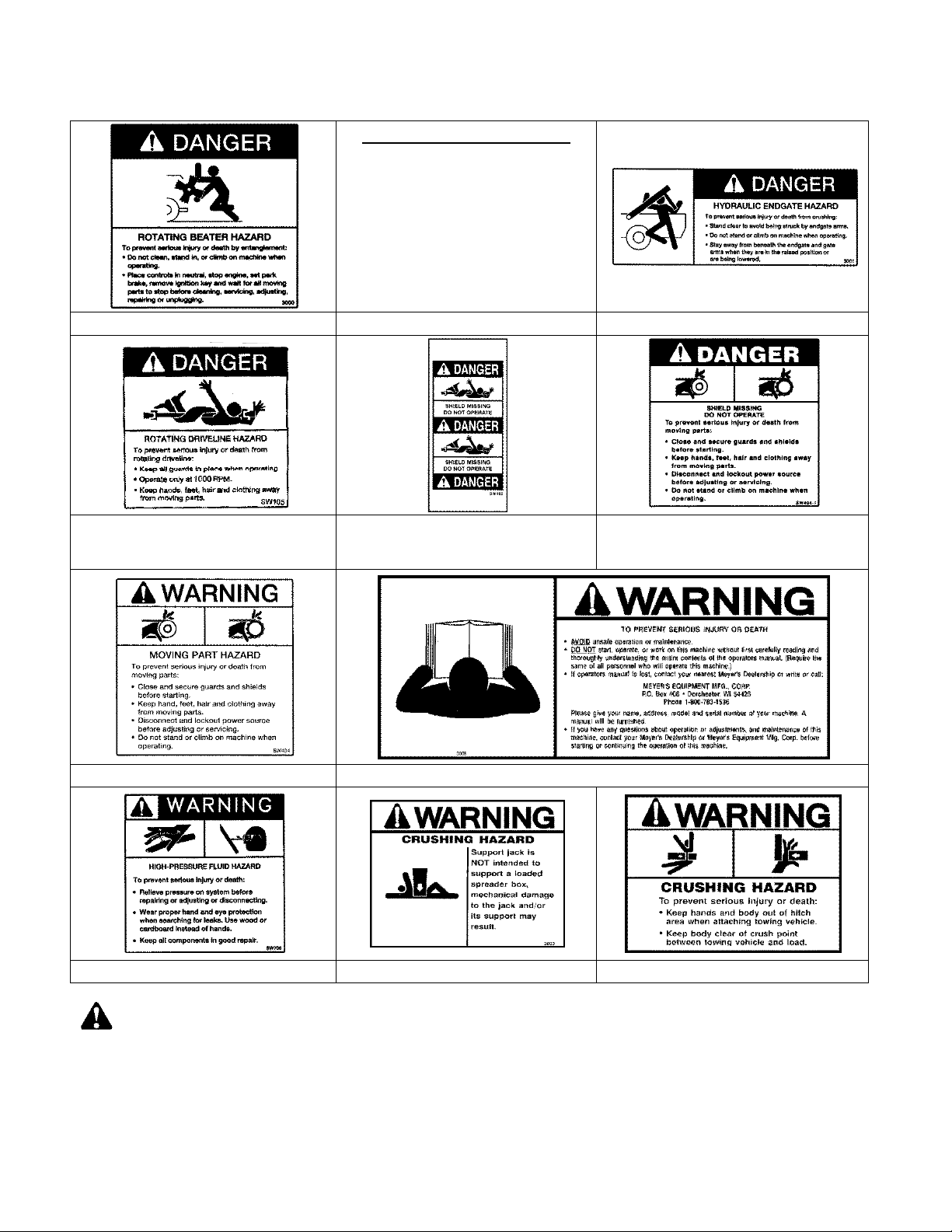

SAFETY.......................................................................................................................................................................................... 4

SAFETY SIGNS.............................................................................................................................................................................. 6

MANURE SPREADER SAFETY..................................................................................................................................................... 8

PRE-OPERATION ........................................................................................................................................................................ 10

General..................................................................................................................................................................................... 10

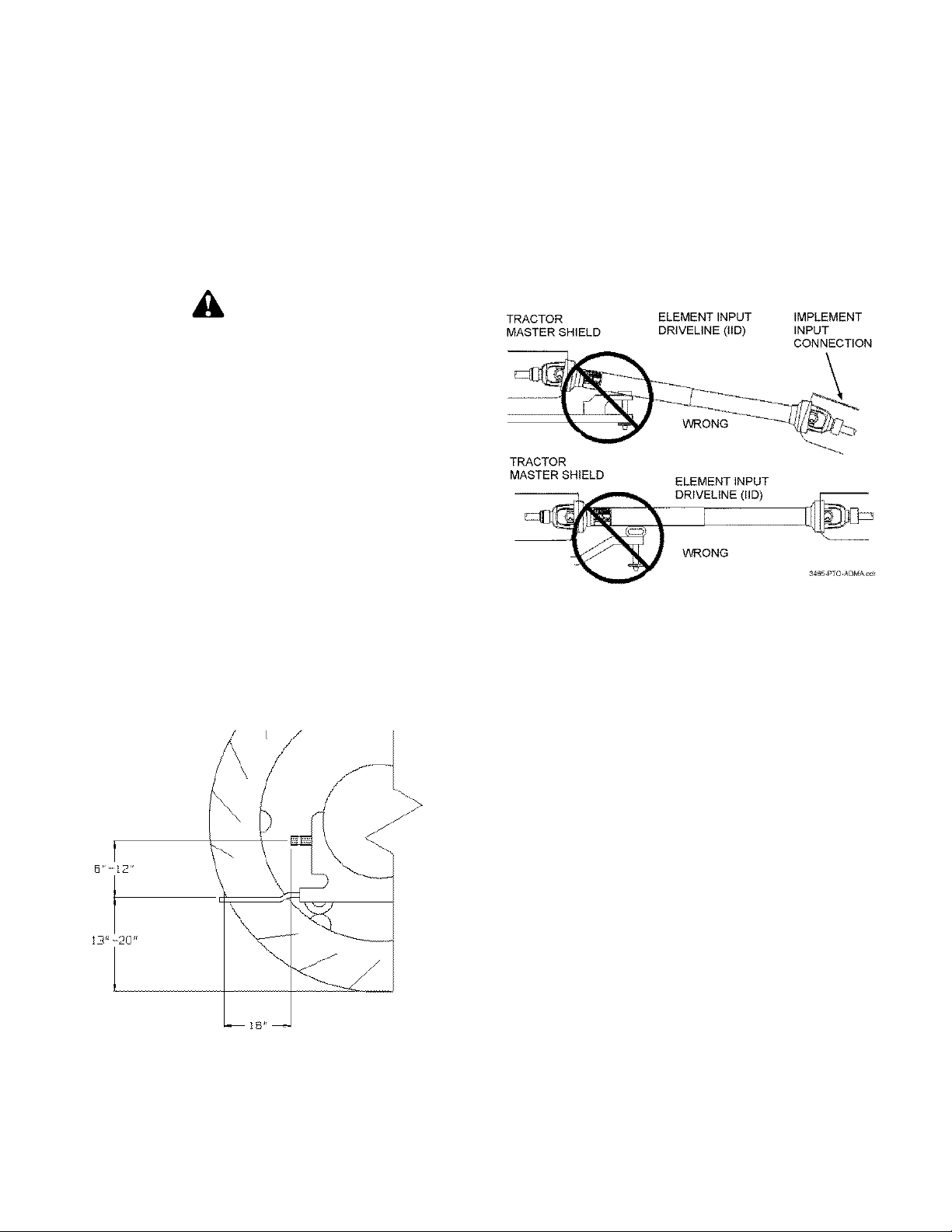

Tractor Hitch And PTO Requirements ...................................................................................................................................... 10

ADMA Recommendations: ....................................................................................................................................................... 10

Tractor Size Requirements ....................................................................................................................................................... 11

Tractor Towing Size Requirements....................................................................................................................................... 11

Material Estimated Weight Per Cubic Foot........................................................................................................................... 11

Hydraulic System...................................................................................................................................................................... 11

General................................................................................................................................................................................. 11

Set Up for Open Or Closed Center Hydraulic Operation ...................................................................................................... 12

Electric Control Installation ................................................................................................................................................... 12

Transporting ............................................................................................................................................................................. 13

General................................................................................................................................................................................. 13

Use Safety Chain.................................................................................................................................................................. 13

Use Lights............................................................................................................................................................................. 13

OPERATION ................................................................................................................................................................................ 14

Tractor Hookup......................................................................................................................................................................... 14

Loading..................................................................................................................................................................................... 14

Unloading ................................................................................................................................................................................. 15

Mandatory Safety Shutdown Procedure ................................................................................................................................... 15

MAINTENANCE, ADJUSTMENTS & LUBRICATION................................................................................................................... 16

Automatic Over Running Clutch

..................................................................................................................................................... 16

Mandatory Safety Shutdown Procedure

......................................................................................................................................... 16

Adjustments.............................................................................................................................................................................. 16

Apron Chain.......................................................................................................................................................................... 16

Roller Chain Adjustment....................................................................................................................................................... 16

Tensioning V-Belt Drive ........................................................................................................................................................ 16

Lubrication ................................................................................................................................................................................ 17

Cleaning And Storage............................................................................................................................................................... 19

REPAIR PARTS ........................................................................................................................................................................... 20

Main Frame & Box Parts........................................................................................................................................................... 20

Hydraulic End Gate & Related Parts......................................................................................................................................... 22

Jack Assembly.......................................................................................................................................................................... 24

End Gate Hydraulic Piping........................................................................................................................................................ 26

Axles, Wheels, Spindles And Related Parts ............................................................................................................................. 28

Side Drive Train........................................................................................................................................................................ 30

Apron & Related Parts .............................................................................................................................................................. 32

Lube Bank ................................................................................................................................................................................ 34

Beaters & Related Parts ........................................................................................................................................................... 36

Front Drive Train....................................................................................................................................................................... 38

Beater Drive Train..................................................................................................................................................................... 40

E00344-05 540 RPM Beater Drive Gear Box ........................................................................................................................... 42

5490-0686 540 RPM Beater Drive Gear Box Complete ........................................................................................................... 44

Upper Beater Drive................................................................................................................................................................... 46

Model 3465 Apron Drive Gearbox ............................................................................................................................................ 48

Removable CV Telescoping Universal Joint Assembly With Over Running Automatic

Clutch & Guard, Trailer To Tractor............................................................................................................................................ 50

Removable CV Telescoping Universal Joint Assembly with Over Running Automatic

Clutch & Guard, Trailer to Tractor............................................................................................................................................. 51

Standard Hydraulic Apron-Flow Control On Spreader And Optional Electric Control ............................................................... 52

Optional Tractor Lever Operated Hydraulic Apron.................................................................................................................... 54

Chain Oiling Kit......................................................................................................................................................................... 56

Standard Highway Lighting With Amber Side Light .................................................................................................................. 57

LIMITED WARRANTY STATEMENT ........................................................................................................................................... 60