Table of Contents

©Copyright 2010 All rights Reserved

Land Pride provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation of this manual, Land

Pride assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Land Pride reserves

the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

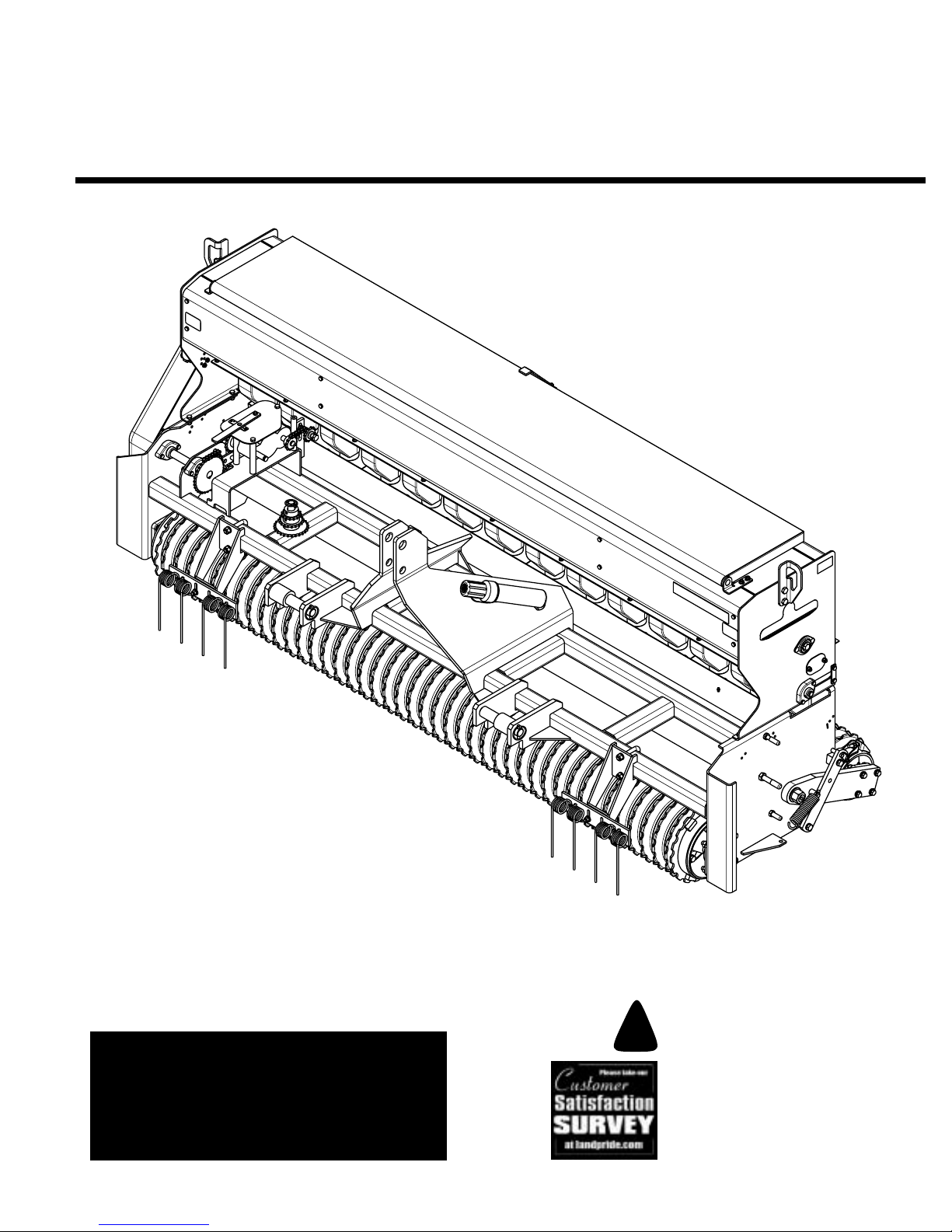

PSN2096 Primary Seeder 313-306M 6/28/11

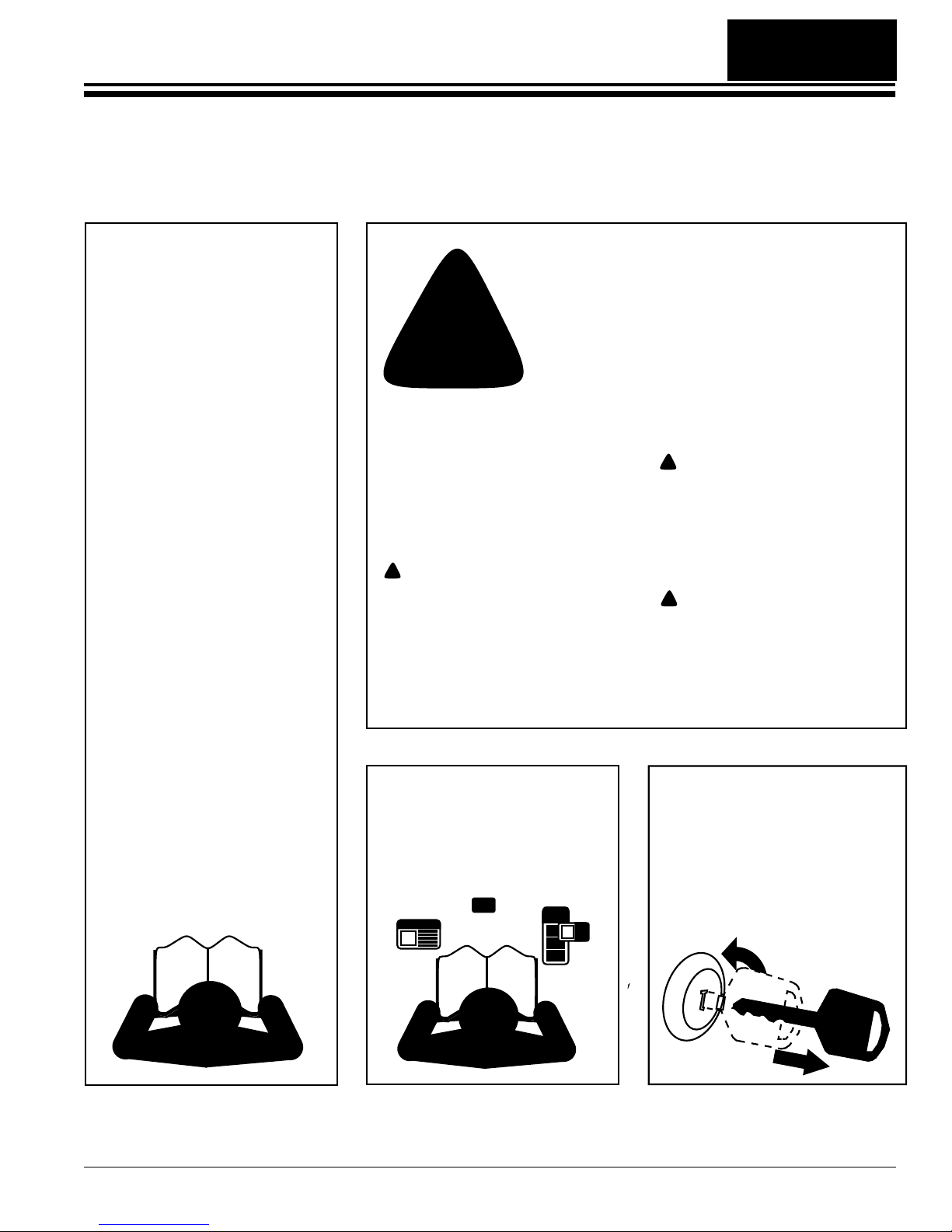

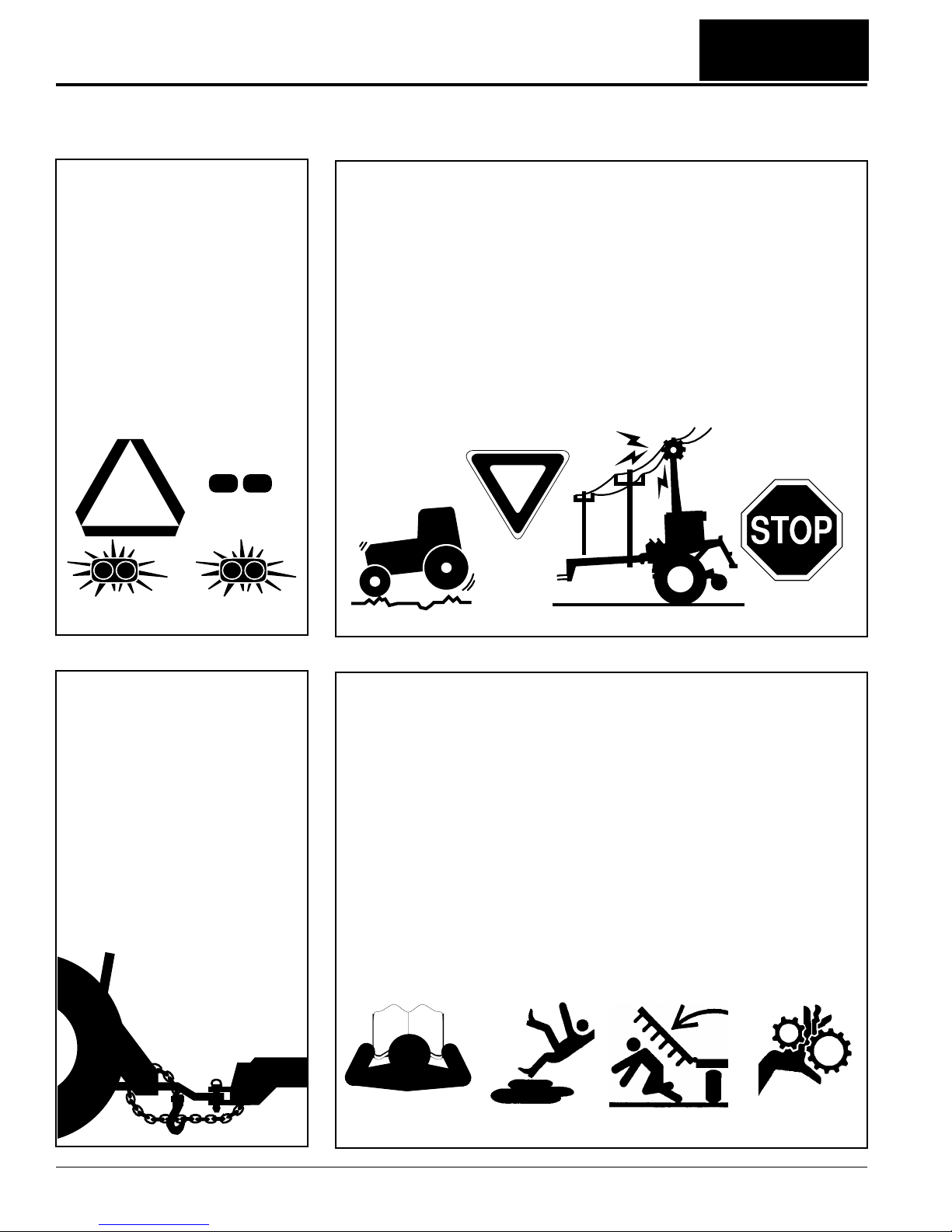

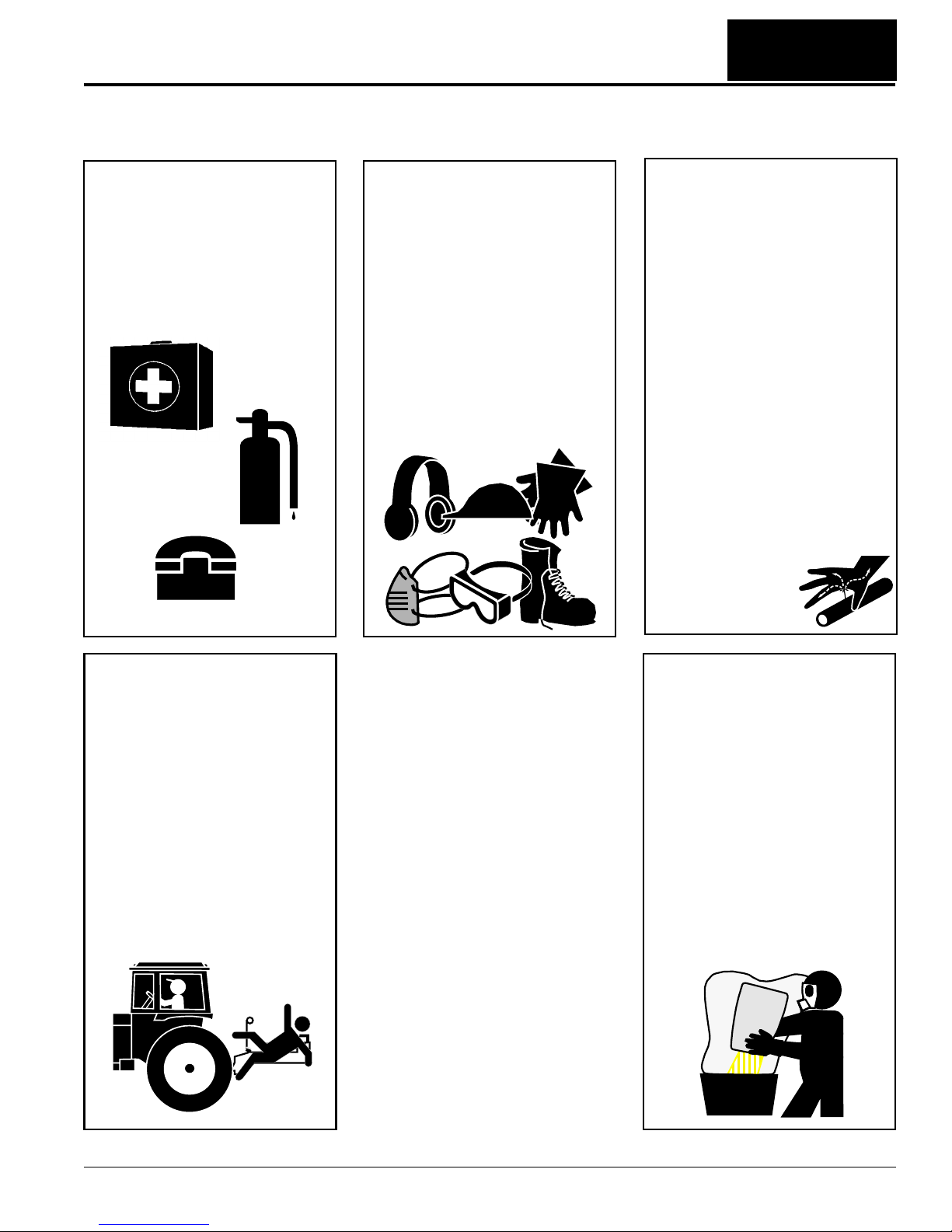

Important Safety Information . . . . . . . . . . . . . . . 1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look For The Safety Alert Symbol . . . . . . . . . . . . .1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . 10

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . 10

Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . 10

Further Assistance . . . . . . . . . . . . . . . . . . . . . . . 10

Section 1: Assembly & Set-Up (Standard) . . . 11

Tractor Requirements. . . . . . . . . . . . . . . . . . . . . . 11

Torque Requirements. . . . . . . . . . . . . . . . . . . . . . 11

Pre-Assembly Checklist . . . . . . . . . . . . . . . . . . . . 11

Sling Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Tire Track Remover Assembly . . . . . . . . . . . . . . . 11

Section 2: Assembly & Set-Up (Optional) . . . 12

Small Seeds Box Assembly . . . . . . . . . . . . . . . . . 12

Small Seeds Box Drive Assembly . . . . . . . . . . . . 13

Standard Seeds Box Assembly . . . . . . . . . . . . . . 14

Standard Seeds Box Drive Assembly. . . . . . . . . . 15

Section 3: Operating . . . . . . . . . . . . . . . . . . . . . 16

Pre-Start Checklist . . . . . . . . . . . . . . . . . . . . . . . . 16

Tractor Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tractor 3-Point Hook-Up . . . . . . . . . . . . . . . . . . 16

Pull Hitch Hook-Up . . . . . . . . . . . . . . . . . . . . . . . 16

Pull Hitch Disconnect . . . . . . . . . . . . . . . . . . . . . 16

Pull Hitch Operating Instructions . . . . . . . . . . . . . 17

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Filling the Seed Box . . . . . . . . . . . . . . . . . . . . . . . 18

Packing Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How the Seeder Works. . . . . . . . . . . . . . . . . . . . . 19

Operating the Seeder. . . . . . . . . . . . . . . . . . . . . . 19

General Operating Instructions. . . . . . . . . . . . . . . 20

Section 4: Seeding Adjustments . . . . . . . . . . 21

Seed Rate Adjustment . . . . . . . . . . . . . . . . . . . . . 21

Native Grass Seedbox . . . . . . . . . . . . . . . . . . . .21

Seed Rate Speed Change . . . . . . . . . . . . . . . . . . 22

Standard Seeds Box Option . . . . . . . . . . . . . . . .22

Small Seeds Box Option . . . . . . . . . . . . . . . . . . .22

Seed Rate Adjustment . . . . . . . . . . . . . . . . . . . . . 23

Standard Seeds Box & Small Seeds Box . . . . . .23

Seed Rate Charts (Standard Seeds Box) . . . . . . . 24

Seed Rate Charts, Metric (Standard Seeds Box) . 26

Seed Rate Charts (Small Seeds Box). . . . . . . . . . 28

Section 5: Options . . . . . . . . . . . . . . . . . . . . . . 29

Standard Seeds Box. . . . . . . . . . . . . . . . . . . . . . . 29

Small Seeds Box . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pull Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Section 6: Maintenance and Lubrication . . . . 30

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Packing Rollers. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Roller Bearings . . . . . . . . . . . . . . . . . . . . . . . . . .31

Roller Bearings . . . . . . . . . . . . . . . . . . . . . . . . . .31

Roller Chains (4 chains) . . . . . . . . . . . . . . . . . . .32

Roller Chains . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Drive Sprocket Hanger Bearing . . . . . . . . . . . . .32

Roller Chains . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Feed Cup Drive Sprocket Square Bore . . . . . . .33

Feed Cup Drive Sprocket Square Bore . . . . . . .33

Axle Pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Locking Mechanism Pivot Points . . . . . . . . . . . .34

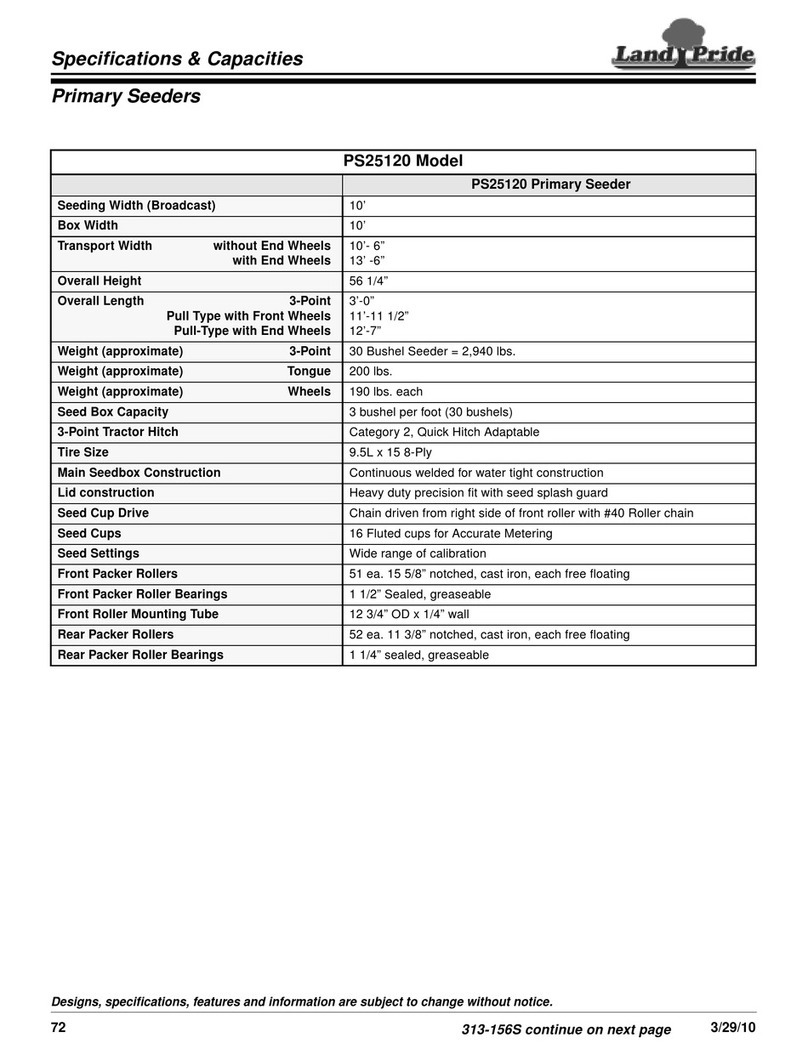

Section 7: Specifications & Capacities . . . . . 35

Section 8: Features & Benefits . . . . . . . . . . . . 36

Section 9: Troubleshooting . . . . . . . . . . . . . . . 37

Section 10: Torque & Tire Inflation Charts . . 38

Section 11: Warranty . . . . . . . . . . . . . . . . . . . . 39

Table of Contents