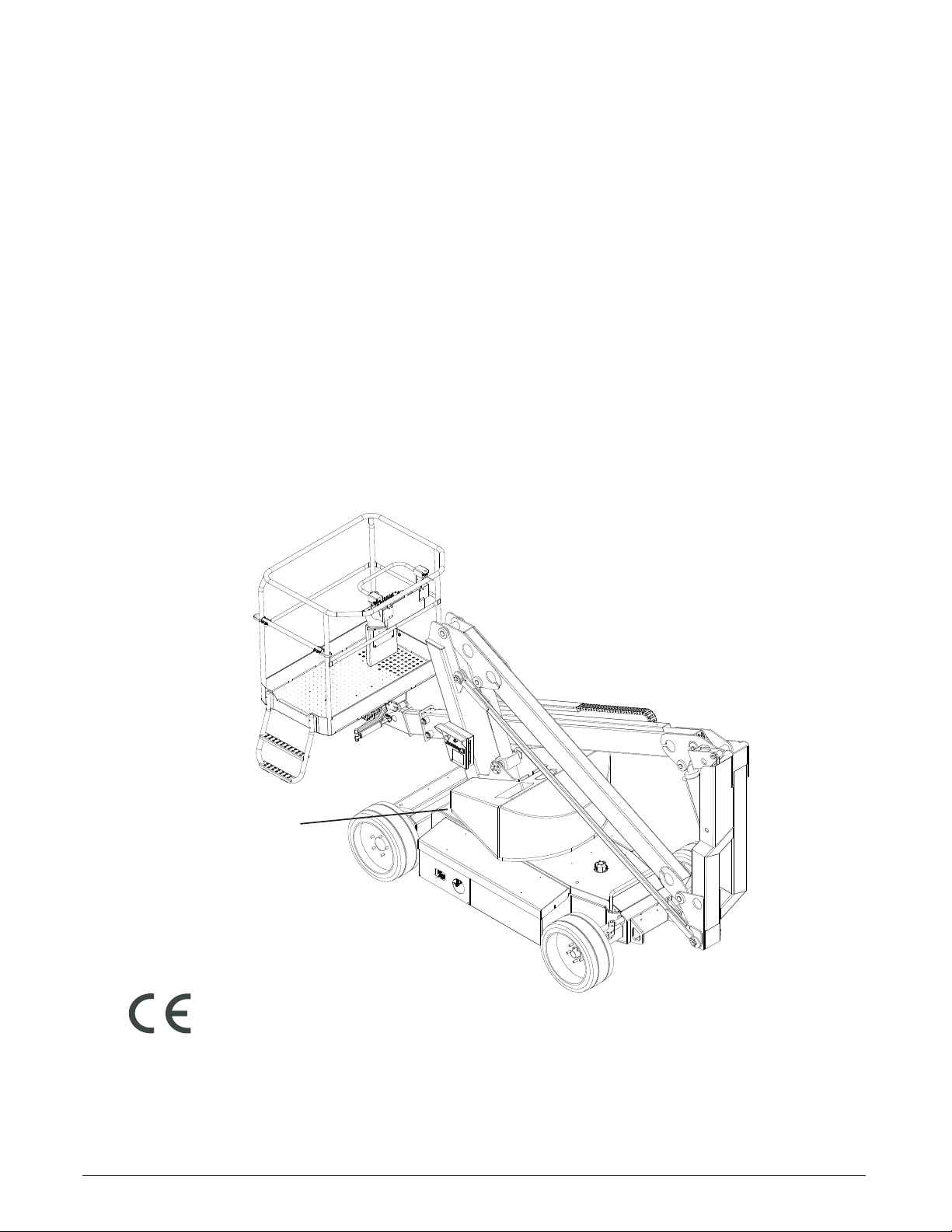

A38E – 514252-201

iii

Service and Parts Information

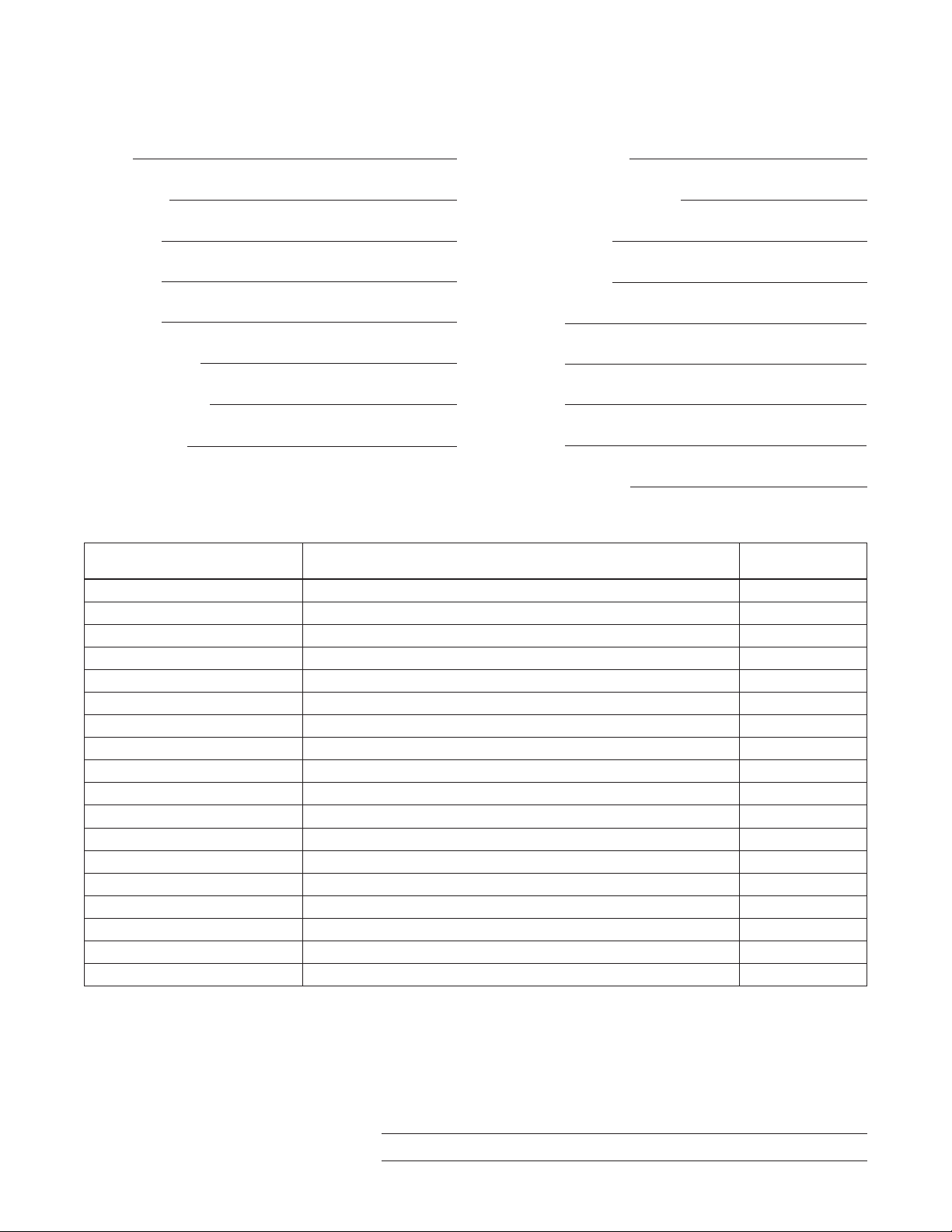

Ordering Parts

When placing an order for service or repair parts, please

have the following machine information readily available.

yModel number

ySerial number

ySnorkel part number

yDescription of part

yQuantity of parts required

yYour purchase order number

yAddress for order to ship to

yThe desired shipment method

If ordering parts off-line, the parts order form on the

following page may be mailed or faxed to the attention

of the Parts Department at the following location:

Snorkel North America

P.O. Box 1160

St. Joseph, MO 64502-1160 USA

Phone: 1-800-255-0317

Parts Fax: 1-785-989-3077

Snorkel Europe

Vigo Centre

Birtley Road

Washington

Tyne & Wear

NE38 9DA

Phone: +44 (0) 845 1550 058

Parts Fax: +44 (0) 1952 607 678

Attention: Parts Department

For your convenience, our electronic on-line ordering

system is accessible from the following Internet location:

http://www.snorkellifts.com

CE Compliance

All users and service personnel using or working on the

aerial platform must read, understand and comply with

all applicable regulations. Refer back the the Operators

Manual for more information on safe use.

The A38E work platform meets and exceeds the require-

ments of En280:2013+A1:2015

ANSI and OSHA Compliance

All owners,users of the aerial platform must read, un-

derstand and comply with all applicable regulations.

Ultimate compliance to OSHA regulations is the respon-

sibility of the user and their employer.

ANSI publications clearly identify the responsibilities

of all personnel who may be involved with the aerial

platform. A reprint of the “Manual of Responsibilities

for Dealers, Owners, Users, Operators, Lessors and

Lessees of ANSI A92.5 (1992) Self-Propelled Elevating

Work Platforms” is available from Snorkel dealers or

from the factory upon request.

Copies are also available from:

Scaffold Industry Association, Inc.

P.O. Box 20574

Phoenix, AZ 85036-0574 USA

Manuals

Manuals are available from Snorkel to support any of

the machines that we produce.

The specic manuals for A38E aerial platforms are as

follows:

A38E Operator’s Manual ANSI / CE

Snorkel part number – 514252-001-EN

S3219E Repair Parts Manual

Snorkel part number – 514252-201-EN

ANSI Manual of Responsibilities

ANSI A92.5 (1992)

Snorkel part number – TBA

Machine Information

Model Number:

Serial Number:

Date of Purchase:

Purchased From:

Snorkel Dealer or Distributor: