The following list is a gentle reminder when

disassembling or assembling the machine.

üAlways be conscious of weight.

üNever attempt to lift heavy objects without the aid of

a mechanical device.

üDo not allow heavy objects to rest in an unstable

condition.

üAlways make sure work platform is in stowed

position - blocked or the weight removed by a

suitable lifting device before disconnecting the

hydraulic hose from the motor/pump unit to the lift

cylinder.

üWhen raising a portion of the machine, be sure that

adequate blocking is properly positioned - Do not

depend on lifting device to hold and secure weight.

üIf a part resists removal, check to see if all fasteners,

electrical wiring, hydraulic lines, etc., have been

removed or that other parts are not interfering.

Parts should be thoroughly inspected before

restoring to service at the time of reassembly. Burrs,

nicks or scratches may be removed from machined

surfaces by honing or polishing with #600 crocus

cloth, followed by a thorough cleaning in an

approved cleaning solvent, and blown dry with

compressed air. Do not alter the contour of any part.

If this operation does not restore the part to a

serviceable condition, replace the part.

Replace all O-rings, seals, and gaskets at

reassembly. Use new roll pins or cotter pins. Dip all

packing rings and seals in hydraulic oil before

reassembling in cylinder and manifold installations.

Replace any part having imperfect threads. In

general, units that have been disassembled can be

reassembled by reversing the order of disassembly.

Remember that the service life of a machine can be

increased by keeping dirt and foreign materials out

of the vital components. Precautions have been

taken to safeguard against this; shields, covers,

seals and filters are provided to keep air and oil

supplies clean; however, these items must be

maintained on a scheduled basis in order to function

properly.

At any time air or oil lines are disconnected, clean

surrounding areas as well as the opening and

fittings themselves. As soon as a line or component

is disconnected, cap or cover all openings to

prevent the entry of dirt or foreign materials.

New parts should remain in their container until they

are ready to be used.

Clearly mark or tag hydraulic lines and electrical

wiring connections when disconnecting or removing

them from unit. This will assure that they are

correctly reinstalled.

Proper assembly is critical to the successful

rebuilding of any unit. Carefully inspect any parts

which are to be reused. If in doubt, replace.

“SAFETY FIRST” is a good slogan.

Replace any guards and protective devices that

have been removed to carry out maintenance and

repair work.

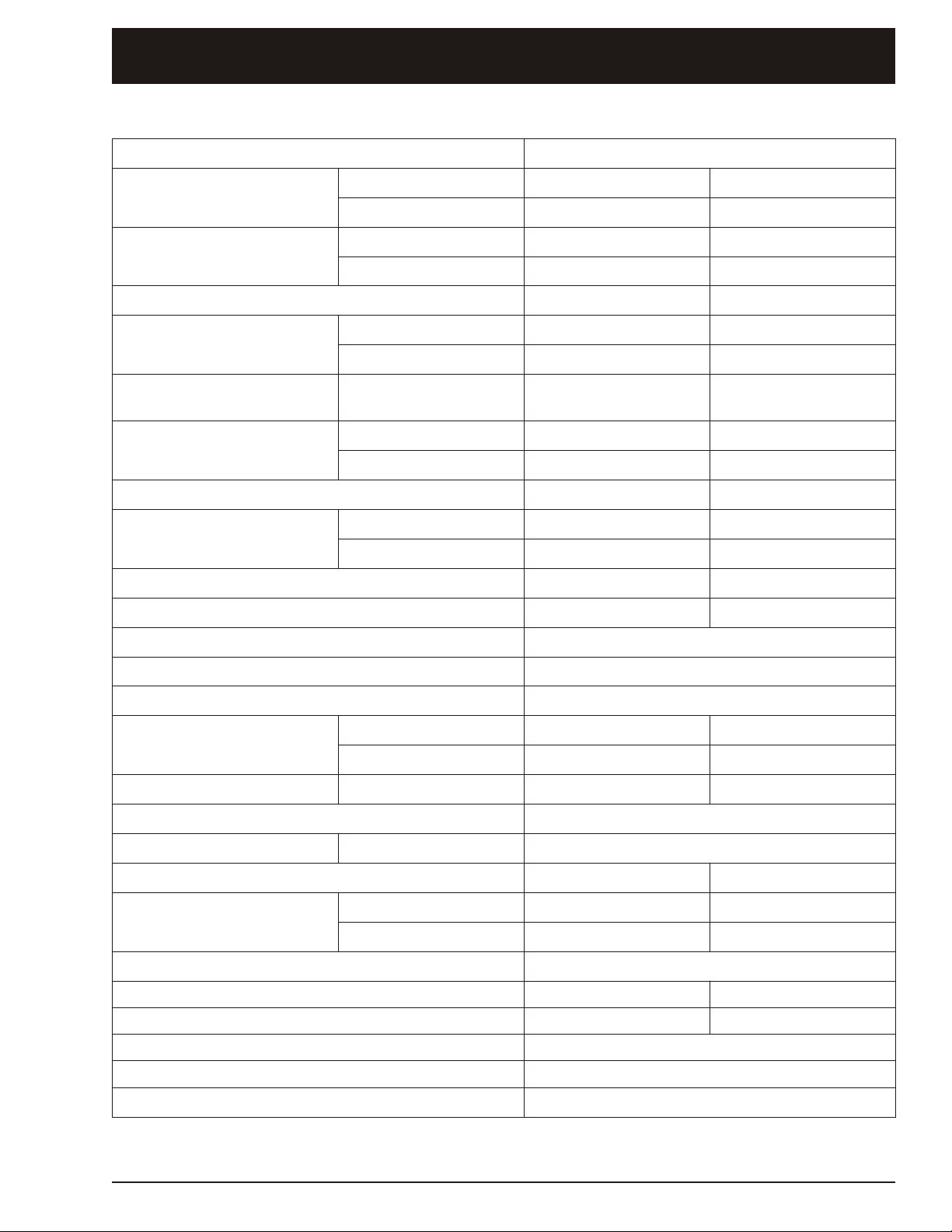

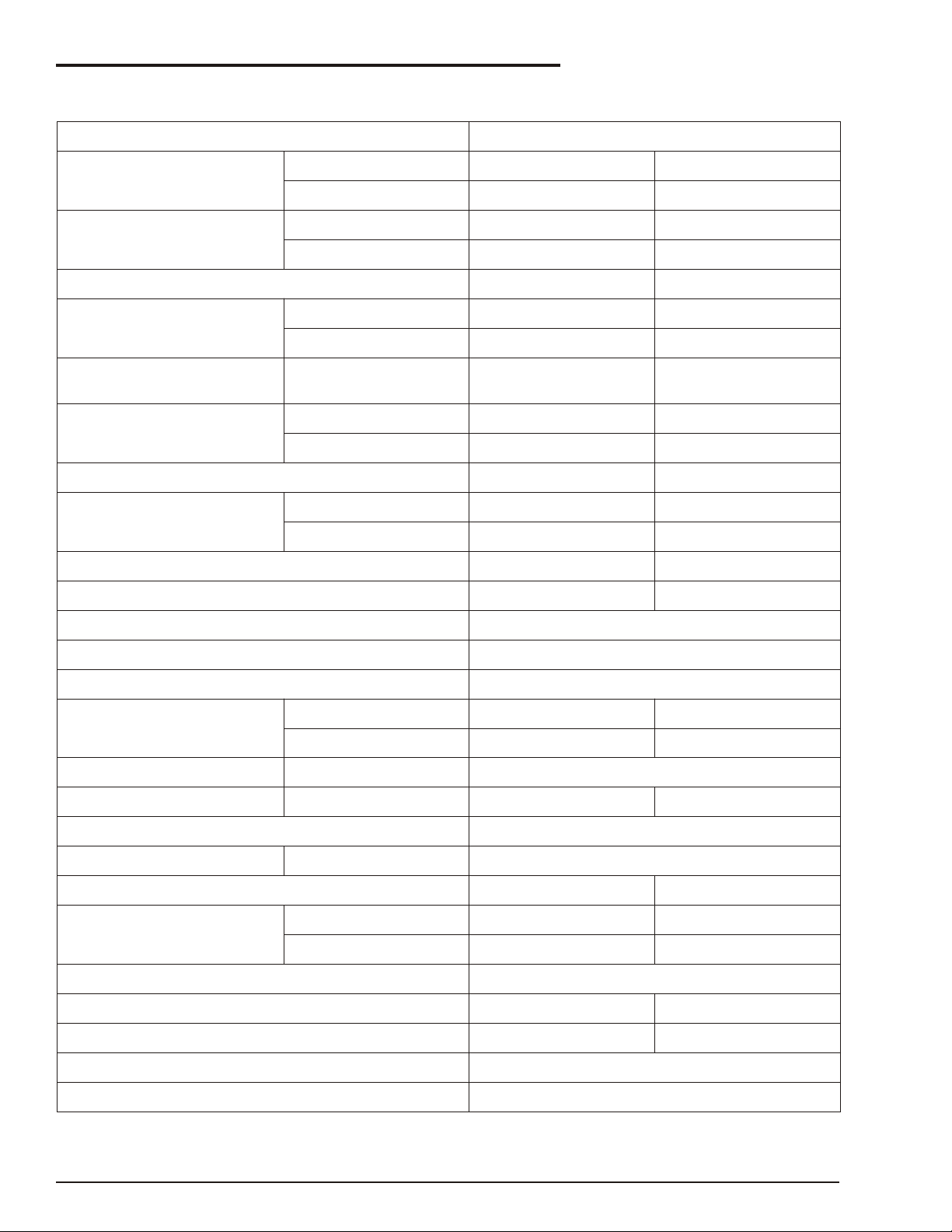

■Maintenance schedules

Snorkel has established a Preventive Maintenance

Schedule that includes:

üDaily Maintenance (Operator’s Inspection)

ü90 Day or 150 Hour (frequent) Maintenance

üYearly or 500 Hour (annual) Maintenance,

These schedules should ensure the detection of any

defective, damaged or improperly secured parts

and provide information regarding lubrication and

other minor maintenance items.

The Maintenance Schedule following, outlines the

requirements of these maintenance checks for each

time interval. The Operator’s Pre-operational

inspection must be performed by a trained operator.

All other maintenance and inspections must be

performed by a trained service technician only.

Note that the 90 Day or 150 hour (frequent) and

yearly or 500 hour (annual) Maintenance, require

use of the Preventive Inspection Maintenance

Checklist to pinpoint all inspection items. Retain a

copy of these forms for your records.

They also require that all placards and decals on the

unit are to be inspected.

All placards and decals must be in place and legible.

Use the placards installation drawing and parts

listing in the repair parts section 1 of this manual to

check these placards and decals.

Snorkel recommends that you make additional

copies of the Preventive Inspection Maintenance

Checklist forms for your use in performing these

Failure to perform the Preventive

Maintenance at the intervals outlined in the

Maintenance Schedule may result in a unit

being operated with a defect that could result

in INJURY or DEATH of the unit operator. DO

NOT allow a unit to be operated that has been

found to be defective.

Repair all defects before returning the unit to service

page 8Rev C S2755RT, S2255RT – 13715-2

Maintenance Information