Snow Performance BOOST COOLER 50005 User manual

INSTALLATION INSTRUCTIONS

FOR PART #50005

DIESEL STAGE 3 MPG-MAX™

WATER / METHANOL INJECTION

SYSTEM

7.3L POWERSTRO E

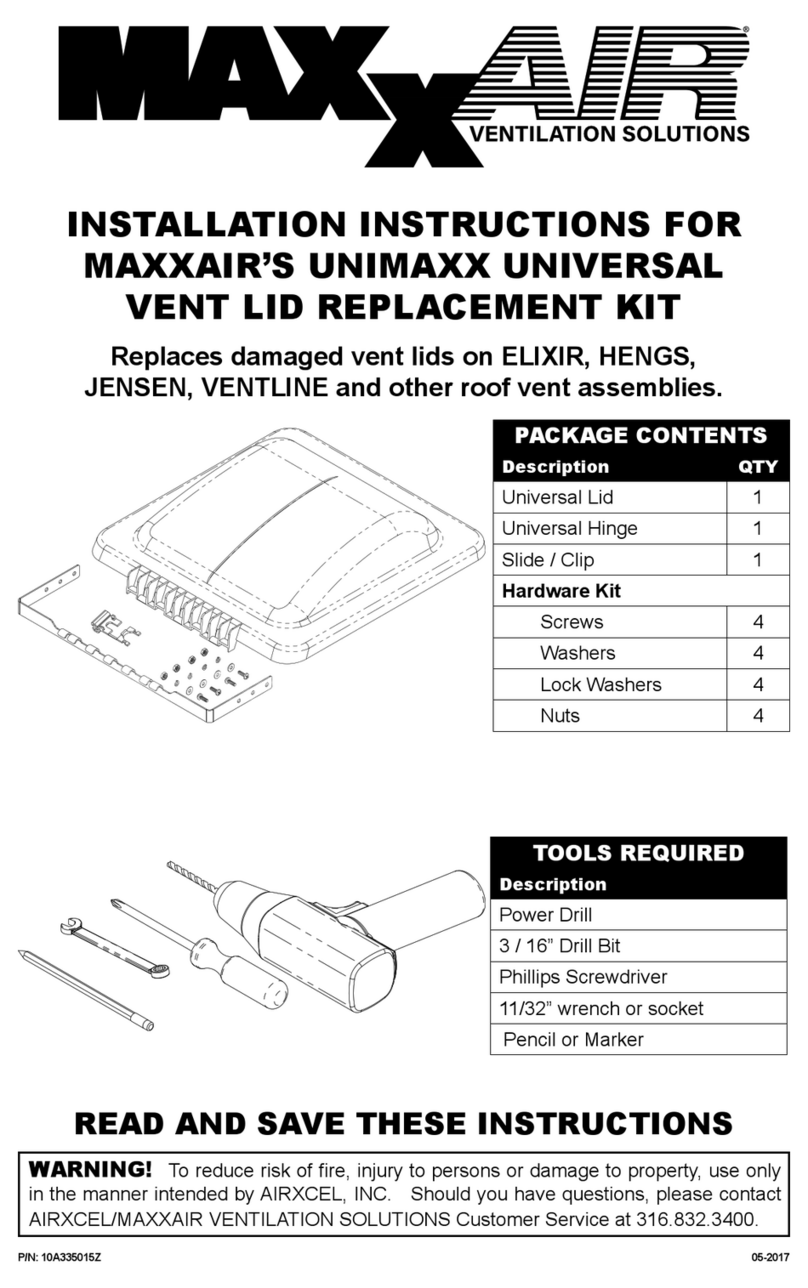

Kit Contents

Parts

o 7 Gallon Reservoir

o UHO Pump (Ultra High

Output)

o 25 ft High Pressure

Tubing

o 3 ft Black Wire Loom

o 18” 1/8” Silicone Tubing

Electrical Packet

o 2 Blue Butt Connectors

o 3 Small Eyehooks

o 1 Male Connector

o 3 emale Connectors

o 10 Tie Wraps

o 1 Arm Switch

o 1 Brass Hose Barb

o 5” Double Sided Tape

o 1 Yellow Temp Probe

Connector

o Diesel Stage 3 MPG

Max Controller

o Temperature Probe

o use holder

o 20 amp fuse

Required Tools

Electric Drill w/ Drill Bits

1/8” – 27 NPT Tap

Screwdriver – Phillips

Assorted Wrenches

Mechanical Packets

o 1 Nozzle Holder

o 4 #8x1&1/2” Screws

o 4 #8 Washers

o 2 Dual Nozzle Upgrades

o 2 Solenoid Upgrade

o 7 Gallon itting Set:

o 90° Elbow

o 3/8” – 1/8” Reducer

o 1 Temp Probe Compression

itting – 3/16”

o 1 E-6000 (GOOP)

o 1 175ml/min Nozzle

o 1 375ml/min Nozzle

o 1 625ml/min Nozzle

Upgrades/Options

o 2.5 Gallon Reservoir

o Hose Adaptor or Bung

o Boost Juice

Introduction

The Snow Performance Boost Cooler® Diesel Stage 3 MPG-MAX™

water/methanol injection system provides more power, cooler EGTs, and

excellent fuel economy increases. The MPG-MAX™ system does not

require a sustained high load state in order to provide maximum fuel

economy gains. The MPG-MAX™ system uses a new injection

management controller that allows for a small spray of water/methanol to

be injected across the power curve. This provides an increase in

combustion efficiency which provides more power without injecting more

diesel fuel. This increase in efficiency translates into an increase in fuel

economy. Typical fuel economy increases are 10%-15% or 1-3 MPG.

The MPG-MAX™ system has a secondary output that is used to activate

a Power Mode. This introduces a second phase of injection. A larger

nozzle(s) is used to inject more fluid to make more power. The Power

Mode activation point is adjustable for best performance.

Because the MPG-MAX™ system injects more frequently, the fluid

consumption rate will be higher than other Boost Cooler systems. The

MPG-MAX™ system has been coupled with the Snow Performance 7

Gallon Reservoir to provide a large fluid tank that fits well into the bed of

a truck. This will provide the longest range possible and includes the

necessary installation hardware.

Refer to the follow installation diagram. Completely read through this

instruction manual before attempting installation. Contact Snow

Performance for any questions or concerns.

Nozzle Identification Chart:

Nozzle

Number Nozzle Size

Nozzle

Number Nozzle Size

1 60 ml/min

4 225 ml/min

2 100 ml/min

5 375 ml/min

3 175 ml/min

6 625 ml/min

Note: The diagram shows three nozzles, but in most applications two

nozzles will provide the optimal flow. See page 8 for details.

Installation - Mechanical

Step 1 Reservoir Install

• Install 90 degree elbow into reducer bushing using E6000

sealant. Turn ½ turn past finger tight. Do not use Teflon sealants

on Snow Performance fittings. Install reducer bushing into

reservoir outlet using E6000 sealant. Turn ½ turn past finger

tight.

• Test fit reservoir in desired mounting location. Typical placement

is tucked up along the side of a pickup bed or in a bed mounted

tool box.

• Check the area under the bed near the desired mounting

location. Note the location of fuel tanks, fuel lines, and wiring.

• Mark the location of the four aluminum mounting strap tab bolt

holes.

• Drill through bed with appropriately sized drill bit. USE

CAUTION WHILE DRILLING.

• Mount reservoir with aluminum mounting straps using

appropriate hardware.

Caution******

To avoid gravity feeding of fluid with rear mount reservoirs, it is essential

to use a solenoid in-line between the reservoir and pump. Do not

operate your rear mount equipped vehicle without a solenoid installed.

Step 2 Pump Install

Mount the pump so the inlet is positioned at the lowest point of the

reservoir or lower. Pump can be mounted horizontally or vertically using

the supplied screws and washers. Ensure that no sharp bends in the

high pressure tube occur near the pump. Sharp bends can cause stress

on the inlet and outlet ports of the pump, causing leaks. Trim tube with a

utility knife or razor blade, making sure to eliminate any burrs or kinks on

the end. Insert firmly into the pump about ½ inch through the light grey

locking collar. Note the arrows indicating flow direction on the top of the

pump. To remove the hose, gently and evenly push the light grey locking

collar into the head unit of the pump, then pull on the hose gently.

Measure the distance from the reservoir outlet to the pump inlet. Cut the

¼” red tubing using utility knife. Make cuts are as square as possible.

Ensure there are no kinks in the tubing and insert tubing into quick

disconnects at pump and reservoir until fully seated. Keep the pump

within 2 feet of the reservoir. The pump can be mounted under the truck

bed in a place protected from road spray.

Caution******

Pump must be shielded from road debris and tire wash.

ailure to do so will result in pump failure

Step 3 Nozzle Selection

Nozzle sizing is a function of horsepower, which approximates the

engine airflow, and boost, which approximates intake charge heat.

Recommended starting points:

HP MPG MAX POWER MODE

350 > WHP 175 ml/min 375 ml/min

400 - 500 WHP 175 ml/min 625 m/min

500 < WHP 175 ml/min 375 + 625 ml/min

Seal the nozzle into the nozzle holder using GOOP®

sealant. Using a sealant that is not permanent will

allow for nozzle changes during tuning. Simply remove the nozzle,

clean the threads, and reinstall using sealant.

Assemble desired nozzle into nozzle holder using E6000® sealant. The

end of the nozzle with the fine mesh screen is to e inserted into

the nozzle holder. Torque 1/2 turn past finger tight. Do not use Teflon

sealants on Snow Performance fittings.

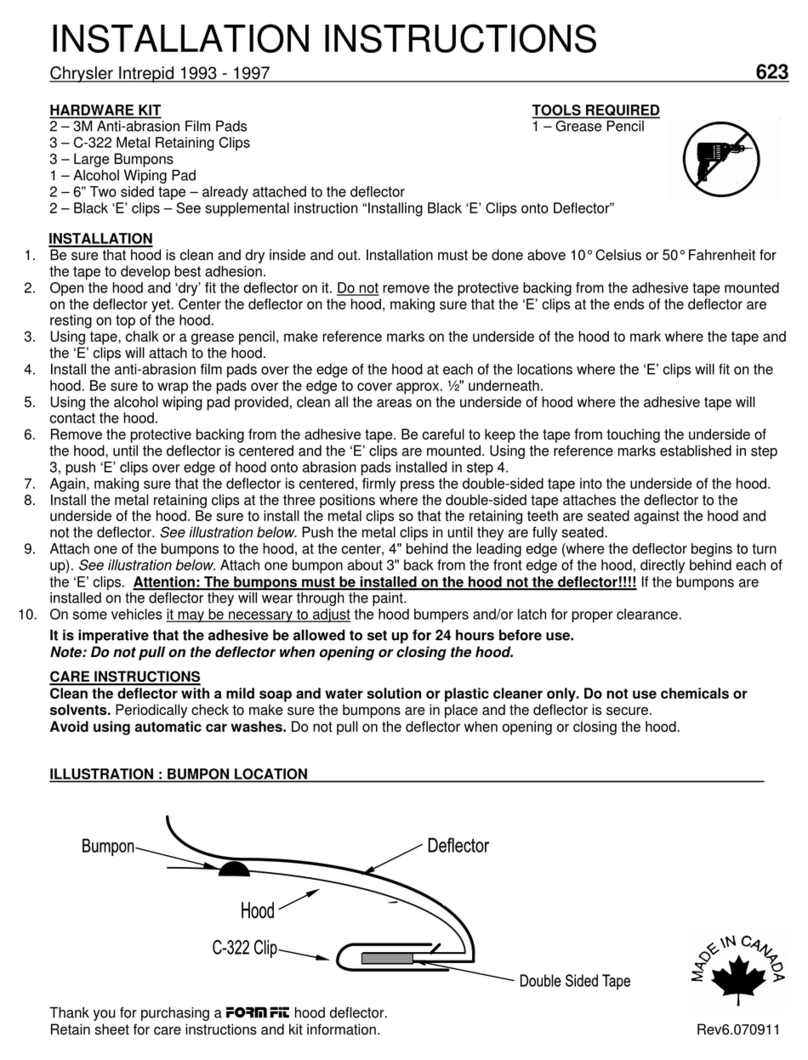

Correct

Incorrect

Step 4 Nozzle Mounting

The nozzle assembly should be installed 90° to the direction of airflow.

On round intake tubes, this is 360° around the tube meaning the nozzle

can be mounted in any direction. This will ensure maximum cooling as

the nozzle sprays in a cone pattern. Choose and mark mounting location

for nozzle placement. Nozzles can be placed on the charge pipe

between the intercooler outlet and the intake inlet, in a location that

allows an unobstructed spray pattern into the airflow.

Remove the selected piece and drill and tap (11/32" pre-drill, 1/8”-27

NPT tap) for two nozzles. Note that NPT is a tapered thread, and be

cautious not to over-tap thin walled pipes. Test fit nozzles into the pipe to

ensure a tight fitment.

The nozzle is mounted using its external 1/8 NPT threads. Tighten the

nozzle and nozzle holder assembly one half turn past finger tight using

E6000® to seal the threads.

Step 5 Nozzle and Solenoid Connection

Solenoid is flow directional. Be sure to note which port is the

INLET/PRESSURE port (2 or IN) and which is the OUTLET port (1 or

OUT).

The main outlet line coming from the Reservoir connects to the first

solenoids inlet. The outlet of this solenoid connects to the inlet of

the pump. The outlet of the pump connects to the Union “T”. One

outlet of the tee goes to the small MPG-MAX™ nozzle and the other

outlet of the tee connects to the second solenoid. The outlet from

the second solenoid will connect to the POWER MODE nozzle(s).

Measure the distance from the pump outlet to the injection location. Cut

the ¼” red tubing using utility knife. Make cuts are as square as

possible. Ensure there are no kinks in the tubing and insert tubing into

quick disconnects until fully seated. Gently pull on tubing to ensure a

good connection. Use tie wraps to help route tubing and to ensure it

doesn't contact moving or hot parts in the engine compartment

Step 6 Install EGT Probe

Drill and tap exhaust manifold pre-turbo. If this is performed with the

exhaust manifold still on the engine, start the engine and let it idle while

drilling and tapping. This will prevent shaving from entering the exhaust

and turbo. During tapping, coat tap with heavy grease so it will collect

any metal shavings.

Mount the Temp Probe using the 3/16” compression fitting (provided).

Installation - Electrical

Variable Controller Installation

Attach controller to secure location with easy access in driver’s

compartment using supplied tape. Install brass hose barb into intake

tubing 3” prior to nozzles. Connect black silicone tubing from brass hose

barb to clear tubing coming from the controller and secure with a tie

wrap.

CAUTION: Disconnect the negative attery terminal while

connecting wires to prevent electrical fire or damage to controller.

• Connect BLACK wire to a good ground location.

• Connect WHITE wire to Pump RED power wire.

• Connect GREEN wire to one BLACK wire from solenoid. Connect

other solenoid BLACK wire to ground.

• Connect RED wire to inline switch and then connect to +12V key on

source.

• Wire the Yellow “K” type temp probe connector to temp probe

installed in Step 6 above. The YELLOW wire connects to the

POSTITIVE terminal, the RED wire connects to the NEGATIVE

terminal of the connector. Connect to the lead from control module.

Always have a good electrical ground connection.

Poor ground will result in erratic operation.

Controller Operation

The controller has an LCD display screen. The display software allows

for seven different display modes and three control/setup screens.

To control the screen selection, the unit has two operator buttons; one to

the left of the screen (button 1) and one to the right of the screen (button

2). Pressing and releasing button 1 will cause the display to sequence to

the next screen. Button 2 is only active in the control/setup screens, and

is used to change the current control setting of the setup screen

displayed.

The system memory will remember the current display setting even if the

unit is turned off. The controller will turn on at the last used display

setting.

Additionally, button 2 is used for the “Injection ON/O ” function.

Note: When the Red LED to the left of utton 2 is illuminated,

the controller is activating the power nozzle.

Pressing and holding utton 2, then pressing utton 1, then

releasing oth uttons will change the system to read only without

changing the display screen. The pump will not activate in read

only. All screen display functions will remain active even when the

injection is turned off. To get the controller out of read only mode,

just repeat the procedure.

Screen 1

This mode displays pressure (P), temperature (T) and injection

percentage (Inj) as three independent bar graphs.

Screen 2

This mode displays the boost pressure and EGT temperature in PSI and

degrees .

Screen 3

This mode displays the boost pressure and EGT temperature in BAR

and degrees C.

P T

Inj

Boost

EGT

Boost

EGT

Screen 4

This mode displays the boost, EGT and injection in Standard units.

Screen 5

This mode displays the Boost, EGT and Injection in Metric units

Screen 6

This display shows both digital and bar graph readings for boost and

EGT in Standard units.

Screen 7

This display shows both digital and bar graph readings for boost and

EGT in Metric units.

Screen 8

This is the setup screen for the control mode. Pressing the right button

(# 2) will toggle the setting between MPG and TOW. If TOW is on, the

2-D matrix value for the injection is used. If MPG is on, injection will be

100% controlled by boost.

Screen 8A

MPG MODE START - UP. Pressing and releasing button 2 will increase

the injection activation point. Typical activation points are 6-8 psig.

Screen 8B

MPG MODE START - DOWN. Pressing and releasing button 2 will

decrease the injection activation point.

Screen 8C

MPG MODE 100% - UP. Pressing and releasing button 2 will increase

the maximum injection point. Typical 100% points are 13-18 psig.

Screen 8D

PSI Deg T

%Inj

BAR DegC

%Inj

PSI

Deg

Bar

DegC

Injection Mode

Change

MPG Mode Start

PSI Up

MPG Mode Start

PSI Down

MPG Mode 100%

PSI Up

MPG Mode 100%

PSI Down

MPG MODE 100% - DOWN. Pressing and releasing button 2 will

decrease the maximum injection point.

Screen 9-(TOW MODE ONLY)

This screen is used to select between LOW, MED, and HI boost when in

TOW mode. For vehicles making 8-18 psig of oost, use LOW

mode. For vehicles making 18-25 psig of oost, use MED mode.

For vehicles making 25+ psig of oost, use HI mode.

Screen 10-(TOW MODE ONLY)

This screen is used to increase the injection gain setting. Pressing and

releasing button 2 will increase the gain setting. 5%-10% changes in

gain will make significant changes in injection while in TOW Mode.

Screen 11-(TOW MODE ONLY)

This screen is used to decrease the injection gain setting. Pressing and

releasing button 2 will decrease the gain setting.

Screen 12 –(MPG MODE ONLY)

POWER MODE START - UP. Pressing and releasing button 2 will

increase the Power Mode injection activation point. Activate Power

mode 6-10 psig efore maximum oost.

Screen 13-(MPG MODE ONLY)

POWER MODE START - DOWN. Pressing and releasing button 2 will

decrease the Power Mode injection activation point.

Variable Controller Tuning

MPG MODE

When MPG mode is selected, injection is a function of boost pressure

only which is desirable when a more immediate injection is desired. With

the MPG mode function activated, an injection start and full point must

be selected.

• Toggle to Screen 8. Select MPG mode.

Boost Range

Change

Inj Gain

Increase

Inj

Inj Gain

Decrease

Power Mode Start

Up

Power Mode Start

Down

• Toggle to Screen 8A/B. Adjust the start point up or down.

Typical start points are 7-8 psig.

• Toggle to Screen 8C/D. Adjust the full 100% point up or down.

Typical 100% points are between 16 and 20 psig.

• Toggle to Screen 9. Select boost level. See “Controller

Operation: Screen 9”.

• Toggle to Screen 12/13. Adjust the POWER MODE activation

point up or down. Initially set the POWER MODE start point to

activate 6-10 psig of your maximum boost pressure. If the max

boost pressure is 30 set the POWER MODE start point to 20-24

psig. If the max boost pressure is 40 set the POWER MODE

start point to 30 psig.

A typical application making 28 psig maximum boost and hitting 7psig

under normal acceleration should select the “HI” Boost range and leave

gain at 100%. MPG Start should be set at 6 psig and MPG 100% should

be set at 14 psig. POWER MODE should be set at 22 psig.

Most 7.3 applications will make around 20 psig stock, and with average

bolt-on modifications reach about 30 psig. A stock 7.3 will usually use the

“MED” boost range rather than the “HI” boost range. A modified 7.3 will

usually use the “HI” boost range.

Tow MODE

When Tow mode is enabled, the controller will measure EGTs and boost

pressure to calculate the injection rate. Based on these two inputs, the

controller uses pre-mapped 2-D matrix to determine how much fluid to

inject. This is ideal in heavily loaded or towing situations. Because the

controller is pre-programmed, there are no start and full points to adjust.

• Toggle to Screen 8. Select Tow mode.

• Toggle to Screen 9. Select boost level. See “Controller

Operation: Screen 9”.

• Toggle to Screen 12/13. Adjust the POWER MODE activation

point up or down. Initially set the POWER MODE start point to

activate 6-10 psig of your maximum boost pressure. If the max

boost pressure is 30 set the POWER MODE start point to 20-24

psig. If the max boost pressure is 40 set the POWER MODE

start point to 30 psig.

ADJUSTING THE CONTROLLER

The MPG MAX phase of injection is meant to inject a small amount of

fluid during moderate load cruising. If combustion quench occurs as

evidenced by engine bucking or bogging, too much fluid is being injected

too soon. To prevent quench try each of the following:

• Toggle to Screen 8A. Adjust the MPG MODE START point to

come on at a higher boost level.

• Change out MPG MAX nozzle to the next size smaller.

If quench occurs when the POWER MODE activates try each of the

following:

• Toggle to Screen 12. Adjust the POWER MODE START point to

come on at a higher boost level.

• Toggle to Screen 11. Adjust the GAIN down to reduce overall

injection amount if in Tow Mode.

• Change out POWER MODE nozzle(s) to the next size smaller.

Activation of pump for short periods (1 - 5 sec.) will purge air bubbles

from the system. This can be accomplished during initial use.

Step 2 Test Controller

• With the nozzles removed from the intake, place the controller in

MPG mode. Set boost mode start to 1 PSI.

• Using a hand pump, apply 10-20 psig of pressure to the boost

line on the controller.

• Pump should activate, fluid should flow, and tank level should go

down.

Tuning Quick Reference

If combustion quench occurs as evidenced by engine “bucking”, reduce

the injection quantity. This can be done by:

1. Using a smaller nozzle(s).

2. Using Screen 9 and Screen 10 to adjust the gain.

Caution******

Prolonged quench may cause lower engine damage over a period of

time.

Also, fresh methanol – less than 1 month old when exposed to

atmosphere – and using a greater methanol concentration – up to 50% -

will reduce combustion quench.

100% water will cool combustion and EGTs and will increase power

approx 20-30 HP.

75/25 water/methanol will reduce EGTs and power will increase

approximately 40 HP.

50/50 water/methanol will reduce EGTs and increase power

approximately 70+ HP.

Caution: To avoid “pooling” in the intake it is recommended that:

1. The engine be run without water/methanol for at least 5 minutes after

injection before turning the engine off.

2. The “armed switch” is turned to the off position when the engine is off.

Testing the System

Note: for best results, prime pump before use

To clear air from the pump and insure that the system is primed:

• ill reservoir with water approx ¼ full.

• Remove tubing from nozzle (or solenoid if solenoid used in-line

between pump and nozzle) and run tube into separate container.

• Apply 12 VDC to red pump wire for approximately 5 seconds or

until fluid flow is consistent.

• Pump is now primed. Reconnect tubing from pump outlet to

nozzle (or solenoid).

If using a solenoid in etween the pump and the reservoir: Remove

the solenoid and place a solid piece of tube between the pump and the

reservoir and prime the system. Then replace the solenoid in between

the pump and reservoir.

Step 1 Test Pump and Mechanical System

Disconnect pump from controller. Using a 12 volt source, apply power to

red wire of pump. Pump should activate and fluid level in tank should go

down. It is recommended to also check the nozzle spray pattern while

following this procedure. Also check for leaks.

If pump goes on and fluid level doesn't go down, there is an obstruction

in the tube or nozzle.

Caution: Do not attempt to inject water/methanol until the engine has

reach operating temperature. A cold engine is more susceptible to

quench and poor performance.

Maintenance –

Remove nozzle(s) and clean screen filters at

least once per year using car cleaner.

The Boost Cooler® has een designed to operate with high

concentrations of methanol. Oil or other additives are not required

for system lu rication.

For est performance, cooling and system life it is recommend that

Snow Performance Boost Juice™ (#40008) e the exclusive fluid

used in the system.

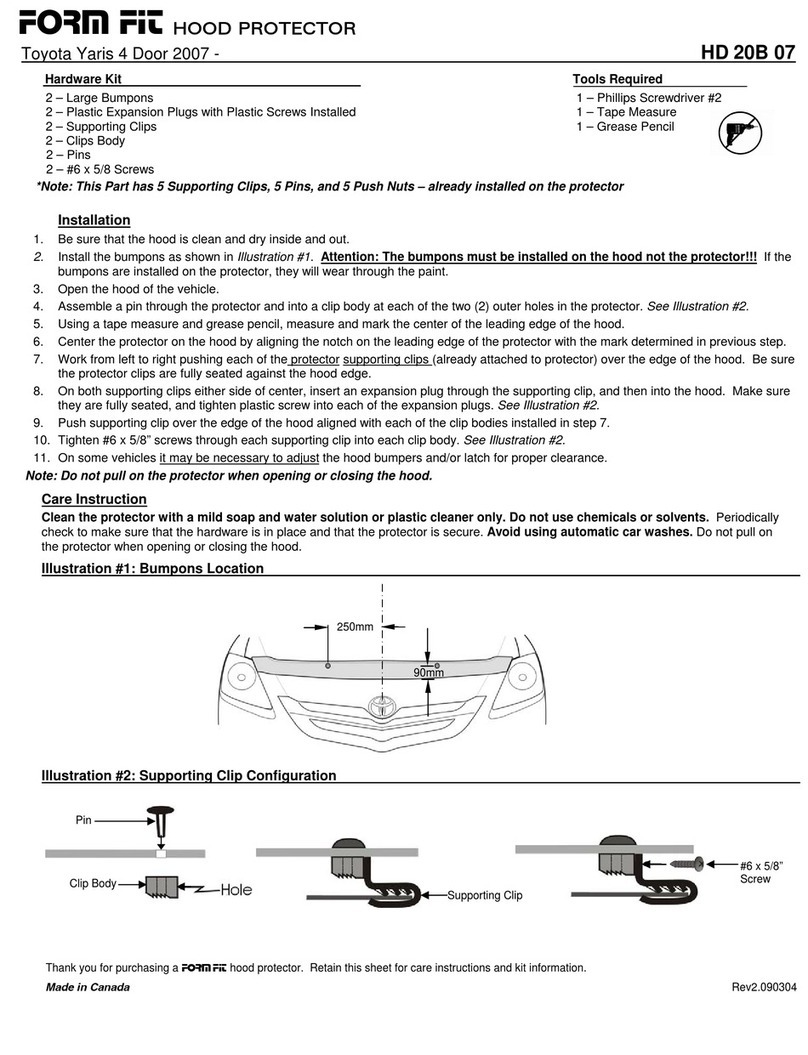

Fluid Level Switch

Instructions

• Locate desired level switch mounting position. Suggested

placement is 1/5 of max reservoir height.

• Carefully drill side of reservoir using 13/16” bit. A step bit is

recommended for best drilling results. Hole

must be free of nicks or shavings for proper

sealing.

• Remove rubber seal from level switch.

Insert seal into reservoir until fully seated.

Goop can be used around the edges of the

hole.

• Lubricate exterior of level switch with water

and insert into seal until fully seated. Position level switch so GT

symbol is at six o’clock position.

• Wait 30 minutes for Goop to cure, then test for leaks. With fluid

level above level switch, float should be angled up. With fluid

level below level switch, float should be in horizontal position.

• Connect one black wire from level switch to ground.

• Connect other black wire from level switch to white wire from

LED.

• Connect red wire from LED to +12 volt key on power source.

Low luid LED

Red

Black

Black

FUEL SYSTEMS

SNOW PERFORMANCE

Table of contents

Other Snow Performance Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

BM PRO

BM PRO TrailSafe Series owner's manual

pro user

pro user DIAMANT I Assembly instruction and safety regulations

Caraudio-Systems

Caraudio-Systems usbLOGiC manual

Steel mate

Steel mate TP-S7 Fact sheet

OPT7

OPT7 Quantum Rock Lights Bluetooth installation guide

Electro motive

Electro motive XDI200 Installation manual & users guide