Snow Performance 20130 User manual

© 2010, Snow Performance, Incorporated

INSTALLATION INSTRUCTIONS

FOR PART #20130 MUSTANG

STAGE 3 BOOST COOLER®

WATER/METHANOL INJECTION

SYSTEM

© 2010, Snow Performance, Inc

Contents:

Parts List...3

Introduction..4

Installation Mechanical.5

Installation Electrical...10

Controller Tuning.....11

Testing the S stem..16

Vehicle Tuning Quick Reference..17

Maintenance..18

Install Notes...21

Warrant .22

Contact Us..24

Have a question?

FAQ: www.snowperformance.net/faqs.php

CAUTION

You must completely read though these instructions before installing and

operating this product. ailure to due so can result in damage to this

product and the vehicle.

© 2010, Snow Performance, Inc

Parts List

o UHO (Ultra High

Output) Pump

o 10 ft. 1/4” OD Tubing

o 3ft. Black Wire Loom

o 18” 1/8” Silicone Tubing

o 3 Quart reservoir

Electrical Packet

o 2 Wire Splices

o 2 Butt Connectors

o Vacuum “T”

o 2 Small Eyehooks

o 1 emale Connector

o 1 Male Connector

o 10 Tie Wraps

o 3” Double Sided Tape

o Stage 3 Controller

o Level Switch Upgrade

Required tools

- Electric drill w/ drill bits

- Adjustable wrench

- Utility knife

- Screw driver – Phillips

- 5/16” open end wrench (for

nozzle)

-1/8” NPT Tap

Mechanical Packet

o 1 Nozzle Holder

o 8 #8x1&1/2in. Screws

o 8-#8 Washers

o 4 #6x1/2in. Screws

o 1 Tube E6000 GOOP®

o 1 Bulkhead itting

o 1 3/8 NPT to ¼” tube

reservoir fitting

Nozzles

o 60ML/MIN (1)

o 100ML/MN (2)

o 175ML/MN (3)

o 225ML/MN (4)

o 375ML/MN (5)

o 625ML/MN (6)

Upgrades

o 2.5 Gallon Reservoir

o Solenoid

o Hose Adaptor or Bung

o SafeInjection®

o Nitrobooster®

o Dual Nozzle

o Carb Plate

© 2010, Snow Performance, Inc

Introduction:

The Stage 3™ Mustang System is designed to deliver precise amounts

of water-methanol in a wide range of operating conditions. This system

can deliver cooler combustion temperatures, lower intake air

temperatures, and 20-25 point octane gains over regular pump gas. It

utilizes the factory washer fluid tank. This does not defeat the original

purpose of the tank and makes for an easy, professional installation.

Naturally aspirated Mustangs will utilize the E I sensor capability of the

controller for injection control, while Mustangs with forced induction of

any kind will use both boost and E I data to control injection.

Red to

switched

12V

2

1

Pump

Air

low

Throttle

P

late

Blue - To uel

Injector

Harness

Clear Boost Tube

White - To

Pump Red Wire

Turbo/

Supercharger/

Air ilter

actory Washer

luid Tank

Black

Black

Green Wire can

be tied out of

the way.

© 2010, Snow Performance, Inc

Contact Us:

Phone

Office (719) 633-3811

ax (719) 633-3496

Tech Support Line (Toll ree) (866) 365-2762

Web

http://www.snowperformance.net

Email

customerservice@snowperformance.net

Mail

Snow Performance, Inc

1017-A East Highway 24

Woodland Park, CO 80863

Notes

The contents of this document are subject to change without prior notice.

No part of or this entire document may be reproduced in any form

without prior written permission of Snow Performance, Inc under the

copyright except for private use.

The names, addresses and telephone numbers mentioned are current as

of January 1, 2009. Note that this information is subject to change.

Please refer to www.snowperformance.net for current information.

© 2010, Snow Performance, Inc

Products returned due to damage or misuse and Products retested with no problem found

will be returned to customer at customer’s expense.

LIMITATION O LIABILITY

REPAIR OR REPLACEMENT O A DE ECTIVE PRODUCT IS THE ORIGINAL RETAIL

PURCHASER’S EXCLUSIVE REMEDY UNDER THIS WARRANTY.

DAMAGE OR INJURY TO THE ORIGINAL RETAIL PURCHASER, TO HIS OR HER

VEHICLE, CARGO, OR PROPERTY, AND/OR TO ANY OTHER PERSON OR

PROPERTY IS NOT COVERED BY THIS WARRANTY.

THIS WARRANTY IS EXPRESSLY MADE IN LIEU O ANY AND ALL OTHER EXPRESS

WARRANTIES, WHETHER ORAL OR WRITTEN. SNOW’S SOLE LIABILITY IS LIMITED

TO THE REMEDY SET ORTH ABOVE. IN NO EVENT WILL SNOW BE LIABLE OR

ANY DIRECT, INDIRECT, CONSEQUENTIAL, INCIDENTAL, SPECIAL, EXEMPLARY, OR

PUNITIVE DAMAGES OR OR ANY OTHER DAMAGES O ANY KIND OR NATURE

(INCLUDING, BUT NOT LIMITED TO, LOST PRO ITS OR LOST SALES). SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION O INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO

YOU.

Non-Warranty Repair/Retest

Products returned due to damage or misuse and Products retested with no problem found

are subject to repair/retest charges. Product will be returned to customer at customer’s

expense. A credit card number must be provided in order to obtain an RMA (Return

Merchandise Authorization) number prior to returning Product.

© 2010, Snow Performance, Inc

Installation- Mechanical

Step 1 Bulkhead itting Install

The factory windshield washer

reservoir is used as the

reservoir for your system.

• Drill 9/16” hole in desired

bulkhead location.

• Remove one nut from

bulkhead and turn the

remaining nut until it is at the

very end.

• eed red tubing through the

drilled hole and up and out of

the top of the reservoir.

• Attach tubing to the bulkhead

on the side opposite the nut.

• Pull the tubing through the

bulkhead hole until the

bulkhead seats against the

inside of the reservoir.

• Apply E6000® sealant

(included) around bulkhead.

• Slide the nut you had

previously removed up onto

the tube and thread onto

bulkhead.

• While pulling firmly on the

red tubing, tighten the outer

nut using a 17mm socket

(only needs to be hand tight).

A ratchet is not needed.

• Once sealant has set, fill

reservoir with water and

check for leaks.

Factor washer tank from a 2007 GT shown with 9/16 hole drilled for

bulkhead fitting. See page 19 for details on mounting the optional

fluid level switch. Note that in some cases it will be easier to mount

the bulkhead fitting in the side of the tank so that the hose exits in

the direction of the pump.

© 2010, Snow Performance, Inc

Caution******

To avoid gravity feeding of fluid with rear mount reservoirs, it is essential

to use a check valve in-line between the reservoir and pump. Do not

operate your rear mount equipped vehicle without a check valve

installed.

Caution*******

Whenever the nozzle is mounted post-throttle plate, to avoid siphoning

fluid at idle, it is essential to use a solenoid upgrade inline between the

reservoir and pump.

Step 2 Pump Install

Mount the pump so the inlet is positioned at the lowest point of the

reservoir or lower. Pump can be mounted horizontally or vertically using

the supplied screws and washers. Ensure that no sharp bends in the

high pressure tube occur near the pump. Sharp bends can cause stress

on the inlet and outlet ports of the pump, causing leaks. Trim tube with a

utility knife or razor blade, making sure to eliminate any burrs or kinks on

the end. Insert firmly into the pump about ½ inch through the light grey

locking collar. Note the arrows indicating flow direction on the top of the

pump. To remove the hose, gently and evenly push the light grey locking

collar into the head unit of the pump, then pull on the hose gently.

© 2010, Snow Performance, Inc

Warrant

Warranty Policy

Snow Performance, Inc. warrants that the Product shall conform to and perform in

accordance with published technical specifications and shall be free of defects in materials

and workmanship for 90-days providing:

1. You are the original purchaser and provide proof of purchase.

2. or 1-year warranty, the Warranty Card that came with system (not applicable to

separate parts purchases) is returned to Snow within 45-days of purchase. If valid warranty

card not on file with Snow, the standard 90 day warranty applies from date of purchase.

3. or Lifetime warranty,

, the Warranty Card that came with system (not applicable to

separate parts purchases) is returned to Snow within 45-days of purchase and Boost

Juice® injection fluid is used exclusively.*

3. An RMA # has been attained and is displayed on package containing returned part.

4. Parts Warranty ~ 90 day warranty on parts purchased separately if used in conjunction

with a Snow System. No warranty implied if used with a non-Snow part/system.

Subject to Snow’s inspection of the product, Snow will remedy defects in materials and/or

workmanship by repairing or replacing, at Snow’s option, the defective product without

charge for parts or labor, subject to the limitations and exclusions described in this

warranty.

This warranty does not cover problems caused by normal wear and tear including aesthetic

oxidation of surfaces, accidents, unlawful vehicle operation, or modifications or repairs to

product not performed or authorized by Snow. This includes any product that is

disassembled or taken apart for any reason.

* Boost Juice® usage evidenced by invoices/ receipts.

In addition, this warranty does not cover problems resulting from conditions beyond Snow’s

control including, but not limited to, theft, misuse, overloading, or failure to assemble,

mount or use the product in accordance with Snow’s written instructions or guidelines

included with the product or made available to the original retail purchaser.

In the event of failure, Snow will repair or replace the part at Snow's sole discretion.

ailures resulting from misapplication or misuse of the Product, failure to adhere to any

specifications or instructions, or failure resulting from neglect, abuse, accidents, or act of

nature are not covered under this warranty.

Warranty service may be obtained by calling 719-633-3811, getting an RMA (Return

Merchandise Authorization), delivering the part to Snow along with proof of purchase.

Customer agrees to insure the Product or assume the risk of loss or damage in transit, to

prepay shipping charges to Snow, and to use the original shipping container or equivalent.

Shipping for Warranty replacement parts shipped outside the continental US will be

charged to customer.

Non-Warranty Repair/Retest

© 2010, Snow Performance, Inc

Install Notes

Pump Setting ____________(psi)

Nozzle Size ____________(ml/min)

Boost / Vacuum setting _________

Misc:

Disclaimer

Do not use this product until you have carefully read the following agreement.

This sets forth the terms and conditions for the use of this product. The installation of this

product indicates that the BUYER has read and understands this agreement and accepts

its terms and conditions.

Performance products by their nature are designed to increase horsepower and

performance not engineered in the original vehicle and the increased stress could result in

damage to related systems. This is a high performance product – use at your own risk.

Snow Performance Inc., Its agents, employees or owners shall not be under any liability

whether in contract or otherwise whether or not resulting from our negligence or contents of

information supplied for any damage or loss resulting from such information.

The BUYER is responsible to fully understand the capability and limitations of his/her

vehicle according to manufacturer specifications and agrees to hold the SELLER harmless

from any damage resulting from failure to adhere to such specifications.

The SELLER disclaims any warranty and expressly disclaims any liability for personal

injury or damages. The BUYER acknowledges and agrees that the disclaimer of any

liability for personal injury is a material term for this agreement and the BUYER agrees to

indemnify the SELLER and to hold the SELLER harmless from any claim related to the

item of the equipment purchased. Under no circumstances will the SELLER be liable for

any damages or expenses by reason of use or sale of any such equipment.

The BUYER is responsible to obey all applicable federal, state, and local laws, statutes,

and ordinances when operating his/her vehicle, and the BUYER agrees to hold SELLER

harmless from any violation thereof.

The SELLER assumes no liability regarding the improper installation or misapplication of its

products.

It is the installer's responsibility to check for proper installation and if in doubt, contact the

manufacturer.

© 2010, Snow Performance, Inc

Measure the distance from the bulkhead fitting on the reservoir to the

pump inlet. Cut the ¼” red tubing using utility knife. Make cuts are as

square as possible.

Ensure there are no kinks in the tubing and insert tubing into quick

disconnects at pump and reservoir until fully seated. Keep the pump

within 2 feet of the reservoir.

Caution******

Pump must be shielded from road debris and tire wash.

ailure to do so will result in pump failure

Step 3 Nozzle Selection

Nozzle sizing is a function of horsepower, which approximates the

engine airflow, and boost, which approximates intake charge heat. The

following are some general guidelines (assuming 50-50 water-methanol).

Engines running mild or high boost and making 400-600 HP will use a

375 ML/MN nozzle or 625 ML/MN nozzle. (Red and Blue colored nozzles

respectively)

Engines making mild boost and 200-400 HP will use a 175 ML/MN

nozzle or a 225 ML/MN nozzle.

A naturally aspirated engine making 300-400 HP will use a 100 ML/MN

nozzle or a 175 ML/MN nozzle.

A naturally aspirated engine making 400-600 HP will use a 225 ML/MN

nozzle or a 375 ML/MN nozzle.

Seal the nozzle into the nozzle holder using

included E6000® sealant. Using a sealant that is

not permanent will allow for nozzle changes during tuning. Simpl

remove the nozzle, clean the threads, and reinstall using sealant.

Assemble desired nozzle into nozzle holder using E6000® sealant. The

end of the nozzle with the fine mesh screen is to be inserted into

the nozzle holder. Torque 1/2 turn past finger tight. Do not use Teflon

sealants on Snow Performance fittings.

© 2010, Snow Performance, Inc

Correct Incorrect

Step 4 Nozzle Mounting

The nozzle should be installed 90° to the direction of airflow. On round

intake tubes, this is 360° around the tube meaning the nozzle can be

mounted in any direction. This will ensure maximum cooling as the

nozzle sprays in a cone pattern. The nozzle should be the highest point

in the system, and its tip should be flush with the inside wall of the tube

or projecting slightly into the airflow to ensure good spray pattern.

Drill and tap (11/32" pre-drill, 1/8”-27 NPT tap) air inlet tube as close as

feasible to throttle body/throttle plate. Be sure to remove the pipe to

avoid getting any shavings into the engine.

© 2010, Snow Performance, Inc

Solenoid Upgrade (optional)

The optional Solenoid Upgrade (#40060) is required if the nozzle is to be

installed after the intake throttle plate (as shown), or the fluid reservoir is

mounted higher then the nozzle. It is highly recommended for trunk-

mount reservoirs.

inger thread the two 1/8” NPT quick connect fittings into ports labeled (2

or IN) and (1 or OUT) on the solenoid. Tighten an additional half turn

past finger tight.

Note: Solenoid must be installed Pre-pump to ensure

correct operation.

Cut high pressure line at location solenoid is to be installed. Insert ends

of cut line into quick connect fittings of solenoid. The port labeled (2 or

IN) is the inlet and the port labeled (1 or OUT) is the outlet. Gently pull

on line to check secure connection. If line pulls out, re-insert farther into

fitting to engage locking clips. If high pressure line removal is required,

firmly press in metal fitting ring to disengage locking clips while pulling

hose from fitting.

Connect one of the BLACK wires from solenoid to the RED positive

pump wire or the WHITE wire from the controller. Note that connecting

the wire to any other power source other then the pump/controller wire

will result in improper operation of solenoid. Connect the second BLACK

wire to a secure chassis ground location.

White from S3

Harness

© 2010, Snow Performance, Inc

Fluid Level Switch

Fluid level switch and Bulkhead fitting shown on ’07 Mustang Washer Bottle.

Instructions

• Locate desired level switch mounting position. Suggested

placement is 1/5 of max reservoir height.

• Carefully drill side of reservoir using 13/16” bit. A step bit is

recommended for best drilling results. Hole

must be free of nicks or shavings for proper

sealing.

• Remove rubber seal from level switch.

Insert seal into reservoir until fully seated.

Goop can be used around the edges of the

hole.

• Lubricate exterior of level switch with water

and insert into seal until fully seated. Position level switch so GT

symbol is at six o’clock position.

• Wait 30 minutes for Goop to cure, then test for leaks. With fluid

level above level switch, float should be angled up. With fluid

level below level switch, float should be in horizontal position.

• Connect one black wire from level switch to ground.

• Connect other black wire from level switch to white wire from

LED.

• Connect red wire from LED to +12 volt key on power source.

© 2010, Snow Performance, Inc

Intake tube from Shelb GT shown. Note that the nozzle mount

adaptor (part number 40100) ma be useful for stock plastic intake

pipes.

The nozzle is mounted using its external 1/8 NPT threads. Tighten the

nozzle and nozzle holder assembly one half turn past finger tight using

E6000® sealant to seal the threads.

The recommended nozzle mounting point is before

the throttle bod /plate and above the level of the

reservoir. If ou mount the nozzle after the throttle bod /plate or

below the reservoir, a Solenoid Upgrade (#40060) must be used to

prevent siphoning at idle or gravit feed.

© 2010, Snow Performance, Inc

Step 5 Nozzle Connection

Measure the distance from the pump outlet to the nozzle holder(s). Cut

the ¼” tubing using a sharp utility knife or razor blade. Make cuts as

square as possible.

Ensure there are no kinks in the tubing and insert tubing into quick

disconnects until fully seated. Gently pull on tubing to ensure a good

connection. Also ensure that engine movement will not stress the tubing

or fittings.

Use tie wraps to help route tubing and to ensure it doesn't contact

moving or hot parts in the engine compartment. Have tubing connect to

quick connect fittings at shallow angles. Having an immediate sharp

bend may unseat the tubing from the internal o-ring and create a leak.

Continual insertion and removal from quick connect fittings will mar the

end of the tubing. Over time the internal gripping teeth may lose their

hold of the tubing which may create a leak. If this occurs simply remove

the tubing and make a fresh cut using a razor blade.

Installation – Electrical

Variable Controller Installation

© 2010, Snow Performance, Inc

For best performance, cooling and s stem life it is recommend that

Snow Performance Boost Juice™, part #40008, be the exclusive

fluid used in the s stem.

© 2010, Snow Performance, Inc

• The Pump should be off at this point. Start the vehicle and apply

pressure to the boost line with a hand pump. A few psig will be

sufficient to start injection. The controller should display an injection

% and a boost reading should also be visible (if you are in the proper

display screen).

• Ensure that the Blue leads are connected to a fuel injector harness.

Unit will show a PW value and also an injection % if you are in the

correct display mode with the vehicle idling. If no PW or injection is

indicated, check the connections to the fuel injector harness.

Tuning Quick Reference

The power potential of the s stem is realized through increased

boost and/or timing. The large gains on octane and cooling

provided b the s stem make this possible, even on standard pump

fuel.

The Boost Cooler® adds an alternate fuel source as well as

significantl cools combustion. With the Boost Cooler®, one does

not need to cool combustion with overl rich air/fuel ratios. To

minimize combustion quench, ou should start with an air to fuel

ratio of 12.0-12.5:1.

Injecting water/methanol lower than 3300-3500 RPM could result in

combustion quench. All vehicles are different. If the engine bogs or

loses power, then it is coming on too earl , the quantit is too

much, or there is not enough methanol in the mixture (50/50

water/methanol recommended).

Caution******

Prolonged quench ma cause lower engine damage over a period of

time.

Maintenance –

Remove nozzle(s) and clean screen filters at

least once per ear using carb cleaner.

The Boost Cooler® has been designed to operate with high

concentrations of methanol. Oil or other additives are not required

for s stem lubrication.

© 2010, Snow Performance, Inc

The Stage 3 controller has an integrated wiring harness for ease of

install and a clean appearance. Refer to the main wiring diagram and

listing below for installation.

CAUTION: Disconnect the negative batter terminal while

connecting wires to prevent electrical fire or damage to controller.

• Connect BLACK wire to a good ground location.

• Tie GREEN wire out of the way.

• Connect RED wire to a 12 volt key on source.

• Connect the two BLUE wires to the two wires leading to a fuel

injector using the provided wire splices. Any injector will suffice, so

choose one that is easy to access. Note: Do not solder electrical

connections to the fuel injector. Use provided wire splices.

• Connect the clear tubing to the black silicone line. This line can be

‘T’ed into any accurate manifold boost pressure source. A boost

gauge line that is tapped into the intake manifold is ideal. In naturally

aspirated applications, this can simply be tied out of the way.

• Connect the WHITE wire to the red power wire of the pump. The

BLACK wire on the pump goes to a good chassis ground.

Alwa s have a good electrical ground connection.

Poor ground will result in erratic operation of

controller and/or damage to the controller. Make

sure boost connection is POST throttle bod .

Tuning the Stage 3 System

The Stage 3 system allows for a large range of tuning on any E I or

forced induction Mustang. It can reference fuel injector pulse-width,

boost, or both simultaneously. The boost and E I data are displayed on

the LCD screen, along with the systems output as a percentage of pump

capability.

All functions of the controller are accessed using the two push buttons to

the left and right of the LCD screen. Pressing button 1 will scroll between

© 2010, Snow Performance, Inc

screens, while pressing button 2 will affect whatever setting is on the

screen.

Displa and Control Screens:

Screen 1

This is a display only screen. It displays boost, fuel injector pulse-width

(PW), and water/methanol injection as independent bar graphs.

Screen 2

This display screen shows boost in psi and injector pulse-width (PW) as

a percentage. 100% pulse-width indicated 100% injector duty cycle and

a fuel system injecting as much as possible

Screen 3

This screen displays boost in psi, while pulse-width (PW) and injection

are shown as a percentage.

Screen 4

This screen displays boost in psi and pulse-width (PW) as a percentage.

Screen 5

This is the first setup screen. It allows you to select BOOST, E I, or

BOTH, using button number two. If BOOST is selected, then boost alone

will determine the injection volume from the nozzle. If E I is selected,

then fuel injector pulse-width (PW) alone will determine injection volume.

If BOTH is selected then both inputs will be used simultaneously to

control injection.

Screen 6A

E I START INCREASE

This screen sets the injector PW point when injection will start through

the nozzle. Typical start points are in the 35% range.

B P

INJ

Boost PSI

EFI Pulse %

PSI %PW

% Injection

PSI

PW

Control = Both

Change

------------

EFI Start%

Increase--------------

© 2010, Snow Performance, Inc

• ill reservoir with water approx ¼ full.

• Remove tubing from nozzle (or solenoid if solenoid used in-line

between pump and nozzle) and run tube into separate container.

• Apply 12 VDC to red pump wire for approximately 5 seconds or

until fluid flow is consistent.

• Pump is now primed. Reconnect tubing from pump outlet to

nozzle (or solenoid).

If using a check valve in between the pump and the reservoir:

Remove the check valve and place a solid piece of tube between the

pump and the reservoir and prime the system. Then replace the check

valve in between the pump and reservoir.

Step 1 Test Pump and Mechanical System

Disconnect all control and SafeInjection® modules. Disconnect tube from

the outlet port of the pump. Using a 12 volt source, apply power to red

wire of pump. Pump should activate and fluid level in tank should go

down. It is recommended to also check the nozzle spray pattern while

following this procedure. Also check for leaks. Do not pump fluid through

a SafeInjection® module without all nozzles connected. This can

overflow the unit and cause damage.

If pump goes on and fluid level doesn't go down, there is an obstruction

in the tube or nozzle. Activation of the pump in 1-5 second intervals will

purge air from the system after installation. This can be accomplished

during initial use.

Step 2 Test Controller

• Turn ignition key on so that the system has 12volt power. If the

pump runs, inspect ground wires for secure connection and repair as

needed.

• Set the controller to inject at 1 psig of boost, and to start injection at

1% PW.

© 2010, Snow Performance, Inc

Boost Start: 4 psig

Boost ull: 15 psig

E I Start: 25%

E I ull: 65%

PW/BOOST 65/35

Under moderately heavy throttle, boost will trigger a small amount of

injection for cooling and efficiency. As more boost builds under higher

throttle positions, the system will add more injection. In the event that

boost reaches higher levels (such as in a race or in a WOT situation on

the street) the system will inject very aggressively for maximum octane

gain and cooling. But because E I data will provide a more gradual

injection curve (boost comes on instantly) the E I values are weighted

more heavily. This makes for a more progressive curve.

Note that in all of the above examples, all of the data needed in terms of

PW and boost can be obtained through the controller display itself.

Simply driving under cruising conditions and trying various levels of

throttle and boost will allow the user to determine good set points for

injection.

Other controller features:

The controller can be put into a “read-only mode” for the purpose of

viewing boost and E I data without injection. To toggle this mode on and

off, press and hold button 2 in any display screen. While holding button 2

down, press and hold button 1. After 1 second, release both buttons. The

controller will give no indication that it is in read only mode except for the

fact that it will not inject under any circumstances.

The controller also has the abilit to be programmed and displa

data in standard or metric units. Holding down button two while

powering up the unit will trigger metric units. Pressing and holding

button one as power is first applied will select standard units.

Testing the S stem

Note: for best results, prime pump before use

To clear air from the pump and insure that the system is primed:

© 2010, Snow Performance, Inc

Screen 6B

E I START DECREASE

This screen sets the injector PW when injection will start through the

nozzle.

Screen 6C

E I ULL INCREASE

This screen sets the fuel injector PW full point when maximum injection

through the nozzle will be reached. Typical E I full points are 60-80%.

Screen 6D

E I ULL DECREASE

This screen sets the fuel injector PW full point when maximum injection

through the nozzle will be reached.

Screen 7A

BOOST START INCREASE

This screen sets the boost pressure required to start injection through

the nozzle. This should be set at a boost that just above normal driving. If

you hit 5 psig leaving a stop light normally, set this to 7 psig.

Screen 7B

BOOST START DECREASE

This screen sets the boost required to start injection.

Screen 7C

BOOST ULL INCREASE

This screen sets the boost full point when maximum injection through the

nozzle will be reached. In most applications, this should be set at a boost

achieved at WOT in hard driving.

EFI Start%

Decrease

--

----------

-

EFI Full%

Increase

--

----------

EFI Full%

Decrease-------------

Boost Start

Increase

---------

Boost Start

Decrease-------------

Boost Full

Increase

--------------

© 2010, Snow Performance, Inc

Screen 7D

BOOST ULL DECREASE

This screen sets the boost full point when maximum injection through the

nozzle will be reached.

Screen 8A

PW/BOOST CONTROL INC

This screen adjusts the balance between boost and PW based injection.

Pressing button 2 will increase the PW importance and decrease the

boost importance by 1%. If it is set at 50/50, then PW and boost are

weighted equally to determine how much to inject at any given time. The

weighting can be adjusted in 1% increments. 50/50 is often a good

starting point.

Screen 8B

PW/BOOST CONTROL DEC

This screen will decrease the importance of PW while increasing the

importance of boost in 1% increments as you press button 2. Decreasing

the weight of boost is useful for quick spooling turbos or positive

displacement superchargers in E I applications. (See Screen 8A)

Screen 9

POWER MODE

Set this screen to Boost

Screen 10A/B/C/D

POWER set points

Set all POWER MODE points to 100. This mode is not used on a 20100

system and should be set such that POWER mode is not engaged.

20100 systems use the primary settings to control all injection.

Tuning Examples:

The following are some guidelines for common applications of the Stage

3 system on Mustangs. They are not meant to be strict rules. Each

application is different and will work best with different settings.

Naturall Aspirated EFI Mustang:

Boost Full

Decrease-------------

PW/Boost Control

5 /5 Inc-------

PW/Boost Control

5 /5

Dec

------

Power Mode Boost

Change

---------

Power Start 1

Increase

--------

---

© 2010, Snow Performance, Inc

Control injection through the E I function. This application idles at about

3% PW, cruises on level ground at 65 MPH at 15% PW, and will climb to

70% PW at WOT and peak RPMs:

Injection Mode: E I

E I Start: 20%

E I ull: 60%

Anytime any moderate throttle is applied, the system provides a small

amount of injection. As more throttle is applied and PW increases, the

system provides progressively more injection.

Moderate Boost EFI Application:

This car makes a peak boost of 12 psig with a Procharger, and at idle

has 5% PW, 65 MPH cruise is about 18%PW, and at WOT and peak

RPMs 85% PW:

Injection Modes: ‘BOTH’

E I Start: 40%

E I ull: 60%

Boost Start: 3 psig

Boost ull: 11psig

PW/BOOST 50/50

Here we are using both boost and PW to control injection. Procharger’s

have a smooth boost ramp that makes for a progressive injection curve.

So we weight boost and E I equally on screen 8. As boost and E I PW

go above normal cruising conditions, we get a small amount of injection.

In the event that high levels of throttle are used and boost goes to 9PSI,

the system will inject at full capacity.

Positive Displacement Blower Application:

This is a Whipple blower making about 15 psig. The blower makes

around 3 psig even in moderate throttle situations, and can hit 15 psig

almost instantly.

Injection Mode: ‘Both’

Other Snow Performance Other manuals

Popular Other manuals by other brands

AutoAqua

AutoAqua Smart AWC touch SAWC-200P manual

AquaCare

AquaCare TKF Series instruction manual

Aodyo Instruments

Aodyo Instruments Sylphyo Link user guide

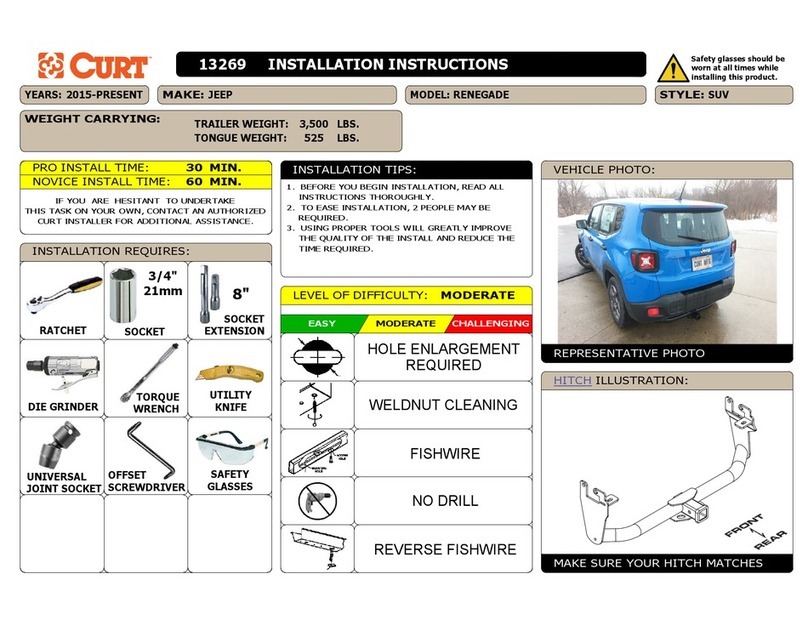

Curt Manufacturing

Curt Manufacturing 13269 installation instructions

F-SECURE

F-SECURE MOBILE SECURITY - QUICK GUIDE FOR BUSINESS Getting started

Arcam

Arcam ALPHA ONE manual