Snow Switch GF PRO User manual

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

This manual refers to the Snow Switch® Model GF Pro control panel

manufactured since October 31, 2013, which uses a universal (100 –

277 VAC; 50/60 Hz) power supply. Older units use a voltage-specic

power supply and have different wiring congurations.

TABLE OF CONTENTS

Safety Information and Warnings................................................................3

Product Testing Record.................................................................................2

Unpacking the Unit........................................................................................3

Inventory.........................................................................................................4

Product Description ......................................................................................5

Selecting the Proper Sensor ........................................................................5

Available Optional Components.................................................................5

Installing the Control.....................................................................................6

Preparation and System Set-Up...................................................................8

System Schematic Diagrams........................................................................9

Post-Installation Testing ..............................................................................12

Operation .....................................................................................................14

Optional Remote Control Operation........................................................17

Maintenance.................................................................................................17

Troubleshooting ..........................................................................................18

Heater Connection ......................................................................................24

Specications ...............................................................................................25

Ordering Information..................................................................................26

MODEL GF PRO

AUTOMATIC SNOW/ICE MELTING SYSTEM CONTROL PANEL

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

2

SAFETY INFORMATION AND WARNINGS

Pilot Duty

The GF Pro snow and ice control cannot be used

for Pilot Duty applications.

Resistive Load Usage Only

This product is not for use with Inductive loads.

Inductive loads may create nuisance tripping of

the Ground Fault Protection Circuit.

Abnormal Odor or Smoke

In the event of smoke or a burning or abnormal

odor, immediately interrupt power to the unit by

turning off the circuit breaker protecting the unit.

Electrical Shock / Fire Hazard

Even when the heat tapes are disconnected, as

long as the circuit breaker is on and power is

running to the unit, voltage is still being applied

to the yellow heat tape leads. Therefore, never

touch the ends of the yellow leads or let the

two leads touch each other. Do not let the two

yellow heat tape leads contact any component

inside the unit.

Any installation involving electric heater wiring must

be grounded to earth to protect against shock and re

hazard. Suitable ground fault detection and interrupting

systems must be in use at all times to reduce shock and

re hazard and to protect equipment.

Electric wiring to heating elements must be installed

in accordance with National Electrical Code (NEC)

requirements, as well as all other local and applicable

electrical codes and any third party standards. Follow the

installation instructions contained in this manual and also

those provided by the heater manufacturer.

Size the circuit breaker in accordance with the size of the

expected load. The maximum current load for the GF

Pro is 30 Amp resistive. This product is intended for use

in residential or light commercial applications. For larger

or more critical installations, the “APS” Series of control

panels from ETI, provides a cost-effective solution offering

enhanced system design and performance features.

Make certain that the heater shield is properly grounded.

Failure to do so may result in damage to equipment or re.

Following installation and prior to beginning system

operation, refer to and perform the Post-Installation Tests

described in this manual.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

3

PRODUCT TESTING RECORD

Use this page to record the results of the testing procedures in this manual. Specically, these are a

mega-ohm test following installation of the heat tape, a post-installation test of the control box, and

a post-installation test of the system sensor(s). This record will be a useful resource throughout the

life of the product.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

4

UNPACKING THE UNIT

Immediately upon receipt, inspect the container and

packing material for any noticeable damage. Unpack the

unit, taking care not to damage the packing materials.

Save the shipping container and related materials until

normal operation has been established. If the unit must

be returned, take care to ensure that it is repackaged as it

was received.

As soon as the unit arrives at your facility, inspect it for

mechanical damage. If any of the following problems is

found, contact ETI, Customer Service immediately:

• contents incomplete or incorrect;

• internal or external mechanical damage; or

• defective operation.

ETI Customer Service is available between 8:00 a.m. and

5:00 p.m. Eastern Time. In the event of shipping damage,

keep the packing materials for inspection by the carrier.

RETURNS AND REPLACEMENT PART PURCHASES

Equipment cannot be returned for credit once it has

been installed. ETI will repair or replace faulty equipment

under warranty. Prior to removal of equipment for

warranty return, please contact ETI Technical Support for

troubleshooting assistance.

Before returning a unit to ETI, obtain a Return Merchandise

Authorization from our Customer Service Department,

available between 8:00 a.m. and 5:00 p.m. Eastern Time. If

possible, use the original container and packing materials

when packing the unit for shipment. It is important to

mark the Return Merchandise Authorization clearly

on the outside of the shipping container so that it may

be correctly processed upon receipt at Environmental

Technology. For more information about replacement

parts or for a replacement Data Sheet or Manual, please

visit www.networketi.com.

INVENTORY

Using the information below, verify that the shipping

packagecontainsallof thepartslisted.NotifyETI,Customer

Service immediately if there are any discrepancies. ETI

Customer Service is available between the hours of 8:00

a.m. and 5:00 p.m. Eastern Time.

Product # Description

1 GF Pro

PN: 23917

2 Accessory Kit

PN: 23731

3 GF Pro Installation Sheet

PN: 24454

4 GF Pro Intallation/Operation Manual

PN: 23918

Depending on the specics of your order, there will

also be up to two sensors included with the system, as

well. These will be either the CIT–1 aerial-mount sensor,

the GIT–1 gutter ice sensor, or the SIT–6E pavement-

mount sensor.

PRODUCT DESCRIPTION

The Snow Switch model GF Pro snow and ice control

with ground fault, when used with up to two compatible

sensors, automatically controls snow and ice melting

heaters for minimal energy costs. Applications include

pavement, sidewalk, loading dock, roof, gutter, and down

spout snow/ice melting in commercial and residential

environments. The GF Pro control can be powered from

an automatically selected operating voltage from 100

VAC up to 277 VAC and is rated for 30 amps resistive load.

An integral 30mA of GFEP provides additional safety and

compliance with national and local electrical codes.

The GF Pro control is housed in an environmentally-

sheltered IP 66, NEMA 4X weather-resistant enclosure to

provide several installation options.

Features and Benets

• Compatible with standard CIT–1, GIT–1, and SIT–6E

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

5

sensors

• Two sensor input to allow for application specic

sensor combination such as:

1. A CIT–1 aerial sensor and a GIT–1 gutter sensor

for roof and gutter deicing

2. A CIT–1 aerial sensor and SIT–6E pavement-

mounted sensor for snow melting

• Adjustable 0 – 8 hour hold-on time

• Integral 30 mA of GFEP with manual and automatic

test features

• Compatible with the RCU–4 remote control

• Durable IP66, NEMA 4X enclosure

• UL Listed to UL 873 Temperature-Indicating and

-Regulating Equipment

• UL Listed to UL 1053 Ground-Fault Sensing and

Relaying Equipment

SELECTING THE PROPER SENSOR

The Snow Switch model GF Pro snow and ice control

is designed for use with up to two compatible sensors.

Compatible sensors include the CIT–1, GIT–1, and SIT–

6E snow and ice melting sensors. These sensors have

provided the industry’s most versatile and cost effective

snow melting control when used with Environmental

Technology control panels. Sensors should be selected

to best suit the intended application.

The CIT–1, GIT–1, and SIT–6E snow and ice melting

sensors combine to reliably detect snow and ice in gutter

and pavement applications. The CIT–1 sensor may be

paired with either the GIT–1 sensor for gutter applications

or the SIT–6E sensor for pavement applications. These

sensors detect precipitation as snow at temperatures

below 38°F (3.3°C). Control panels are signaled only if

moisture occurs below this temperature, saving energy

and ensuring reliable melting.

(Table 1) presents the recommended sensor combinations

for use

with the GF Pro snow and ice control.

One or two CIT–1 Sensors

One GIT–1 Sensor

One GIT–1 and one CIT–1 Sensor

One SIT–6E Sensor and one CIT–1 Sensor

For more complete information regarding the sensors

and their individual capabilities, refer to the Products link

on the ETI website, www.networketi.com.

AVAILABLE OPTIONAL COMPONENTS

Prior to installation and set-up, it is rst useful to discuss

two important optional components available for the

Snow Switch GF Pro system. The rst of these optional

components is a Remote Control Unit, RCU–4 (Part

Number 21358), which allows remote operation of the

system away from the control box. The second optional

component is a Temperature Sensor Assembly (Part

Number 19272) which regulates the heating cycle to make

it more efcient. Neither of these optional components

comes with the basic system so either or both of them

must be ordered separately and installed along with the

system, not only to facilitate their installation but also to

optimize their performance.

With the Remote Control Unit, RCU–4, the operator is able

to access the full range of system functions and controls

from a second location. With the RCU–4, the operator can

manually set the Cycle Time, equivalent to the Hold-On

Time setting on the face of the unit itself; manually initiate

or terminate a heating cycle; and test and reset the GFCI

circuitry. The capability for remote operation is especially

useful if the control box is installed either outside or in

TABLE 1. Recommended Sensor Combinations

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

6

a location of the building not easily or readily accessible

by ofce personnel who may well be in a better location

than building maintenance personnel to assess the need

to melt ice or snow from walkways or parking areas.

Also available for the GF Pro system is an optional

temperature sensor assembly which senses the

temperature at the cable end and regulates the Hold-On

Time period once precipitation has ended and the call

for heat has passed. Installed with the cable end placed

at or near the heat tape, the optional temperature sensor

assembly or thermistor is a high-temperature shut-off

and regulates the Hold-On Time period by automatically

suspending an active heating cycle if at any time during

that cycle, the temperature at the sensor end rises to

above 45°F. Then, if, during the Hold-On Time period, the

temperature drops to below 44°F, the heating cycle will

resume automatically and continue until the end of the

Hold-On Time period as set on the face of the unit. This

not only lowers system operating costs but also protects

the heat tape from over-heating.

As the placement of the RCU–4 remote control unit

is a key factor in the overall conguration of, as well

as customer satisfaction with, the GF Pro system, it is

important that it be installed as part of the system initially.

Similarly, as the temperature sensor assembly monitors

the temperature at the point of the cable end to keep the

heat tape from over-heating, so it is necessary, for best

results, to lay the temperature sensor at the same time as

the heat tape to ensure proper placement and routing.

It is not recommended to try and retrot either of these

optional assemblies once the system is already installed

and operational.

To ensure proper installation and to facilitate placement,

wiring, routing, and function of either or both the optional

RCU–4 or temperature sensor, it is strongly advised and

suggested that these assemblies, whether together or

individually, be installed with the system initially rather than

retrotted afterwards. Use the information below to order

either or both of these important optional components.

Order # Description

21358 Optional Remote Control Unit RCU–4

19272 Optional Temperature Sensor Assembly

To order either or both of these optional components for

your system, contact the ETI Sales Department between

the hours of 8:00 a.m. and 5:00 p.m. Eastern Time.

INSTALLING THE CONTROL

Install this unit in compliance with National Electrical Code

(NEC) standards, as well as all other local and applicable

electricalcodesforyourarea.Priortobeginninginstallation,

make sure that the facility has properly sized electric

service and breaker. For additional information regarding

electrical ratings and facility power requirements, refer to

the Specications section of this manual.

This unit is intended for wall mount installation only.

The wall used for the installation should be capable of

supporting four times the weight of the unit, or about 20

pounds. Although the IP 66, NEMA 4X weather-resistant

enclosure can be installed outside, make sure to install the

unit directly to a solid, stable surface. Before connecting

any optional remote control unit or system sensor(s),

as applicable, to the terminal block inside the unit, rst

install the box itself. Internal connections for any optional

remote control unit or system sensor(s) will be made in

the next section.

During installation, leave all mounting hardware loose enough to allow for slight adjustments to component

placement. Once all components and the front panel and clear plastic cover have been installed, then, as

the nal step in installation, fully tighten all mounting hardware and weather-tight ttings. Make sure all

connections and ttings are snug, air-tight, and water-tight.

NOTE:

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

7

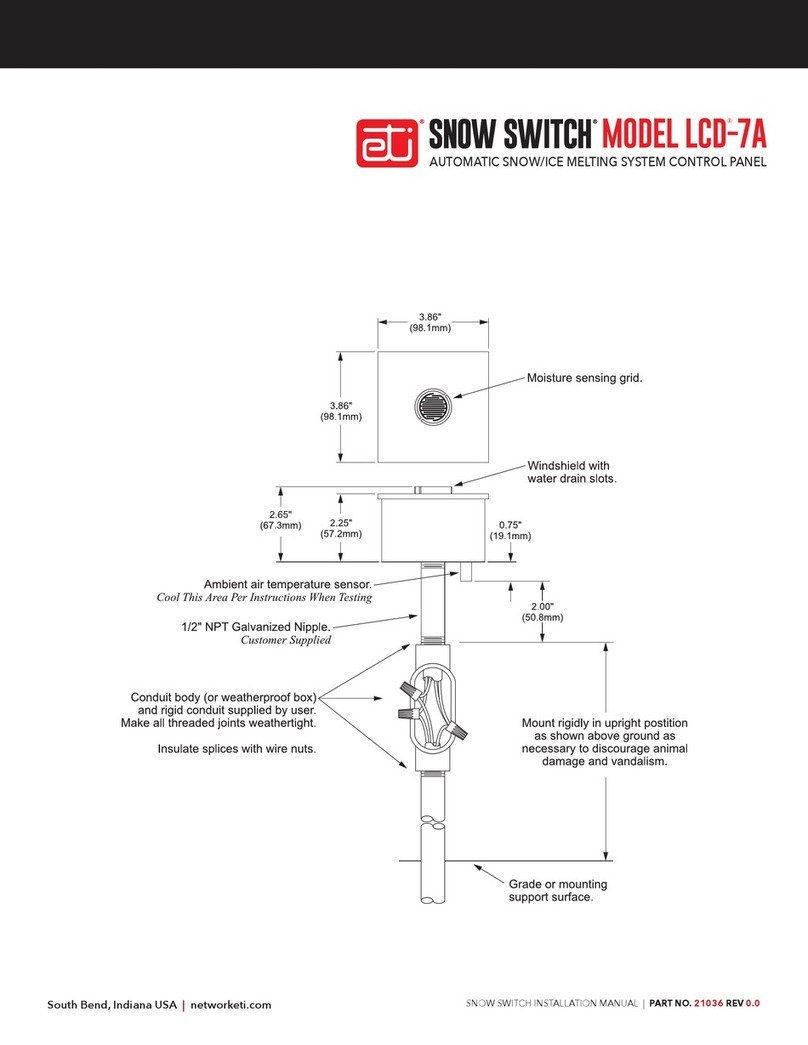

The dimensions shown in the Top View of Figure 1 below are for the mounting hole location footprint

and run from centerline to centerline of the four slotted mounting holes. The dimension shown in the

Right Side View of Figure 1 is from the bottom of the enclosure to the top of the clear plastic lid and

shows the distance that the unit will protrude from the mounting surface.

FIGURE 1. GF PRO Mounting Hole Footprint

To install the control box, perform the steps below.

1. Use the box as a template to determine the mounting

hole footprint pattern. Hold the unit up against the

wall onto which it will be mounted, with the mounting

blocks against the wall, then mark the wall at the

locations of the slotted mounting holes to determine

the location of the mounting holes on the wall.

2. As desired, to hold the box in place during the

installation process, you may loosely install one or

both of the top mounting bolts as the remaining holes

are marked. To ensure accurate and level installation,

however, do not fully tighten any of the mounting

hardware until the locations for all the mounting holes

have been determined and marked.

3. Once the four mounting holes have been located and

marked, install the box to the wall using properly sized

mountinghardware.Besuretouse mounting hardware

appropriate for the job, heavy-duty and long enough

to fasten the unit securely to the mounting surface.

Make sure to use all four mounting holes. Because

conduit will also be installed to protect the cables

running from the control box, install the box, but leave

the mounting hardware loose enough to work the

conduit into place. The conduit will be installed later

in this process, at which time all mounting hardware

will be securely tightened.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

8

PREPARATION AND SYSTEM SET-UP

Install the conduit, system sensor(s) and cables, heater

cables, and power cable. Refer to Figures 2 and 3, as

well as Table 2. Remove the clear plastic unit cover and

face plate to access the inside of the unit. These will be

replaced at the end of the installation process. A post-

installation test will be performed in the next section to

verify proper function.

Installing the Conduit

Only UL listed, Type 4X,raintight conduit hubs and cable

glands are to be used. The hub is to be connected to

the conduit of a rigid conduit system before the hub is

connectedtotheenclosure.Select,measure,cut,andinstall

the conduit in accordance with all National Electrical Code

(NEC) requirements, all local and applicable building and

electrical codes, as well as the manufacturer’s instructions.

Ensure a sealed, watertight installation.

Installing the Sensor(s)

Refer to the enclosed Installation Sheet(s) and Instruction

Manual(s)forsensorinstallationandoperatinginstructions.

Installing the Sensor Cables

Route the sensor cables through the weather-tight

connection ports on the right side of the unit, as shown

in Figure 2, then connect the red, black, and white leads

to the front panel PC board terminal block J1 terminals.

If using two sensors in the system, even if they are of the

same type, it does not matter which one is wired into which

set of terminal blocks, upper or lower. After connecting

the red, black, and white leads, push a little more of the

cable into the connection port to create a little more

slack to relieve some of the tension from the wires at the

point of the terminal strip, then fully tighten the weather-

tight connection to secure the cable in place. If installing

an extension onto the sensor cable(s), a junction box is

required in accordance with applicable code.

Installing the Heater Cables

Lay-out, congure, and install the system heater cables

in accordance with National Electrical Code (NEC) and

manufacturers’ requirements, as well as all other local and

applicable building and electrical codes. Make sure to

properly seal and waterproof all cable runs. If using a SIT–

6E pavement-mount sensor, position the heater cabling

so it does not interfere with the sensor wiring.

Upon conclusion of heater cable installation, perform

a mega-ohm or “megger” test on the heater cables as

directed by the heater cable manufacturer. Record the

results on page 2 of this manual and retain for future

reference.

Installing the Optional Components

Route the remote control (RCU–4) cables through the

conduit then into the enclosure. Connect the remote

cables to the front panel PC board terminal block J1

terminals labeled REMOTE.

Route the optional temperature sensor assembly wiring

through the same conduit as the RCU–4 cable then into

the enclosure. Connect the temperature sensor assembly

cables to the front panel PC board terminal block J1

terminals labeled AUX.

Installing the Power Cable

With the circuit breaker off, install the power cable. As

shown in the wiring charts, the power cable is provided

by the customer. Size the cable for a 30 Amp maximum

load. Run the cable through conduit and connect the

leads to the control box wiring. The line is black, neutral is

white, and ground is green. The unit has no power switch

so remember that power is running to the system as soon

as power is applied.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

9

SYSTEM SCHEMATIC DIAGRAMS

Figure 2 is a schematic diagram of an entire GF Pro system,

including the available optional components.

TABLE 2. Cable Ratings and Connections

FIGURE 2. Representative GF PRO System Schematic

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

10

A representative schematic diagram of an SIT–6E pavement sensor installation is shown

below in Figure 3. Note how the heat tape and other components do not cross.

FIGURE 3. Representative SIT–6E Pavement Installation

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

11

FIGURE 4. The GF PRO Front Panel PC Board

Refer to Figure 4 for useful information regarding the front panel PC board.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

12

POST-INSTALLATION TESTING

Installation errors cause the majority of system problems.

Therefore, thoroughly check the system before placing it

into service. Simple electrical tests and visual inspection

can identify any wiring errors, as well as improper

waterproong. Visually inspect for proper wiring and

waterproong, making sure that all box joints are sealed

and that all wiring is properly terminated.

In performing the post-installation test procedure as

described below, the heat tape will activate, even if

only for a brief time, so that system performance can be

accurately simulated and measured. For that reason, and

depending specically on the ambient temperature or

general conditions in which the system is being installed,

it is recommended to continuously and carefully monitor

the system and its components during the entire testing

process. High temperatures can cause damage to asphalt

and similar paving materials. Never leave the site during

testing. Never leave the system unattended during

testing. If re or smoke or an abnormal odor is observed

during testing, shut off power to the system and suspend

the test.

To most accurately simulate and measure system

performance, leave the heat tape connected to the

control during testing and use a clamp-on amp meter

as directed in this procedure. Using the clamp-on amp

meter clamped around the wires prevents the operator

from having to touch bare or exposed metal or wiring and

also keeps the operator from having to break the circuit,

all while still allowing the accurate simulation and testing

of the system, including the Ground Fault Equipment

Protection circuitry, if your system is so equipped.

It is the responsibility of the on-site installer to assess

the overall safety concerns at the site and to disconnect

the heat tape, as necessary or desired, whether before

or during this test, as well as to re-establish those wiring

connections at the conclusion of this procedure.

This procedure requires a clamp-on amp meter or

voltmeter. Make sure the gutter and downspout are both

dry before testing the GIT–1 sensor. Record test results

in the appropriate section on page 2 of this manual for

future reference.

CONTROL TESTING

1. Remove system power. There may be two or more

points of disconnect.

2. Open the clear plastic cover and remove faceplate

from the unit. Retain all parts and mounting hardware.

If the heaters have been disconnected for testing,

using a voltmeter, measure the voltage across the two

yellow leads. If the heaters have not been removed

tor testing, using a clamp-on amp meter, measure the

current through the yellow lead.

3. Restore power to the unit. After a brief initialization

routine, the SUPPLY LED should be on, but no other

LEDs. Once initialization is complete, the amp meter

should read 0.

4. With power still running to the unit, turn up the Hold-

On Time dial to a setting higher than 0, then press the

Heater Cycle button. The HEAT LED should come on

and the amp meter should show a reading of less than

the maximum system load as shown on the faceplate.

The voltage across the yellow leads will match the

system voltage. Do not touch the yellow lead ends.

5. Press the Heater Cycle button again. The HEAT LED

will go off and the amp meter reading should drop

back to 0 or the voltage will drop to 0.

Even when the heat tapes are disconnected, as

long as the circuit breaker is on and power is

running to the unit, voltage is still being applied

to the yellow heat tape leads. Therefore, never

touch the ends of the yellow leads or let the

two leads touch each other. Do not let the two

yellow heat tape leads contact any component

inside the unit.

WARNING

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

13

6. Now, press the GFEP Test/Reset button on the unit

face plate. The GFEP LED should ash, during which

time you should hearing some clicking sounds

from the relays inside the unit, and the amp meter

reading should again read 0 after the GFEP self-test

is complete. Record results on page 3 of this manual.

Remove the amp meter or voltmeter. Do not yet re-

install the unit front plastic cover or face plate.

7. Proceed to sensor testing below.

CIT–1 AND GIT–1 SENSOR TESTING

The CIT–1 and GIT–1 sensors have two interrelated

systems: the temperature sensing system and the moisture

detection system. Complete testing of the sensor involves

manipulation of both. The tools needed for this procedure

are a voltmeter and an aerosol circuit cooler (“Freeze

Spray” is preferred) or cup of ice water. The Freeze Spray

is available at most electric supply stores.

Ensure that the moisture sensing grid on the sensor is

clean and dry.

Follow the steps below to perform the CIT–1 and GIT–1

sensor post-installation test procedure. The SIT–6E testing

procedure is on the next page.

1. Connect the voltmeter across the black and red leads

from the sensor (low-voltage wiring terminals at the

control). Connect the black test lead to the black wire.

You should obtain a reading of 23 to 28 VDC. Now,

check the reading across the black and white sensor

leads. You should read 22 to 28 VDC with a warm

(above 38°F) and dry sensor. Both the SNOW LED and

HEAT LED should remain off.

2. Cool the temperature probe of the sensor with

the Freeze Spray. You should see frost form on the

temperature probe.Alternately, place the temperature

probe in ice water. The SNOW LED and HEAT LED

should remain off.

3. Using a moist nger, touch the moisture sensing grid

on top of the sensor. Both the SNOW LED and HEAT

LED should come on and the voltage between the white

and black sensor leads should be less than 2 VDC.

4. With the unit cold and the sensing grid moist, allow

the unit to warm up to above 38°F. The SNOW LED

should turn off and the HEAT LED should stay on and

the voltage should return to 22 to 28 VDC. Record

results on page 2 of this manual.

5. If testing a SIT–6E sensor, proceed to the next section

now. If testing is complete, with unit powered off,

restore all wiring connections and re- install the face

plate and clear plastic cover. Set the Hold-On Time

control dial to the desired setting.

SIT–6E SENSOR TESTING

If paving material or other residue adheres to the sensing

elements, clean the surface with a Scotch™ Brite Pad.

Avoid using metallic or coarse abrasives or detergents.

Regardless of weather conditions,the functional operation

of an installed SIT–6E sensor can be determined using a

digital voltmeter (DVM) and a 10-pound (4.54kg) bag of

crushed ice as described below.

1. With the DVM set to the 100 VDC range, verify the

sensor supply voltage by connecting the negative

(–) test lead to the sensor black wire and the positive

(+) test lead to the sensor red wire. A DVM reading

between 23 and 28 VDC is acceptable.

2. With the negative (–) test lead remaining in place,

reconnect the positive (+) test lead to the sensor white

wire and conrm there is 22 to 28 VDC present. Both

the HEAT LED and the SNOW LED should be off.

3. Place the entire contents of the bag of crushed

ice on top of the sensor and allow a time lapse in

excess of 20 minutes before observing that less

than 2 VDC is indicated by the DVM. Depending on

ambient conditions, however, this might take only a

few minutes, in which case, that is not a problem. (A

nominal temperature below 38°F or 3.3°C must be

detected before the sensor’s normally-open contact

is closed. If the sensor surface temperature was

excessive prior to beginning this procedure, it will be

necessary to extend the cool-down time interval by as

much as an additional 20 minutes.) Most importantly,

make sure both the HEAT LED and the SNOW LED

come on. Record results on page 2 of this manual.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

14

4. With satisfactory results, control and sensor pre-

operational testing is now complete. Disconnect and

remove all testing devices from the system.

5. Once all post-installation testing is complete and with

unit power off, restore all wiring connections.

6. Re-install the face plate and clear plastic cover onto

the control. Set the Hold-On Time control dial to the

desired setting.

OPERATION

This section presents operating instructions for the unit

and begins with a picture of the front panel. Refer to

Figure 5. Note the system information on the left side of

the panel, as well as the operator controls and indicators

located on the right side of the panel. The controls and

indicators are explained in this section.

Note that because the unit has no ON/OFF power

switch, power runs to the unit as soon as facility power

is connected to it. For as long as power is running to the

unit, the green SUPPLY LED will always be lit. The unit

initiates a heating cycle when the system sensor(s) detect

snow or ice at or below 38°F (3.3°C).

Upon initial Start-Up, all of the LEDs will come on for 2.5

seconds, and then shut off for 2.5 seconds. Following

this, the unit performs a ground fault self-test which lasts

about two seconds, during which the GFEP LED will blink

rapidly, about 8 times per second. During this phase of

the test, the yellow heat tape leads are live. After this, the

device goes into normal operation.

FIGURE 5. The GF PRO Front Panel

NOTE: Cover screws maximum torque: 4 In-Lbs.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

15

FIGURE 6. The GF PRO Operator Controls and Indicators

SUPPLY The SUPPLY LED lights up and stays lit as long as power is running to the unit,

whether it is currently in a heating cycle or not.

HEAT When the HEAT LED is lit, the unit is currently engaging power to the heater

outputs in response to sensor input. The HEAT LED stays on for the duration of

the heating cycle. As desired, press the Heater Cycle button to stop a current

heating cycle, unless the SNOW LED is lit.

SNOW The SNOW LED lights up when any of the sensors detect snow or ice at or below

38°F (3.3°C) and stays on until the sensors no longer detect snow or ice or the

temperature surpasses 38°F (3.3°C). Note that the Heater Cycle button cannot be

used to cancel a current heating cycle if the SNOW LED is lit.

GFEP If solid, the GFEP LED indicates the presence of a Ground Fault. Press the GFEP

TEST/RESET button to try and clear the situation. If blinking, that indicates that a

ground fault test is currently in progress and it will autom

Operator controls and indicators are explained below. Refer to Figure 6

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

16

SETTING THE HOLD-ON TIME

Heating action begins a few seconds after the system

sensor(s) detect moisture at or below 38°F (3.3°C).

However, heating action continues even after the sensor

no longer detects moisture based on the Hold-On Time

setting. The Hold-On Time control knob allows you to set

the length of time the unit will continue heating even after

the sensor(s) no longer detect moisture. This is benecial

because it typically takes longer for ice to melt than it took

to form initially and also because it keeps moisture from

re-freezing before it has fully melted. As indicated on the

front panel, the Hold-On Time can be set for anywhere

from 0 to 8 hours as indicated by the arrow on the control

knob. Note that if the Hold-On Time control knob is set at

0 (as shown in Figure 6), the system will produce heat only

for as long as the sensor(s) detect moisture but no longer.

For that reason, and to ensure more effective heating, it is

recommended that the Hold-On Time be set up closer to

the mid-way point, corresponding to about 2 to 6 hours.

Set or increase the Hold-On Time as desired by rotating

the control knob to the right or clockwise. Decrease the

Hold-On Time setting by rotating the control knob to the

left or counterclockwise. Again, remember that if the Hold-

On Time control knob is set at 0, the unit will produce heat

only for as long as the system sensor(s) detect moisture

and no longer.

USING THE HEATER CYCLE BUTTON

The Heater Cycle control button allows you to manually

initiate a heating cycle regardless of weather conditions,

whether or not the sensor currently detects moisture, and

regardless of the temperature. The Heater Cycle control

button also allows the operator to cancel a heating

cycle currently in progress, regardless of the Hold-On

Time setting, unless the SNOW LED is on, indicating

the sensor(s) currently detect moisture at or below 38°F

(3.3°C). Remember, if you manually initiate a heating

cycle by pressing the Heater Cycle button, that heating

cycle will last for the duration of the current Hold-On Time

setting, unless manually cancelled by pressing the Heater

Cycle button a second time.

It is not necessary for the Hold-On Time setting on the

control box and the Hold-On Time setting on the RCU

to be identical. Note, however, that if a heating cycle is

manually started by pressing the Heater Cycle button on

the control box, that the resulting heating cycle will last

as long as the Hold-On Time setting on the control box.

Similarly, if a heating cycle is initiated using the RCU, the

resulting heating cycle will last as long as the Hold-On

Time setting on the RCU.

USING THE GFEP TEST/RESET BUTTON

GFEP (Ground Fault Equipment Protection) circuitry is

present inside this unit. The system software checks for

ground fault conditions continuously at set intervals. If the

GFEP LED is lit, press the GFEP Test/Reset button to try

and clear the situation and reset the ground fault circuitry.

The GFEP will perform a test of the ground fault circuitry,

during which time, the GFEP LED will blink. Pressing the

button will not clear a “hard” fault. When the GFEP LED

is lit, the heaters are turned off and will remain off until

the condition is cleared. When the GFEP LED is not lit,

the operator may press the GFEP Test/Reset button, as

desired, to manually initiate a test of the GFEP circuitry.

During the test, the GFEP LED will ash rapidly for a few

seconds while the circuitry rst tests the inside of the unit,

then the system heater coils, and will then shut off.

In the event of a ground fault condition that is not cleared

by pressing the GFEP Test/Reset Button, perform the

steps below.

1. If the GFEP LED on the control box is still lit after

pressing the GFEP Test/Reset Button, remove power

from the unit using the service disconnect or the

circuit breaker.

2. Perform a “megger” test of the heater cables and compare

the results to those obtained during Post-Installation

Testing and recorded on page 2 of this manual.

3. Locate and x the problem, typically found along the

run of the heat tape.

4. Restore system power. Because the presence of a

ground fault condition is stored in memory, even after

repairing the ground fault condition, the GFEP LED

might still be lit following restoration of system power.

In this case, press the GFEP Test/Reset button again

and the LED should go out and normal operations

may resume.

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

17

OPTIONAL REMOTE CONTROL OPERATION

The GF Pro can be operated either “locally” on the face

of the unit itself or by using the optional Remote Control

Unit, RCU–4. Refer to Figure 7.

The RCU Cycle Time control dial moves in discrete

increments rather than in a continuous motion as on the

control box. Cycle Time on the RCU applies only to a

manual heating cycle initiated at the RCU, not the Cycle

Time setting on the control box. The RCU cannot be used

to manually cancel a heating cycle which was manually set

on the control box.

To manually start a heating cycle using the RCU, press

the RCU Heater Cycle control button. The RCU HEAT LED

light will come on. This will start a heating cycle which will

last as long as the RCU Cycle Time setting.

To manually cancel a current heating cycle which was

manually set at the RCU, press the RCU Heater Cycle

button. The RCU HEAT LED light will go out.

To use the RCU to change the duration of a heating

cycle that was manually set on the RCU, turn the RCU

CYCLE TIME control dial to the desired setting, either

higher or lower.

If a ground fault condition occurs, the RCU HEAT LED light

will blink on and off. To test or reset, press the RCU GFEP

Test/Reset button once and release. The GFEP circuitry

will initiate a self-test. During the test of the ground fault

circuitry, the HEAT and SUPPLY LED lights will both ash,

alternating back and forth between them.

If, following the test of the ground fault circuitry, the HEAT

LED still blinks, this indicates the presence of a ground

fault condition which will require repair before system

operations may continue. Refer to Using the GFEP Test/

Reset Button on page 23.

MAINTENANCE

To ensure the best function and results,it is recommended

to always keep the area around the sensors clean from

debris and general obstructions to maximize the ability of

the sensor to do its job. Clean the sensor using a cleansing

pad and water. Keep the gutters clean and the area around

the sensor free of leaves or other debris which could limit

the ability of the sensor to detect the conditions necessary

for optimum system performance. Finally, once monthly,

visually inspect the fuse LED located on the front panel

circuit board to make sure it’s on. If the fuse LED is not on,

change the fuse.

FIGURE 7. Remote Control Unit RCU–4

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

18

TROUBLESHOOTING

If any of the following conditions occurs with the unit, review the Troubleshooting Charts in this section. Prior to removal of

any equipment, contact ETI, Technical Support between 8:00 a.m. and 5:00 p.m., Eastern Time, to begin the troubleshooting

process.

TROUBLESHOOTING FLOWCHART 1

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

19

TROUBLESHOOTING FLOWCHART 2

South Bend, Indiana USA | networketi.com SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 23918 REV B

20

TROUBLESHOOTING FLOWCHART 3

Table of contents

Other Snow Switch Control Panel manuals

Popular Control Panel manuals by other brands

Erreka

Erreka CLEVER01 Installer manual

Nakanishi

Nakanishi E4000-PB Operation manual

Oray

Oray OPTCOMMANDRAD8 quick start guide

NAPCO

NAPCO Magnum Alert 1010LKDL Operating & installation instructions

Belden

Belden Miranda iMC-Panel-100 Operator's guide

FIREtec

FIREtec FTEP SERIES Installation instructions and user guide