Snowex DSM-175 Drop Side Mount

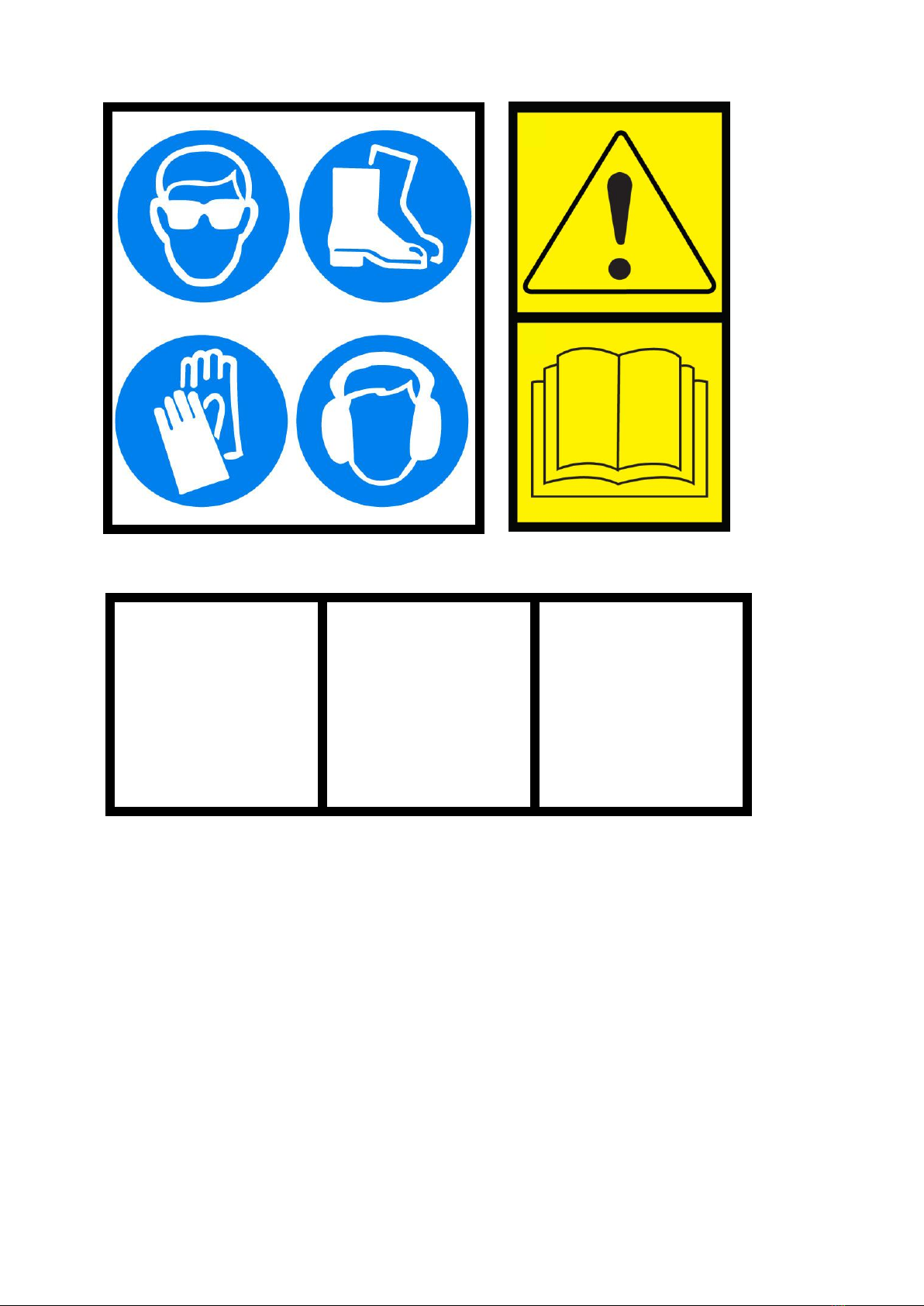

The DSM-175 is resigned for use with the Snowex SP-1875 only. The hitch is multi adjustable and designed for

the use with drop sided commercial vehicles fitted with a 50mm towing ball. The DSM-175 should not be used

with ‘Flare side’ pick ups or vehicles that are considered too fragile or easily damaged by the use of the mount.

the drop side of the vehicle intended for use must be made from steel or se a strong alloy design.

No claim will be upheld by the manufacturer for damage to vehicles or paint finish how ever caused relating to

part fitment or unsuitable vehicle choice or pairing in relation to use of the DSM-175.

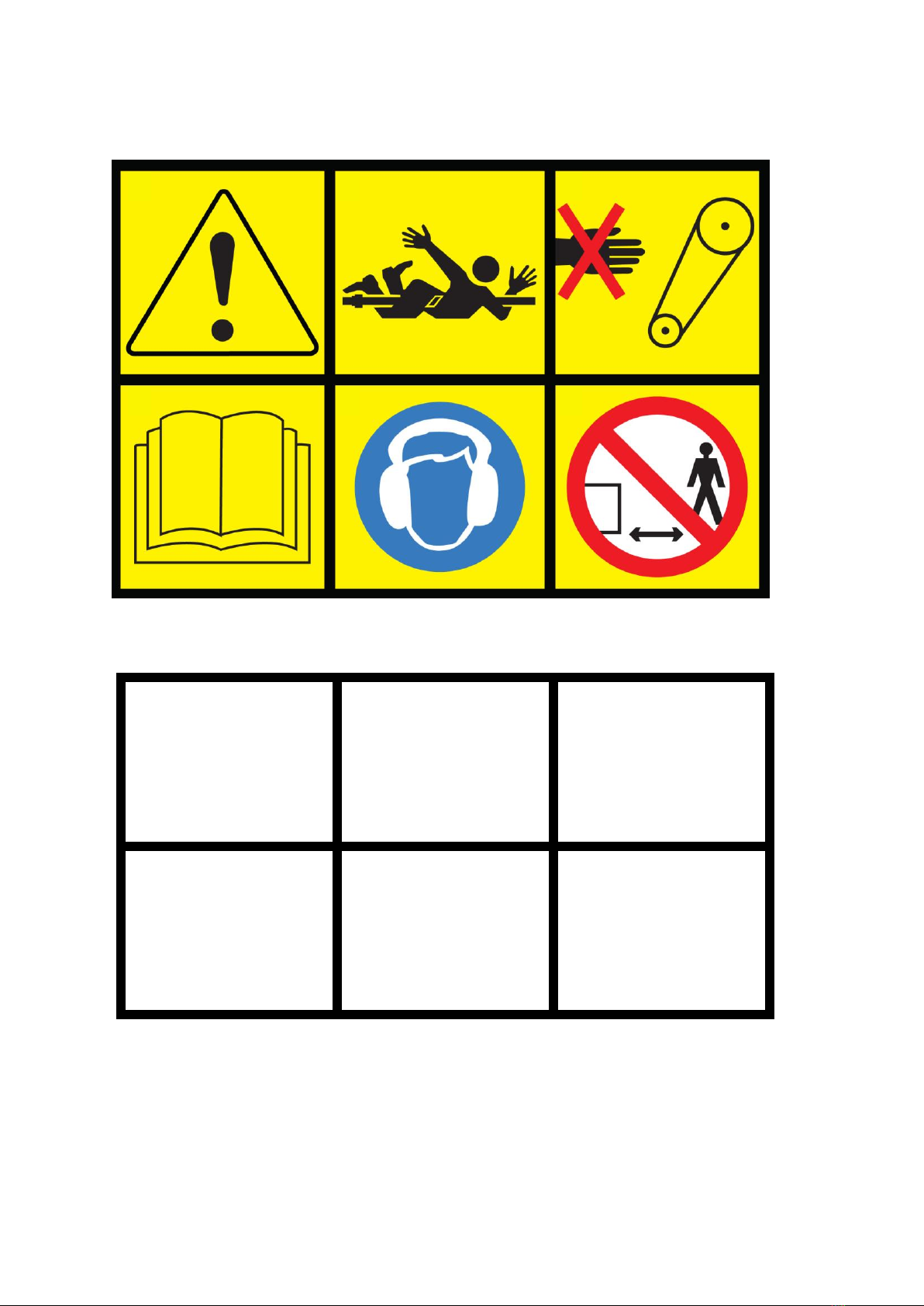

Road speed must not exceed 15mph when carrying spreading material in the spreader hopper. Care should be

taken when speading or when travelling over speed bumps, curbs or other traffic calming devices. Particularly

when spreading material is being carried in the spreader hopper, do not exceed 2 mph.when crossing such

devices

Weight on the DSM-175 should not exceed 335kgs.

Before operating or travelling with a DSM-175 mounted on your vehicle, ensure that it is correctly adjusted to

suit your vehicle and that all bolts and straps are tight. Ensure that the vehicle lights and number plate are not

obscured, suplimentary lights and number plate may be required.