Sofraser MIVI 9610 User manual

Quality System certified

instruments

9612 Version

Technical Manual

MIVI 9610

Réf : 254-31/0

Technical Manual MIVI 9612

Réf. 254-31/0 2

IMPORTANT

BEFORE STARTING THE PROCESS, IT IS VERY

IMPORTANT TO PROCEED TO THE OFFSET

ADJUSTMENT IN AIR:

The procedure of the offset adjustment is detailed in the user manual

§ 5.1:

1.

CLEAN AND DRY THE SENSOR ROD.

2.

BE SURE THE PROCESS IS EMPTY. THE ROD MUST VIBRATE IN AIR.

3.

INSTALL THE SENSOR ON THE PROCESS AND FIX IT WITH ITS 4 SCREWS.

4. REACH THE OFFSET ADJUSTMENT FUNCTION STARTING FROM THE

BLOCK “SETTINGS” AND WITH THE SECURITY CODE 2.

5. FOLLOW THE INSTRUCTIONS DISPLAYED ON THE ELECTRONICS SCREEN.

6. PRESS ON “F3” AND “OK” TO ADJUST THE OFFSET. IT MEANS THAT V

BRUT

WILL BE

SHIFTED TO THE REFERENCE 900 mV.

PRESSING ON “OK” IS POSSIBLE ONLY IF V

BRUT

IS WELL SHIFTED TO 900 mV.

A MESSAGE SAYING THE OPERATION WAS SUCCESSFUL APPEARS.

Technical Manual MIVI 9612

Réf. 254-31/0 3

TABLE OF CONTENT

1. GENERAL PRESENTATION .......................................................................................................5

1.1.

T

HE SENSOR

...............................................................................................................................5

1.2.

T

HE PROCESSOR

.........................................................................................................................5

1.3.

C

HECKING THE EQUIPMENT AT THE RECEIPT

..................................................................................6

1.4.

C

HECKING THE EQUIPMENT WHEN PLACED AT THE PROCESS

..........................................................6

1.5.

P

ERIODIC CHECKING

....................................................................................................................6

1.5.1. Offset adjustment in air.......................................................................................................6

1.5.2. Modification of the previous calibration................................................................................7

1.6.

D

IRECTIVES AND

S

TANDARDS

......................................................................................................7

1.6.1. Certification ATEX...............................................................................................................7

1.6.2. Installation in hazardous area .............................................................................................7

1.6.3. European Pressure Equipment Directive.............................................................................8

1.6.4. EMC and low voltage directive............................................................................................8

2. VISCOSITY SENSOR...................................................................................................................9

2.1.

V

ARIOUS MODELS

........................................................................................................................9

2.2.

S

ENSOR INSTALLATION

................................................................................................................9

2.2.1. Elbow mounting ................................................................................................................10

2.2.2. Plane side mounting..........................................................................................................10

2.2.3. Pot mounting, for small flow rates, or pilot plant ................................................................10

2.2.4. Special mountings.............................................................................................................10

2.2.5. Replacement cap..............................................................................................................10

2.3.

P

RACTICAL ADVICES

..................................................................................................................11

2.4.

C

HECKING

................................................................................................................................11

2.5.

S

ENSOR WIRING

........................................................................................................................11

2.6.

M

ODELS AND DIMENSIONS

.........................................................................................................13

2.7.

T

IGHTNESS

...............................................................................................................................14

3. TRANSDUCER’S MECHANICAL CHARACTERISTICS............................................................15

3.1.

H

OUSING

’

S MECHANICAL CHARACTERISTICS

................................................................................15

3.2.

T

RANSDUCER

’

S ELECTRONIC BOARD WIRING

...............................................................................15

4. PROCESSOR TECHNICAL CHARACTERISTICS.....................................................................16

4.1.

M

ECHANICAL CHARACTERISTICS

.................................................................................................16

4.2.

D

ISPLAY

...................................................................................................................................16

4.3.

K

EYBOARD

................................................................................................................................16

4.4.

B

ATTERY

..................................................................................................................................16

4.5.

C

ONSUMPTION

..........................................................................................................................17

4.6.

P

OWER SUPPLY WIRING

.............................................................................................................17

4.7.

C

ONNECTION BLOCKS

................................................................................................................17

4.8.

A

NALOG

I

NPUTS

........................................................................................................................18

4.9.

A

NALOG INPUTS CONNECTION

(

DENSIMETERS

)............................................................................18

4.10.

R

ELAY OUTPUTS

......................................................................................................................19

4.11.

A

NALOG OUTPUTS

...................................................................................................................19

4.12.

O

UTPUTS WIRING SCHEME

.......................................................................................................20

4.13.

G

ENERAL INFORMATION

...........................................................................................................20

4.14.

W

ASTES HANDLING

..................................................................................................................20

5. MOUNTING THE PROCESSOR - INSTALLATION....................................................................21

Technical Manual MIVI 9612

Réf. 254-31/0 4

6. COMMUNICATION.....................................................................................................................23

6.1.

RS232

INTERFACE

....................................................................................................................23

6.2.

RS485

INTERFACE

....................................................................................................................23

7. POWER SUPPLY.......................................................................................................................25

7.1.

C

HARACTERISTICS

....................................................................................................................25

7.2.

S

AFETY CONSIDERATIONS

..........................................................................................................25

7.3.

P

OWER SUPPLY WIRING

.............................................................................................................26

8. GENERAL CABLING SCHEMATICS.........................................................................................27

9. SPECIFIC NOTES AND MANUFACTURING PARAMETERS ...................................................29

9.1.

B

LOCK

S

ETTINGS

......................................................................................................................29

9.2.

B

LOCK

P

ARAMETERS

.................................................................................................................30

9.3.

B

LOCK

C

ONFIGURATION

............................................................................................................31

Technical Manual MIVI 9612

Réf. 254-31/0 5

1. General presentation

The measuring chain is composed of two indissociable elements : the sensor and the electronic

processor.

1.1. The sensor

Each sensor is matched with its own electronics. Before switching on, be sure that serial

numbers at the sensor and the electronics identification plates are corresponding.

The operation principle of the equipment makes that the provided viscosity information is

relative : in the same fluid, at the same conditions the information is the same. But for 2 rheologically

different fluids the response can be different (despite it is perfectly repeatable).

The sensor active part is protected by an stainless tube which must not be removed.

The sensor is fixed upon its mounting flange by means of the provided 4 long screws.

See the detailed leaflet, § 2.

1.2. The processor

Its functions:

- Powers the sensor,

- Processes the sensor’s information,

- Displays and transmits the process information : viscosity, temperature,

sensor’s frequency, outputs and relays states….

The processor is composed of two modes :

“UTILISATION” Mode :

The “UTILISATION” Mode makes it possible to visualize in different forms viscosity and

temperature values.

- Visualization with bargraphs, acquisition graph

- Access to the sensor identification data

- Access to the “ADAPTATION” Mode blocks starting from the principal menu

“ADAPTATION” Mode :

The “ADAPTATION” Mode makes it possible to adapt the displayed data, parameters, settings

and configuration of the processor according to the using conditions.

- Display block : makes it possible to display outputs and relays states, rough data, to

choose viscosity and temperature units and to choose the viscosity correction to active.

- Settings block : makes it possible to set current outputs, alarms, bargraphs and graph

scales, to choose and set the modalities parameters of kinematic viscosity calculation, to

proceed to the mounting offset adjustment, to activate and define viscosity filter and to

change the Pt100 status.

- Parameters block : makes it possible to parameter viscosity corrections, to read and

modify the compensation table, to modify security codes and to set the density coefficient.

- Configuration block : makes it possible to SOFRASER to configure the processor with the

manufacturing data (thermal drift, calibration) and to define the viscosity adjustment data.

Technical Manual MIVI 9612

Réf. 254-31/0 6

1.3. Checking the equipment at the receipt

a) At first, check the supply conformity with the ordered equipment, mainly the presence of the

parts necessary for the equipment mounting. Those to be used at the process will be given to

the concerned department, for the installation preparation.

b) Place the sensor on a soft foam plate, connect it to processor (see §3.10) and switch on. The

vibration appears at the rod, the viscosity indication is close to zero (or close to the minimal

required current value of the analog output). When touching the rod, the information has to

increase.

In case of subnormal operation a) or b), check as follows :

-

Power supply, connections, cables,

-

The good condition of the vibrating rod (no bending on knock damages).

Consult your distributor.

1.4. Checking the equipment when placed at the process

Before filling the network check that the viscosity information is stable (vibrating rod in air). If

not, check the strength of the sensor fitting, then rotate the sensor of 90° (4 possible positions).

Choose the position where the information is the most stable.

Locate this position, in order to restore it when the sensor is removed – put in place.

Adjust the mounting offset, at room temperature. The rod is vibrating in air.

When possible, note the viscosity information when a cleaning or rinsing solution is flowing.

If the original calibration is convenient, one of the 2 above mentioned values can be taken as

reference for periodic control of the equipment operation each time that the same conditions will occur

(rod in air, or in the cleaning solution). Such an operation can be assimilated to a self-checking.

If the original calibration has been modified the reference values will be of course those

obtained with the new calibration.

1.5. Periodic checking

Conformity to regulations relative to Quality Insurance implicates a periodic control of the

measuring equipment used in the manufacturing operations, taking in consideration (or correcting)

their drift in time.

It is proved that this equipment drift is negligible. However, it is good to check their aspect and

their response once a year, at the same time as the other process equipment.

A fast test is many times available, when the sensor active part is in air, or immersed in a

cleaning or rinsing solution. As long as these values stay similar, we can say that the sensor

operation is right among its whole range (if no intermediate re-programming occurred).

1.5.1. Offset adjustment in air

The clean and dry rod is vibrating in air when the offset adjustment is carried out.

The amplitude, corrected in offset, Vbrut, must be shift to the reference of 900 mV.

See User Manual §5.1.

Technical Manual MIVI 9612

Réf. 254-31/0 7

1.5.2. Modification of the previous calibration

The device has been programmed in order to answer to your needs. These features

programming steps are noticed on the features specification pages at the end of this document.

At first, be sure that the modification is necessary, and not consecutive of a non

coherent comparative information (different measuring conditions, bad standards, inaccurate

or wrong laboratory measurements,…).

The calibration parameters are protected and can only be modified with the security code.

For modifications of calibration, contact your distributor.

1.6. Directives and Standards

1.6.1. Certification ATEX

MIVI sensors are in agreement with 94/9/EC directive (ATEX) for equipments installed in

explosive gas atmospheres or in presence of combustible dust :

II 2G (gas) or II 2D (dust)

Ex d IIC T1 to T6 : gas

Ex tD A21 IP67 T75°C, T90°C, T125°C, T190°C, T290°C, T300°C : dust

Be sure the sensor’s certification is in accordance with the security level required on your

process location : Area classification, equipments group, protection method, gas type, temperature

codes…

Area classification and equipments installation rules are detailed into IEC 7910 and EN 60 079

standards for gas or EN 61 241 standards for dust.

To always keep the maximum security level of the viscometer, don’t open it. Furthermore, we

advice to install the sensor with the cable gland orientated to the floor.

Check periodically information indicated on the sensor’s identification plate are still visible.

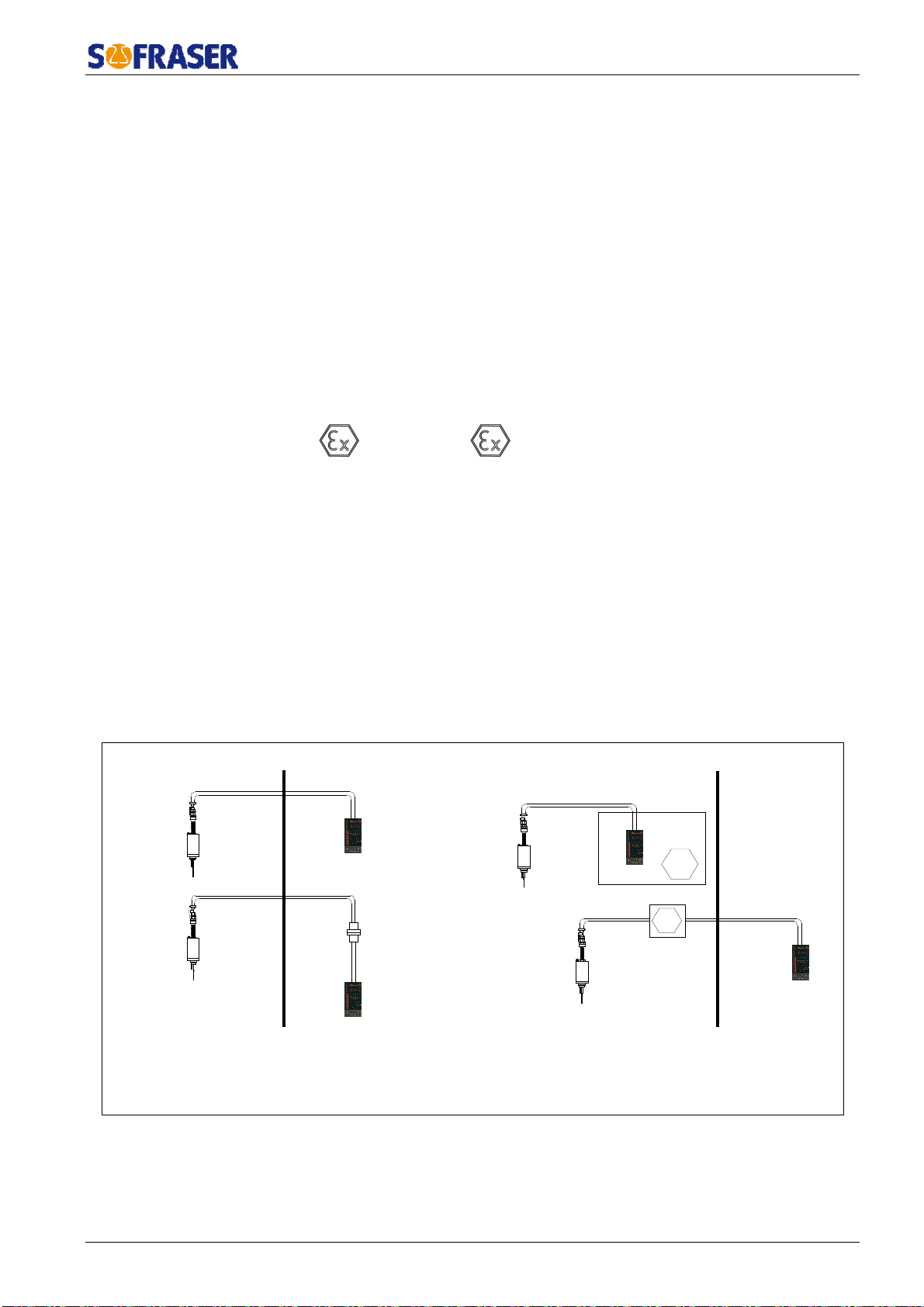

1.6.2. Installation in hazardous area

Here are the possible ways to install MIVI 9601sensors in hazardous area.

SAFE AREA

HAZARDOUS AREA SAFE AREAHAZARDOUS AREA

(1)

(2)

(3)

(1) : non-exproof connectors

(2) : exproof box (3) : exproof connection box

Ex

Ex

IMPORTANT : Always connect the sensor's body (screw on the top of the body) to the ground.

Technical Manual MIVI 9612

Réf. 254-31/0 8

1.6.3. European Pressure Equipment Directive

Up to 60 bars, MIVI sensors are in agreement with the article 3.3 of the PED 97/23/EC. In case

of higher pressure, sensors are certified one by one.

The mounting flange is an accessory to be welded on the process line. It means it can not be

individually certified but with the whole process line.

1.6.4. EMC and low voltage directive

The processor 9601 is in agreement with EMC specifications detailed into 89/336/EEC

(modified by 92/31/EEC and 93/68/EEC).

Processors 9601 are supplied by 24 VDC. So they are not subjected to the Directive Low

tension 73/23/CEEC (modified by 93/68/CEE).

MIVI sensors have been designed and manufactured according to the electrical safety rules.

Technical Manual MIVI 9612

Réf. 254-31/0 9

2.Viscosity sensor

2.1. Various models

•

General-purpose sensors.

•

Sanitary sensors.

•

Ex-proof sensors (ATEX, FM, JIS).

•

High pressure sensors (up to 150 bars).

•

Special models, according to the requirements (material and design).

•

When required, a temperature probe can be incorporated to the MIVI sensor.

2.2. Sensor installation

It operates at any position, even upside down. Its active part has to be permanently immersed in

the fluid (low part of the network or reactor). If the fluid temperature varies widely and fast, choose the

upside down or horizontal position, in order to allow a convenient air convection among the sensor

body.

It is screwed to its mounting flange by means of 4 screws M6X100 (or 8 screws M8 for high

pressures). The mounting flange has to be welded close to the device generating the viscosity

variations (heater, mixer, reactor, etc…). Retention, high flow velocities, strong vibrations and high

magnetic fields have to be avoided.

According to the application the mounting flange material can be :

Stainless steel Z3CND 17/11-02 (316L).

Carbon steel XC38.

Other materials, according to the requirement.

Manuel Technique MIVI 9612

Réf. 254-30/0 10

2.2.1. Elbow mounting

•

The flange is welded on a right angle tee as indicated in

pic.1.

•

The minimal pipe diameter is of 32 mm.

•

The flange and the pipe axes have to be the same.

•

The flow direction is as indicated on fig.1 (unless for

fibrous fluids where the flow is inverted and the rod

protector removed. (See §2.2.5).

•

A free area of at least 150 mm length is necessary.

Advice : choose a sensor position in order to assure a

permanent fluid renewal and to avoid the existence of

“dead zone”.

2.2.2. Plane side mounting

•

The flange is welded on a metal plate as indicated on

pic.2.

•

The free area around the vibrating rod has to be at least

∅40, 150 mm length.

•

In order to avoid parasitic vibrations, the plate where the

flange is welded must be thicker than 5 mm.

Advice : preferably choose a sensor position with the rod

to the top in order to have a total immersion of the

vibrating rod and to avoid the formation of “dead zone“.

2.2.3. Pot mounting, for small flow rates, or pilot plant

See picture 3.

2.2.4. Special mountings

The small sensor size allows numerous personalization

of its fitting according to the user's requirements. Consult

your distributor.

2.2.5. Replacement cap

Each mounting flange is provided with an obturation kit :

-

Cap and O-ring

-

4 fixing screws CHC M6 (or 8 fixing screws M8 for high

pressure sensor)

It allows the installation working when the sensor has to be

removed.

Mounting flange,

welded

150 mm mini

5 mm max.

int.

∅

32 mm mini

Pic. 1

¼

gas

Pic.3

On circulation pot

Eart terminal

Pic. 2

∅

40 mm mini

150 mm mini

17

Mounting flange

welded

Technical Manual MIVI 9612

Réf. 254-30/0 11

2.3. Practical advices

Torque at the mounting screws: 9 N.m ±1 at the M6×100 screws, or 22 N.m ±1 at the M8 screws

(for the high pressure design).

Tightness is assured by a O-ring (2 for sanitary model). Connections of ground of the sensor and

electronics must be equipotential.

Warning :

Each sensor is equipped with a guard tube in order to protect the vibrating rod. This protector must

be left on the sensor at the time of the assembly on the mounting flange. The fluid renewal is done

through the slits of the protector. He has not to be removed unless when the sensor is used in particular

conditions : on pot mounting, sanitary use, very viscous and fibrous fluids.

WARNING !

In this case, the mounting / removing of the sensor must be made with precaution, in order to

avoid to bend the vibrating rod.

A ring, with the same dimensions of the protector’s base must be placed on the head of the

sensor in order to maintain the O-ring.

IMPORTANT :

•

As soon as the sensor is removed, screw immediately its guard tube.

•

IP 67 rightness is only obtained when firmly screwing either the cable connectors, their replacing

caps, and the cable glands.

•

The minimal bending radius at the flexible pipe (electric outlet) is of 100 mm. Less radius can

generate leakage, then failure.

2.4. Checking

In case of subnormal operation, check the following points:

•

Electrical connections (connectors, cables, power supply…)

•

Remove the sensor from the process and clean it

•

Check that the vibrating rod is not bent.

When powered, check with the finger that the vibration is existing at the rod end. At this

moment, the viscosity information has to increase.

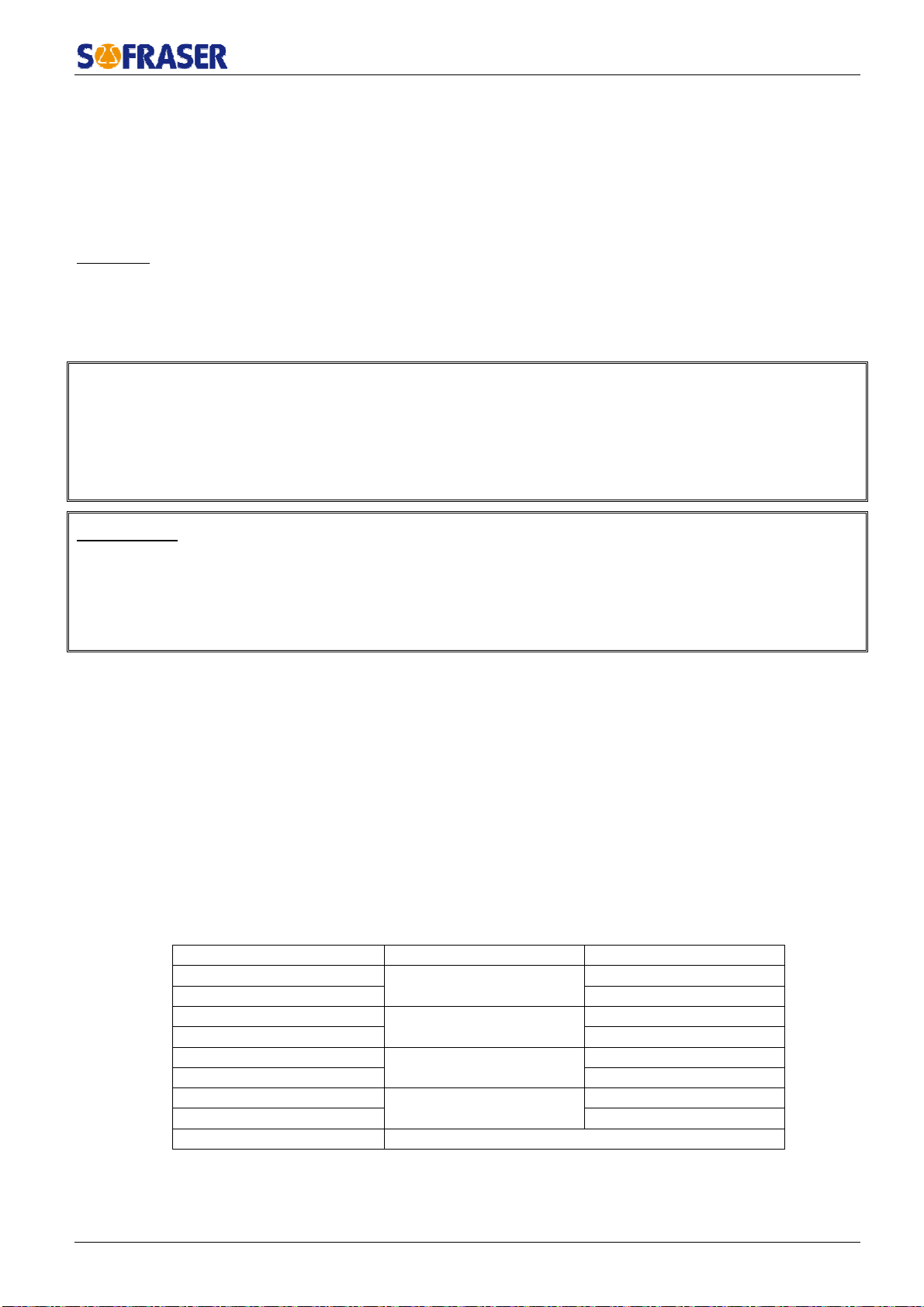

2.5. Sensor wiring

Repèrecâble

Correspondance

Couleur

A Receivingcoil Blue

B Brown

C Drivingcoil Transparent

D Black

E PT100 Red

F Yellow

J NTC Green

K White

/ Shielding

Technical Manual MIVI 9612

Réf. 254-30/0 12

Standard and explosion proof models are both equipped with cable glands. Those ones can match

the ATEX norm, depending on the MIVI version.

Eart terminal

Pic. 4

S ielding

Cable

Receiving

coil

Driving

coil

Temperature

probe

A B C D E F J K

NTC

Technical Manual MIVI 9612

Réf. 254-30/0 13

2.6. Models and dimensions

Bride de

montage

1 joint

torique

Bride de

montage

3 joints

toriques

Pic. 5

GENERAL PURPOSE

Ex

-

proof 200°C

Std 200°C

135 mm

120 mm

100 mm

17 mm

30 mm

Guard tube s ort slits Pot ¼ gas

156 mm

156 mm

HIGH PRESSURE

HP 200°C HP ex-proof 200°C

Pot ¼ gas

Guard tube long slits

Low pressure

Hig pressure

∅ 76

∅ 60

Mounting flange

∅ 99

1 o’ring

Sanitary low pressure Sanitary ig pressure

Mounting flange

∅

70

Replacement ring

Sanitary

Pic. 5

Technical Manual MIVI 9612

Réf. 254-30/0 14

2.7. Tightness

O’ ring Ø 29.82 x 2.62

Ø 76 or 79 Ø 70 or 99

O’ ring Ø 21.

95 x 1.78

O’ ring Ø 30.00 x 2.00

O’ ring Ø 30.00 x 2.50

Pic.6

Technical Manual MIVI 9612

Réf. 254-30/0 15

3. Transducer’s mechanical characteristics

3.1. Housing’s mechanical characteristics

non-ATEX version

External dimensions : (Height) 80mm * (Width) 100mm * (Length) 160mm

Tightness : IP66

Material : Aluminium

Temperature : from 0°C to 45°C

3.2. Transducer’s electronic board wiring

The transducer’s board is wired through the connector, which is plugged in the metallic box.

IMPORTANT : All boards must have the same power supply.

Connector linked to the transducer : wired by

SOFRASER

Technical Manual MIVI 9612

Réf. 254-30/0 16

4. Processor technical characteristics

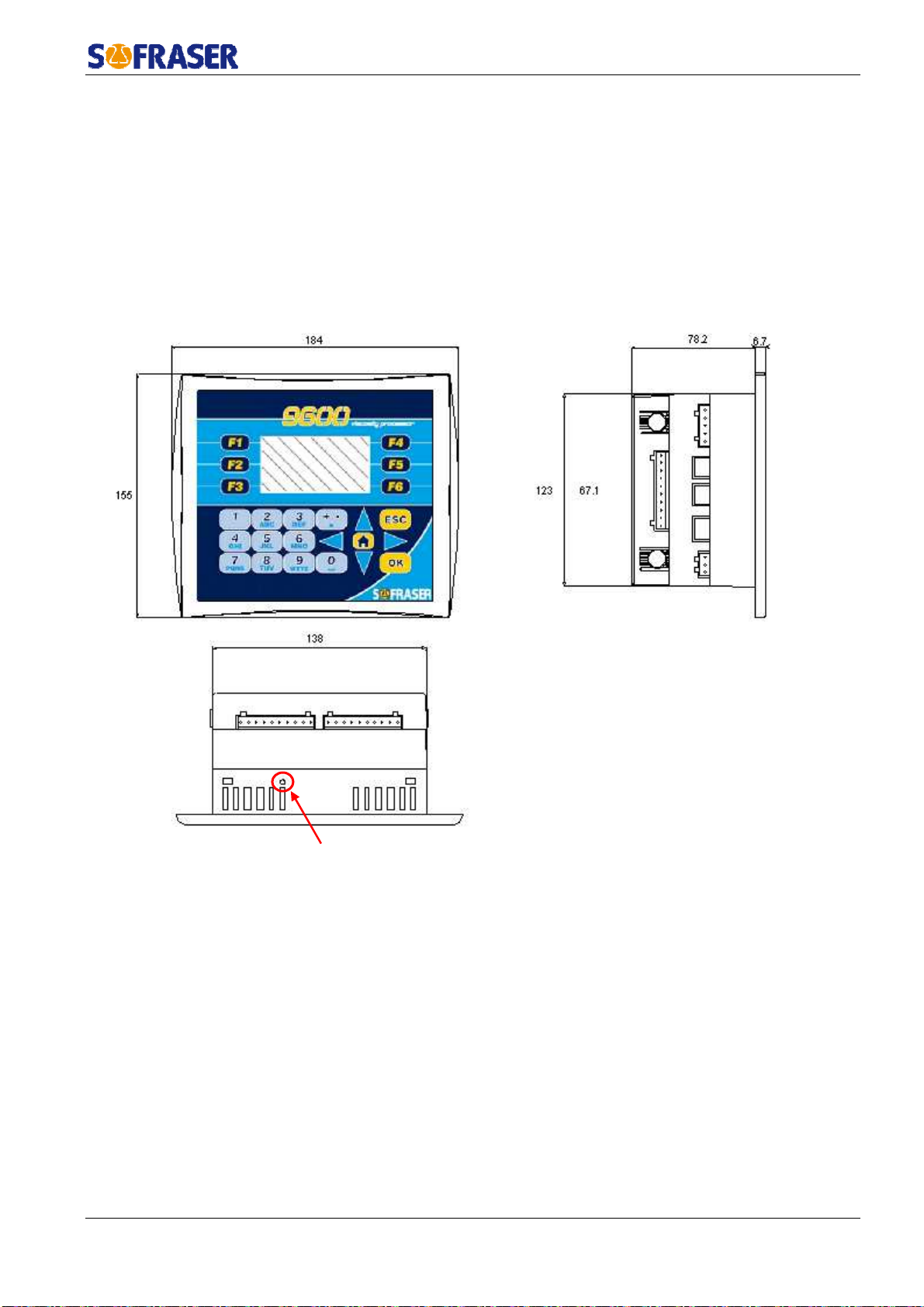

4.1. Mechanical characteristics

Dimensions behind the collar : 138 x 123 x 78.2 mm

Collar dimensions : 184 x 155 x 6.7 mm

Cut-out for assembly on panel : 141 x 126 mm. Thickness ≤5mm

Weight : about 515 g

Tightness : IP 65 with panel mounting and IP20 on rear panel

Operational temperature : 0°C to 45°C

4.2. Display

Display type : STN LCD

Illumination backlight : LED yellow

Display resolution : 128 x 64 pixels

The brightness can be adjusted using the screw on the top panel.

4.3. Keyboard

24 keys : alphanumeric keys and function keys.

4.4. Battery

The battery lifespan is about 7 years at 25°C.

Screw for brig tness

Technical Manual MIVI 9612

Réf. 254-30/0 17

4.5. Consumption

Typical power consumption : 7,2 W maximum

Current consumption : 300 mA maximum

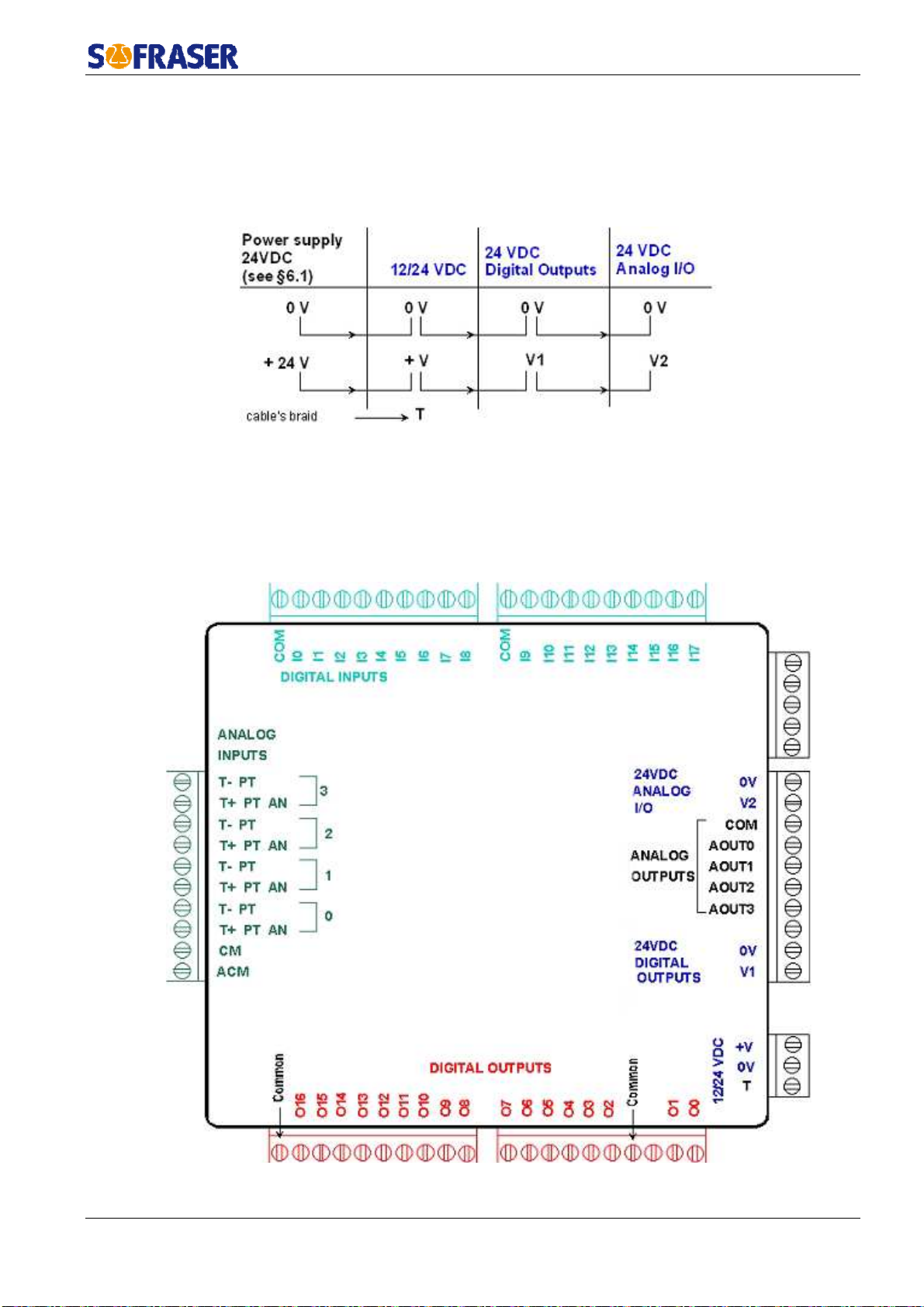

4.6. Power supply wiring

4.7. Connection blocks

On the processor back module, various categories are identified (example : Digital Inputs,

Analog Outputs).

We will call these categories "connection blocks". The diagram below identifies the various

connection blocks. The colours codes used and the name of these connection blocks are taken again

for each connection diagram.

Technical Manual MIVI 9612

Réf. 254-30/0 18

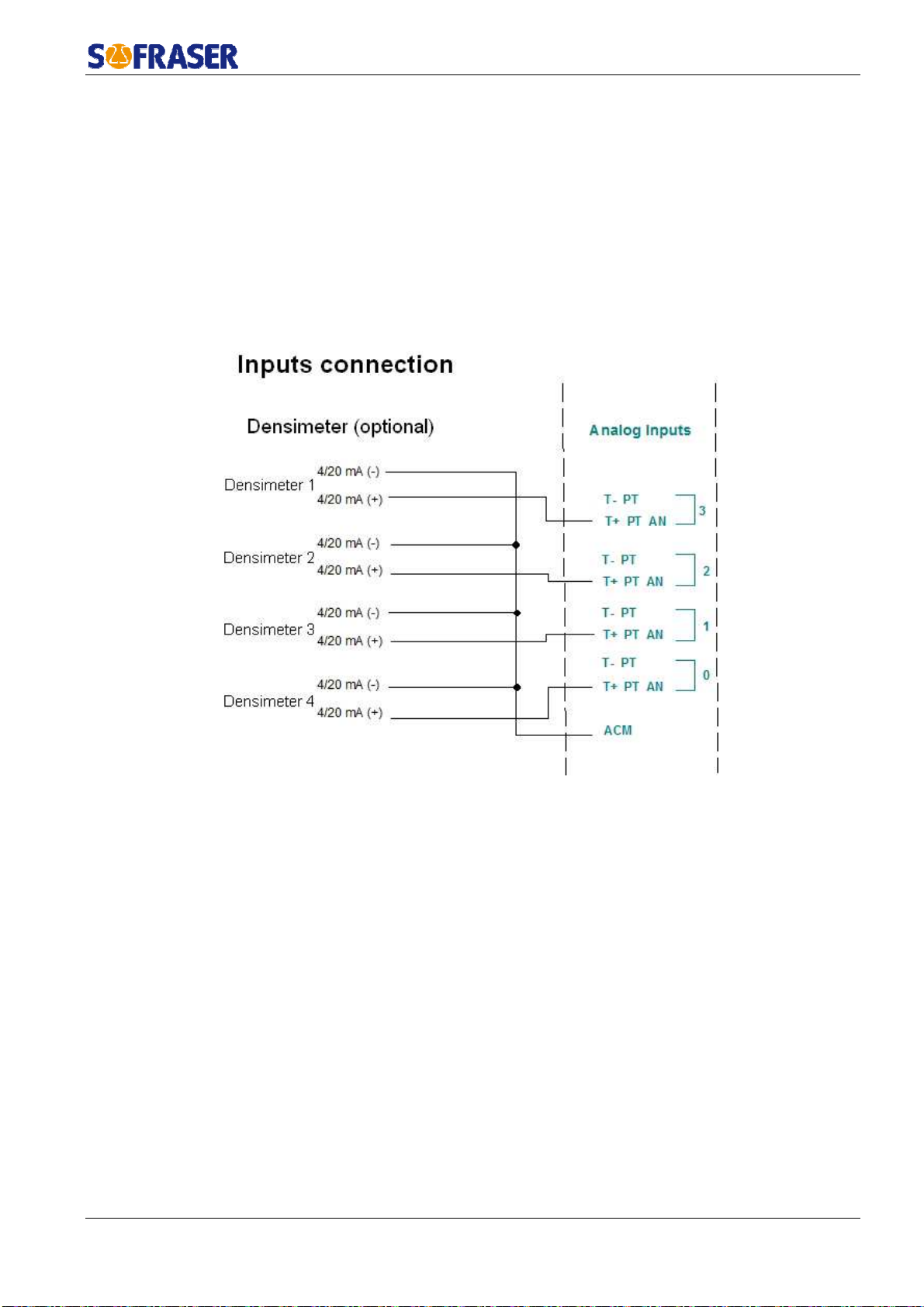

4.8. Analog Inputs

4 analog inputs are available. Resolution : 14 bits.

Analog inputs type : voltage 0-10 V, current 0-20 mA or 4-20 mA. These inputs can be used

with thermocouple or Pt100.

On 9612 electronics, these inputs are connected as 4-20mA and are specific to the plug of a

densimeter. Four densimeters can hence be connected to the 9612 module for the first four detected

sensors.

4.9. Analog inputs connection (densimeters)

Technical Manual MIVI 9612

Réf. 254-30/0 19

4.10. Relay outputs

15 relay outputs are available on this device. Based on our configuration, 13 of them are

defined, as follow :

-

12 relay outputs are attributable to the module by the user (cf User Manual § 5.2.2).

They can be used as alerts for :

-

LOW viscosity

-

HIGH viscosity

-

LOW and HIGH viscosity

-

LOW and HIGH temperature

-

1 relay output as a stand-by alert for the general working process.

How the relays operate :

-

Normal behaviour :

The relays coils are supplied and contacts are closed.

-

In case of a troubling parameter :

The relays coils stop being supplied and contacts are opened : measurements out of range,

unsupplied processor…

Tolerance for the relays :

From 02 to 07 and from 08 to 013 : 3 A max, 250VAC or 30VDC

Common : 8 A max (common plug not written, see the connecting plan)

Minimum load :

1mA à 5VDC

Lifespan :

100 000 operations with a maximum load

Response time :

10 ms

If the relays are used in order to commute some inductive loads, we clearly advise to add some

RC circuits to the load terminals or to the contacts terminals. The purpose is to decrease the impacts

of electromagnetic effects.

4.11. Analog outputs

Four analog outputs are available on the module. Their resolution is 12 bits.

They can be calibrated as 4-20mA current outputs or as 0-10V tension outputs.

The user is the one to choose how to configure the current outputs (see User Manual § 5.3.2).

The 9612 module can manage up to six sensors. So only the four first listed sensors will be able

to be connected to current outputs.

They can be used to display the viscosity and the temperature.

Technical Manual MIVI 9612

Réf. 254-30/0 20

4.12. Outputs wiring scheme

Analog outputs Digital outputs

COM Common outputs 4/20mA O16 Working process stand-by relay

AOUT0

AOUT1

Outputs assigned by t e user

AOUT2

AOUT3

4.13. General information

List of the device generic standards :

4.14. Wastes handling

Within the framework of the directive 2002/96-CE application, commonly named directive

DEEE, relating to the wastes of electric and electronic equipments, SOFRASER envisages to take in

charge the equipments arriving at the end of the lifetime.

Do not throw the equipments to the dustbin. If the user does not have the means to take in

charge the wastes of our electronic equipments, he should returned these equipments to our factory

with a signed letter confirming that it is an equipment that has to be destroyed/recycled.

Low Voltage Directive EN 61131-2 Power supply 24 VDC-not submitted

CEM Immunity EN 61000-6-2 Electro-statical discharges

Radio-frequency

Burst quick transients

CEM Emission EN 61000-6-3

EN 61000-6-4 Radio-frequency

Process variable CEI 751 Pt100

Protection CEI 529 IP 65 on front panel and IP 20 on rear

panel

Size CEI 473 Front panel : 184 * 155 mm

Cut-out : 141 * 126 mm

Climatic conditions Storage -20 to 60°C

5 to 90% HR non-condensing

Work 0 to 45°C

5 to 90% HR non-condensing

O13

O12

O11

O10

O9

O8

O7

O6

O5

O4

O3

O2

Outputs assigned by t e user

This manual suits for next models

1

Table of contents

Other Sofraser Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Keysight Technologies

Keysight Technologies U1701B quick start guide

Water Specialties

Water Specialties Propeller meter ML03 Operation and maintenance manual

MICRO-EPSILON

MICRO-EPSILON confocalDT IFD2410 Series operating instructions

Bushnell GOLF

Bushnell GOLF PHANTOM 2 SLOPE user manual

ROOTECH

ROOTECH Accura 2300 Quick setup guide

Microtest

Microtest 6632 Series user manual