SOGEDIS HP T2 User manual

TUMBLE DRYER

SERVICE MANUAL

HP T2 PANEL- A+++ (Inverter)

CONTENTS

1. OVERVIEW AND WORKING PRINCIPLE.............................................................................................4

1.2. Working Principle:....................................................................................................................4

2. TECHNICAL SPECIFICATIONS............................................................................................................5

3. INSTALLATION.................................................................................................................................5

3.1. Issues that should be informed to customer.............................................................................5

4. CONTROL PANEL AND PROGRAM SELECTION TABLE........................................................................6

4.1. Control Panel ...........................................................................................................................6

4.2.Program List..............................................................................................................................6

4.3. Children’s Safety ......................................................................................................................7

5. FAILURE MODES AND SERVICE AUTOTEST .......................................................................................8

5.1. Failure Modes and Warning Leds..............................................................................................8

5.2. Service Autotest Steps..............................................................................................................9

6. DISASSEMBLY................................................................................................................................12

6.1. Top Plate................................................................................................................................12

6.2. Control Panel .........................................................................................................................13

6.3. Inverter Card Box ...................................................................................................................16

6.3. Inverter Card Box ...................................................................................................................17

6.4. Electronic Card.......................................................................................................................18

6.5. Dısplay Card ...........................................................................................................................19

6.6. Side Panel ..............................................................................................................................20

6.7. Supply Cable ..........................................................................................................................22

6.8. Emi Filter................................................................................................................................23

6.9. Rear Cover .............................................................................................................................24

6.10.Pump ....................................................................................................................................25

6.11.Process Fan ...........................................................................................................................27

6.12. Rear Panel............................................................................................................................28

6.13.Rear Isolation Group .............................................................................................................30

6.14. Rear Bearing Group..............................................................................................................31

6.15.Water Tank Housing..............................................................................................................32

6.16.Drum.....................................................................................................................................33

6.18.Capacitors.............................................................................................................................35

6.19.Belt .......................................................................................................................................36

6.20. Humidity Sensor...................................................................................................................37

6.21. Door latch ............................................................................................................................38

6.21. Plinth ...................................................................................................................................39

6.22. Cooling Fan ..........................................................................................................................40

6.23. Plinth Cover..........................................................................................................................41

6.24. Door.....................................................................................................................................42

6.26. Drum Bearing Wheel ............................................................................................................43

6.27. Drumlight.............................................................................................................................44

6.27. Front Panel...........................................................................................................................45

6.29. Door NTC..............................................................................................................................46

6.30. Side Bracket .........................................................................................................................47

6.31. Front Shield..........................................................................................................................48

6.32.Front Isolation Foam .............................................................................................................49

6.33. Cable Group .........................................................................................................................50

7. 7. COMPONENT SPECIFICATIONS AND MEASUREMENTS ...............................................................52

7.1. Motor ....................................................................................................................................52

7.1.1. Motor Measurements .........................................................................................................53

7.2. Pump .....................................................................................................................................54

7.2.1 Pump Measurements ...........................................................................................................55

7.3. Electronic Card.......................................................................................................................56

7.4. Door/Compressor NTC Sensor................................................................................................56

7.4.1. Door NTC Sensor Measurements.........................................................................................57

7.5. Compressor............................................................................................................................57

7.5.1. Compressor Measurements ................................................................................................59

7.6. Door Latch .............................................................................................................................60

7.6.1 Door Latch Measurements ...................................................................................................60

7.7. Humidity Sensor.....................................................................................................................61

7.7.1 Humidity Sensor Measurements...........................................................................................61

7.8. Cooling Fan ............................................................................................................................62

7.8.1. Cooling Fan Measurements .................................................................................................63

7.9. Drumlight...............................................................................................................................63

8. TROUBLESHOOTING......................................................................................................................64

HP T2 PANEL

SERVICE MANUAL

1. OVERVIEW AND WORKING PRINCIPLE

1. Top Plate

2. Control Panel

3. Loading Door

4. Plinth

5. Plinth opening slot

6. Ventilation grills

7. Adjustable feet

8. Plinth cover

9. Type plate

10. Lint filter

11. Drawer Cover

1.2. Working Principle:

In the heat pump dryer machine, heated air is sent to the wet laundry in the drum from the

heater side of the coil which called by condenser. The humidity of the laundry is taken and

reaches the cold side of the coil which called by evaporator via filter. With a compressor,

refrigerant is passed through inside of the tubes of coils both condenser and evaporator. A

capillary causes resistance against to refrigerant flow. By this way, the evaporator surface is

cooled and condenser surface is heated. The hot and humid air from the drum is reached cold

evaporator surface and the humidity on it is left as water. The condensing water in the

evaporator is pumped to the water tank by the pump.

HP T2 PANEL

SERVICE MANUAL

2. TECHNICAL SPECIFICATIONS

Manufacturer

Vestel White Goods

Capacity (max)

7 kg (100LT)

8 kg / 9kg (112LT)

H x W x D

845x596x563 mm

845x596x609 mm

Net weight (with plastic door)

42,6 kg

44 kg

Net weight (with glass door)

45 kg

46,4 kg

Voltage

220-240V / 50 Hz

Working Temp.

+5°C -+35°C

Electrical Current (A)

10 A

Power

1000 W

3. INSTALLATION

3.1. Issues that should be informed to customer

1. Drying machine must be grounded.

2. Lint filter must be cleaned after each use

3. Water tank must be unloaded after each use

4. Even if the heat exchanger cleaning warning les is not on : clean the heat exchanger

after every 30 drying processes or once a month

5. The amount of laundry should be appropriate to program.

6. Use this product only for laundry with a label that indicates it is suitable for drying.

7. Children should not play with appliance.

8. This product contains environmental friendly but flammable R290 gas. Keep open

flame and fire sources away from the product.

9. Ventilation grills should not be closed.

10. The service life time of tumble dryer is 10 years.

11. Adjustable feet should not be removed.

12. There should not be lockable or sliding door in the installation area

13. Never spray or pour water onto the dryer to wash it. There is a risk of electric shock.

Please ensure that customer reads the user manual

1. Check the environmental conditions. (Voltage, current etc.)

2. Ensure that product is used correctly

3. If the system displays failure code, find the corresponding code in the failure code list

then act according to this.

4. Check the electronic connections

HP T2 PANEL

SERVICE MANUAL

4. CONTROL PANEL AND PROGRAM SELECTION TABLE

4.1. Control Panel

Display Symbols

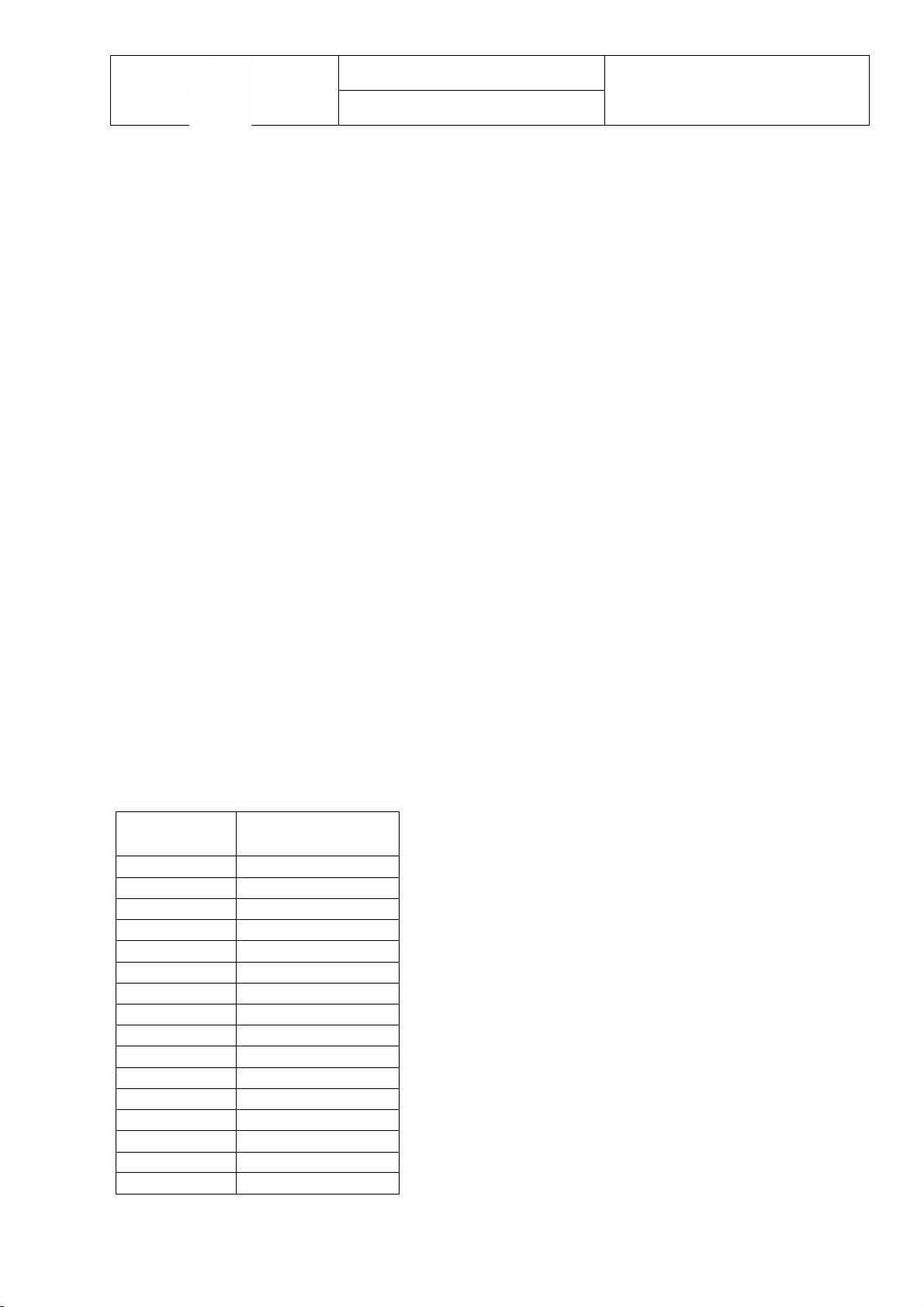

4.2.Program List

KNOB

POSITION

PROGRAM

1

Cotton Extra Dry

2

Cotton Cupboard Dry

3

Cotton Iron Dry

4

Synthetics Cupboard Dry

5

Synthetics Iron Dry

6

Delicate

7

Time Drying

8

Baby Care

9

Duvet

10

Extra Silent

11

Mix

12

Wool

13

Refresh

14

Express 45’

15

Shirts 30’

16

OFF

HP T2 PANEL

SERVICE MANUAL

***The machine has humidity sensor that detects whether the laundry dry or not. At the

programs that work with humidity sensor laundry does not dry in fixed time. Duration is

constantly updates according to humidity data taking from laundry.

***Time Drying Program: Humidity sensor is deactivated. The program ends when the time is up,

without checking the humidity of the laundry.

***Express 45’/ Shirts 30 ‘: Humidity sensor is activated. The program time may extend, if the

customer use different laundry according to the load in the program description.

Express 45' : 1 kg of cotton shirts spun at high speed in the washing machine are dried in 45 minutes

Shirts 30' : 2 to 3 shirts are ready for to be ironed in 30 minutes.

***Delicate: This programme dries synthetics, such as shirts, t-shirts, blouses, at a lower

temperature compared to the cottons programme.

*** Refresh: Time drying option is selected from 10 minutes to 150 minutes without providing hot

air, refresh is done and bad odors can be eliminated.

4.3. Children’s Safety

There is a child lock option to avoid changes in the program

flow when keys are pressed during the program. To activate child lock,

press and hold “sw2” and “sw3” keys simultaneously for 3 seconds.

When the child lock is active, all keys will be deactivated. Child lock will

be deactivated automatically at the end of the program. When the

child lock is being activated/deactivated, “CL” will flash on the display

for 2 seconds and an audio warning will be heard.

Warning: when the product is running or the child lock is active, if you turn the program selection knob,

you will hear an audible warning. Even if you set the program knob to another program, the previous

program will continue running. To select a new program, you need to deactivate the child lock and

then set the program selection knob to “Cancel” position. Then, you can select and start the desired

program.

HP T2 PANEL

SERVICE MANUAL

5. FAILURE MODES AND SERVICE AUTOTEST

***Service auto test must be run for every service call.

5.1. Failure Modes and Warning Leds

Notes For Service autotest:

*Service can not pass the current step before completing the minimum duration

*When minimum duration for each step (5 sec) is completed, filter led makes slow blink to indicate

that service can pass the next step

*For error codes, leds must make fast blink

ERROR CODE REASON

E00 Touch UI board doesn't receive communication from mainboard

E03

Aquaswitch connector is disconnected

E04 Compressor connector is disconnected

E05 Compressor NTC connector is disconnected

E06 Door NTC connector is disconnected

E07

Motor connector is disconnected, motor is locked

E08

Voltage fluctuation

HEAT PUMP MODEL ERROR CODES

SW5

SW2

SW3

SW1

SW4

SW6

HP T2 PANEL

SERVICE MANUAL

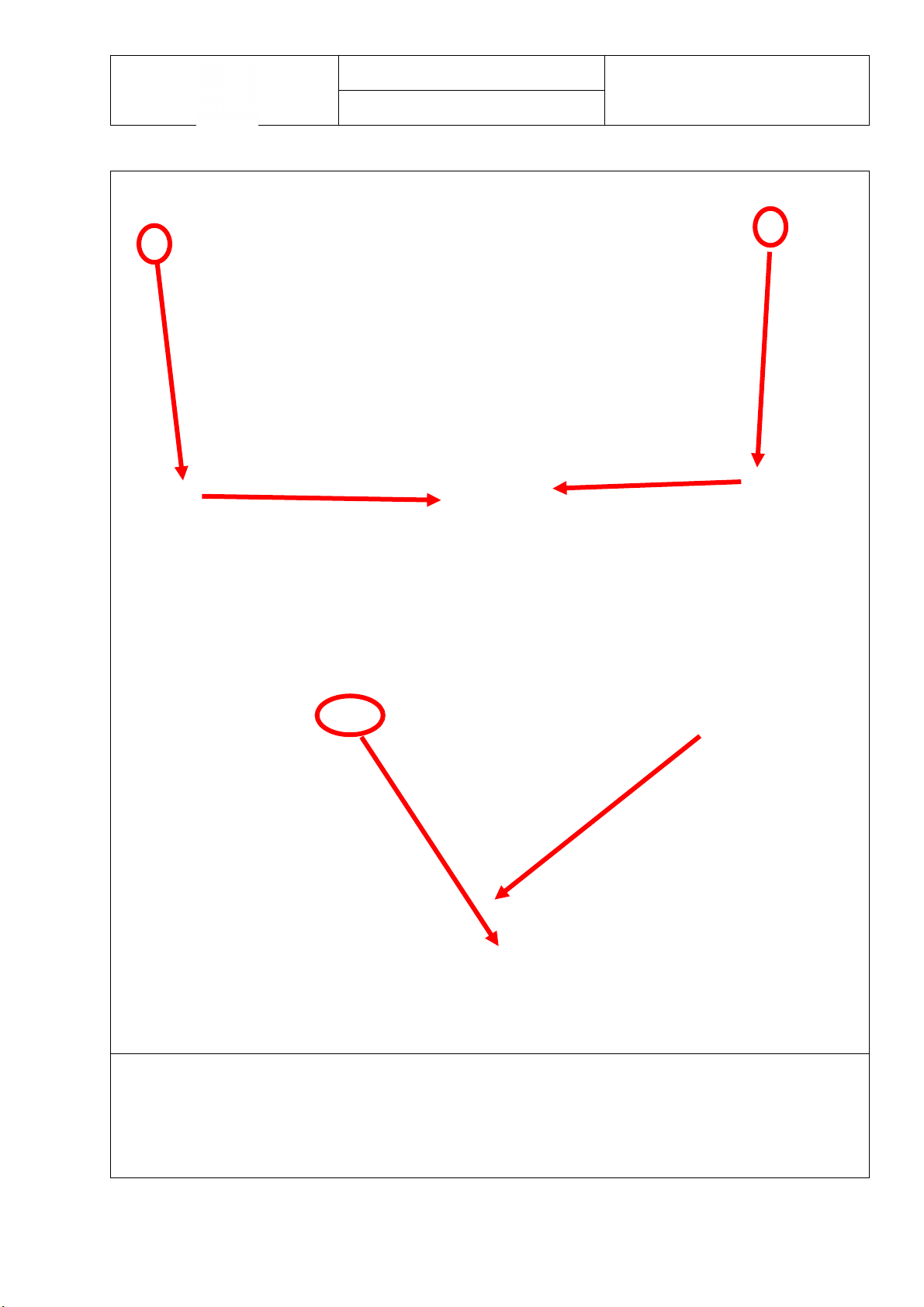

5.2. Service Autotest Steps

STEPS

Control

Minimum Step

Duration*

Error

code

Led Indication

Possible Errors

The Routine to

Enter Servis

Autotest

Set program knob at position 3. Push SW5

button.

Keeping SW5 button pushed, turn program

knob to position 1. After 3 sec, SAU is shown

in display.

Then press Start/Pause button. Machine

enters to service autotest.

For T2: When machine enters service

autotest, SAU becomes fix on for 2 sec and all

warning leds make fast blink for 2 sec and

then becomes fix off

For T2: Machine shows the last error saved

by machine. If there is no error, "- - -"

visualise on the display

When knob positioned to program 2, control

steps starts.

5 sec

-

Step 2

(Knob Position

2)

Dryer check Aquaswitch, if aquaswitch ON go

to next step (pump activation), if aquaswitch

OFF give water tank full error

10sec

E03

-

*Aquaswitch connector is

taken out

*Aquaswitch connector is

short circuit

*Styrofoam is borken or not

HP T2 PANEL

SERVICE MANUAL

Step 3

(Knob Position

3)

Pump is on

5 sec

-

-

Service must pour water to

pump reservoir and check

whether water is pumped to

tank.

If water is not pumped to

water tank;

*Pump connector is taken out

Step 4

(Knob Position

4)

Motor CCW (Tumble CW)-Motor stops

10 sec

-

-

Service must check whether

tumble is moving to CW. If

not;

*Motor connector is taken out

*Motor might be locked

*Motor belt might be

dislocated

Step 5

(Knob Position

5)

Motor CW (Tumble CCW) -Motor stops

10 sec

-

-

Service must check whether

tumble is moving to CCW

*If tumble is moving to CW

again, then motor relay short

circuit CCW

Step 6

(Knob Position

6)

Check Heater NTC if heater NTC T=255

5 sec

E05

-

*Heater NTC connector is

taken out or short circuit

Step 7

(Knob Position

7)

Check Door NTC if heater NTC T=255

5 sec

E06

-

*Door NTC connector is taken

out or short circuit

HP T2 PANEL

SERVICE MANUAL

Step 8

(Knob Position

8)

Compressor OFF- Motor CCW (Tumble CW)

OFF- Cooling fan ON

10 sec

-

-

Service must check power of

at the home voltage and fan

will be controlled manually by

technical service.

Step 9

(Knob Position

9)

Compressor ON- Motor CCW (Tumble CW) -

motor off

10 sec

-

-

Service must check power of

at the home voltage.

Step 9

(Knob Position

9)

Check conductivity sensor when door is

opened and motor is off

5 sec

E01

-

Service puts his hand on the

humidity sensor plates and

software checks sensor data

*If sensor data=0, humidity

sensor connector is taken out

Remove the

last error (Knob

Position 1)

5 sec

DEL

DL is visualized on

display and make

fast blink for 2 sec

for T0.DEL is

visualized on

display and make

fast blink for 2 sec

When the knop positioned to

program 1, service will pust

the both SW4 and SW5 for

T0/T1 (child lock mode).

When the knop positioned to

program 1, service will pust

the both SW2 and SW3 for T2

(child lock mode).

HP T2 PANEL

SERVICE MANUAL

6. DISASSEMBLY

6.1. Top Plate

1. Remove two screws that fix the top plate at the back.

2. Remove by pulling the top plate to yourself.

HP T2 PANEL

SERVICE MANUAL

6.2. Control Panel

1. Remove 2 screws from the top

2. After the water tank removed, the plastic screw in the center of the control panel should

be removed.

HP T2 PANEL

SERVICE MANUAL

6.2. Control Panel

1. After removing the screws on the control panel, the control panel is removed as shown in the

photo from the upper support bracket.

2. The cables on the control panel are carefully removed from the cable paths.

3. All sockets which is connected with electronic card must be removed carefully as shown in the

photo.

HP T2 PANEL

SERVICE MANUAL

6.2. Control Panel

4. Remove the PCB box by pressing clips which provide fixing to panel So, PCB box will be separated

from control panel

HP T2 PANEL

SERVICE MANUAL

6.3. Inverter Card Box

1. All sockets which is connected with inverter card box must be removed carefully as shown in the

photo.

2. After removing the sockets on the card box, the inverter card box is removed as shown in the

photo from the side panel.

HP T2 PANEL

SERVICE MANUAL

6.3. Inverter Card Box

1. For opening the Inverter card box, press the clips (6 units) Care should be taken not to break the

clips here.

2. The inverter card inside is removed from the nails as shown in the photo.

HP T2 PANEL

SERVICE MANUAL

6.4. Electronic Card

3. For opening the PCB box, press the clips (6 units) Care should be taken not to break the clips

here.

4. The electronic card inside is removed from the nails. Remove the electronic card from pcb box

as shown in the photo

HP T2 PANEL

SERVICE MANUAL

6.5. UI Card

1. Remove screw on UI card as shown in photo.

2. Display card on control panel is disassembled as shown in photo.

HP T2 PANEL

SERVICE MANUAL

6.6. Side Panel

1. Remove 10 screws on side panels

Other manuals for HP T2

1

Table of contents

Other SOGEDIS Dryer manuals

Popular Dryer manuals by other brands

Frigidaire

Frigidaire GLEQ221A Factory parts catalog

JLA

JLA D3030 installation manual

Grundig

Grundig GT77823WHF12 user manual

Bosch

Bosch WTN85420ME Installation and operating instructions

Beko

Beko DRYPOINT M PLUS DM 40-61 C-N Instructions for installation and operation

Miele

Miele T 4819 Ci operating instructions