SOLAR VISION TX360 User manual

installation ManUal

tx360 & tx180 commercial solar lighting system

Solar Vision inc. www.solar-vision.ca info@solar-vision.ca T. 1-819-729-0450

Revision 4.0 | May 25, 2023

IMPORTANT: Always install the system assembly on the pole before inserting the batteries.

The assembly system should never be handled when the batteries are installed inside.

LIST OF MATERIAL BY MODEL

TX180 SYSTEM: TX360 SYSTEM:

Battery/Control main enclosure Battery/Control main enclosure

Battery, 12V (1 per system) Battery, 12V (2 per system, in series)

L shape prole, 30in long (2 per system) L shape prole, 30in long (2 per system)

L shape prole, 26in long (2 per system) L shape prole, 53in long (2 per system)

Solar Module 180W (1 per system) Solar Module 180W (2 per system)

3/8” stainless steel hardware for assembly 3/8” 5/16 stainless steel hardware for assembly

5/16” stainless steel hardware for solar module

assembly

5/16” stainless steel hardware for solar module

assembly

LED luminaire, 12Vdc compatible, with tenon LED luminaire, 24Vdc compatible, with tenon

Note 1: The TX180 system is a 12Vdc system with one (1) 12V battery and one (1) 180W solar module. This system is

compatible with an LED luminaire operating at 12Vdc only.

Note 2: The TX360 system is a 24Vdc system with two (2) 12V batteries in series and two (2) 180W solar modules. This

system is compatible with an LED luminaire operating at 24Vdc. Do not use a 12Vdc luminaire on a 24Vdc system.

This will cause permanent damage to the LED driver.

TX180 System Components TX360 System Components

*Elliptical tube mounting arm and luminaire NOT shown *Elliptical tube mounting arm and luminaire NOT shown

P.1/11

installation ManUal

tx360 & tx180 commercial solar lighting system

Solar Vision inc. www.solar-vision.ca info@solar-vision.ca T. 1-819-729-0450

Solar Vision inc. www.solar-vision.ca inf[email protected] T. 1-819-729-0450

Revision 4.0 | May 25, 2023

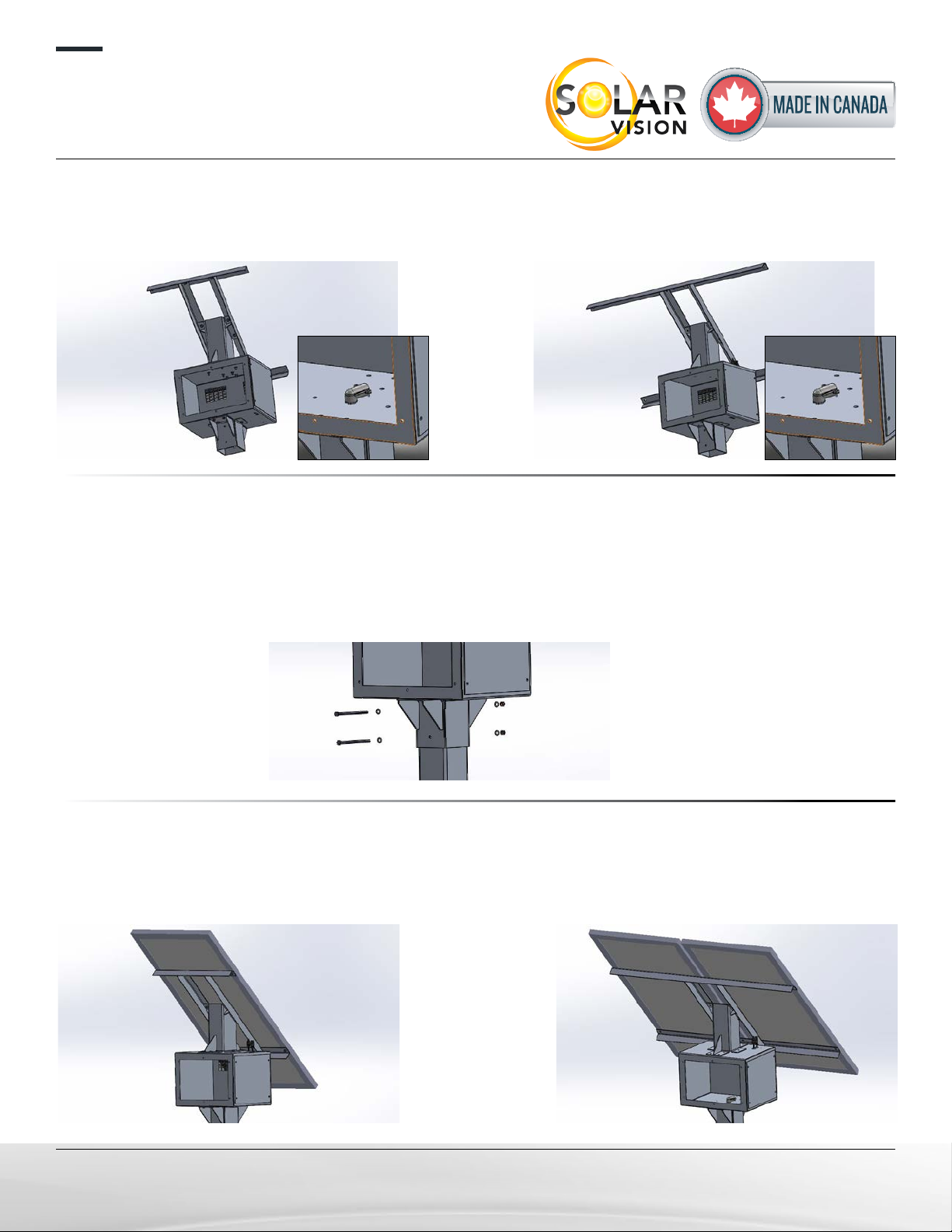

STEP 1:

Using the 3/8-16 x 1¼” bolts and hardware (hex bolt, at washer, lock washer and hex nut), tighten the

two 30in “L” channels to the “main support” as indicated on the image.

STEP 2:

Using the 3/8-16 x 1” bolts and hardware (hex bolt, at washer, lock washer and hex nut), tighten the

two “L” channels (26in or 53in according to model) to the “30in L channel” as indicated on the image.

TX180 FINAL ASSEMBLY TX360 FINAL ASSEMBLY

This step is identical

for the TX180 & TX360

TX360

TX180

P.2/11

installation ManUal

tx360 & tx180 commercial solar lighting system

Solar Vision inc. www.solar-vision.ca info@solar-vision.ca T. 1-819-729-0450

Solar Vision inc. www.solar-vision.ca inf[email protected] T. 1-819-729-0450

Revision 4.0 | May 25, 2023

STEP 3:

Pass through the luminaire power cable (preinstalled in the battery box) into the 90 degree connector

to make it available for the luminaire connection. 10FT, #16 AWG is pre-wired.

STEP 4:

1. Determine the system’s orientation so that the solar panels are facing South.

2. Once the orientation is determined, use the drilling guide at the end of the document to drill holes

at the proper location.

3. Slide the system on the pole and use the 3/8”-16 x 6½” bolts and hardware to secure the system

into position. Bolts crosses the pole.

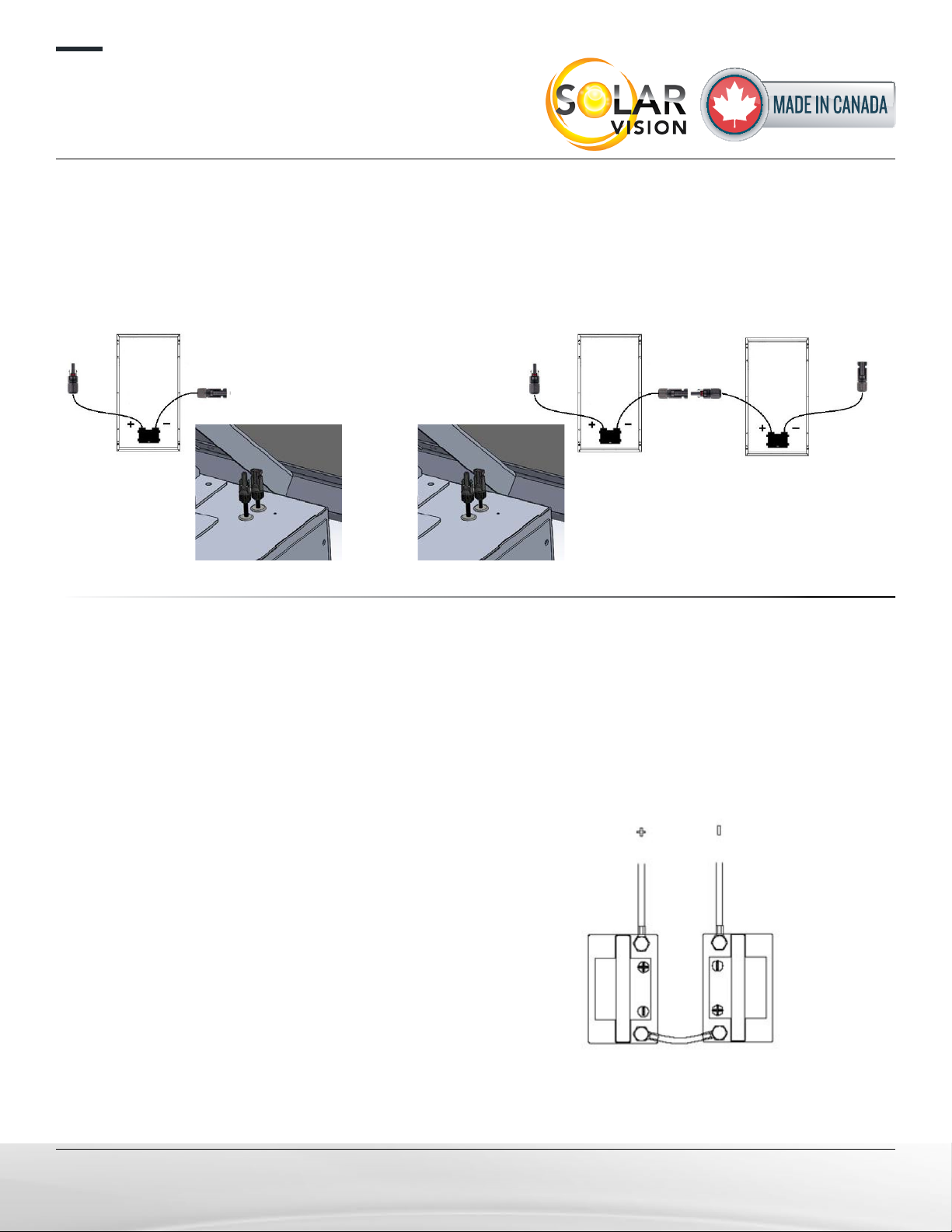

STEP 5:

Using the 5/16-18 x 1” bolts and hardware (hex bolt, at washer, lock washer and hex nut), install the

solar panels using their precut frame holes.

Note: The solar panel junction boxe needs to be on the down side.

TX180 TX360

TX180 TX360

P.3/11

installation ManUal

tx360 & tx180 commercial solar lighting system

Solar Vision inc. www.solar-vision.ca info@solar-vision.ca T. 1-819-729-0450

Solar Vision inc. www.solar-vision.ca inf[email protected] T. 1-819-729-0450

Revision 4.0 | May 25, 2023

STEP 6:

1. For the TX360 only, make a serial connection between the solar panels, as shown in the picture

(The positive cable of one panel with the negative cable of the other panel).

2. Then connect the two remaining cables to the MC4 (pre-wired) connector on the main battery com-

partment as shown on the image.

STEP 7:

1. Following the + and - (positive and negative) orientation as indicated in the battery compartment,

insert the batteries.

2. For the TX300 only, using the supplied cable, make a serial connection between the batteries

(The positive terminal of one battery with the negative terminal of the other battery).

3. Then, by respecting the cable polarities, complete the batteries connection by using the pre wired

cables in the battery compartment.

TX180 TX360

TX360

ONLY

P.4/11

installation ManUal

tx360 & tx180 commercial solar lighting system

Solar Vision inc. www.solar-vision.ca inf[email protected] T. 1-819-729-0450

Revision 4.0 | May 25, 2023

STEP 8:

Close the battery compartment door using the 1/4”-20 bolts

and neopren washers.

STEP 9:

Install the pole arm and the luminaire at the desired location,

minimum 18in underneath the battery compartment.

Hardware not provided for the pole arm.

Pole arm and luminaire specications are included herein.

The DC lighting xture has 3 wires:

Positive Red(+), Negative Black(-), and Dimming White

(signal). Please make all 3 connections for proper opera-

tion.

DAY-NIGHT TRANSITION

The TX360 solar system uses the solar panel to detect day and night periods. The night transition re-

quires a very low brightness level for 5 continuous minutes. This constraint prevents false night transi-

tions that could be caused by storm clouds in the evening. If the solar module is covered with debris,

the solar module voltage may be too low and may cause light synchronization errors. If the light works

erratically, make sure the solar module is clean. The light automatically corrects synchronization errors

whithin 24 hours.

IMPORTANT

If you wish to store the batteries, they need to be recharged before storing for a period of 15 days or

more in order to prevent damage to the battery. The batteries must be stored at 20°C room temperature.

The light must be installed in an open area, no trees or nearby structure, this could favor snow accu-

mulation and shading.

Never manipulate the battery compartment when the batteries are inside. Use the quick access door to

remove the batteries before handling. Failing to follow these recommendations can result in seri-

ous danger and dammage.

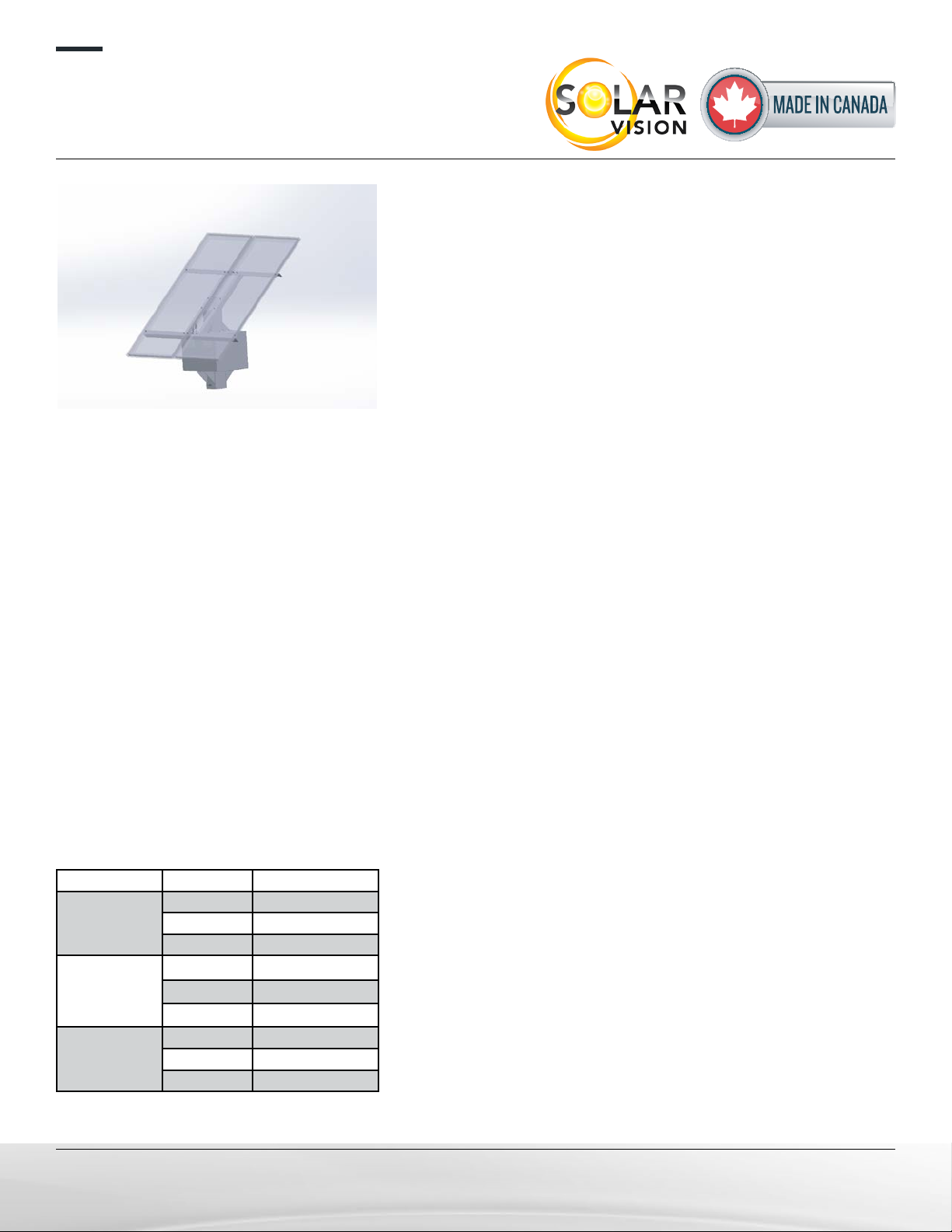

Orientation Period Autonomy losses

South (≈ optimal)

Annual 0%

Summer 0%

Winter 0%

East / West

Annual -21%

Summer -15%

Winter -40%

North

Annual -50%

Summer -41%

Winter -72%

SOLAR PANNEL ORIENTATION AND AUTONOMY

P.5/11

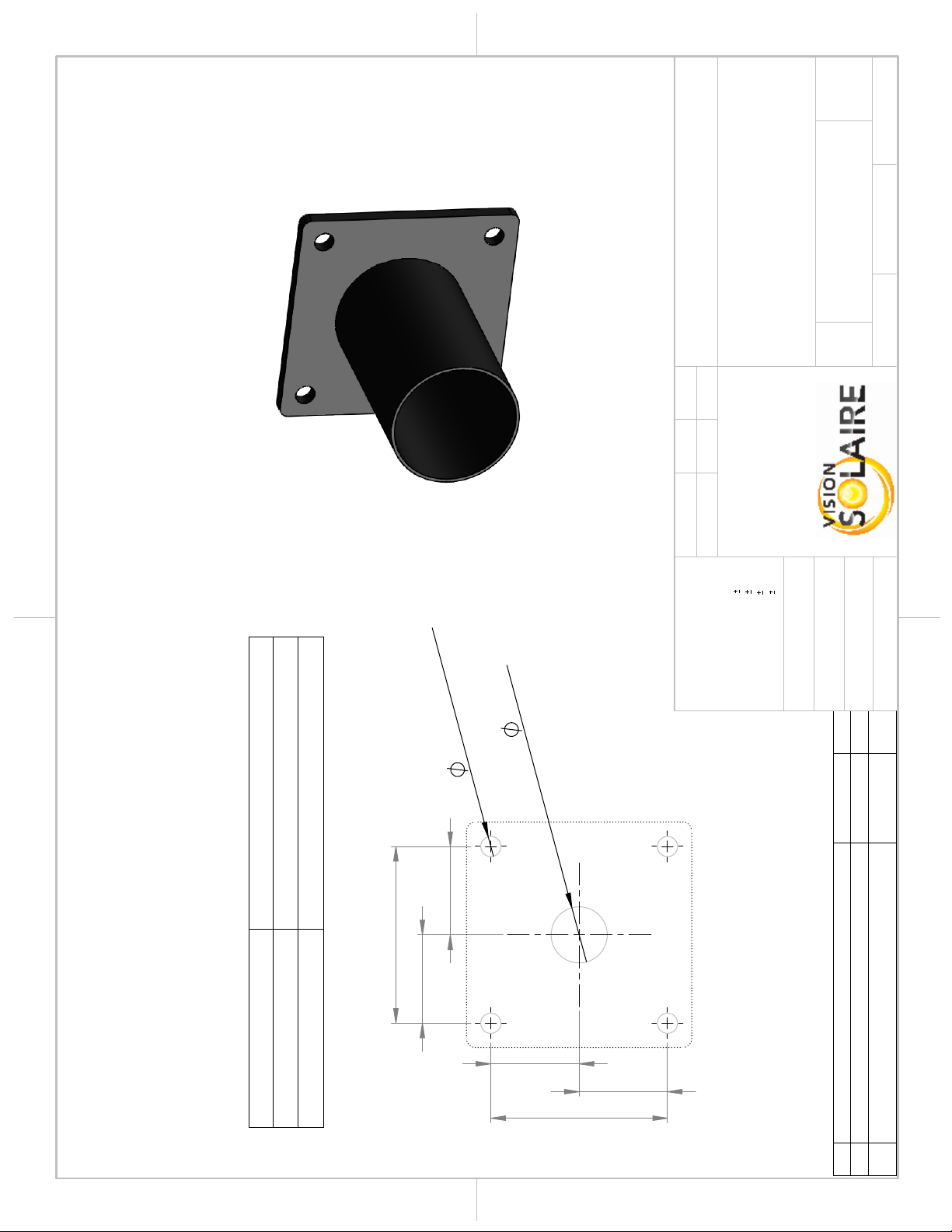

.50 x8

5.50

2.50

4.00

NOTE:

The installation of

the lamp on the

top of the post

requires drilling the

post as per the

presented drilling

pattern. The lamp

will be secured

using two bolts

through the lamp

post.

REV.

DESCRIPTION

DATE

PAR

5

DISTANCE BETWEEN MOUNTING HOLES

3 AVR 2023

JFOL

4

DRAWING PER MODEL

15 SEP 2022

JFOL

3

SIMPLIFICATION OF THE DRILLING PATTERN

27 JUN 2022

JFOL

2

HOLE SIZE AND POSITION ADJUSTED

13 OCT 2020

JFOL

1

UPDATE OF THE NOTE

26 MAR 2020

JFOL

A A

B B

2

2

1

1

PROJECT:

WEIGHT: 44.52

"

THICKNESS

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

VISION SOLAIRE INC ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

VISION SOLAIRE COM IS

PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

DIMENSIONS ARE IN INCHES

DEFAULT TOLERANCES:

ANGULAR

1°

TWO PLACE DECIMAL

.06"

THREE PLACE DECIMAL

.031"

HOLES

.005"

MATERIAL

FINISH

DRAWN

DATE

NAME

VS

TITLE:

SIZE

A

DWG. NO.

REV

SCALE: 1:5

UNLESS OTHERWISE SPECIFIED:

JFOL

26 MAR 2020

SHEET 1 OF 1

H55S_DRL_TX

DO NOT SCALE DRAWING

5IN POST

DRILLING PATTERN FOR

TX

5

POLE NOT INCLUDED

Tenon drilling pattern not

shown here.

P.6/11

P.7/11

3.20

3.20

1.60

1.60

1.60

1.60

0.359" TYP.X4

1.00"

PROVIDED BY DEFAULT FOR THE ZX & TX SERIES WHEN NO OTHER OPTIONAL

POLE ARM IS PURCHASED

HARDWARE 1/4-20X1" (4X) INCLUDED FOR INSTALLING THE TENON

PLEASE COORDINATE DRILLING HOLES WITH YOUR POLE MANUFACTURER.

THE FIXTURE'S TENON MUST BE INSTALLED AT A MINIMUM DISTANCE BELOW

BELOW THE TOP OF THE POST AS PER THE FOLLOWING TABLE:

PERCEMENTS

DIMENSIONS IN INCHES

REV.

DESCRIPTION

DATE

PAR

1 MOUNTING LOCATION

25 MAI 2022

JFOL

0

ORIGINAL

2 AOUT 2021

JFOL

DISTANCE MIN.

MODÈLE

12" (305mm)

ZX30 & ZX60

18" (457mm)

ZX100, ZX170, TX150 & TX300

A A

B B

2

2

1

1

PROJECT:

WEIGHT:

"

THICKNESS

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

VISION SOLAIRE INC ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

VISION SOLAIRE COM IS

PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

DIMENSIONS ARE IN INCHES

DEFAULT TOLERANCES:

ANGULAR

1°

TWO PLACE DECIMAL

.06"

THREE PLACE DECIMAL

.031"

HOLES

.005"

MATERIAL

FINISH

DRAWN

DATE

NAME

ZX - TX

TITLE:

SIZE

A

DWG. NO.

REV

SCALE: 1:2

UNLESS OTHERWISE SPECIFIED:

JFOL

2 AUG 2021

SHEET 1 OF 1

TENSQ45

DO NOT SCALE DRAWING

DRILLING PATTERN

HORIZONTAL TENON FOR

4" & 5" SQUARE POLE

PAINTED STEEL

1

Power Modules Dimension Weight

EPA

C

P.8/11

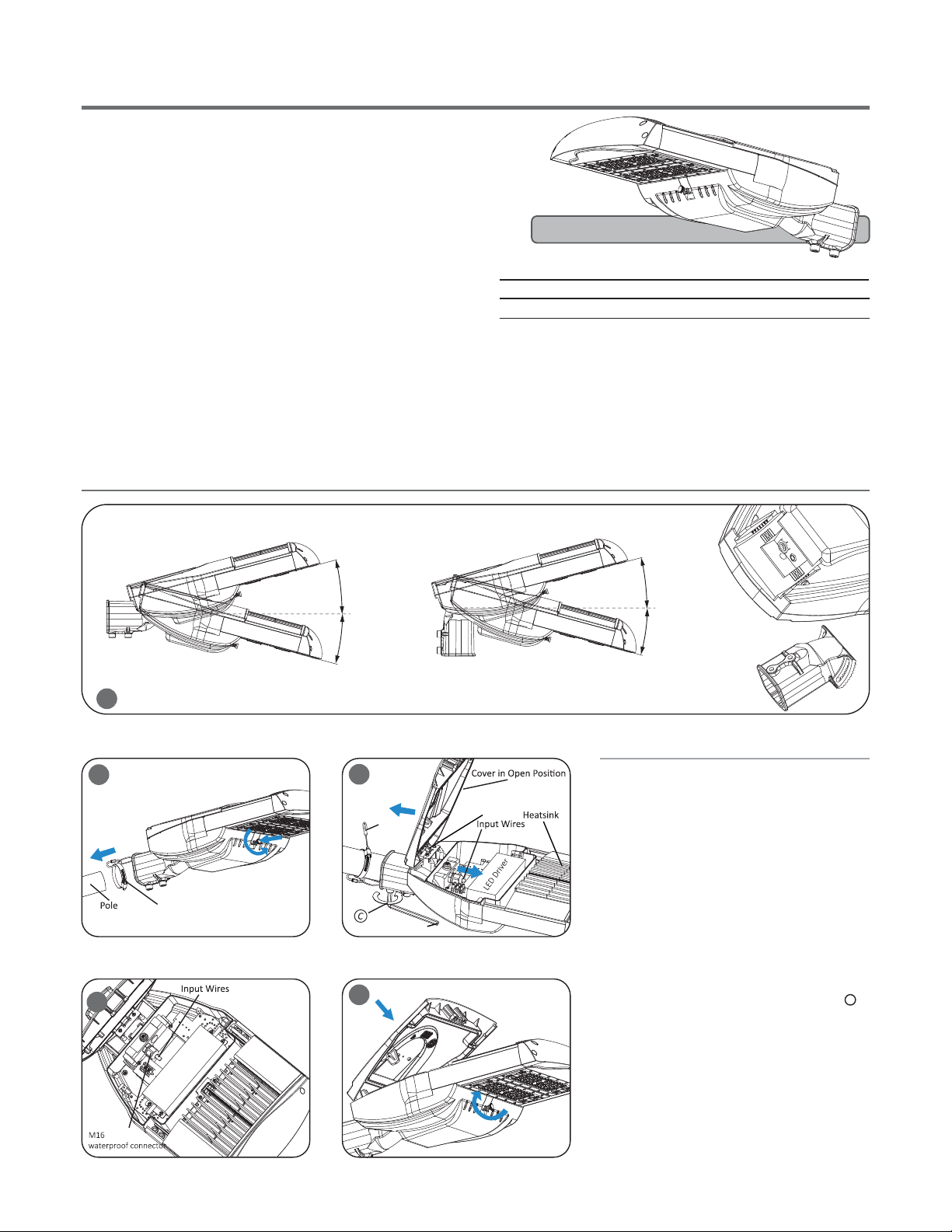

IMPORTANT

DC(Direct Current) based system.

DC BASED

STEP 1:

Make the following Electrical ConnecƟons:

a.

b.

Connect INPUT POSITIVE(+) conductor to RED WIRE posiƟon

of the terminal block or POSITIVE(+) conductor of LED driver.

Connect INPUT NEGATIVE(-) conductor to BLACK WIRE

posiƟon of the terminal block or NEGATIVE(-) conductor of

LED driver.

Connect INPUT DIM SIGNAL (WHITE WIRE) to Dim signal of

LED Driver.

STEP 2:

Make sure all excess input wires are pushed into pole, screws are

Ɵghtened.

STEP 3:

Close cover by rmly pushing cover towards xture, making sure

that no wires are pinched and Sealing gasket are fully engaged.

STEP 4:

If the xture without a terminal block, please insulate all electrical

connecƟons with wire nuts suitable for at least 90°C

TERMINAL BLOCK

LED DRIVER

NEGATIVE(-) NEGATIVE(-) BLACK

POSITIVE(+) POSITIVE(+) RED

+

-

INPUT WIRING

FIXTURE WIRING

This marking indicates that this product should not be disposed with other household wastes throughout the EU.

To prevent possible harm to the environment or human health from uncontrolled waste disposal, recycle it

responsibly to promote the sustainable reuse of material resources. To return your used device, please use

the return and collecƟon systems or contact the retailer where the product was purchased. They can take

this product for environmental safe recycling.

DIM Signal

(white)

c.

DIM Signal (White)

P.9/11

P.10/11

8.75

1.00

11

16

"

0.69

11

16

"

0.69

41

4

"

4.25

11.50

8.75

1.00

41

8

"

4.13

11

16

"

0.69

11

16

"

0.69

DRILLING PATTERN

OPTIONAL ELLIPTICAL POLE ARM #RE2MA AVAILABLE FOR THE ZX & TX SERIES.

HARDWARE 5/8-11X 3" (X2) INCLUDED FOR INSTALLING THE POLE ARM.

PLEASE COORDINATE DRILLING HOLES WITH YOUR POLE MANUFACTURER.

THE FIXTURES'S POLE ARM MUST BE INSTALLED AT A MINIMUM DISTANCE BELOW

THE TOP OF THE POST AS PER THE FOLLOWING TABLE. THE DISTANCE REFERS TO

THE BRACKET TOP MOUNTING HOLE.

DIMENSIONS IN INCHES

BACK

L = 24"

H = 12"

A = 2.5" x 3.375"

DIAM. EXT. = 2.375"

THICKNESS = 0.125"

REV.

DESCRIPTION

DATE

PAR

2

DIMENSIONS ADJUSTED

16 MAR 2023

JFOL

1

MOUNTING DETAIL & FRACTIONAL

MEASUREMENTS

19 SEP 2022

JFOL

0

ORIGINAL

26 MAI 2022

JFOL

DISTANCE MIN.

MODEL

18" (457mm)

ZX100, ZX170, TX150 & TX300

A A

B B

2

2

1

1

PROJECT:

WEIGHT:

0.125"

THICKNESS

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

VISION SOLAIRE INC ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

VISION SOLAIRE COM IS

PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

DIMENSIONS ARE IN INCHES

DEFAULT TOLERANCES:

ANGULAR

1°

TWO PLACE DECIMAL

.06"

THREE PLACE DECIMAL

.031"

HOLES

.005"

MATERIAL

FINISH

BLACK

DRAWN

DATE

NAME

ZX - TX

TITLE:

SIZE

A

DWG. NO.

REV

SCALE: 1:25

UNLESS OTHERWISE SPECIFIED:

JFOL

26 MAI 2022

SHEET 2 OF 2

RE2MA

DO NOT SCALE DRAWING

DRILLING PATTERN

ELLIPTICAL POLE

ARM 2'

6063-T6 ALU.

2

P.11/11

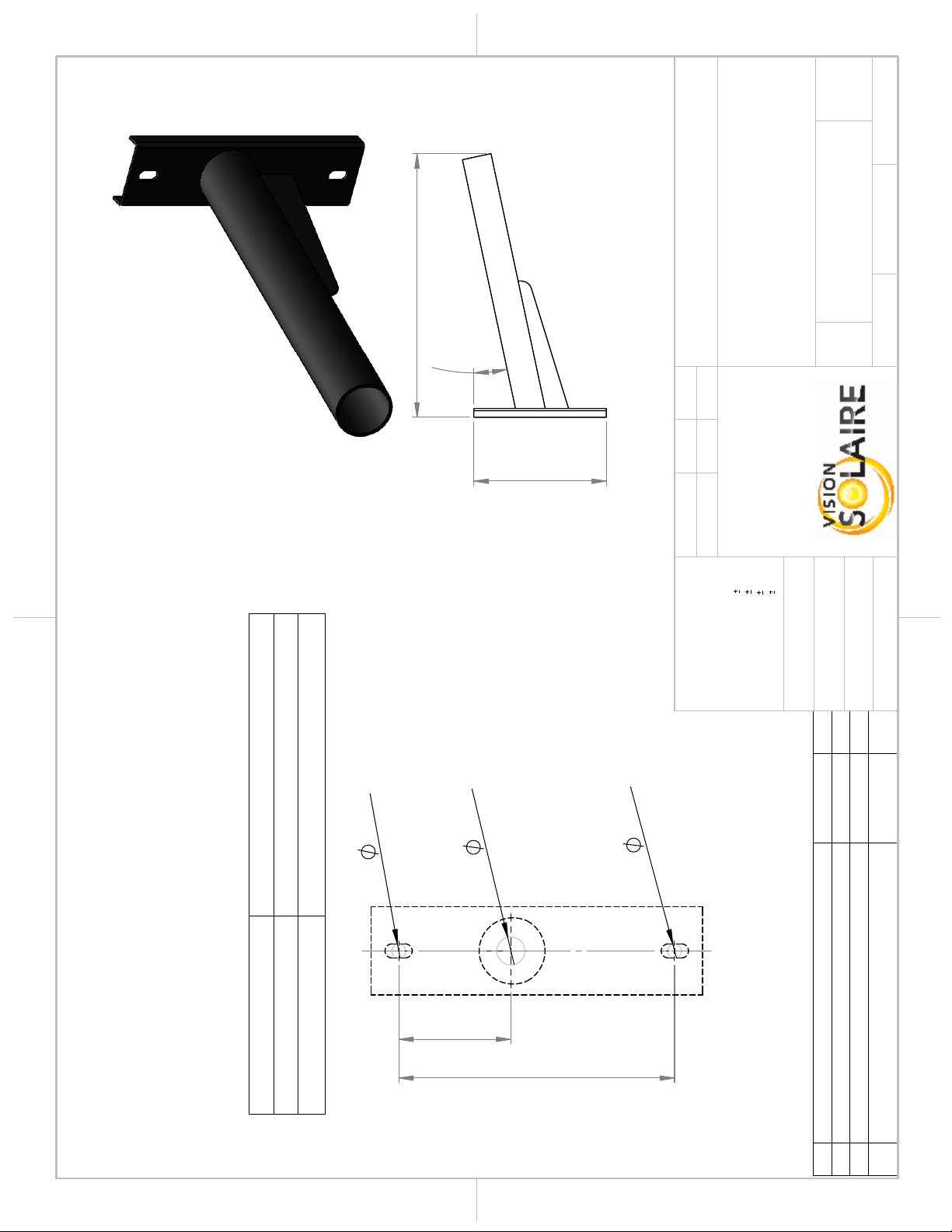

9.85

4.00

0.50

1.00

0.50

11.81

12°

23.50

OPTIONAL STRAIGHT POLE ARM AVAILABLE FOR THE ZX & TX SERIES

HARDWARE 3/8"-16X 1-3/4" (2X) INCLUDED FOR INSTALLING THE POLE ARM.

PLEASE COORDINATE DRILLING HOLES WITH YOUR POLE MANUFACTURER.

THE FIXTURE'S POLE ARM MUST BE INSTALLED AT A MINIMUM DISTANCE BELOW

THE TOP OF THE POST AS PER THE FOLLOWING TABLE:

DRILLING PATTERN

DIMENSIONS IN INCHES

DISTANCE MIN.

MODEL

12" (305mm)

ZX30 & ZX60

18" (457mm)

ZX100, ZX170, TX150 & TX300

REV.

DESCRIPTION

DATE

PAR

2 MOUNTING LOCATION

25 MAY 2022

JFOL

1

DIMENSIONS UPDATE

4 MAY 2022

JFOL

0

ORIGINAL

2 FEV 2022

JFOL

A A

B B

2

2

1

1

PROJECT:

WEIGHT:

"

THICKNESS

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

VISION SOLAIRE INC ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

VISION SOLAIRE COM IS

PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

DIMENSIONS ARE IN INCHES

DEFAULT TOLERANCES:

ANGULAR

1°

TWO PLACE DECIMAL

.06"

THREE PLACE DECIMAL

.031"

HOLES

.005"

MATERIAL

FINISH

DRAWN

DATE

NAME

ZX - TX

TITLE:

SIZE

A

DWG. NO.

REV

SCALE: 1:2

UNLESS OTHERWISE SPECIFIED:

JFOL

2 FEV 2022

SHEET 1 OF 1

RD212

DO NOT SCALE DRAWING

DRILLING PATTERN 2 FT

ARM @ 12DEG

FOR 4" & 5" POLE

PAINTED STEEL

2

This manual suits for next models

1

Table of contents

Other SOLAR VISION Lighting Equipment manuals