Page 2

9-11501696

',#'

'&!$#%'"''#%'&"&'%('#""( %( ,#%"&' "#%(&"'$%#('2# #*"

'&"&'%('#"&* "&(%'',#(%)"' '#"&,&'!&"&' 4#!!&&#""(&$%#$% ,"

#"'"(&'##$%'') ,2'% * "#' %&$#"& "* "#' $' ',#%",

!(&'#$%&#"&#%$%#$%','%#( (%'## #*'("$%#)"'&!"( 2'

&#( *,&) *''$%#('#%&,%%"2

#(%("'&*'#2'&&"'#%("#"'"(#(& ,2'&&*'#"##%

$# ('"'"!#&'(% ) &!,"%&2

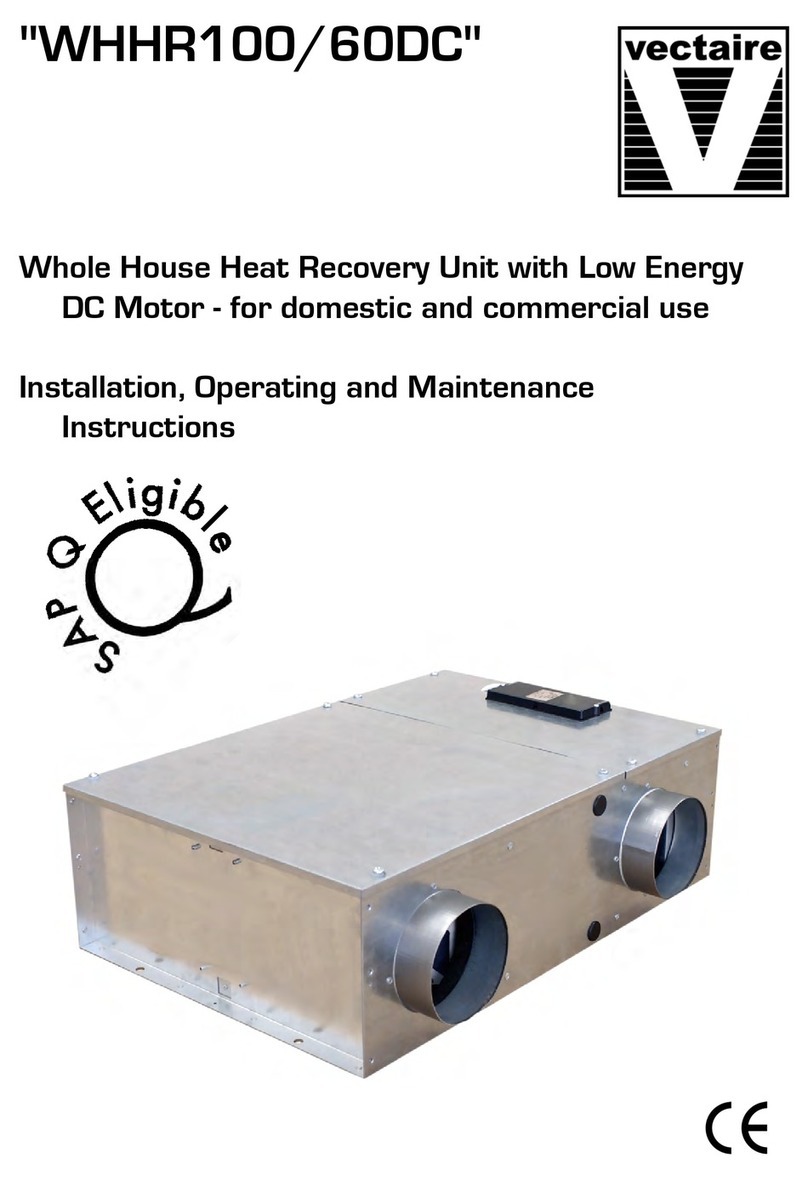

-115016 (&3 5"/125mm spigot, for dwe ings up to 200m2, max capacity 80 /sec

"% "#%!'#"

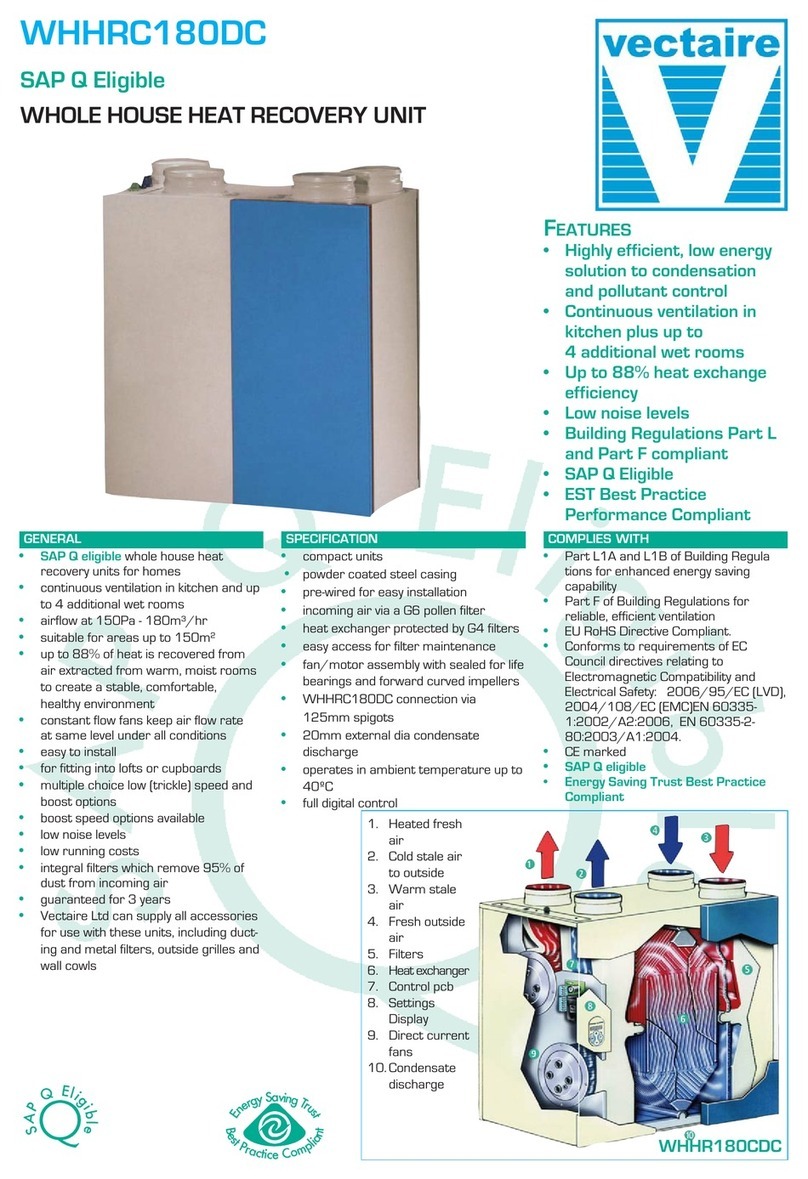

The Vectaire WHHR100/90DC-B P us heat recovery system pro-

vides who e house mechanica venti ation to iving areas, bedrooms,

kitchen and bathrooms. It extracts sta e, contaminated air from

kitchens, uti ity rooms and bathrooms, and uses the heat recovered

from this air to warm fresh, incoming air to create a f ow of fresh air

throughout the dwe ing. The extract and intake air streams are sep-

arated to avoid contamination.

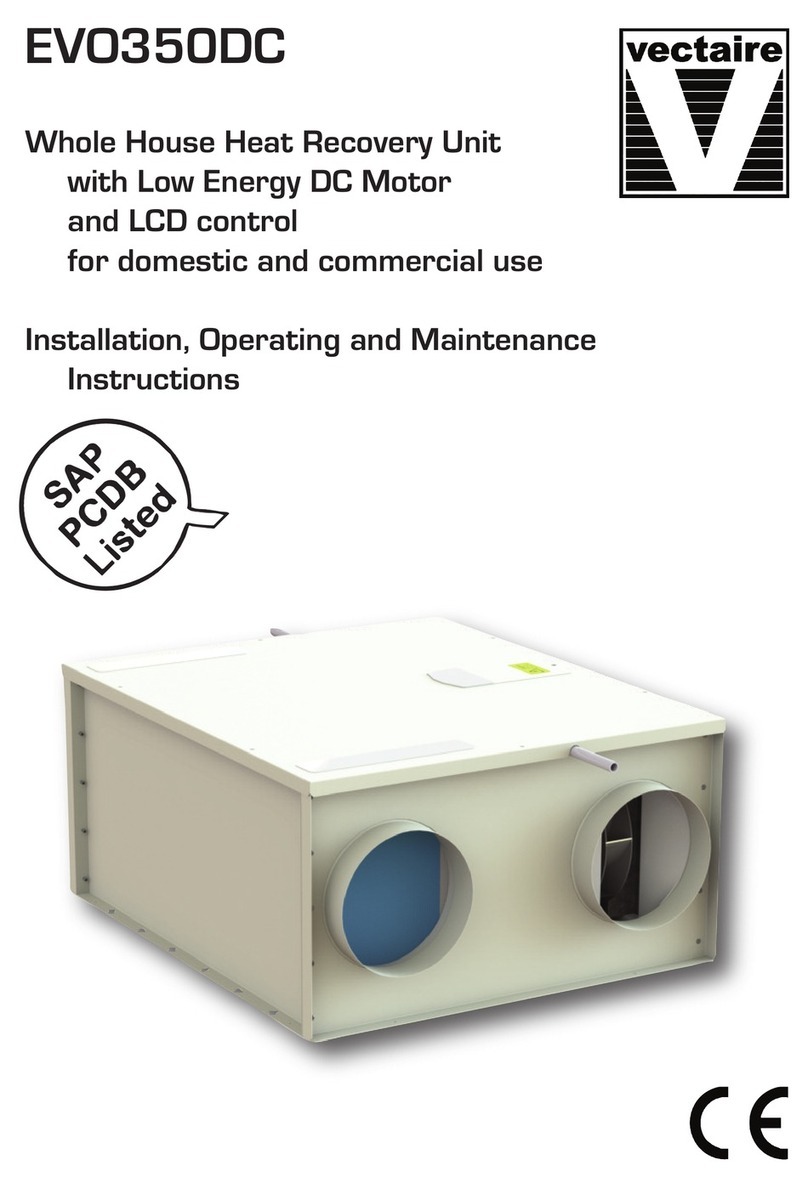

Heat is rec aimed from extracted air and used, via the heat exchange

process, to warm incoming fresh air. The system wi operate contin-

uous y to create a stab e, comfortab e, hea thy environment avoiding

the use of excessive energy and saving heat a ready generated.

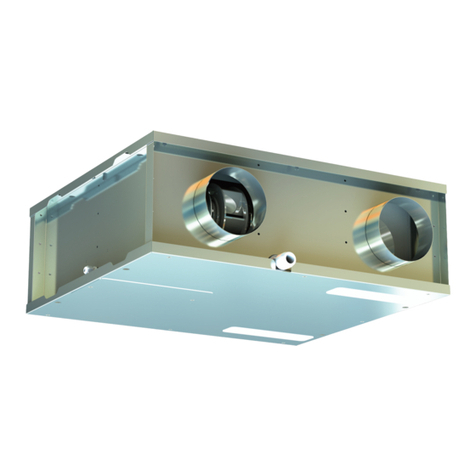

The heat recovery unit wi genera y be insta ed in the oft of a house

or the void above the cei ing in an apartment (but may be insta ed in

a cupboard) and wi be connected by hidden ductwork to vents sited

in the cei ings of the rooms which require venti ation. Each unit is

commissioned individua y a owing its performance to be tai ored to

suit the performance required. There wi be a faci ity to boost the

extraction rate when desired (e.g when cooking or bathing or po utant eve s rise). This may be done automati-

ca y or manua y.

&,&'!&&"'#%("#"'"(#(& ,"&#( &*'#+$'#%!"'""#% '%

%$ !"'2

'(%&

: who e house heat recovery unit giving continuous venti ation in the kitchen and up to four

additiona wet rooms (using rigid ducting)

:ow noise eve s

:variab e choice ow (trick e) speed and boost options for optimum setting at insta ation

:boost speed can be triggered by a switched ive connection from a variety of externa devices inc uding:

- PIRFF (passive infra red)8

- DRH240 (dynamic remote humidistat)8

- THM (thermostat)8

- a ight switch (if more than one ight switch is used, #"!(&'#( $# &*'7

- a remote switch/pu cord

(8PIRFF, DRH240 and THM may have integra over-run timer which contro s the ength of time that the fan

wi continue to operate at its boost speed after the boost has been switched off.)

:Insta ation MUST be carried out by suitab y qua ified personne and MUST be in accordance with current IEE

regu ations and a appropriate standards and app icab e regu atory guidance.