Solaris LoCor Recessed Electronic Dispenser User manual

8777002

Released February 22 2019

SOLARIS LOCOR® RECESSED ELECTRONIC ROLL TOWEL DISPENSER USER GUIDE (SKU NUMBERS D68011-A)

The LoCor Recessed Electronic Dispenser isdesigned to be mounted into the wall orinside arecessed cabinet onthe wall toyield maximum space in the

busy bathroom environment. The paper is delivered automatically by positioning a hand underneath the center bottom of the dispenser. The remaining

roll towel is maintained inside the unit to avoid cross contamination. With the stainless steel cover, the dispenser offers both attractive appearance and

easy cleaning ability; all together providing a maximum sanitation.

The dispenser is designed for an opening of 10 5/8” Width x 15 1/8” Length x 4” Depth.

TABLE OF CONTENT

I. Dispenser Installation Instruction ………………………………………………………………………………………………………….

1. Install Directly into the Wall – Using A Picture-Frame Panel …………………………………..……….……….

2. Install into Existing Recessed Cabinets on the Wall - Using Filler Panels ……………..……….……….….

Page 2

2a. Use Insert Filler Panel ………………………………………………………….……………….…………….

2b. Use Hanging Filler Panel ……………………….…………………………………………………………….

II. Changing Mounting Side of Cover …………………………………………………………………………………………………………..

III. Roll Support Installation …………………………………………………………………………………………………………………………

1. For 7” Width Solaris LoCor Paper Towel SKU Numbers 46897, 46989, 46899, 46902 ……………….

2. For 8” Width Solaris LoCor Paper Towel SKU Numbers 46896, 46901 ……………………………………..

IV. Power-up the Dispenser .....……………………………………………………………………………………………………………………

IX.Failure Diagnostics …………………………………………………………………………………………………………………………………

1

Outer dimension is 18.17" x 14.67" x 10.97", weighs approximately 9.8 lbs.

VI.Switch Control Settings ………………………………………………………………………………………………………………………....

VII.LED Indicator Light Function ………………………………………………………………………………………………………………...

VIII.Stub-Roll Transfer Loading ……………………………………………………………………………………………………………………..

V. Paper Loading andInitiate the First Dispense .......…………………………………………………………………………………

Page 2

Page 4

Page 5

Page 5

Page 7

Page 8

Page 8

Page 8

Page 9

Page 9

Page 10

Page 10

Page 10

Page 10

I. DISPENSER INSTALLATION INSTRUCTION

1. Install Directly into the Wall – Use A Picture-Frame Panel

Hardware provided with the dispenser:

oKey

o(4) Screws #10 x 1”L, Phillips Head

o(4) Wall Anchors

Tools and materials required (not provided):

-Stud Finder

-Pencil

-Tape Measure

-Level

-Knife or Saw (to cut drywall)

-Powered Screwdriver with Phillips Head and 1/4" Hex Head Drive

-Cotton Gloves

-(2) Studs 2” x 4” x 12”L

-(6) Screws #10 x 1 1/2”L, Phillips Head

Step 1: Dispenser Location

Determine the location of the dispenser to be mounted. Ensure there will be

no interference during the opening and closing of the cover or when paper is

dispensed at the bottom of the dispenser.

Step 2: Studs’ Location

Use a Stud Finder to find the location of the two studs on both sides of the

area where the dispenser will be mounted. Mark the locations of the studs.

Step 3: Cut the Opening on Drywall

Knowing the studs’ location, the dispenser should be mounted roughly in the

middle, between the two studs. The bottom of the dispenser should be 48

inches from the floor.

To install the dispenser into the wall, it is required to cut an opening of

10 5/8” W x 15 1/8”L on the drywall.

Recommend to use a pencil outlining the opening before cutting into the

drywall:

-Using a tape measure, place a mark of 48” from the floor. Then use a

level to draw a horizontal line from the mark. This is the bottom line

of the opening.

-Using a tape measure, place a mark of 15 1/8” from the bottom line

drawn from the last step. Then use a level to draw a horizontal line

from the mark. This is the top line of the opening.

-Use the level to draw two vertical lines to connect the top and

bottom lines. These two lines should be 10 5/8” apart from each

other. These two lines should be roughly in the middle, between the

two studs.

Now use a knife or a saw to carefully cut the opening out of the drywall.

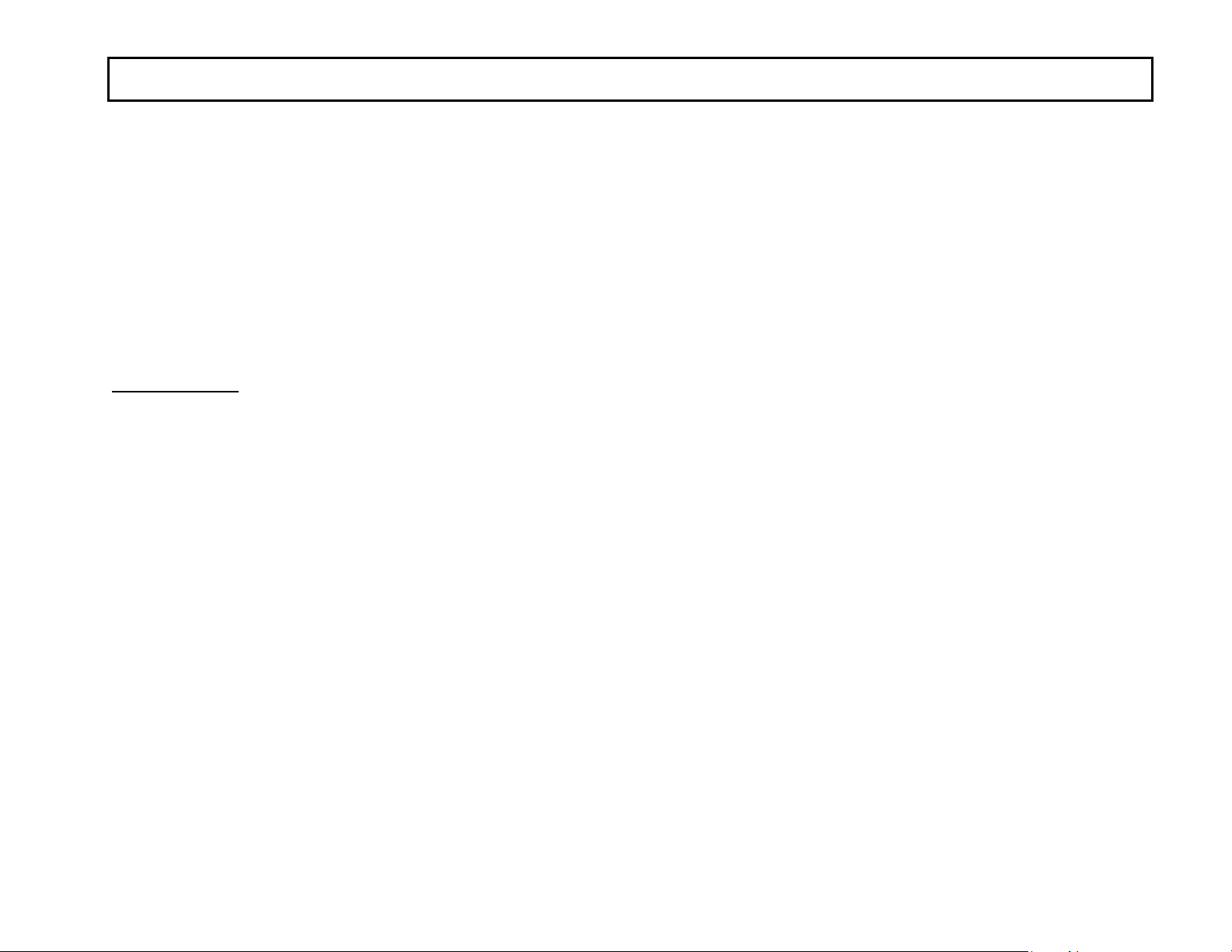

See Figure 1 for more details.

Floor

Figure 1.

10 5/8"

15 1/8"

48"

8777002

Released February 22 2019

2

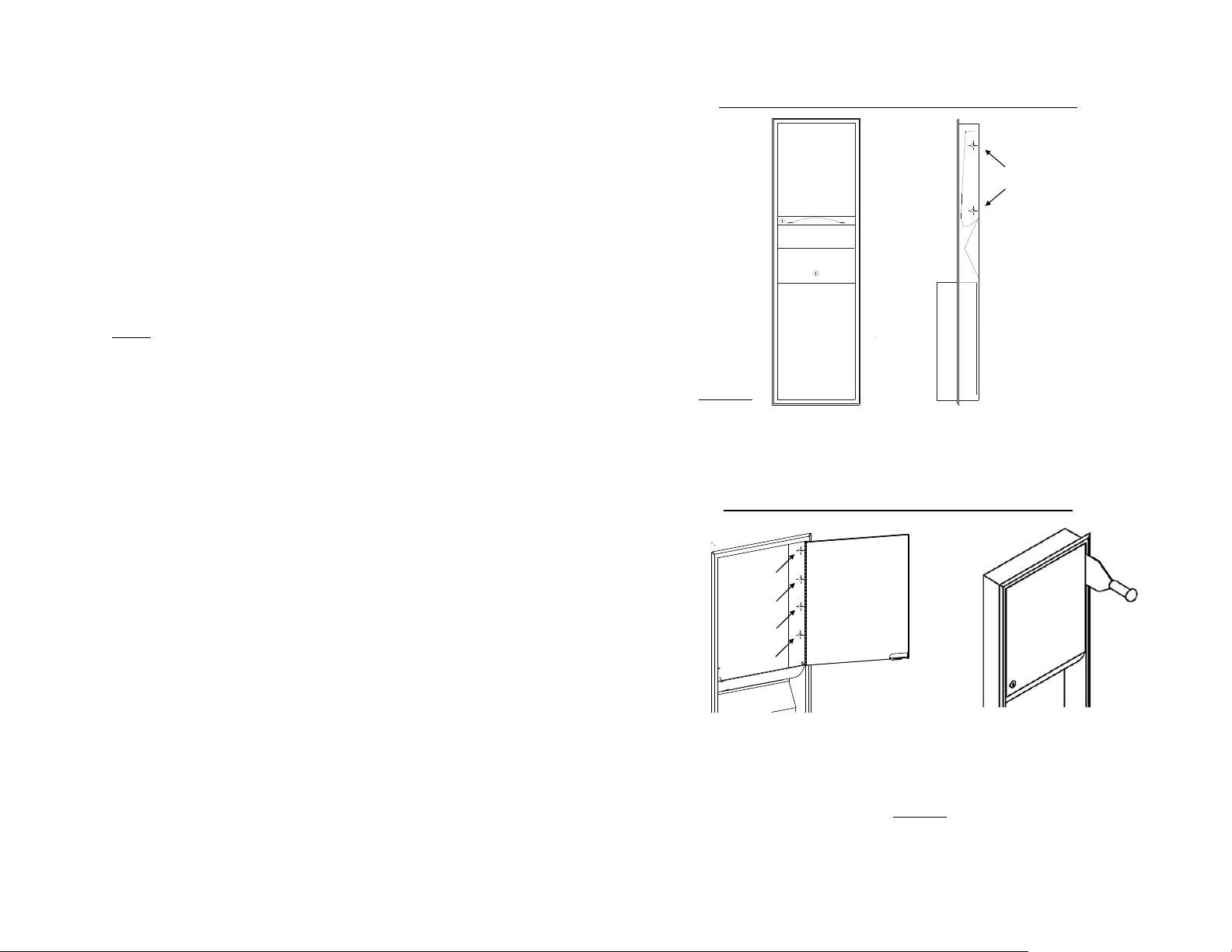

Step 4: Install the Two Supporting Studs

Install thetwostuds(2” x 4” x 12”L) onthe left side and right side of

the opening, behind the drywall (Figure 2). Drive three screws #10 (1 1/2" L)

through the drywall into each stud on both sides (total of six screws to be

used).

Step 5:Install the Picture-Frame panel and the dispenser into the wall.

Remove the protecting film on the outside of the panel. Recommend touse

cotton gloves to handle the panel after the film is removed to avoid finger

prints.

Carefully place the dispenser into the big opening on the panel. Then install

the assembly (of the cover and the panel together) into the opening on the

wall. Slide the dispenser all the way in; ensure there is no gap between the

panel and the wall.

Use the key (provided) toopen the cover. Drivefour #10 screws (also

provided) into the mounting holes on the left and right sides ofthe dispenser

to secure the dispenser in position. See Figure 3 formore details.

The dispenser isnowready for Roll Support installation and paper loading.

Figure 2.

Figure 3.

PICTURE-FRAME

PANEL

screw# 10 in step 4

mounting holes

inside the

dispenser

supporting studs

8777002

Released February 22 2019

3

2. Install into Existing Recessed Cabinets on the Wall – Use Filler

Panels

Tools and materials required (not provided):

-Power Drill with:

oPhillips Head Drive

o1/4” Hex Head Drive

o1/8” Drill Bit

-Marker

-Cotton Gloves

-Other tools may be required, depends on the type of the existing

dispenser in the recessed cabinet

Step 1: Remove the Existing Dispenser from the Recessed Cabinet

Open the cover of the existing dispenser and remove the paper towel (if it is

present) to examine whether the dispenser was secured in the cabinet by

screws/nuts, rivets or by spot welding.

*If the existing dispenser is secured by screws, use the power drill with the

Phillips Head Drive to loosen the screws to remove the dispenser out of the

cabinet.

* If the existing dispenser is secured by nuts, use the appropriate socket to

loosen the nuts to remove the dispenser out of the unit.

* If the existing dispenser has the cover riveted or spot welded to the

recessed cabinet, use the power drill with the 1/8” drill-bit to drill out the

rivets and spot-welds inside of the dispenser. Then carefully use a hammer

and a chisel to separate the hinge side of the cover from the cabinet frame.

See Figure 5 for more details.

Here are some examples of the existing recessed dispensers:

Recessed Paper Towel Dispenser secured by screws/nuts

Recessed Paper Towel Dispenser secured by spot welds

Open the cover and

loosen screws/nuts on

the sides to remove

the existing dispenser

Use a hammer and a chisel to

separate the hinge side of the

cover from the cabinet frame.

Use power drill and 1/8” drill bit todrill out

the rivets or spot welds (from the inside of

the existing dispenser).

Figure 4.

Figure 5.

8777002

Released February 22 2019

4

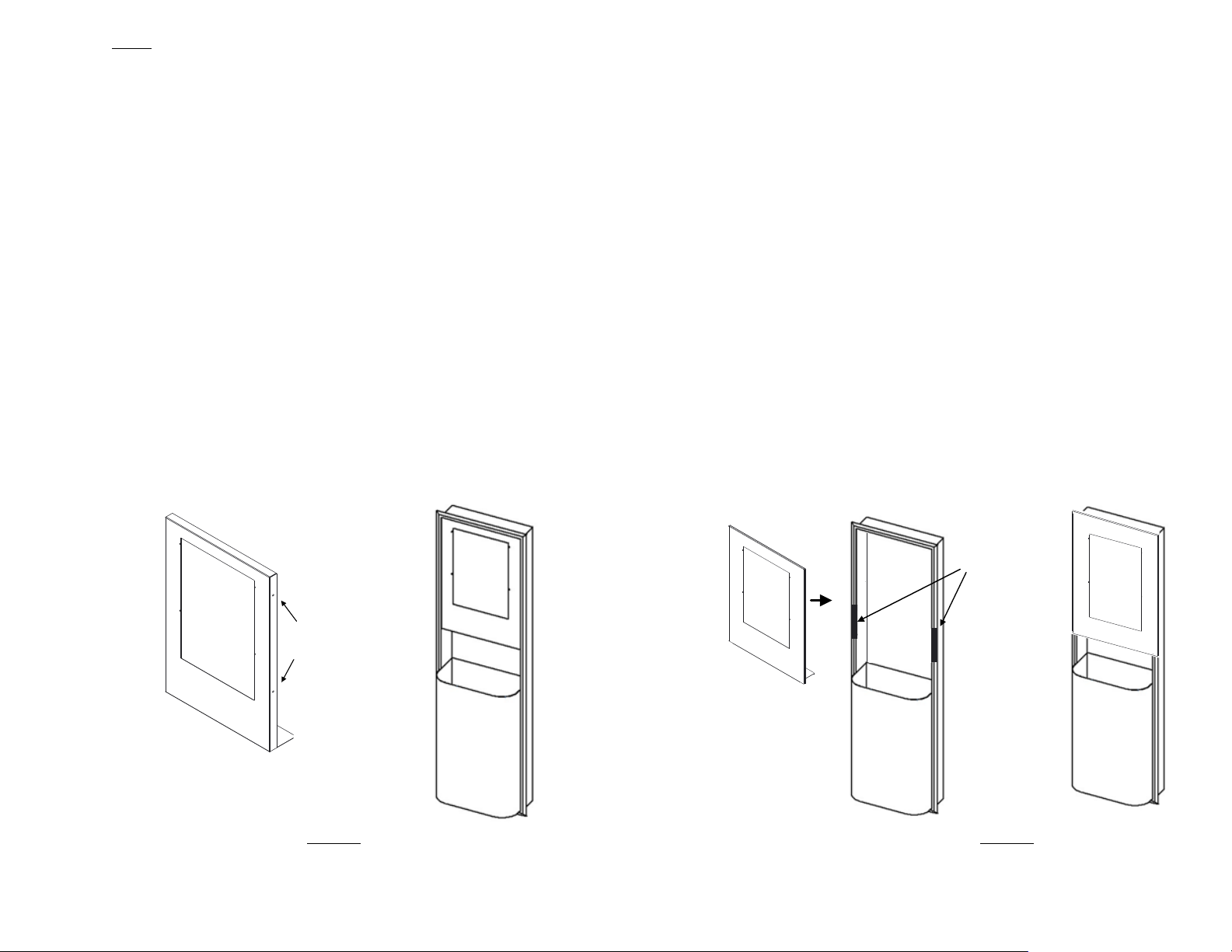

Step 2: Filler Panel Installation

a. Use Insert Filler Panel

Hardware provided with the Insert Filler Panel:

o(4) Screws #8 x 3/4”L, Hex Head

o(4) Screws #6 x 1 1/4”L, Phillips Head

Do not remove the protecting film on the outside of the panel yet.

-Place the panel (with theprotecting film still on) into the cabinet

with the top of the panel tobein the contact with the top of the

cabinet.

-Note that there are two mounting holes on each of the left and right

sidesof the panel.Use the marker to mark the holes’ locations.

Carefully remove the panel out of the cabinet.

-Use the power drill with the 1/8” drill-bit to drill four holes at the

marks. Each hole should be roughly 1-inch deep.

-Remove the protecting film on the outside of the panel. Recommend

to use cotton gloves to handle the panel after the film is removed to

avoid finger prints.

-Carefully slide the panel into the cabinet. Drive four #8x 3/4”L Hex

Head screws (provided) into the mounting holes on the left and right

sides of the panel to secure the panel tothe cabinet.

Figure 6.

b. Use Hanging Filler Panel

Hardware provided with the Hanging Filler Panel:

o(4) Screws #6 x 1 1/4”L, Phillips Head

o(3) Double Sided Tape Strips

Remove the protecting film on the outside of the panel. Recommend to put

the cotton glove on the one hand that is used to hold the panel to avoid

finger prints. The other hand that is used to peel the film will not need glove.

Use two double-sided tape strips (provided).

-Remove the backings on one side of the tape and place them with

the adhesive side onto the bezel as showed in Figure 7. Keep the

backings remaining on the front face of the tape.

-Loosen the screws that were used to secure the cabinet to the studs

(typically these screws locate on the left and right sides ofthe

cabinet). Store these screws for later use.Then pull the top part of

the cabinet out slightly, just enough to hook the top of the panel

onto the top of the cabinet.

-After the top of the panel ishung, remove the backings of the tape

and then press the panel onto the tape tosecure it in place.

-Install the mounting screws on the left and right sides the cabinet

to complete the panel installation.

Figure 7.

tape

mounting holes

double sided

Finished Look

Finished Look

8777002

Released February 22 2019

5

Step 3: Dispenser Installation

Hardware provided with the dispenser:

oKey

o(4) Screws #10 x 1”L, Phillips Head

o(4) Wall Anchors

Through the front opening of the panel, slide the dispenser all the way in,

make sure that the back of the dispenser is in contact evenly with the back of

the cabinet. There are two options to secure the dispenser:

Option 1: Drive the four screw# 10 (provided) into the mounting

holes on the back ofthe dispenser tosecure the dispenser tothe

cabinet.

Caution Note: The length of the screw# 10 is1 inch, which may be

longer than the thickness ofthe drywall on the back ofthe cabinet.

Ifitisnot acceptable, please use option 2.

Option 2:Drive the four screw# 8 (provided) into the front mounting

holes on the stainless steel panel tosecure the dispenser into place.

The dispenser is now ready for Roll Support installation and paper loading.

Figure 8.

8777002

Released February 22 2019

6

Note: If using the method described in option 2, it is recommended

to enlarge the front mounting holes of the panel (using an 1/8" drill

bit) prior to the installation. That will help drive the screws in the

metal easier.

The cover is designed to be mounted on either left or right side of the

housing. Manufacturing setting is left-side mounting. To change to right-side

mounting, follow steps 1 - 5:

Step 1:Remove Hinge Pins (Top & Bottom)

First remove the e-clips atthe end of the pins. Then remove the pins.

Step 2:Remove the Removable Hinges (Top & Bottom)

First remove the screws. Then remove the hinges.

Step 3: Remove the Door Seal Plug

Flex one of the legs to push the door plug out.

Step 4:Remove the Lock

First remove the screws. Then remove the lock.

Step 5:Reverse steps1 - 4 and switch side when install the components back

on the cover. Note that the Hinges and Pins should be installed on the same

side that the cover is desired to be mounted on. The Lock should be installed

on the opposite side of the Hinges. And the Plug should be installed on the

same side as the Hinges.

See Figure 9 for more details.

Pin

Removable Hinge

E-clip

Top Hinge

E-clip

Removable Hinge

Pin

Lock

Screws

Door Seal Plug

Flex one of

the three legs

to push the

plug out

II.CHANGING MOUNTING SIDE OF COVER

Figure 9.

Bottom Hinge

8777002

Released February 22 2019

7

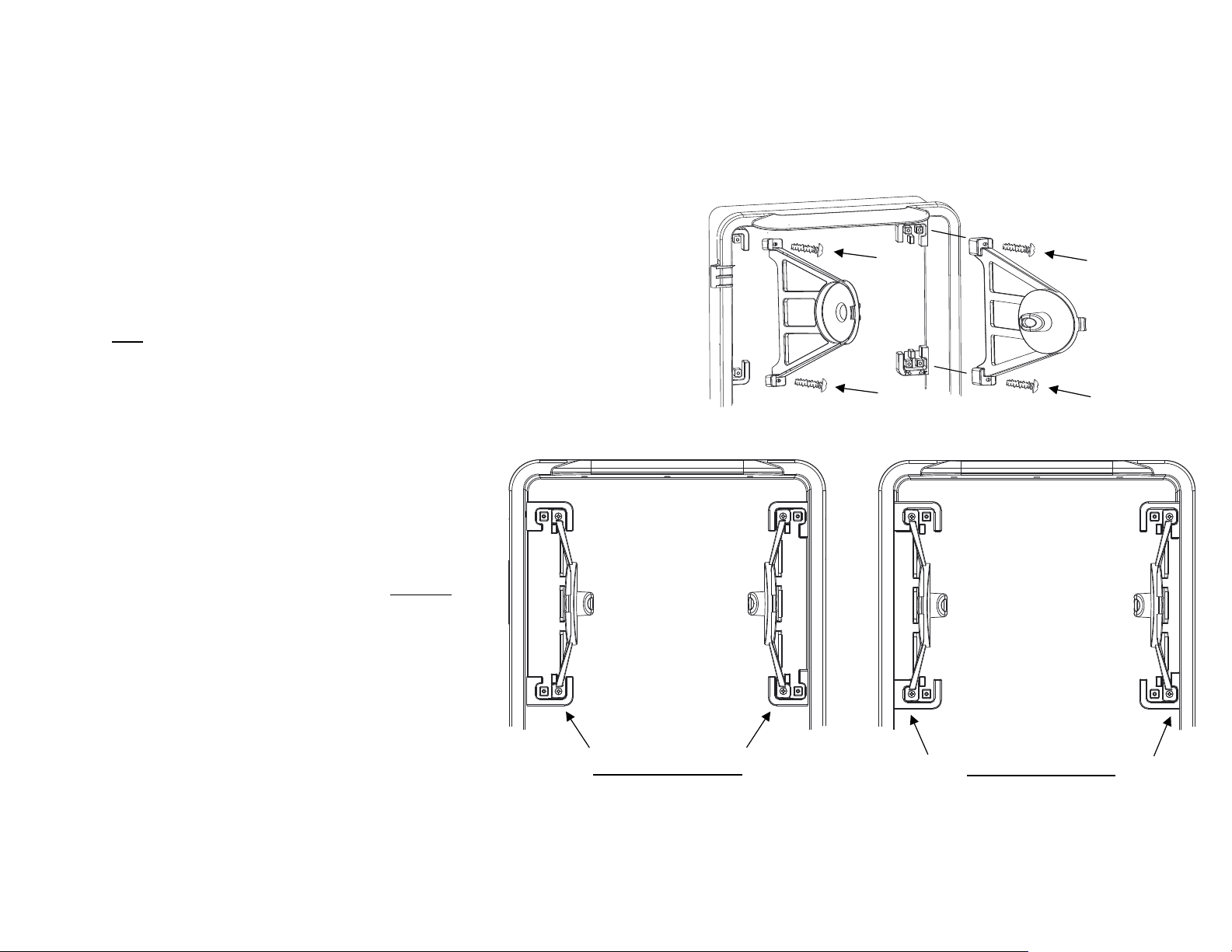

The dispenser isdesigned to accept both the 7”and 8” wide LoCor Roll

Towels. Itisvery important toidentify the width of the paper roll before

installing the Roll Supports:

SKU Numbers for 7”Width LoCor Paper Towel:46897, 46898, 46899, 46902

SKU Numbers for 8”Width LoCor Paper Towel:46896, 46901

After identifying the paper roll width, install the Roll Supports from the

supplied kit included with the package:

- Two Roll Supports

- Four Screws

- Roll Support Installation Instruction Sheet

7" WIDTH ROLL SUPPORTS 8" WIDTH ROLL SUPPORTS

III.ROLL SUPPORTS INSTALLATION

Note: Need to use a Phillips Head Screwdriver for the installtion. Use four

screws (provided) to install the Roll Supports into the correct places on the

back of the housing. See Figure 10 for more details.

Figure 10.

8777002

Released February 22 2019

8

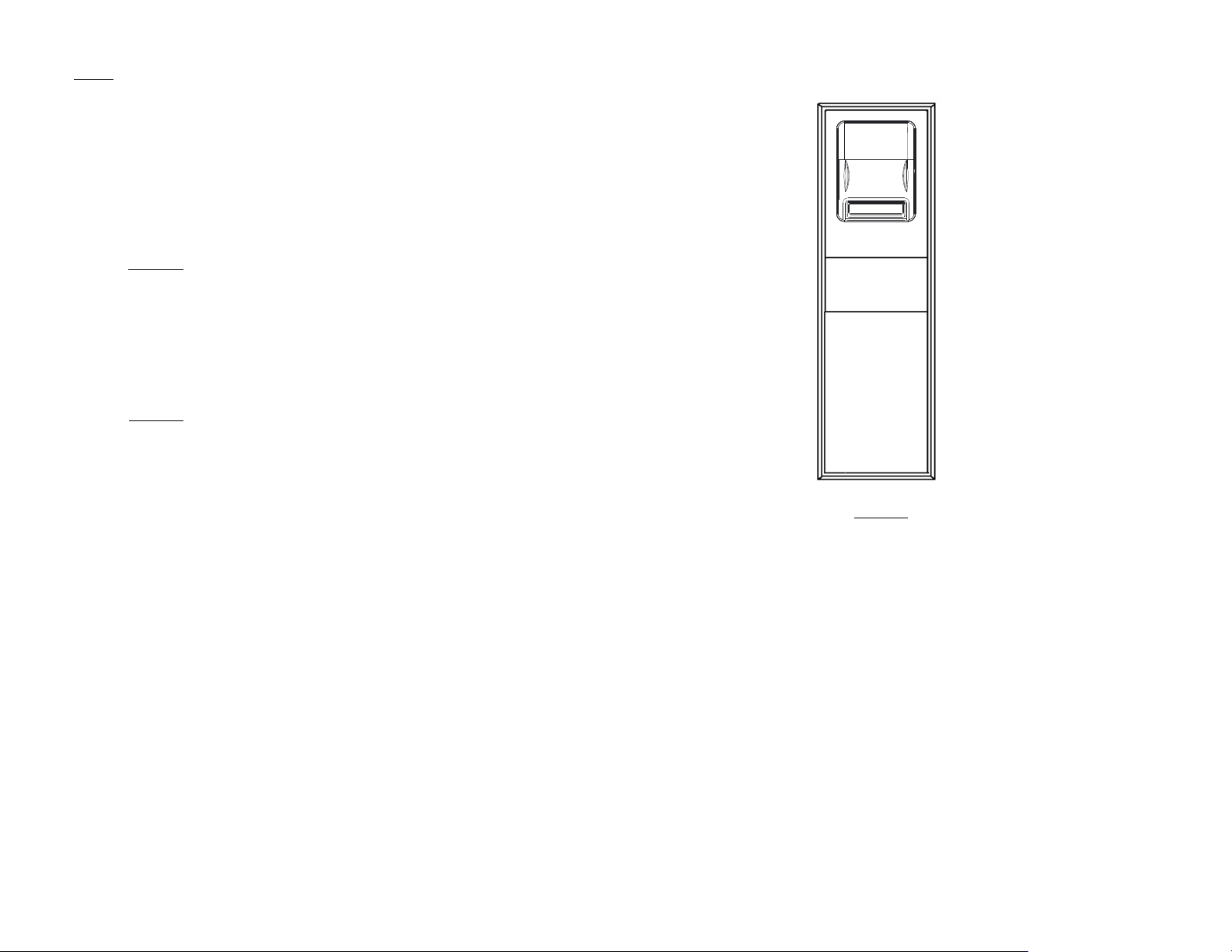

Figure 11. Top View Section-Cut of the Dispenser

STUB ROLL SUPPORTS

BATTERY

COVER

STUB-ROLL

MONITOR

TRANSFER

ARM

DC JACK

CONTROL

SWITCH

LED

LIGHT

Paper should be loaded with the paper “tail” unwinding from the back of

the roll. Place the paper "tail" under the Transfer Arm (Figure 11). Close

the cover and wait for the first LED flashing to indicate that the dispenser

is now ready for dispensing. Place a hand underneath the bottom center

of the dispenser to initiate the first dispense.

V.PAPER LOADING AND INITIATE THE FIRST DISPENSE

IV.POWER-UP THE DISPENSER

For use with LoCor paper towels only(SKU numbers 46896,

46897, 46898, 46899, 46901 and 46902). Other types ofpaper are

not acceptable.

Power-up the Dispenser Using Batteries

Recommend to use the four batteries provided with the

dispenser or use D-size alkaline batteries labeled with "LR20"

designation only.

Open the cover using the key supplied in the hardware pack.

Note that the battery compartment locating at the front of the

dispenser (Figure 11). Remove the Battery Cover by pushing on

the tab inward and lifting up. Install four batteries into the

battery-compartment with the orientation as showed on the

bottom of the compartment. Close the Battery Cover.

Power-up the Dispenser Using a Power Converter Plug

Recommend to use the power converter plug provided with the

dispenser only.

First, verify the dispenser does not have batteries installed.

Remove the dispenser from the mounting cabinet/wall if the

dispenser was mounted. Note the location of the DC Jack in in

the back of the dispenser (Figure 11). Make sure there is an

access hole and enough space to safely route the wire into the

cabinet or into the wall. Plug the power converter into the DC

Jack. Install the dispenser. Plug the converter into the outlet.

For warranty and safety purposes, it is required the power

converter must be plugged in an AC outlet that is not accessible

to the users. If not available, consult a licensed electrical

contractor. The power converter output is to be routed through

the mounting wall as a low voltage, energy limited circuit, similar

to a thermostat wire, with no requirement for electrical box or

attachment strain relief.

8777002

Released February 22 2019

9

For further assistance, please contact technical dispenser support at (920) 940-8904

VI.SWITCH CONTROL SETTINGS

There are three switches available to customize the control system. These

switches are inside, to the back-right corner of the dispenser (see Figure 11).

Switch# 1 is designed for paper saving method. Using this method, any dispense

that occurs within 3 seconds of the previous dispense will result in a sheet that is

shorter (paper saving) than the initial dispense.

Switch# 2 is designed to control the delay-time between two dispense actuations.

Switch# 3 is designed to control the sheet length of each regular dispense.

Switch# 1: Paper Saving Mode

Switch# 2: Dispensing Delay

Switch# 3: Paper Length

12.5% Saving

0% Saving

25% Saving

Approximately 2 seconds

Approximately 1 seconds

Approximately 1/2 seconds

Long

Medium

Short

VII.LED INDICATOR LIGHT FUNCTION

The LED indicator light located at the right top corner of the opening where the

paper is dispensed.

If using batteries, the LED light will flash one time after the batteries are installed

correctly to indicate that the unit is powered up. The LED light will also flash

once after every dispense to indicate the unit is ready for the next use. When the

batteries need replacement, the LED light will flash every 1.5 seconds.

1. If the LED is flashing, batteries may need to be replaced (if using batteries).

2. If the LED is not flashing, make sure batteries are present and loaded in

the correct orientation. If using Power Converter Plug, check the plug-

connections.

3. Open the cover:

a. Make sure paper is loaded correctly, on the correct roll holders.

b. Make sure paper is not jammed, paper roll turns freely and the

paper path is clear of obstructions.

8777002

Released February 22 2019

10

If using Power Converter Plug, the LED light will flash every 1.5 seconds to indicate

that the plug is connected to the power supply.

VIII.STUB-ROLL TRANSFER LOADING

When the paper roll gets down to 3-inch in diameter or smaller, the roll can be

transfered to the stub-roll holders in the lower, rear section of the dispenser.

Place the paper "tail" underneath the Stub-Roll Monitor so that paper from the

stub-roll can be used up first.

Install a new full roll of paper in the upper roll holders. Place the new paper

"tail" on top of the Stub-Roll Monitor and under the Transfer Arm as showed

in the "Stub-Roll Transfering" instruction graphic inside the cover. Paper from

the new roll will automatically engage and feed out of the dispenser when the

stub-roll paper runs out.

IX.FAILURE DIAGNOSTICS

If the unit is not dispense:

Note: When the Paper Saving Mode is activated (switch# 1 is positioning at

12.5% or 25% saving), the system will overide the time-delay setting, which

means the delay time will always be 1/2 seconds between every dispense.

This manual suits for next models

1

Table of contents

Other Solaris Dispenser manuals