Solatube Brighten Up 160 DS User manual

Other manuals for Brighten Up 160 DS

1

This manual suits for next models

1

Table of contents

Popular Ventilation Hood manuals by other brands

Franke

Franke FDF 6354 XS Instructions for use and installation

Beko

Beko HCP 61310 I user manual

ELICA

ELICA Spot Plus 120 Instruction on mounting and use

NuTone

NuTone RANGEMASTER RM60000 Series Installation instructions and user manual

Smeg

Smeg SHB450X instruction manual

Sharp

Sharp KL-611TBMH-UK user manual

Kernau

Kernau KCH 5560.1 B AUTOMATIC instruction manual

Miele

Miele DA 6690 W Operating and installation instructions

KOBE

KOBE INX2830SQH-700-1 Installation instructions and operation manual

FALMEC

FALMEC SKEMA120W Instruction booklet

Kuppersberg

Kuppersberg Grande 90 X Technical Passport

Wolf

Wolf Ventilation Hood installation guide

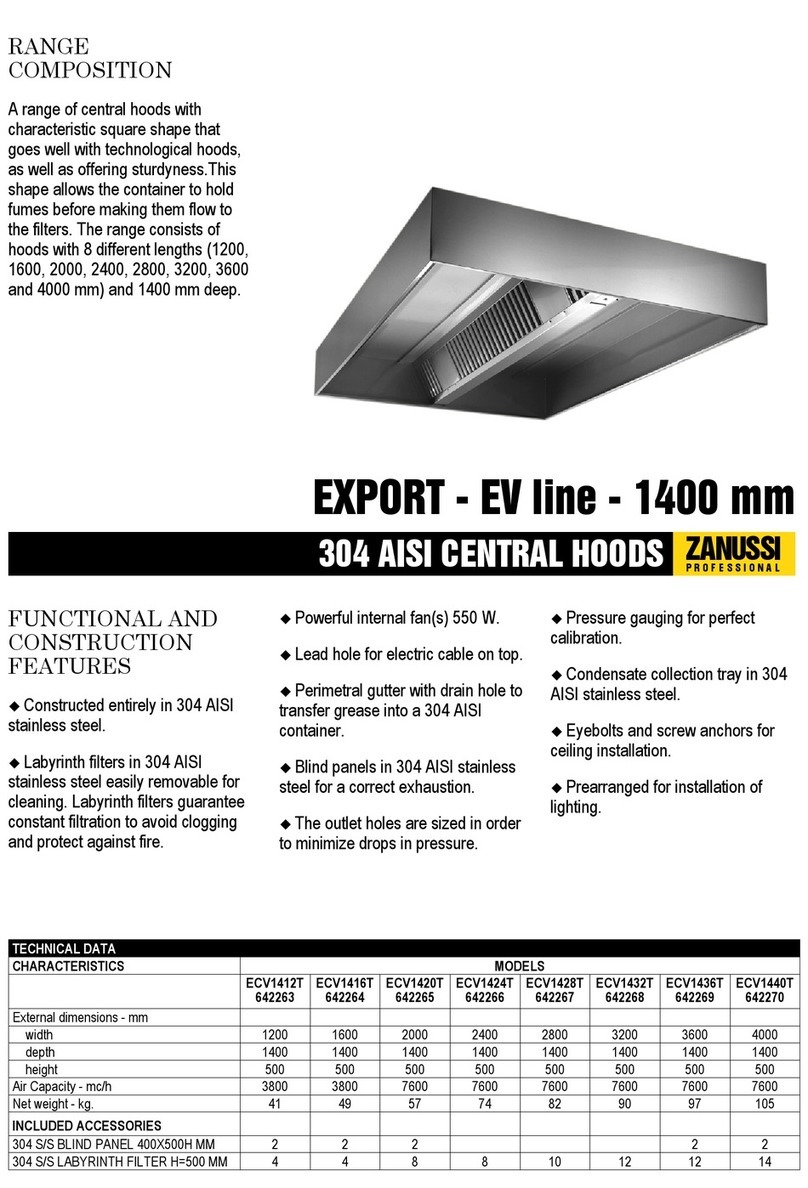

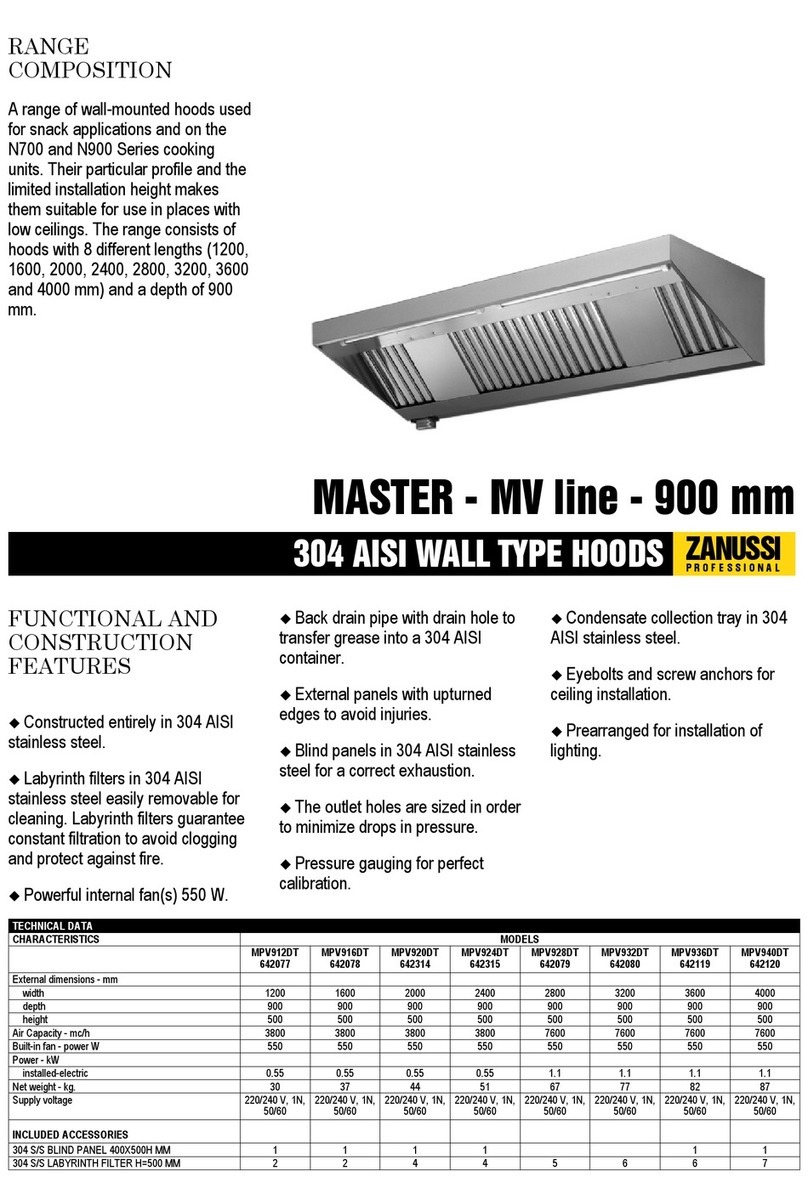

Zanussi

Zanussi Professional Export 642263 Specifications

Zanussi

Zanussi ZHC 96 Installation, use and maintenance handbook

Zanussi

Zanussi Professional Master 642077 Specifications

Manrose

Manrose Roof Cowl Kits manual

ETS NORD

ETS NORD NORDcanopy HN Instructions for installation, use and maintenance manual

Teka

Teka DHT 97670 user manual