14

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

GB

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

INSTALLATION

This canopy hood is designed to be fixed to any rigid vertical surface, over a gas or

electric hotplate and can be used either in the extraction mode (ducted to the outside) or

in the recirculation mode (internal recycling).

Safety warn ngs

• Before commenc ng the nstallat on, cons derat on should be g ven to the d ff cult es

to be found dur ng nstallat on and to the bulky we ght of the hood. The nstallat on

work must be undertaken by a qual f ed and competent person n conform ty to the

rules concern ng the evacuat on of contam nated a r. The manufacturer d scla ms all

l ab l ty for any damage or njury caused as a result of not follow ng the nstruct ons

for nstallat on conta ned n the follow ng text.

• When used n the extract on mode the cooker hood duct ng must not be connected to

a flue wh ch s used for exhaust ng fumes from appl ances suppl ed w th energy other

than electr c such as a central heat ng flue or water heat ng flue.

• When stalled, the hood must be pos t oned at least 65 cm above a cook ng appl ance.

• Never do flambé cook ng under th s cooker hood.

• Never leave fry ng pans unattended dur ng use as overheated fats and o ls may catch

f re.

• If the room where the cooker hood s to be used conta ns a fuel burn ng appl ance

such as a central heat ng bo ler then th s must be of the room sealed or balanced flue

type. If other types of flue or appl ance are f tted ensure that there s an adequate

supply of a r nto the room. When the cooker hood s used n conjunct on w th other

appl ances suppl ed w th energy other than electr c, the negat ve pressure n the room

must not exceed 0,04 mbar to prevent fumes be ng drawn back nto the room by the

cooker hood.

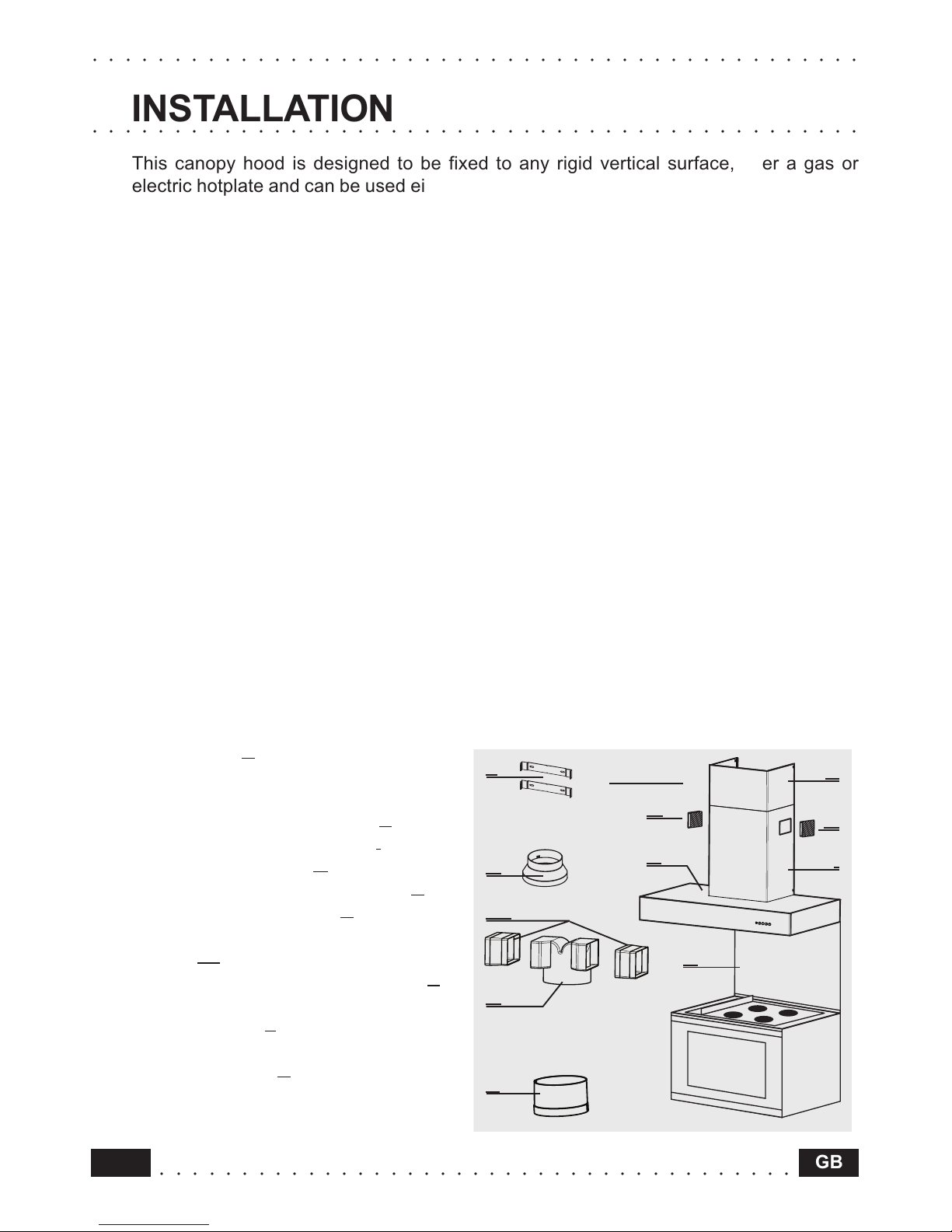

Components

The hood comprises the following (f g.1):

• No.1 canopy C complete with controls,

lighting and ventilator unit

• No.1 telescopic chimney, comprising:

No.1 upper chimney element S

No.1 lower chimney element I

• No.2 directional grills G

• No.1 reduction flange Ø 150-120 A

• No.1 recirculation spigot R

• No.2 additional side recirculation

spigots P1

• No.1 additional recirculation spigot P

• No.1 bag containing:

No.2 brackets 2 to fix the chimney,

screws, rawl plugs and documents.

• No.1 splashback B (optional)