SolaX Power T-BAT-SYS-HV User manual

320101034403

Triple Power Lithium-ion Battery

User Manual

100 Ah

SolaX Power Network Technology (Zhejiang) Co., Ltd.

Add.: No. 288, Shizhu Road, Tonglu Economic Development Zone, Tonglu City,

Zhejiang Province, 310000 P.R. CHINA

Tel.: +86 (0) 571-5626 0011

E-mail: info@solaxpower.com

Copyright © SolaX Power Technology (Zhejiang) Co., Ltd. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without

prior written consent of SolaX Power Technology (Zhejiang) Co., Ltd. (hereinafter referred to as

SolaX). SolaX reserves the right of final interpretation.

Contents

1 NOTE ON THIS MANUAL 1

1.1 SCOPE OF VALIDITY 1

1.2 TARGET GROUP1

1.3 SYMBOLS1

2 SAFETY2

2.1 SAFETY INSTRUCTIONS2

2.1.1 GENERAL SAFETY PRECAUTIONS2

2.1.2 EXPLANATION OF SYMBOLS3

2.2 RESPONSE TO EMERGENCY SITUATIONS4

2.2.1 LEAKING BATTERIES4

2.2.2 FIRE4

2.2.3 WET BATTERIES AND DAMAGED BATTERIES4

2.3 QUALIFIED INSTALLER5

3 PRODUCT INTRODUCTION6

3.1 PRODUCT OVERVIEW6

3.1.1 DIMENSIONS AND WEIGHT6

3.1.2 INSTALLATION SPACE7

3.1.3 APPEARANCE8

3.2 BASIC FEATURES1 0

3.2.1 FEATURES1 0

3.2.2 CERTIFICATIONS1 0

3.3 SPECIFICATIONS1 1

3.3.1 T-BAT SYS-HV CONFIGURATION LIST1 1

3.3.2 PERFORMANCE1 1

4 INSTALLATION1 2

4.1 INSTALLATION PREREQUISITES1 2

4.2 SAFETY GEAR1 2

4.3 TOOLS1 3

4.4 INSTALLATION1 3

4.4.1 CHECK FOR TRANSPORT DAMAGE1 3

4.4.2 UNPACKING1 3

4.4.3 ACCESSORIES1 4

5 EQUIPMENT INSTALLMENT1 6

5.1 INSTALLATION ENVIRONMENT REQUIREMENTS16

5.2 INSTALLATION MODE16

5.3 WALL MOUNTING16

5.3.1 OVERVIEW16

5.3.2 STEPS1 8

5.4 FLOOR MOUNTING2 5

5.4.1 OVERVIEW2 5

5.4.2 STEPS 2 6

5.5 STEPS FOR INCREASING BATTERY CAPACITY3 1

6 WIRING3 2

7 COMMISSIONING33

7.1 COMMISSIONING33

7.2 STATUS INDICATORS35

7.2.1 BMS (TBMS-MCS60060)35

7.3 SHUTTING DOWN T-BAT SYSTEM37

8 TROUBLESHOOTING3 8

8.1 TROUBLESHOOTING38

9 DECOMMISSIONING4 0

9.1 DISMANTLING THE BATTERY40

9.2 PACKING40

10 MAINTENANCE4 1

11 DISCLAIMER4 2

1 NOTE ON THIS MANUAL 1

1.1 SCOPE OF VALIDITY 1

1.2 TARGET GROUP1

1.3 SYMBOLS1

2 SAFETY2

2.1 SAFETY INSTRUCTIONS2

2.1.1 GENERAL SAFETY PRECAUTIONS2

2.1.2 EXPLANATION OF SYMBOLS3

2.2 RESPONSE TO EMERGENCY SITUATIONS4

2.2.1 LEAKING BATTERIES4

2.2.2 FIRE4

2.2.3 WET BATTERIES AND DAMAGED BATTERIES4

2.3 QUALIFIED INSTALLER5

3 PRODUCT INTRODUCTION6

3.1 PRODUCT OVERVIEW6

3.1.1 DIMENSIONS AND WEIGHT6

3.1.2 INSTALLATION SPACE7

3.1.3 APPEARANCE8

3.2 BASIC FEATURES1 0

3.2.1 FEATURES1 0

3.2.2 CERTIFICATIONS1 0

3.3 SPECIFICATIONS1 1

3.3.1 T-BAT SYS-HV CONFIGURATION LIST1 1

3.3.2 PERFORMANCE1 1

4 INSTALLATION1 2

4.1 INSTALLATION PREREQUISITES1 2

4.2 SAFETY GEAR1 2

4.3 TOOLS1 3

4.4 INSTALLATION1 3

4.4.1 CHECK FOR TRANSPORT DAMAGE1 3

4.4.2 UNPACKING1 3

4.4.3 ACCESSORIES1 4

5 EQUIPMENT INSTALLMENT1 6

5.1 INSTALLATION ENVIRONMENT REQUIREMENTS16

5.2 INSTALLATION MODE16

5.3 WALL MOUNTING16

5.3.1 OVERVIEW16

5.3.2 STEPS1 8

5.4 FLOOR MOUNTING2 5

5.4.1 OVERVIEW2 5

5.4.2 STEPS 2 6

5.5 STEPS FOR INCREASING BATTERY CAPACITY3 1

6 WIRING3 2

7 COMMISSIONING33

7.1 COMMISSIONING33

7.2 STATUS INDICATORS35

7.2.1 BMS (TBMS-MCS60060)35

7.3 SHUTTING DOWN T-BAT SYSTEM37

8 TROUBLESHOOTING3 8

8.1 TROUBLESHOOTING38

9 DECOMMISSIONING4 0

9.1 DISMANTLING THE BATTERY40

9.2 PACKING40

10 MAINTENANCE4 1

11 DISCLAIMER4 2

1 NOTE ON THIS MANUAL..................................................1

1.1 SCOPE OF VALIDITY .................................................1

1.2 TARGET GROUP .....................................................1

1.3 SYMBOLS...........................................................1

2 SAFETY ...........................................................2

2.1 SAFETY INSTRUCTIONS..............................................2

2.1.1 GENERAL SAFETY PRECAUTIONS.................................2

2.1.2 EXPLANATION OF SYMBOLS .....................................3

2.2 RESPONSE TO EMERGENCY SITUATIONS ..............................4

2.2.1 LEAKING BATTERIES.............................................4

2.2.2 FIRE .......................................................4

2.2.3 WET BATTERIES AND DAMAGED BATTERIES...................4

2.3 QUALIFIED INSTALLER ...............................................5

3 PRODUCT INFORMATION ................................................6

3.1 DIMENSIONS AND WEIGHT ..........................................6

3.2 APPEARANCE .......................................................7

3.3 BASIC FEATURES ....................................................9

3.2.1 FEATURES ......................................................9

3.2.2 CERTIFICATIONS............................................9

3.4 SPECIFICATIONS ...................................................10

3.4.1 T-BAT SYS-HV CONFIGURATION LIST ........................10

3.4.2 PERFORMANCE ...........................................10

4 PREPARATION BEFORE INSTALLATION ....................................11

4.1 PREREQUISITES ....................................................11

4.2 SAFETY GEAR......................................................12

4.3 TOOLS ..........................................................12

4.4 INSPECTION .......................................................13

4.4.1 CHECK FOR TRANSPORT DAMAGE..........................13

4.4.2 UNPACKING ...............................................13

4.4.3 ACCESSORIES.............................................14

5 INSTALLMENT ..........................................................16

5.1 INSTALLATION ENVIRONMENT REQUIREMENTS .......................16

5.2 INSTALLATION MODE ...............................................16

5.3 FLOOR MOUNTING .................................................17

5.3.1 OVERVIEW ....................................................17

5.3.2 STEP .....................................................20

5.4 WALL MOUNTING ..................................................28

5.4.1 OVERVIEW ................................................28

5.4.2 STEP......................................................31

5.5 STEPS FOR INCREASING BATTERY CAPACITY .........................40

1 Note on this Manual

1.1 Scope of Validity

This manual is an integral part of theT-BAT Series. It describes the assembly,

installation, commissioning, maintenance and failure of the product. Read it

carefully prior to operation.

T-BAT-SYS-HV-5.0 Module

T-BAT-SYS-HV-5.0 BMS

1.2 Target Group

This manual is for qualifiedelectricians. The tasks described in this manual may

only be performed by qualified electricians.

1.3 Symbols

The following types of safety instructions appear in this document and are

described below:

NOTE!

“NOTE” provides tips that are valuable for the optimal operation of

your product.

TP-HS50

TBMS-MCS60060

CAUTION!

“CAUTION” indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

WARNING!

“WARNING” indicates a hazardous situation which, if not avoided,

could result in serious injury or death.

DANGER!

“DANGER” indicates a hazardous situation which, if not avoided,

will result in serious injury or death.

1.Notes on this Manual

Note: There are 3 models of T-BAT system, which includes the BMS, battery

module(s) and base. Refer to section 3.3.1 T-BAT-SYS-HV Configuration List

on Page 11 for detailed models.

* WARRANTY REGISTRATION FORM

6 WIRING ..........................................................41

7 COMMISSIONING ......................................................43

7.1 COMMISSIONING ..................................................43

7.2 STATUS INDICATORS ...............................................44

7.2.1 BMS (TBMS-MCS60060) ........................................44

7.3 SHUTTING DOWN T-BAT SYSTEM....................................46

8 TROUBLESHOOTING ...................................................47

8.1 TROUBLESHOOTING ...............................................47

9 DECOMMISSIONING....................................................51

9.1 DISMANTLING THE BATTERY ........................................51

9.2 PACKING ..........................................................51

10 MAINTENANCE.........................................................52

11 DISCLAIMER ..........................................................53

Slave3

2

2 Safety

2.1 Safety Instructions

For safety reasons, installers are responsible for familiarizing themselves with the

contents of this manual and all warnings before performing installation.

2.1.1 General Safety Precautions

2. Safety

Observe the following precautions:

Risks of explosion:

Risks of fire:

Do not subject the battery module to heavy impacts.

Do not crush or puncture the battery module.

Do not dispose of the battery module in a fire.

Do not expose the battery module to temperatures in excess of 140°F (6°C).

Do not place the battery module near a heat source, such as a fireplace.

Do not expose the battery module to direct sunlight.

Do not allow the battery connectors to touch conductive objects such as

wires.

Risks of electric shock:

Do not disassemble the battery module.

Do not touch the battery module with wet hands.

Do not expose the battery module to moisture or liquids.

Keep the battery module away from children and animals.

Risks of damage to the battery module:

Do not expose the battery module to liquids.

Do not subject the battery module to high pressures.

Do not place any objects on top of the battery module.

WARNING!

Do not crush or impact the battery, and always dispose of it

according to safety regulations.

CAUTION!

3

2. Safety

2.1.2 Explanation of Symbols

2.1.2 Explanation of Symbols

Symbol Explanation

The inverter complies with the requirements of the applicable

CE guildlines.

Observe enclosed documentation.

Keep the battery system away from open flames or ignition

sources.

Keep the battery system away from children.

The battery module may explode.

The battery system must be disposed of at a proper facility

for environmentally-safe recycling.

The battery system should not be disposed of together

with household waste. Disposal information can be found

in the enclosed documentation.

Danger of high voltages.

Danger. Risk of electric shock.

TUV mark for IEC62619

Compliant with UKNI standards.

Compliant with UKCA standards.

T-BAT SYS-HV should only be installed for residential applications and not be for

commercial applications.

If the battery is not installed within one month after receipt, it must be

charged for maintenance. Non-operational batteries should be discarded

according to local regulations.

Symbol Explanation

Keep the battery system away from open flames or ignition

sources.

The battery module may explode.

The battery system must be disposed of at a proper facility

for environmentally-safe recycling.

Keep the battery system away from children.

CSA mark for UL1973

272687

CE mark of conformity

TUV certification

Do not dispose of the battery together with household

waste.

Read the enclosed documentation.

Caution, risk of electric shock

Caution, risk of danger

Fcc mark of conformity

45

2. Safety 2. Safety

2.3 Qualified Installer

WARNING!

2.2 Response to Emergency Situations

2.2.1 Leaking Batteries

2.2.2 Fire

2.2.3 Wet Batteries and Damaged Batteries

Please keep a Class ABC fire extinguisher or a carbon dioxide extinguisher near the

equipment.

In case the leakage of electrolyte solution occurs, please avoid direct contact with

the electrolyte solution and the gas that may be generated by it. Direct contact may

lead to skin irritation or chemical burns. If the user comes into contact with the

electrolyte solution, please do as follows:

Accidental inhalation of harmful substances: Evacuate from the contaminated area,

and seek medical attention immediately.

Eye contact: Rinse eyes with flowing water for 15 minutes, and seek medical

attention immediately.

Dermal contact: Wash the affected area thoroughly with soap and water, and seek

medical attention immediately.

Ingestion: Induce vomiting, and seek medical attention immediately.

WARNING!

The battery module may catch fire when heated

above 302°F.

If a fire breaks out where the battery module is installed, please do

as follows:

1) Extinguish the fire before the battery module catches fire;

2) If the battery module cathes fire, please do not try to put out the

fire, and evacuate immediately.

WARNING!

In case of catching fire, the battery module will produce noxious and

poisonous gases, and please keep away the battery.

Do not touch the battery module after being wet from and soaked in the water.

Do not use the battery module if it is damaged. Otherwise, the loss to life and

property will be caused.

Please pack the battery in its original packaging, and return it to SolaX or the

distributor.

CAUTION!

Damaged batteries may leak electrolyte or produce flammable gas. If a

user suspects that the battery is damaged, please immediately contact

SolaX for advice and information.

All operations of T-BAT-SYS-HV relating to electrical connection and

installation must be carried out by qualified personnel.

A skilled worker is defined as a trained and qualified electrician or installer who

has all of the following skills and experience:

• Knowledge of the functional principles and operation of grid-tied systems;

• Knowledge of the dangers and risks associated with installing and using

electrical devices and acceptable mitigation methods;

• Knowledge of the installation of electrical devices;

• Knowledge of and adherence to this manual and all safety precautions and

best practices.

67

3. Product Infromation

3 Product Information

3.1 Overview

3.1 Dimensions and Weight

3. Product Information

3.1.2 Installation Space

33.46 in

850.00 mm

5.83 in

148.00 mm

5.24 in

133.00 mm

1.02 in

26.00 mm

33.46 in

850.00 mm

5.83 in

148.00 mm

11.81 in

300.00 mm

1.02 in

26.00 mm

2.95 in

75.00 mm

33.46 in

850.00 mm

5.83 in

148.00 mm

Scheme A

Scheme B

Scheme C

BMS

(TBMS-MCS60060)

5.83 in.

148.00mm

5.24 in.

133.00 mm

33.46 in.

850.00 mm

Battery Module

(TP-HS50)

11.81 in.

300.00 mm

33.46 in.

850.00 mm

5.83 in.

148.00mm

1.02 in.

26.00mm

Base

2.95 in.

75.00mm

33.46 in.

850.00 mm

For safety reasons, installers are responsible for familiarizing themselves with

the contents of this manual and all warnings before performing installation.

A battery management system (BMS) is an electronic system that manages a

rechargeable battery.

A battery module is a type of electrical battery which can charge or discharge

loads.

The whole system mainly comprises a BMS, a battery module and a base.

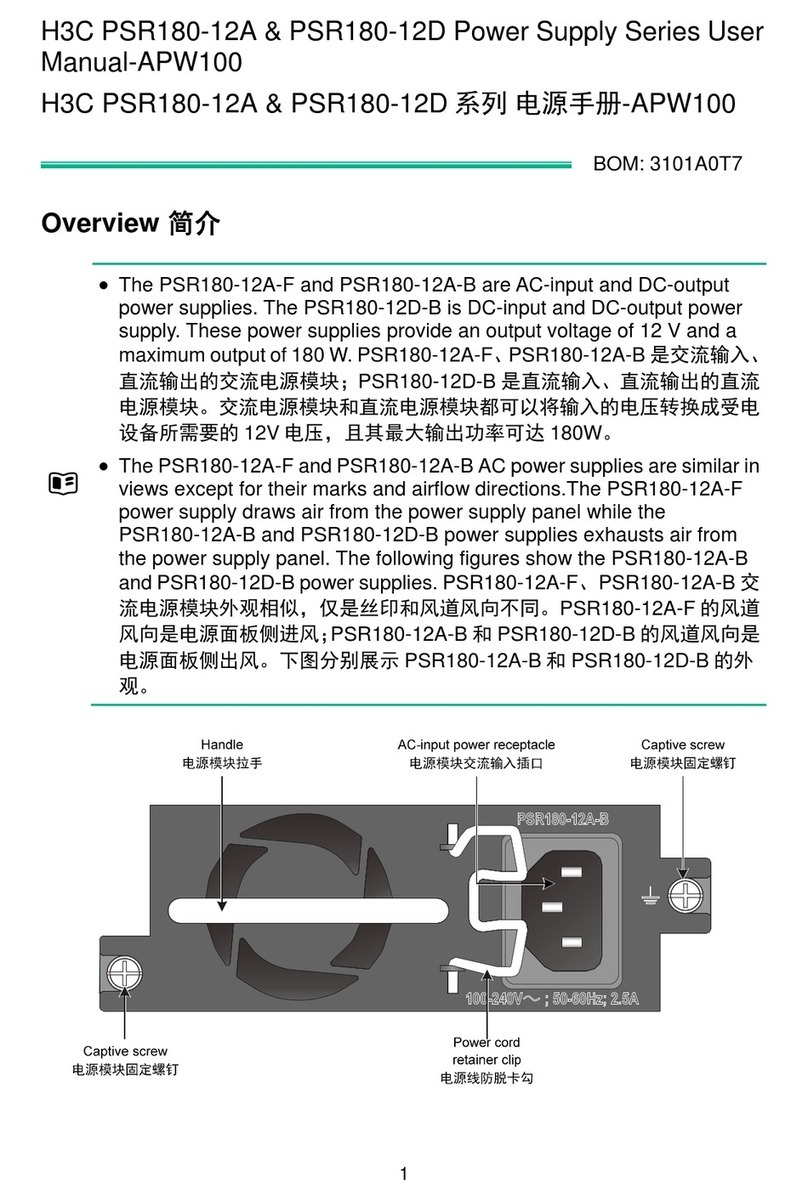

3.2 Appearance

ŸSection View of BMS

Item Description

Circuit breaker: A switch for battery’s input and output

①

DIP switch 1: A reserved function

DIP switch 2: A reserved function

DIP switch 3: A reserved function

DIP switch 4: Terminal resistance

DIP

BMS

BAT+

POWER

BAT-

①

②②

③

④

⑤

⑥

⑦

Item Description

BAT+: Connect BMS’s BAT+ to the inverter’s BAT+

Button: BMS’s power button

BAT-: Connect BMS’s BAT- to the inverter’s BAT-

DIP: Realize the battery’s parallel function (A reserved function)

BMS: Connect the inverter to BMS’s communication

GND: BMS’s GND

Lamp Panel: Status light and SOC power indicators to display battery status

Right

Left

5.83 in.

148.00 mm

1.02 in.

26.00 mm

Base TBMS-MCS60060 TP-HS50

Length 33.46 in./850.00 mm 33.46 in./850.00 mm 33.46 in./850.00 mm

Width 5.83 in./148.00 mm 5.83 in./148.00 mm 5.83 in./148.00 mm

Height 2.95 in./75.00 mm 5.24 in./133.00 mm 11.81 in./300.00 mm

Weight 9.92 lbs/4.50 kg 22.05 lbs/10.00 kg 117.95 lbs/54.00 kg

89

3. Product Information

ŸSection view of battery module

①

②

BAT+: Battery's positive output pole (+)

BAT-: Battery's negative output pole (-)

The hot-plug interface is connected to BMS or the bottom of battery

Connect the next battery's positive pole or base's shorting stub

Connect the next battery's negative pole or base's shorting stub

The hot-plug interface is connected to base or the top of battery

③

④

3. Product Information

Top

Bottom

3.3 Basic Features

3.2.1 Features

Ÿ90% DOD

Ÿ95% Battery Roundtrip Efficiency

ŸCycle Life > 6000 Cycles

ŸSecondary Protection

ŸIP65 Protection Level

ŸSafety & Reliability

ŸSmall Occupied Area

ŸFloor or Wall Mounting

3.2.2 Certification

BAT system safety

UN number

Hazardous materials classification

UN transportation testing requirements

International protection marking

UL9540A,UL1973, CE, RCM, IEC 62619

UN 3480

Class 9

UN 38.3

IP 65

The T-BAT-SYS-HV, adopting advanced technology and having the characteristics

of high reliability and convenient to control, is one of the most advanced energy

storage systems in today's market, with details as below:

10 11

3. Product Information 4. Preparation before Installation

3.4 Specifications

3.4.1 T-BAT-SYS-HVConfiguration List

Note:

① Test conditions: 100% DOD, 0.2C charge & discharge @+ 77°F/25°C.

② 90% DOD; System usable energy may vary with inverter different setting.

③ Discharge: In case of the battery core's temperature range of 14°F~41°F/-10°C~5°C and

113°F~127.4°F/45°C~53°C, the discharge current will be reduced; Charge: In case of the

battery core's temperature range of 32°F~68°F/0°C~20°C and 113°F~127.4°F/45°C~53°C,

the charge current will be reduced. Product charge or discharge power depends on the

actual temperature of the battery pack.

④ The battery can only be discharged and cannot be charged at -14°F~32°F/-10°C~0°C.

3.4.2 Performance Parameters

Q.+ BAT-G1

Nominal Voltage (Vdc)

Operating Voltage (Vdc)

Nominal Capacity (Ah)

Max. Charge/Discharge Current (A)

Recommend Charge/Discharge Current (A)

Standard Power (kW)

Max. Power (kW)

153.6

135-174

100

54

50

7.68

9.2

Battery Roundtrip Effciency(0.2C,25°C/77°F)

Expected Lifetime(25°C/77°F)

Cycle Life90% DOD(25°C/77°F)

95%

10 years

6000 cycles

Model

Nominal Energy (kWh) 15

Usable Energy 90% DOD (kWh) 13.8

90-116

100

54

50

5.12

6.1

102.4

10

9.2

180-232

100

54

50

12.3

20

18.4

204.8

10.24

①

①

②

③

Storage Temperature

Ingress Protection IP65

-4°F~122°F/-20°C~50°C (3 months)

32°F~104°F/0°C~40°C (12 months)

Charge Temperature

Discharge Temperature

32°F~127.4°F/0°C~53°C

-14°F~127.4°F/-10°C~53°C

④

④

T-BAT H 10.0 T-BAT H 15.0 T-BAT H 20.0

Model BMS

TBMS-MCS60060×1

Battery Module

TP-HS50 × 2

Energy(kWh)

10

15

20

Voltage (V)

90-116

135-174

180-232

TP-HS50 × 3

TP-HS50 × 4

T-BAT H 10.0

T-BAT H 15.0

T-BAT H 20.0

TBMS-MCS60060×1

TBMS-MCS60060×1

No.

1

2

3

4 Prepration before Installation

4.1 Prerequisites

When assembling the system, avoid touching the battery terminals with any metal

object or bare hands. According to the design principles, T-BAT-SYS-HV will

provide a safe and reliable energy. Improper operation and equipment damage may

cause overheating and electrolyte leakage. Therefore, the above-mentioned safety

precautions and warning information mentioned in this part shall be strictly

observed. If you have any question, please contact customer service. The “2

Safety” does not contain the provisions of all laws and regulations at the place

where the user located.

Before installation, make sure that the installation site meets the following

conditions:

ŸThe building can stand up to earthquakes;

ŸThe floor shall be flat;

ŸNo inflammable and explosive goods are placed within at least of 3 ft/0.91m;

ŸThe temperature and humidity remain at a constant level;

ŸThe installation site requires less dust and dirt; and

ŸThere are no corrosive gases, including ammonia and acid vapor.

ŸThe site shall be over 0.62 miles/997.79 m away from the sea, to avoid damage

caused by salt water and humidity;

ŸThe ambiance shall be shady and cool, away from heat sources and direct

sunlight;

NOTE!

If the ambient temperature exceeds the operating range, the battery

pack will stop running to protect itself. The optimal temperature range

for running is 59°F/15°C to 86°F/30°C. Frequent exposure to harsh

temperatures may deteriorate the performance and lifetime of the

battery.

12 13

4.2 Safety Gear

4. Preparation before Installation

Installation and maintenance personnel must strictly comply with the applicable

federal, state, and local regulations as well as industry standards on product

installation. To avoid short circuit and personal injury, respirator, gloves, goggles and

shoes must be worn.

4. Preparation before Installation

4.3 Tools

Torque Screw Driver Phillips-Screw Driver Hexagon Wrench

Phillips-Head Screw Driver Torque Wrench Pencil or Marker

4.4 Inspection

4.4.1 Check for Transport Damage

4.4.2 Unpacking

Tape Measure Drill Spirit Level

Insulated Gloves Safety Goggles Safety Shoes

Anti-dust respirator

WARNING!

Strictly follow the installation steps. SolaX will not be responsible for

any injury or loss incurred by improper installation and operation.

NOTE!

For the first installation, the interval among manufacture dates of

battery modules shall not exceed 3 months.

Please prepare the following tools before installation.

Ensure that the battery has been received in good condition. If there is any damage

or obvious defect, please contact the dealer immediately.

Before opening the battery package, remove the packing tape. After opening the

package, ensure that the battery modules and relevant accessories are in good

condition, and carefully check the quantity and type of accessories are consistent

with the “4.4.3 Accessory”. If any accessory is missing, contact SolaX or the

distributor immediately.

CAUTION!

According to the local regulations, more than one person is required

to carry the equipment.

4. Preparation before Installation

14

4.4.3 Accessory

4. Preparation before Installation

15

BMS (TBMS-MCS60060):

OneBattery Module (TP-HS50×1):

All Accessories Required for Two Installation Modes

Note: The above-mentioned accessories are only for one battery module. SolaX

will provide corresponding accessories according to the number of battery

modules.

Note: The above-mentioned accessories are necessities for both floor and wall

mounting.

4.4.3 Accessory

BMS (TBMS-MCS60060):

OneBattery Module (TP-HS50×1):

All Accessories Required for Two Installation Modes

Note: The above-mentioned accessories are only for one battery module. SolaX

will provide corresponding accessories according to the number of battery

modules.

G1

A1

B1

C1 D1

E1

F1

A2 B2

C2 D2 E2 F2

Note: The above-mentioned accessories are necessities for both floor and wall

mounting.

A

Item Description Quantity

A Documentation 2

Accessories included are shown as follows:

H1

Item Description Quantity

A2 Base Support 2

B2 Transverse Plate 1

C2 Expansion Screw 6

D2 M5*8 Countersunk Head Screw 4

E2 M5*20 Countersunk Screw 6

F2 Adjustment Screw 2

Accessories included are shown as follows:

Item Description Quantity

A1 Wall Bracket 2

B1 Expansion Bolt 4

C1 Tapping Screw 2

D1 Gasket 2

E1 Platen (3 holes) 2

F1 Platen (2 holes) 2

G1 M5*10 Phillips-head Screw 10

H1 Documentation 1

Accessories included are shown as follows:

A1 C1

D1

E1

B1

F1 G1

H1

I1

Item Description Quantity

A1 Wall Bracket 2

B1 Expansion Bolt 4

C1 Tapping Screw 2

D1 Gasket 2

E1 Platen (3 holes) 2

F1 Platen (2 holes) 2

G1 M5*10 Phillips-head Screw 10

H1 Battery Module 1

I1 Document 1

Accessories included are shown as follows:

A2

B2 C2

D2 E2 F2 G2

Item Description Quantity

A2 Base Support 2

B2 Transverse Plate 1

C2 Expansion Screw 6

D2 M5*8 Countersunk Head Screw 4

E2 M5*20 Countersunk Screw 6

F2 Adjustment Screw 2

G2 Self-tapping Screw 6

Accessories included are shown as follows:

Base for BAT50-G2 Battery:

A3

Item Description Quantity

A3 Base 1

Accessories included are shown as follows:

A B C

Item Description Quantity

A BMS 1

B User Manual 1

C Safety Instructions 1

Accessories included are shown as follows:

5. Installation

5. Installation

5.1 Installation Environment Requirements

● Ensure that the equipment is installed in a well ventilated environment.

● To prevent fire due to high temperature, ensure that the ventilation vents or

heat dissipation system are not blocked when the equipment is running.

● Do not expose the equipment to flammable or explosive gas or smoke. Do

not perform any operation on the equipment in such environments.

● Make sure the wall is strong enough to withstand the weight of battery. In

case of wooden wall, it must bear the load of at least 551.16 lbs/250.00 kg.

● Keep at least 1.5 in/38 mm away from the edge of concrete bricks.

● In case of Wall Mounting, do not install on the hollow concrete block wall.

5.2 Installation Mode

There are two alternative installation modes (wall mounting and floor

mounting) and three schemes available for users. Please leave sufficient

room for adding battery modules.

5.3 Wall Mounting

5.3.1 Overview

4 kinds of stub spacing are provided in Plotting Sheet. There are three

schemes available for users:

Scheme A: Inverter + BMS + Two Batteries + Base Support + Base;

● Scheme B: Inverter + BMS + Three Batteries + Base Support + Base

(Ignore hole locations of Base Support in Scheme A);

● Scheme C: Inverter + BMS + Four Batteries + Base Support + Base (Ignore

hole locations of Base Support in Scheme A & B).

For example: In case of Scheme A with a stub spacing of 32 in/812.80 mm,

please fold along dashed line B-A and punch the holes (Battery: A-32*4 &

WB-32*2; Inverter: WB-32*4) (See markings in Figure 1).

Before installation, please determine the inverter's location, and punch holes

strictly in accordance with the stub spacing in the Plotting Sheet.

5.3 Floor Mounting

5.3.1 Overview

There are three schemes available for users.

5.1 Installation Environment Requirements

● Ensure that the equipment is installed in a well ventilated environment.

● To prevent fire due to high temperature, ensure that the ventilation vents or heat

dissipation system are not blocked when the equipment is running.

● Do not expose the equipment to flammable or explosive gas or smoke. Do not

perform any operation on the equipment in such environment.

● A distance of at least 11.81 in./300 mm shall be set aside from the equipment to

both left and right sides.

● In case of Wall Mounting, make sure the wall is strong enough to withstand the

weight of battery. In case of wooden wall, it must bear the load of at least 2,204.62

lbs/1,000.00 kg.

● In case of Wall Mounting, do not install on the hollow concrete block wall.

5.2 Installation Mode

There are two alternative installation modes and three schemes available for users.

For details, refer to the following table.

A distance set aside from the equipment to the ground may be determined

according to regulations at the place where the user is located.

BMS

Battery

Module

Base BMS

Battery

Module

Base

Base

Support

Scheme A 1 2 1 1 2 1 1

Scheme B 1 3 1 1 3 1 1

Scheme C 1 4 1 1 4 1 1

Wall Mounting

Floor Mounting

Note: The equipment supports the following stub spacing: 20, 24, 28 and 32 in.

5. Installation

Scheme A

Distance from the equipment:

To left side: ≥11.81 in./300 mm

To right side: ≥11.81 in./300 mm

16 17

BMS

Battery

Battery

Base

BMS

Battery

Battery

Base

31.81 in./808 mm

2 * Wall Bracket

2 * Expansion Bolt

2 * Tapping Screw

2 * Gasket

14 * M5*10 Screws

2 * Platen (3 holes)

4 * Platen (2 holes)

BMS

Battery

Battery

Base

5. Installation 5. Installation

Scheme B

Distance from the equipment:

To left side: ≥11.81 in./300 mm

To right side: ≥11.81 in./300 mm

Scheme C

Distance from the equipment:

To left side: ≥11.81 in./300 mm

To right side: ≥11.81 in./300 mm

18 19

BMS

Battery

Battery

Base

Battery

4 * Wall Bracket

4 * Expansion Bolt

4 * Tapping Screw

4 * Gasket

20 * M5*10 Screw

4 * Platen (3 holes)

4 * Platen (2 holes)

43.62 in./1,108 mm

BMS

Battery

Battery

Base

Battery

Battery

4 * Wall Bracket

4 * Expansion Bolt

4 * Tapping Screw

4 * Gasket

24 * M5*10 Screw

4 * Platen (3 holes)

6 * Platen (2 holes)

55.43 in/1,408 mm

BMS

Battery

Battery

Base

Battery

BMS

Battery

Battery

Base

Battery

Battery

BMS

Battery

Battery

Base

Battery

BMS

Battery

Battery

Base

Battery

Battery

5. Installation 5. Installation

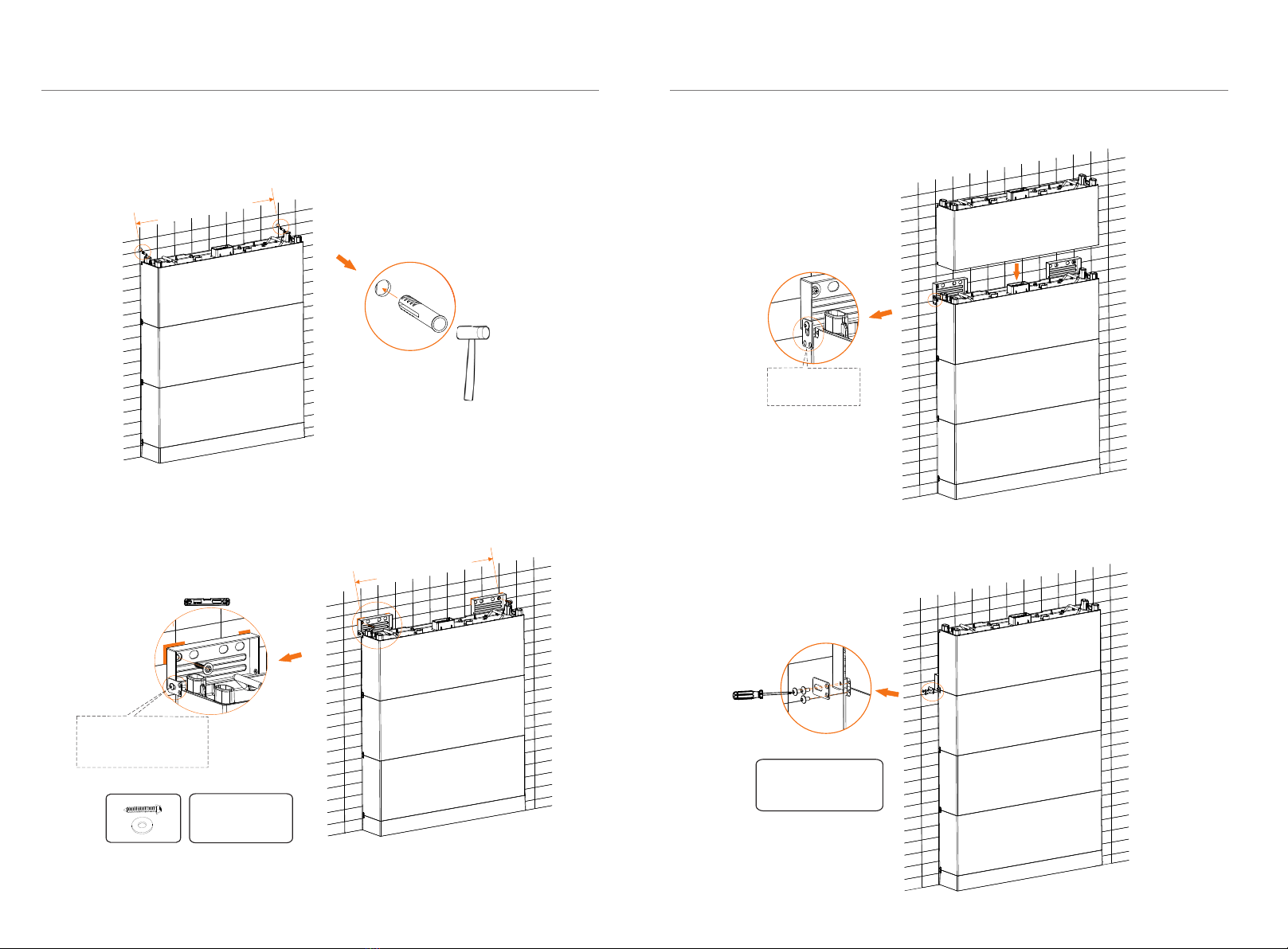

5.3.2 Step

Please reserve enough distance from the equipment to the ceiling/ground for

capacity expansion.

Take Scheme C as an example.

Step 1: Place Base.

(1) Remove the dust cover.

(2) Insert M8*85 Adjustment Screws (2) from the bottom of Base, to ensure that the

Base is even.

(a) Use a spirit level to measure the sides of the Base to ensure they are even.

(b) If not, please adjust the Adjustment Screws by a torque wrench being to ensure

that the Base is even.

Note!

Step 2: Locate the Base 1.57 in./40 mm away from the wall, accurately mark the

location of the Base on both sides with a pen.

Step 3: Place Battery Module on the Base.

(1) Remove the top and bottom dust covers.

(2) Place the Battery Module on the Base.

20 21

Right View

If the Base is shifted after placing a Battery Module, move it to its original location

according to the mark previously drawn.

Note!

1.57 in

40 mm

1.57 in

40 mm

Mark

5. Installation 5. Installation

(3) Fix the Platen (2 holes) using M5 * 10 Phillips-head screw, and secure M5*10

screws (2) to connect Base and Battery Module (Torque: 1.0 N·m).

Step 4: Place two Battery Modules in turn, and secure both left and right sides with

screws (4 × M5*10 countersunk screw) (Tighten torque: 1.0 N·m). Refer to the Step

2 (3).

Step 5:

(1) Attach M5 * 10 screw to Wall Bracket but be sure not to tighten;

(2) Place such Wall Bracket to the wall, align its holes to the holes on the Battery

Module, and use a spirit level to measure the Wall Bracket to ensure it's even;

(3) Accurately mark the location of the Wall Bracket on both sides with a pen;

(4) Circle along the inner ring of the holes;

(5) Remove the Wall Bracket, and then drill the two holes (at least 3.54 in./90 mm)

by a Drill (φ 0.39 in./10 mm).

Electric drill dust collector is recommended.

Note!

22 23

Platen (2 holes) × 2

M5*10 Screw × 4

1.0 N·m

Step 3 (3) Step 3 (3)

Attach screw but

not tighten

Φ 0.39 in./10 mm for

Wall Bracket

Insert and secure

it but not lock up

Mark

φ 0.39 inch/10 mm

for Wall Bracket

Mark

32 in./812.80 mm

5. Installation 5. Installation

Step 6: Place Expansion Bolts into the two holes (the Expansion Bolt is not required

in case of solid wood wall).

Step 7: Place the Wall Bracket on the wall where the mark is drawn previously, and

then secure the Wall Brackets on the wall using Tapping Screws and Gaskets.

Step 8: Place the fourth battery module.

24 25

Tapping Screw × 2

Gasket × 2

Wall Bracket × 2

Attach screw but not

tighten, and align the

hole location of

battery

Let the Platen

down

Step 9: Fix the Platen (3 holes) on both sides of Battery Module using M5 * 10

Phillips-head screw, and then tighten M5*10 screws (Torque: 1.0 N·m).

Platen (3 holes) × 2

M5*10 Screw × 6

1.0 N·m

Mark

32 in./812.80 mm

32 in./812.80 mm

This manual suits for next models

3

Table of contents

Other SolaX Power Power Supply manuals