Solene SLAR32DC-66 User manual

OPEN LOOP DOMESTIC HOT WATER SOLAR SYSTEM

WITH DIFFERENTIAL CONTROL

MODELS SLAR32DC-66, SLAR40DC-80

SLAR64DC-120, SLAR80DC-120

INSTALLATION MANUAL

Solene™

™

927 Fern St. Suite 1500

Altamonte Springs, FL 32701

(866) 902-0060

SRCC OG-300 Certified

The solar energy system described by this manual, when properly installed and maintained, meets the

minimum standards established by the Florida Solar energy center, in accordance with section 377.705,

Florida Statutes. This certification does not imply endorsement or warranty of this product by the Florida

Solar Energy Center or the State of Florida.

The solar energy system described by this manual, when properly installed and maintained, meets the

minimum standards established by the Florida Solar Energy Center, in accordance with Section 377.705,

Florida Statutes. This certification does not imply or endorse warranty of the product by the Florida Solar

Energy Center of the State of Florida. Solar Water Heating System

SLAR-IMDC

9-04-09

2

TABLE OF CONTENTS

egaP

3snoituacerPytefaS

3snoitcurtsnInoitallatsnI

3noitatneirO&gniziS

4noitallatsnIhsulF-gnit

nuoMrotcelloC

6noitallatsnIdelgnA–gnitnuoMrotcelloC

8noitallatsnIepiP

9gnibmulP

9lortno

ClaitnereffiDcitamotuA

01stnemeriuqeRgniriW&lacirtcelE

01sretemomrehT

01serudecorPpU-trat

SmetsyS

11noitarepOmetsyS

11noitarepOraloSlatoT

11taeH-erPraloS

11rewoPytilitUlatoT

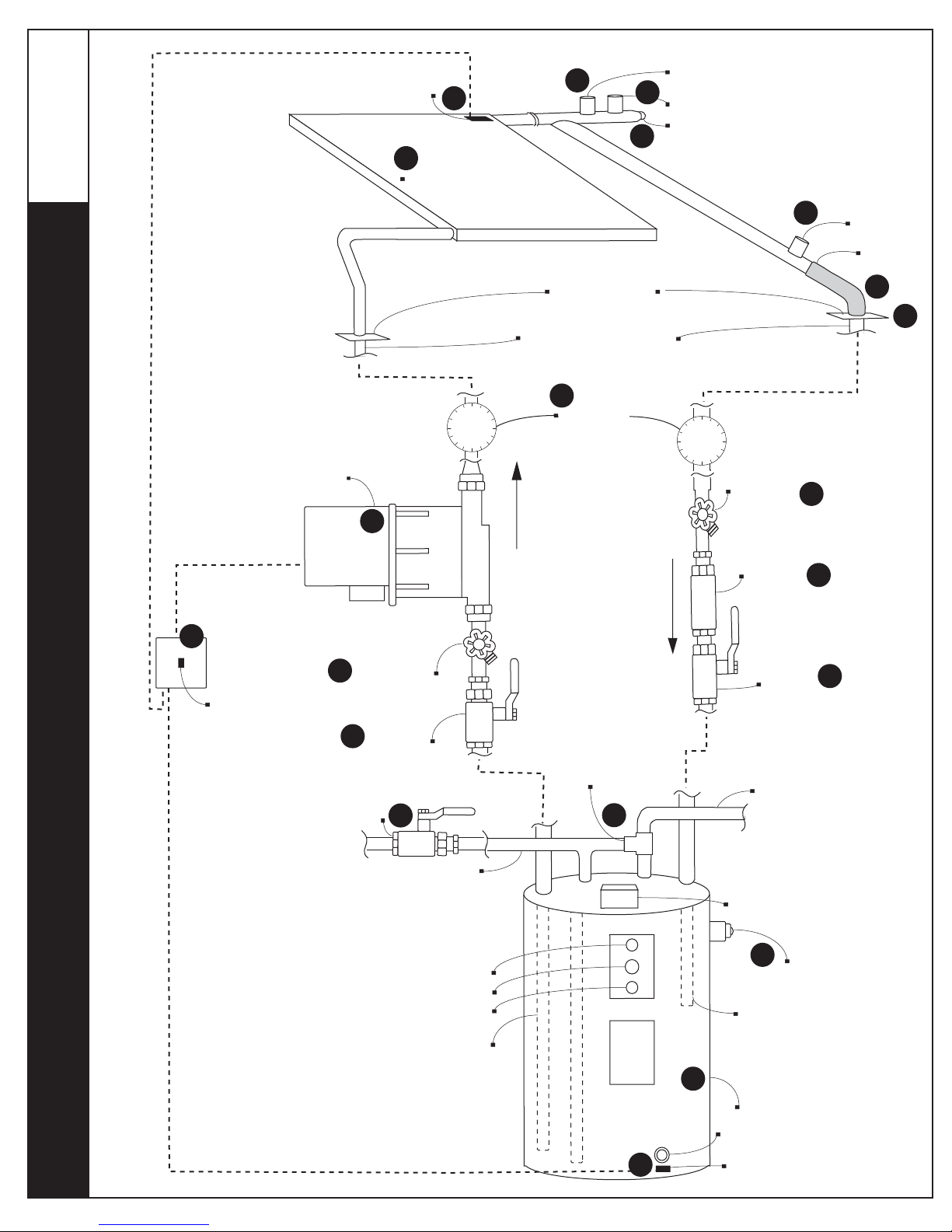

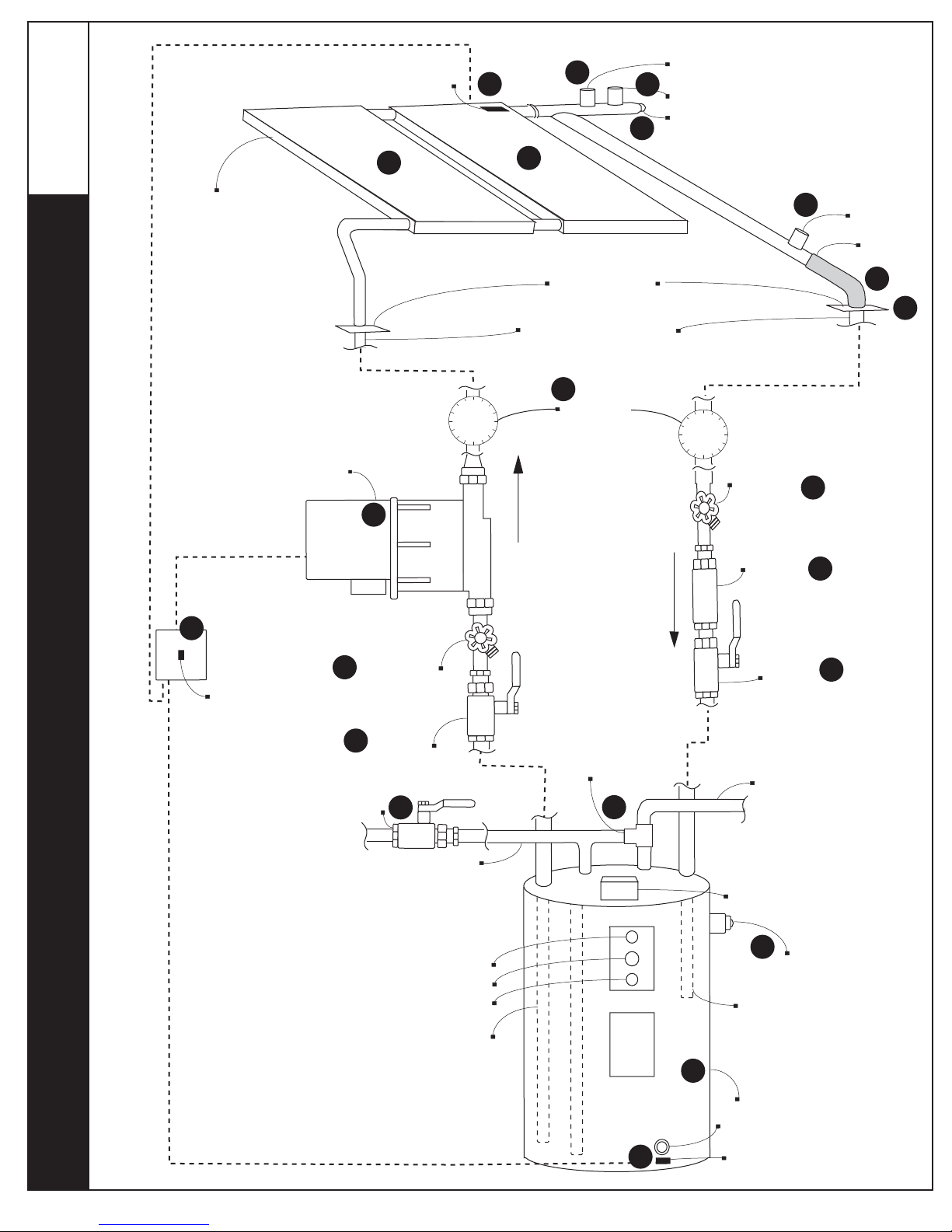

System Schematic (SLAR32DC-66 & SLAR40DC-80) 12

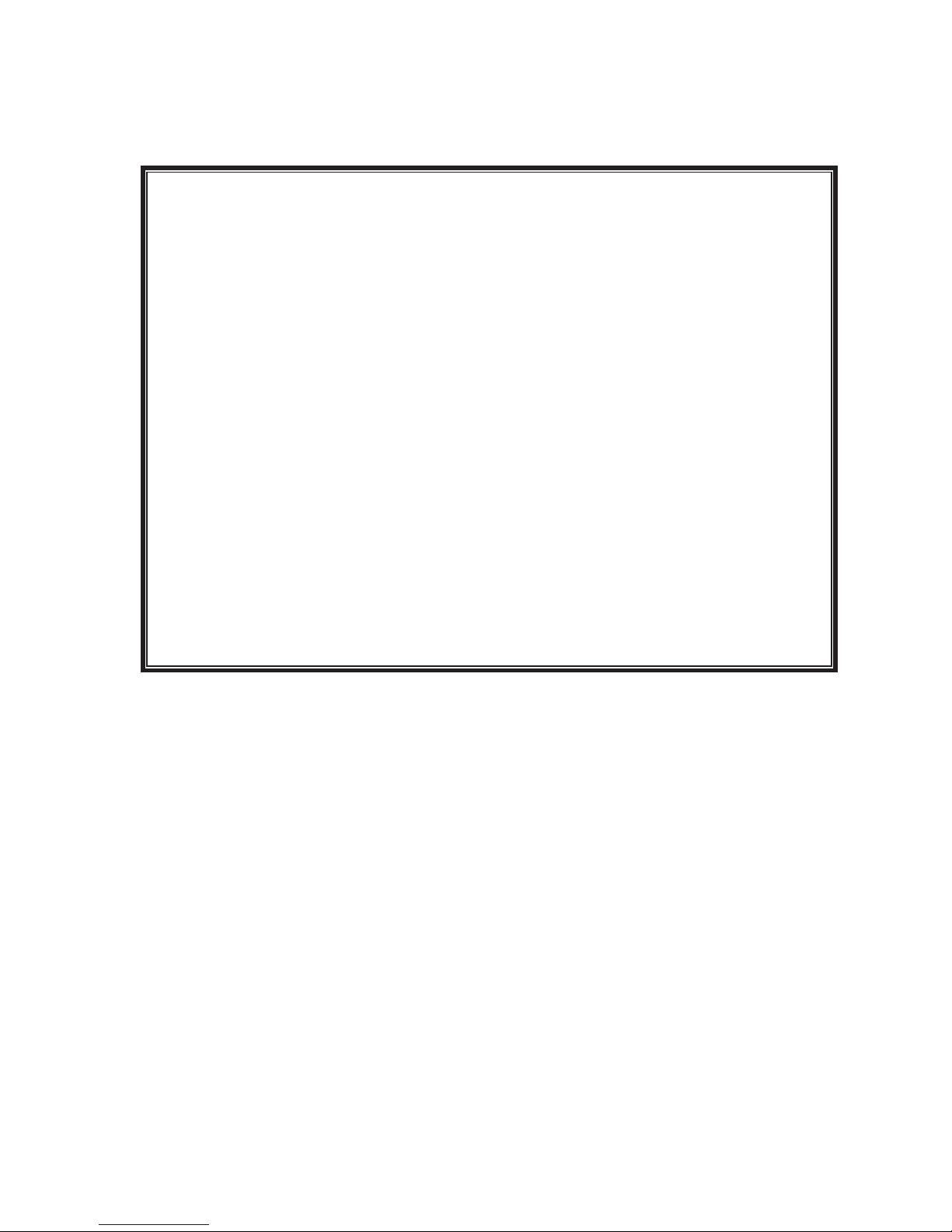

System Schematic (SLAR64DC-120 & SLAR80DC-120) 13

41

noitcnuFdnatsiLstraPtnenopmoC

51ycnatcepxEefiLtnenopmoC

51noitamrofnItcatnoC

61slebaLAurora

81ytnarraWAurora

3

SAFETY PRECAUTIONS

There is no substitute for safety. Always exercise extreme caution, care and good judgment

when working on or around a roof. Here are just a few installation precautions to keep in mind:

When working on the roof, always take care to avoid hazards such as overhead electrical

wires or loose shingles. Secure ladders so they will not slip or fall. Wear shoes with

proper tread to prevent slipping on the ladder or sloped roof areas.

Always check that power is turned off before attempting any wiring or electrical hook-

ups, especially when water is present. It’s always a good idea to shut power off to both

the solar storage tank and to the automatic control when there is water leaking at the tank.

Do not hook up or turn on any electricity to the solar storage tank until it is full of water. If the

heating element is not covered in water prior to being turned on, it will burn out.

Always consult the proper authorities or check with your local building department for the

permit requirements and codes applicable before you start the job. Installation should always be

in accordance with the National Fire Code and with all local codes.

INSTALLATION INSTRUCTIONS

SIZING & ORIENTATION

The vast majority of Solar Domestic Hot Water (SDHW) systems are comprised of “Medium

Temperature” solar collectors manufactured using tempered glass and some type of metal

absorber plate. They differ from “Low Temperature” systems predominantly utilized in

swimming pool heating applications. These systems are typically manufactured using plastic

resins. “High Temperature” systems are utilized to generate steam for industrial applications.

Corona collectors belong to the “Medium Temperature” category.

Normally, only one or two Aurora collectors are needed for a SDHW system. The number of

collectors is determined not only by the amount of water that is needed, but also by the latitude

of the installation and the collector’s orientation. The following table details Corona’s

recommended minimum system sizing guide for a typical installation:

Tank

Capacity # of Collectors

Needed Collector Type Control Type System Model

Number

66 gallon 1 SLAR-32 (4’ x 8’) Differential

Control SLAR32DC-66

80 gallon 1 SLAR-40 (4’ x 10’) Differential

Control SLAR40DC-80

120 gallon 2 SLAR-32 (4’ x 8’) Differential

Control SLAR64DC-120

120 gallon 2 SLAR-40 (4’ x 10’) Differential

Control SLAR80DC-120

4

Normally, collectors are installed on roofs, as close as possible to the tank, to minimize heat loss

through the pipe. The pipes between the tank and the collectors MUST be insulated with at least

½” thick insulation, for the same reason.

The solar collectors must be located in a structurally sound area of the roof that will be exposed

to the sun for the majority of the day, all year round.

The recommended angle of the collectors is the angle of the installation location’s LATITUDE.

This angle is designed to maximize solar absorption during winter months when the sun is low.

A variation of +/- 15 degrees is acceptable. The orientation of the collectors must be due south

55 degrees. Flush mounts on available roof slopes are recommended to allow convenience and

cost effectiveness, since these variations from the exact angle and orientation will affect the

system’s performance only by about 5%.

COLLECTOR MOUNTING

There are two basic roof-mounting methods:

FLUSH MOUNT INSTALLATION - Parallel to the roof line, as illustrated below.

Figure #1, Flush mounted collector

Flush Mount Installations are recommended when the roof’s slope conforms to the orientation

requirements as stated previously. This is the easiest and most aesthetically pleasing installation

method. After the collector(s) are installed, it should resemble skylight. The flush mount

consists of four (4) U-channels (SL-UC) and four (4) Gripper Sets (SL-GS), two set each for the

top and bottom.

1. Start from the bottom. The bottom side of the Corona collector is marked by two weep

holes placed about 20” apart on the short anodized aluminum edge of the collector.

When elevating the collector to the roof, make sure that the “weep holes” are facing

down. It is recommended to install the collectors vertically (length up the roof’s slope),

but the collectors may be installed horizontally as well.

2. Once the collector’s location is determined, anchor two (2) U channels to the roof using

two (2) stainless steel 2” x 5/8” lag bolts for each U-channel. The U-channels should

5

be spaced approximately 30” apart. The collectors will rest on top of the U-channels.

(Picture 1)

Picture #1

3. Verify a secure connection to the trusses. If lagging directly into the roof trusses is not

possible, secure a 2’ x 4’ wood beam perpendicular to the trusses, inside the attic, and

anchor the bolts to this member. Again, verify a secure connection into the new

member.

4. Connect the Latch to the Gripper (Picture 2) utilizing the provided nut and bolt. Slide

the Latch into the top of the U channel so that the Gripper remains on top of the

opening. Place them at the middle of the U-channel’s top and tighten. (Picture 3)

Picture #2 Picture #3

5. Loosen the Gripper providing space to insert the slot at the collector’s edge between the

Gripper’s hook and the U-channel’s top. Once both Grippers are grabbing the

collector’s edge slot, tighten both Grippers. (Picture 4)

Picture #4 Figure #3

6. Repeat steps 2-5 for the top. That’s it. The collector is anchored.

6

ANGLE MOUNT INSTALLATION - Not parallel to the roofline, normally used on flat roofs and

ground mounts, as illustrated below.

Figure #2, Angle mounted collector

Angle Mount Installations involve positioning the collector(s) at an angle so that the upper part

of the collector is higher than the lower in reference to the mounting surface. The “angle

mounting” is used on horizontal surfaces or on roofs that slope in directions other than south 55

degrees.

1. Use the Angle Mounting kit (SL-MK), see picture 5. Connect the U-channels to the

roof just like in the Flush Mounting method. Assemble the mounting clips to both U-

channels utilizing the provided bolts (Picture 6).

Picture #5 Picture #6

2. Screw the mounting clips to the BOTTOM part of the collector (the weep hole side)

using two (2) stainless steel or aluminum screws each. (Picture 7)

Picture #7

3. Assemble both rods and top mounting clips (picture 8). Connect the clips to the

collector’s top by stainless steel or aluminum screws. (Figure 4)

7

Picture#8 Figure#4

4. Connect to the U-channels to the opposite side of the rod, using the provided nuts and

bolts. (Picture #10)

Picture #10

5. Lift the collector’s top with the assembled rod kits and anchor the U-channels to the

roof, ensuring the proper angle to the collectors. (Picture 11)

Picture #11

Install all components in accordance with local code so that the performance of any structural

member or fire rated assembly is not reduced.

8

PIPE INSTALLATION

Careful consideration of the proper piping of the system should be done prior to a final decision

being made on the collector mounting. The collectors and piping should slope slightly

downward, toward the tank, in order to allow for draining in freezing conditions.

Piping should consist of copper tube (Type M), insulated with at least ½” Armaflex pipe

insulation or similar and be wrapped with aluminum tape in all areas exposed to UV radiation.

All soldered connections require 95/5 solder.

The cold-water inlet (supply) pipe connection should be made at the lowest corner of the

collector. The hot-water outlet (return) pipe connection should be made at the opposite corner of

the cold-water inlet. The hot-water return should have the shortest possible run back to the

storage tank to avoid heat loss.

The Vacuum Relief Valve (Part #6), Automatic Air Vent (Part #7), Pressure Relief Valve (Part

#8), and Freeze Protection Valve (Part #5), should be plumbed into the return line as illustrated

in the System Schematic on page 12 of this manual.

It is extremely important to take special care in weather proofing the piping installation through

the roof.

1. Drill a hole the same diameter as the copper piping being utilized in the system

installation being careful not to place the opening above the collector supply point.

The system will not drain properly if the opening is above the above the supply point.

2. Cement a copper roof flashing around the pre-drilled hole. The upper edge of the

flashing should slide underneath the adjoining shingle.

3. Push the copper tube up through the roof flashing. Slide the flashing cap over the

copper tubing so it rests on the flashing opening. The wiring for the Photovoltaic

Module should also be run through this the return line flashing.

4. After all of the piping is completed, solder the flashing cap into place.

5. Utilizing a polybutalyne adhesive, finish weather proofing the roof flashing.

9

PLUMBING

The storage tank should be placed in a location to best minimize heat loss. It should be placed as

close to the system return line as possible. Adequate ventilation and access for possible future

service work are important considerations. In order to prevent possible water damage in case of

tank leakage, a pan with a ¾” drain line should be installed.

As illustrated in the System Schematic on page 12 of this manual there are very specific

requirements as to valve, thermostat, and pump placement.

The following component equipment should solder in place according to their specific relative

locations as outlined in the System Schematic.

1. Circulation Pump (Part #4) - Taco 006BC4 Circulation Pump

2. Thermometers (Part #11) - Letro SL-2D In-Line Thermometer w/ temperature range

of 50to 220 F.

3. Boiler Drains (Part # 12) - BD-050 (½”), or BD-075 (¾”) Boiler Drains on both

Supply and Return lines.

4. Ball Valves (Part #14) - BV-050 (½”), or BV-075 (¾”) Ball Valves on both

Supply and Return lines.

5. Cold Water Inlet Valve - GV-075 (¾”) Gate Valve.

6. Mixing Valve - Watts 70A-075 (¾”) Mixing Valve.

AUTOMATIC DIFFERENTIAL CONTROL

Power to the circulation pumps is controlled by an automatic differential control that has two

temperature sensors. One sensor is located on the outlet of the solar collector and the other

sensor is located on the storage tank behind the lower access panel. When the storage tank

sensor detects water temperatures cooler than the desired temperature set on the control, and if

the collector sensor is 8F warmer than the storage tank sensor, the automatic control turns on

the circulation pump to harvest the energy available from the sun. When the desired temperature

is met, or when the solar collector sensor drops to within 4 degrees of the storage tank sensor, the

control turns off the circulation pump. (This on/off differential can be set to 24º/4º rather than

the 8º/4º.)

The automatic control has a three-position switch - ON, AUTO or OFF. (Sometimes this switch

is located on the inside of the cover.) During normal operation, the control is switched to AUTO

where the control will turn the circulation pump on and off at the appropriate times. When

switched to ON, the control sends power to the circulation pump. When switched to OFF, the

control turns the circulation pump off.

THE AUTOMATIC CONTROL HAS A HIGH LIMIT STORAGE SETTING THAT CAN BE ADJUSTED

FROM 110°F TO 200ºFAND IS TYPICALLY PRESET TO 140°F.

10

ELECTRICAL AND WIRING REQUIREMENTS

A properly licensed contractor must make the 230-volt electrical connection to the water heater

or solar storage tank and the electronic time switch (Optional). If your solar contractor is not

allowed by law to make these connections consult a licensed electrician.

NEVER ACTIVATE THE CIRCUIT BREAKER CONTROLLING THE ELECTRICAL HEATING ELEMENT

UNTIL THE SOLAR STORAGE TANK IS COMPLETELY FILLED WITH WATER.This will prevent

“dry firing” of the heating element. The electrical heating element will be destroyed almost

instantaneously if not completely submerged in water when activated. Make sure the water

heater circuit breaker is off until the solar storage tank is completely filled.

We recommend the use of a 115-volt differential control with a factory installed six-foot line

cord. The installation requires one 115-volt outlet to be installed near the solar storage tank.

Plug the control into the outlet. The circulation pump line cord is plugged into the receptacle on

the side of the controller. A 230-volt control and circulation pump may be substituted, but

troubleshooting the components in the future becomes more difficult. The specified differential

thermostat is the Goldline model GL-30-LCO.

THERMOMETERS

Locate two thermometers; one at the supply line and one on the return line of the solar loop so

that the temperature rise across the collector can be determined.

LABELS

Label installation is mandatory at several locations of the system. Please insure compliance by

affixing labels at the designated locations.

SYSTEM START-UP

The Start-up Procedures are detailed in the Solene Open Loop (SLAR-HMDC) Homeowner’s

Manual.

11

SYSTEM OPERATION

Solene systems are designed to accommodate three separate modes of operation. Your solar

water heating system can (1) provide 100% solar operation during good weather, or (2) serve as

a pre-heater to your electric water heater adding solar energy when and as available, or (3) 100 %

on utility power during inclement weather.

TOTAL SOLAR OPERATION

Turn off the circuit breaker to your solar storage tank. If a water heater time switch has been

installed, set the switch to the “off” position. If you have a mechanical timer remove the trippers

from the face of the switch.

TOTAL PREHEAT

Leave the circuit breaker to your solar storage tank on and set the tank thermostat to the lowest

acceptable temperature setting. The electric resistance heating elements will come on only when

the tank temperature falls below the thermostatic set point. If the solar heated water entering the

tank is warmer than the thermostatic set point, the electric heating elements will not come on. If

you have a water heater timer, you may preset the timer to turn the heating element on and off at

specified times throughout the day if desired.

TOTAL UTILITY POWER

Leave the circuit breaker to your solar storage tank on and close the isolation ball valves in the

collector loop. In this mode of operation you must turn off the circulation pump. To turn the

pump off, open the controller and change the operational setting from automatic to off. Failure

to turn off the pump can quickly damage the pump motor, shaft, bearings or impeller.

14

COMPONENT PARTS LIST AND FUNCTION

While specific products are mentioned below, there are many components that can be substituted

with like or equal products. For instance there are several different mixing valves or isolation

valves that can be utilized, not just the one specifically listed. Sometimes sweat or threaded

connections or varying fitting sizes are dealer preference. All of the components listed below are

available from Solene at 927 Fern St. Suite 1500, Altamonte Springs, FL 32701 (866) 902-0060.

See the schematics on page #12 & #13 for the location of the following list of components.

1. Aurora Solar Collector –Aurora SLAR40 4 x 10, or SLAR32 4 x 8 with all copper chrome

plated absorber plate.

2. Solar Storage Tank – Lochinvar FTA066K 66 Gallon, or FTA082K 80 Gallon, or FTA120K

120 Gallon Solar Storage Tank with Single 4500W Backup Element.

3. Differential Control – Goldline Differential Control with Adjustable High Limit determines

when system is on or off.

4. Circulation Pump – Taco 006BC, Grunfos, or March 80AC, circulate water through system.

5. Freeze Valve – Dole FP-45 Freeze Valve protects system from freezing.

6. Vacuum Relief Valve – Watts N-36 Vacuum Relief Valve allows air into the system when

draining collector.

7. Air Vent – Sparco FV-147 Air Vent allows air trapped in collector to purge.

8. Pressure Relief Valve – Watts 530C Pressure Relief Valve protects system from excessive

pressure.

9. Pipe Insulation – ACT05834 Armaflex Copper Pipe Insulation to prevent heat loss through

pipes. Any Pipe Insulation that is exposed to sunlight must be wrapped with foil tape or coated

with a water-based acrylic resin coating as specified by the Insulation Manufacturer.

10. Roof Penetration Flashing – All Copper Roof Flashing. Gooseneck type flashing is

recommended for feed line to accommodate sensor wire.

11. Thermometer – Letro SL-2D In-Line Thermometer w/ temperature range of 50°F to 220°F.

12. Boiler Drains – BD-050 ½’, or BD 075 ¾’ Boiler Drains on both Feed and Return lines used in

conjunction with #13 Ball Valves, allow for manually draining the solar system.

13. Check Valve – Heliodyne SCV 75/50 Check Valve for PV Systems prevents thermo-siphoning

from storage tank through solar collectors.

14. Ball Valves – BV-050 ½”, or BV-075 ¾” Ball Valves used as Isolation Valves in conjunction

with #11 Boiler Drains to manually drain the solar system.

15. Cold Water Inlet Valve – GV-075 ¾” Gate Valve gives ability to turn off the cold feed to the

Solar Storage Tank.

16. Mixing Valve – Watts 70A-075 ¾” Mixing Valve tempers temperature of hot feed line to home.

17. Pressure & Temperature Relief – Watts 100XL-4 P&T Relief Valve located on the solar

storage tank opens at 150psi or 210°F.

MODEL SLAR40DC-80

MODEL SLAR32DC-66

ROOF PENETRATION

COPPER TUBING & INSULATION

COLLECTOR SENSOR

AUTOMATIC FREEZE

VALVE

VACUUM RELIEF VALVE

AUTOMATIC AIR VENT

PRESSURE RELIEF VALVE

MANUALDRAIN

BALL VALVE

(ISOLATION VALVE)

ELECTRICALSUPPLY

PRESSURE &

TEMPERATURE RELIEF VALVE

SOLAR RETURN FROM

COLLECTOR

SOLAR HOT WATER TANK

TANK DRAIN

DIFFERENTIAL

TEMPERATURE

CONTROL

120v

COLD WATER

FROM HOUSE

RESET BUTTON

HEATING ELEMENT

THERMOSTAT CONTROL

SOLAR FEED TO COLLECTOR

SOLAR COLLECTOR

TANK SENSOR

CONTROL

SWITCH

HOT WATER TO HOUSE

MIXING VALVE

(BYPASS)

MANUALDRAIN

CHECK VALVE

BALLVALVE

(ISOLATION VALVE)

E

NI

L

NRUT

ER

R

A

L

O

S

CIRCULATION PUMP

ENILDE

E

F

RALOS

SOLENE DHW SYSTEM SCHEMATIC

PIPE

INSULATION

COLD SERVICE VALVE

1

18

16

14

15

13

5

8

9

12

10

7

6

4

2

3

18

12

14

17

11

THERMOMETER

9-04-09

ROOF PENETRATION

COPPER TUBING & INSULATION

AUTOMATIC FREEZE

VALVE

VACUUM RELIEF VALVE

AUTOMATIC AIR VENT

PRESSURE RELIEF VALVE

MANUALDRAIN

BALLVALVE

(ISOLATION VALVE)

ELECTRICALSUPPLY

PRESSURE &

TEMPERATURE RELIEF VALVE

SOLAR RETURN FROM

COLLECTOR

SOLAR HOT WATER TANK

TANK DRAIN

DIFFERENTIAL

TEMPERATURE

CONTROL

120v

COLD WATER

FROM HOUSE

RESET BUTTON

HEATING ELEMENT

THERMOSTAT CONTROL

SOLAR FEED TO COLLECTOR

TANK SENSOR

CONTROL

SWITCH

HOT WATER TO HOUSE

MIXING VALVE

(BYPASS)

CIRCULATION PUMP

SOLENE DHW SYSTEM SCHEMATIC

PIPE

INSULATION

COLD SERVICE VALVE

18

16

15

5

8

9

10

7

6

4

2

3

16

12

14

17

SOLAR

COLLECTORS

COLLECTOR SENSOR

11

MANUALDRAIN

CHECK VALVE

BALLVALVE

(ISOLATION VALVE)

E

NI

L

N

RUTE

R

RA

L

OS

ENILDEEFRALOS

14

13

12

11

THERMOMETER

MODEL SLAR80DC-120

MODEL SLAR64DC-120

MODEL SLAR60DC-80

9-04-09

15

COMPONENT LIFE EXPECTANCY

Installed and maintained properly, your Solene Solar Hot Water Heating System should provide

many years of trouble free, uninterrupted service. The main component of the system, the

Aurora Solar Collector, is designed to last 25 to 30 years. Solar Storage Tanks have a life

expectancy anywhere from 10 to 20 years depending greatly upon regional water quality. (Tank

life can be extended by replacing the internal sacrificial anode rod from time to time.)

Differential Control and Circulation Pump life expectancies run from 5 to 10 years. As electrical

components, they are susceptible to lightning strikes or electrical surges. Valve life expectancy

varies greatly depending water quality and usage.

FOR MORE INFORMATION

Detailed information regarding System Operation, Routine Maintenance, Freeze Protection, and

Start-up and Shutdown procedures can be found in the Solene Open Loop (DC) Domestic Hot

Water Solar System Homeowner’s Manual (SLAR-HMDC).

CONTACT INFORMATION

If you have any questions regarding the operation of your system, please contact your Installing

Solene Dealer.

Solene™

™

927 Fer n St. Suite 1500

Altamonte Springs, FL 32701

(866) 902-0060

Solene Dealer Contact Information

16

SOLENE OPEN LOOP OG-300 SYSTEM LABELS

(Whole page will be embossed foil)

The following labels provide the system owner with important safety and operating information.

Be sure to cut out the labels below and apply them to the proper system components as

described below. Refer to the Solene DHW System Schematic in this manual for reference

numbers.

Place these labels on Isolation Valves (#13)

Place these labels on Circulation Pump (#4), Manual Drains (#11) and Mixing Valve (#15)

Place this label in visible location on Solar Tank

Place these labels on Solar Feed and

Return Line above Solar Tank

Solene System Isolation Valve

Normall

y

O

p

en

WARNING HOT

Solene System Isolation Valve

Normall

y

O

p

en

WARNING HOT

WARNING HOTWARNING HOT

FREEZE PROTECTION

Collector loop lled with water is protected by Freeze

Valve under normal conditions. When air

temperatures are expected to be below 32ºF for

extended periods of time, drain solar loop as

instructed in manual.

Maximum Operating:

Temperature: 200ºF Pressure: 130psi

WARNING

Ungrounded Piping

Stay clear during any thunderstorm activity.

WARNING

Ungrounded Piping

Stay clear during any thunderstorm activity.

17

(5 X 7 Freeze Protection Label)

SOLENE FREEZE PROTECTION INSTRUCTIONS

(Models SLAR32DC-66, SLAR40DC-80, SLAR64DC-120, SLAR80DC-120)

Your Solene Solar System has a Freeze Valve on the roof that protects your system from freezing. During

near freezing conditions this valve will allow water to flow through the collector from the storage tank

and trickle onto the roof. This Freeze Valve needs water pressure to operate properly. DO NOT CLOSE

THE ISOLATION VALVES unless you are going to completely drain your solar system as described

below.

MANUAL DRAIN DOWN FREEZE PROTECTION – Follow these steps:

Disconnect the wires from the PV Panel to the Circulation Pump.

Close both Isolation Valves.

Connect drain hose to the Drain Valve on the return line of the solar system, or

use a water vessel to catch the water. Open the Drain Valve on the return line.

(CAUTION - WATER MAY BE EXTREMELY HOT - POSSIBLE STEAM)

Allow all water to drain out of the solar system.

Move drain hose or water vessel to the Drain Valve on the feed line below the

circulation pump and open the Drain Valve on the feed line.

Leave these Drain Valves open while your system is turned off.

Ten (10) Year Warranty

Plus Lifetime Limited Warranty

Warranty

This warranty is issued by SOLENE LLC, 927 Fern Street, Suite1500, Altamonte Springs, Florida 32701, and

applies to all new AURORA collectors when purchased for use on residential or commercial water heating

applications. SOLENE LLC, warrants to the original purchaser only that the AURORA collector will be free from

defect in materials and workmanship in the manufacturing process under normal use and service for a period of ten

(10) years from the date of initial installation when purchased from and properly installed by an AUTHORIZED

DEALER within that dealer’s authorized territory. During that time, should AURORA collector or component

exhibit a manufacturing defect, the defective collector or component will be repaired or replaced, without charge for

the equipment by SOLENE LLC, or its authorized dealer or distributor. Labor expenses to repair or replace a

defective AURORA collector is reimbursable, to an authorized dealer, up to $100 in years one (1) and two (2), $75

in years three (3) through five (5), and $50 in years six (6) through ten (10).

Your dealer is __________________________, ___________________

Authorized Dealer Phone

Bonus Lifetime Limited Warranty

AURORA collectors carry a Lifetime Limited Warranty. Any AURORA Collector found to be defective in material

or workmanship subsequent to the initial Ten Year (10) Warranty will be replaced, so long as the purchaser pays

fifty percent (50%) of the published collector list price at the time the replacement is required.

Exceptions

SOLENE, LLC will not be liable for inspection, freight, removal, or any other charges arising from this warranty

unless specifically stated in this warranty statement. Neither SOLENE LLC, its dealers, nor its distributors shall be

liable for incidental or consequential damages, damage of any sort or nature resulting from abuse, misuse, neglect,

abnormal weather conditions, freezing, scaling due to hard water, acts of God, or damage caused by improper

installation. This warranty does not apply to installation components or to solar collectors which have not been

installed and maintained in strict compliance with SOLENE’s installation and operation manuals and instructions

and/or applicable ordinances or codes or to systems not installed by an authorized dealer within its authorized

territory. In no event shall the liability exceed the purchase price of the product. There are no implied warranties of

merchantability or implied warranty of fitness, which extends beyond the description of the face hereof.

Proof of Purchase

It is the responsibility of the consumer to establish the original purchase date for warranty purposes. We

recommend that a bill of sale, canceled check, or some other appropriate payment record be kept for that purpose. If

the system is registered within 10 days of installation at www.solene-usa.com, the electronic registration

confirmation is the only future proof of purchase necessary. The completion of the Online System Registration

Form is a condition precedent to coverage under this warranty.

Note

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state.

Solene LLC

927 Fern Street, Suite 1500

Altamonte Springs, FL 32701

Rev 08/27/09

This manual suits for next models

3

Table of contents

Popular Solar Panel manuals by other brands

solarwatt

solarwatt Blue 60P/M instructions

COMFORTPOOL

COMFORTPOOL CP-80021 Installation & operation manual

GRIDFREE

GRIDFREE TINY HOUSE installation manual

AKO-Agrartechnik

AKO-Agrartechnik BA-1161 instruction manual

Ningbo

Ningbo Sun Earth TPB Series installation manual

Ansult

Ansult 019394 operating instructions