SOLID AIR FDC2 User manual

1| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

TECHNICAL MANUAL

Round re damper

FDC25 |FDC40

INDEX

1. PRODUCT OVERVIEW..............................................................................................................2

2. DIMENSIONS...............................................................................................................................9

3. INSTALLATIONS..........................................................................................................................17

4. ACTUATORS................................................................................................................................45

5. ACCESSORIES ............................................................................................................................53

6. REPLACEMENTS.......................................................................................................................56

7. MAINTENANCE AND OPERATION................................................................................... 62

2| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

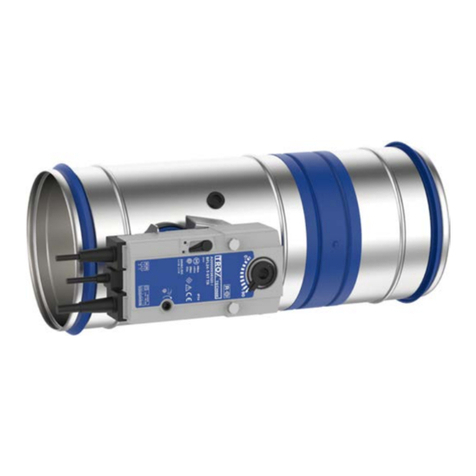

1. P

Fire dampers FDC are used for prevention of

re spread trough the ventilation ducts and

between re sections. Fire dampers consist of

cylindrical casing, calcium silicate damper blade,

damper blade mechanism outside of the airow

and a manual, electromagnetic or electric

actuator.

Fire damper casing is made out of galvanized

steel sheet. Variants produced from stainless

steel and powder coated steel are also available.

Calcium silicate blade is equipped with brass

bearings and seals made out of polyurethane

and elastomer rubber. Fire dampers FDC25

are produced up to size d315 and have 25 mm

thick damper blade. Fire dampers FDC40 are

produced in sizes from d355 till d800 and have

40 mm thick damper blade. FDC25 re dampers

are equipped with R25 manual mechanism and

FDC40 re dampers are equipped with R40

manual mechanism.

Manual spring return mechanism is equipped

with thermal fuse that is triggered automatically

when the temperature inside the duct reaches

72 °C. It can also be activated manually by the

push of the button on the mechanism.

Additional equipment for manual mechanism

include end contact switches for damper

position signalling. Electromagnetic

actuators feature spring return mechanism

with electromagnet for remote activation.

Additional equipment for electromagnetic

mechanism include end contact switches for

damper position signalling. Rearming of the

electromagnetic actuator is manual.

Fire dampers with electric actuators are

equipped with Belimo actuator drives in 24 V

or 230 V versions. Activation of re dampers

equipped with electric drives can be via 72 °C or

95 °C thermal fuse or remotely via control signal.

Rearming of the electric re damper can also

be done remotely via control signal. All electric

actuators are equipped with end switches for

position signalling.

ATEX rated versions of re dampers can be

delivered with Schischek 24 V / 230 V electric

actuators that are rated for installation in

explosive atmosphere areas. All re dampers are

tested according to the EN 1751 for airtightness

and retain class 2 leakage on the closed damper

blade and class C on the casing air leakage.

3| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

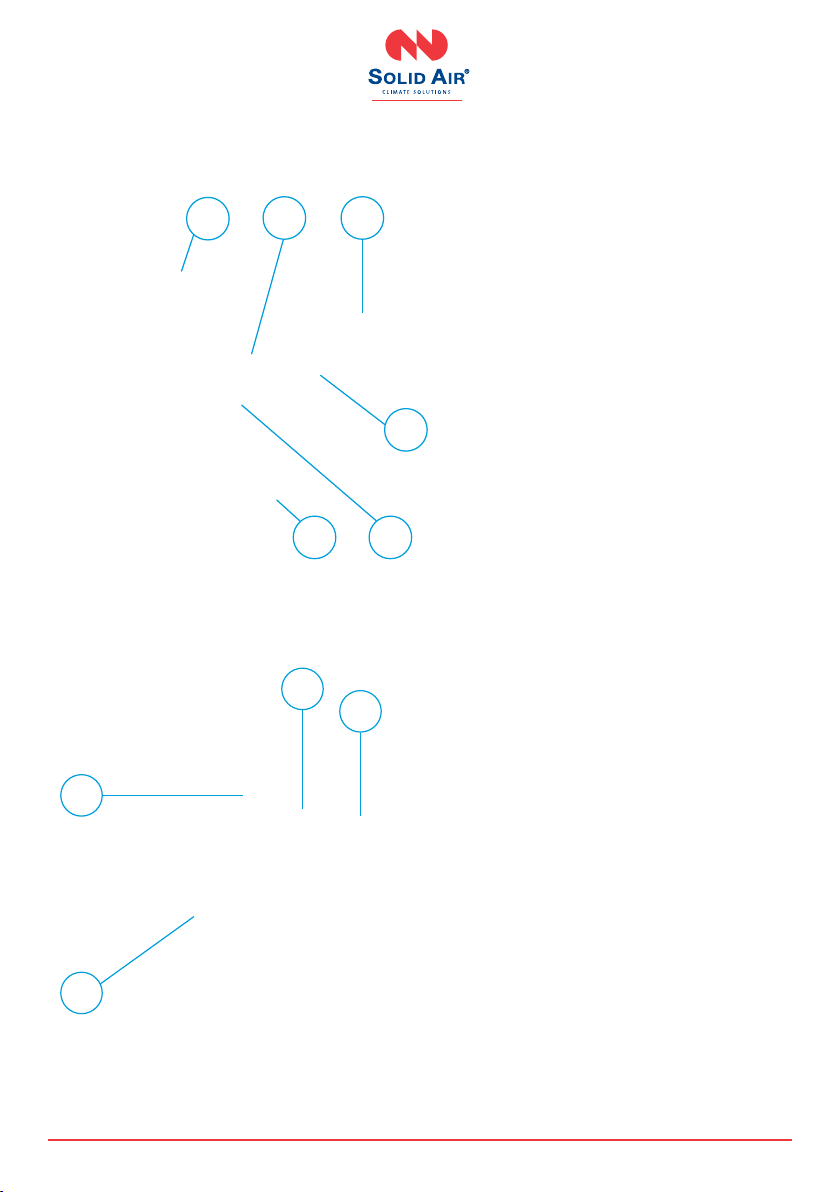

1. Galvanized steel casing

2. Fire resistant damper blade

3. Actuator

4. Intumescent joint

5. Connection anges

6. Thermal fuse

1. Gypsum layers

2. Intumescent strip

3. Cold smoke seal

4. Contact layer

123

6

4

5

21

4

3

4| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

1. P

TESTS AND CERTIFICATES

All our dampers are submitted to a number of

tests by ocial test institutes. Reports of these

tests form the basis for the approvals of our

dampers. Klimaoprema re dampers are also

suitable for installation in buildings with high

hygienic demands such as hospitals, clinics

and pharmaceutical areas. To conrm this, out

products are tested by an independent Institute

of Hygiene, based in Gelsenkirchen, Ruhr, and

comply with directives and guidelines in VDI

6022.

FIRE RESISTANCE CLASSIFICATION

FDC re resistance is tested according to

EN 1366-2 “Fire resistance tests for service

installations- Part 2: Fire dampers”. Classication

of the re dampers is dened according to

EN 13501-3 Fire classication of construction

products and building elements.

Installation in both, vertical and horizontal axis

of rotation of the dampers blade is acceptable

(with the axis angle 0 - 360°). Fire resistance of

re damper depends on classication of walls

or ceilings. It is allowed to install products to

walls or ceilings only according to products

Declaration of Performance. Walls or ceilings

with greater re resistance can also be used.

Fire damper should be installed according to the

installation manual which can be found within

this document.

Please consult latest Declaration of Performance: solid-air.nl/downloads (DoP FDC25/40)

For more information about certicates, visit our website: solid-air.nl/brandwerend

E- Integrity

I- Insulation

120/90/60 - Classication time in minutes

S- Smoke leakage

ve - Damper installed in vertical compartment

ho - Damper installed in horizontal compartment

i↔o - Fire performance criteria are met on both sides

5| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

Fire damper casing is manufactured from galvanized steel sheet, but on demand can be produced out of:

• Galvanized steel and powder coated

• Stainless steel (AISI 304/316)

• Stainless steel (AISI 304/316) and powder coated

Fire damper for areas with potentially explosive

atmospheres are also available.

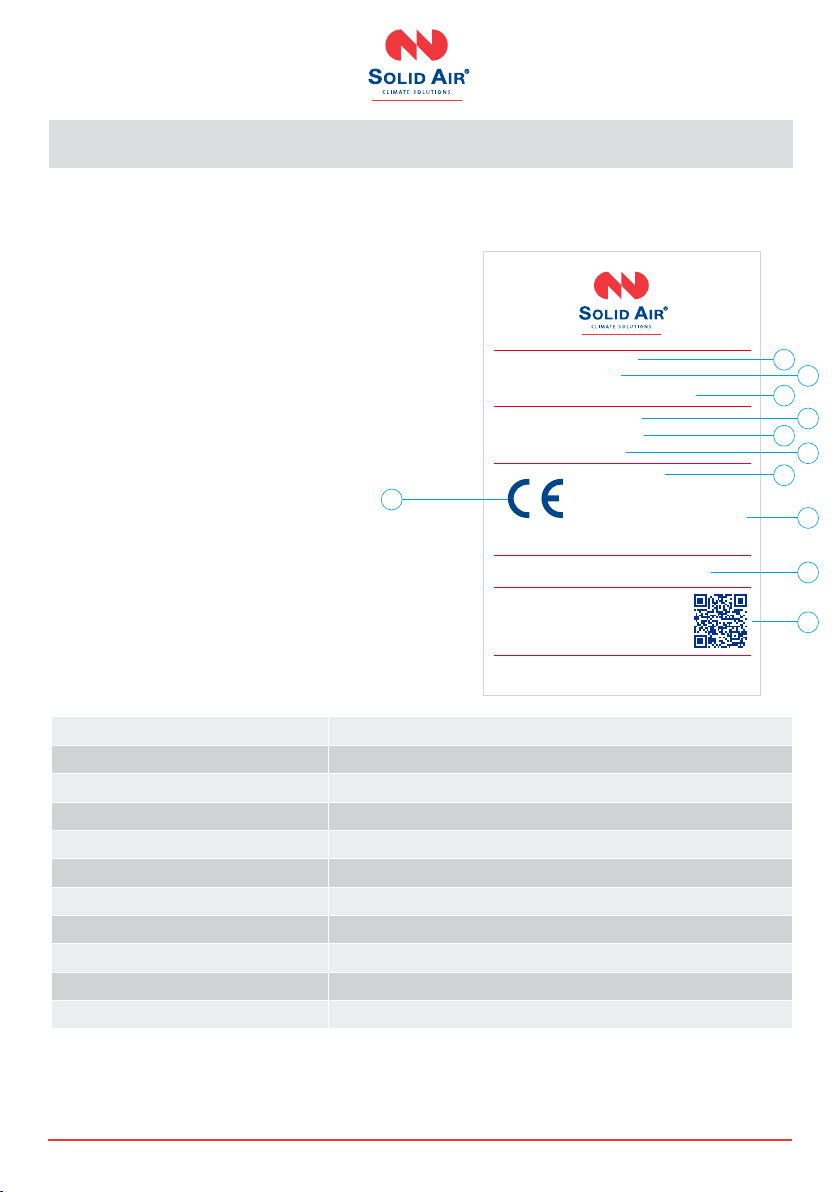

Product label

1. Serial number

2. Dimension of the re damper

3. Type

4. Serial number

5. Production date

6. Mechanism type

7. Classication according to EN 13501-3

8. Declaration of performance

9. Number of the European standard and

year of its publication

10. Barcode

11. CE-mark

Product specicaties

T

Nominal sizes 100 - 800 mm

Casing length 380 mm

Temperature range -20 °C … 50 °C

Release temperature 72 °C (standard) of 95 °C (optional with electric actuator)

Volume ow rate range up to 21.700 m³/h

Dierential pressure range up to 2.000 Pa

Casing air leakage Class C/ATC3, EN 1751

Closed blade air leakage Class 2, EN 1751

Upstream velocity < 12 m/s

EC conformity EN 13501-3, EN 1366-2, EN 15650, EN 1751, CPR no. 305/2011

Declaration of performance DoP 711/2020_4_EN

1

3

5

2

4

6

8

9

10

7

11

Article number:

Size:

Type:

Serial number:

Production date:

Actuator mechanism:

xxxxxxx

d100

FDC25-d100-m230-S4

0000001

14.10.2019

M230

EN15650:2010

Eltt (Ve-Ho) S Cxx

For the re classication of

this product please consult

declaration of performance.

DOP 711/2017 N

EI 60/90/120 (Ve-Ho i < - > 0) S 500 Pa

This damper should be installed according

to the installation instructions.

For more information: www.solid-air.com

Manufactured by Klimaoprema d.d.

Gradna 78A - 10430 Samobor - HR/Croatia

1812 17 1812-CPD-1161

6| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

Diameter (mm) Cross section (dm²) Net area (dm²)

FDC25

100 0.74 0.50

125 1.17 0.87

160 1.93 1.55

200 3.05 2.56

250 4.79 4.18

300 6.18 5.74

315 7.64 6.87

FDC40

355 9.73 8.33

400 12.37 10.79

450 15.69 13.91

500 19.39 17.41

630 30.86 28.36

710 39.24 36.42

800 49.86 46.68

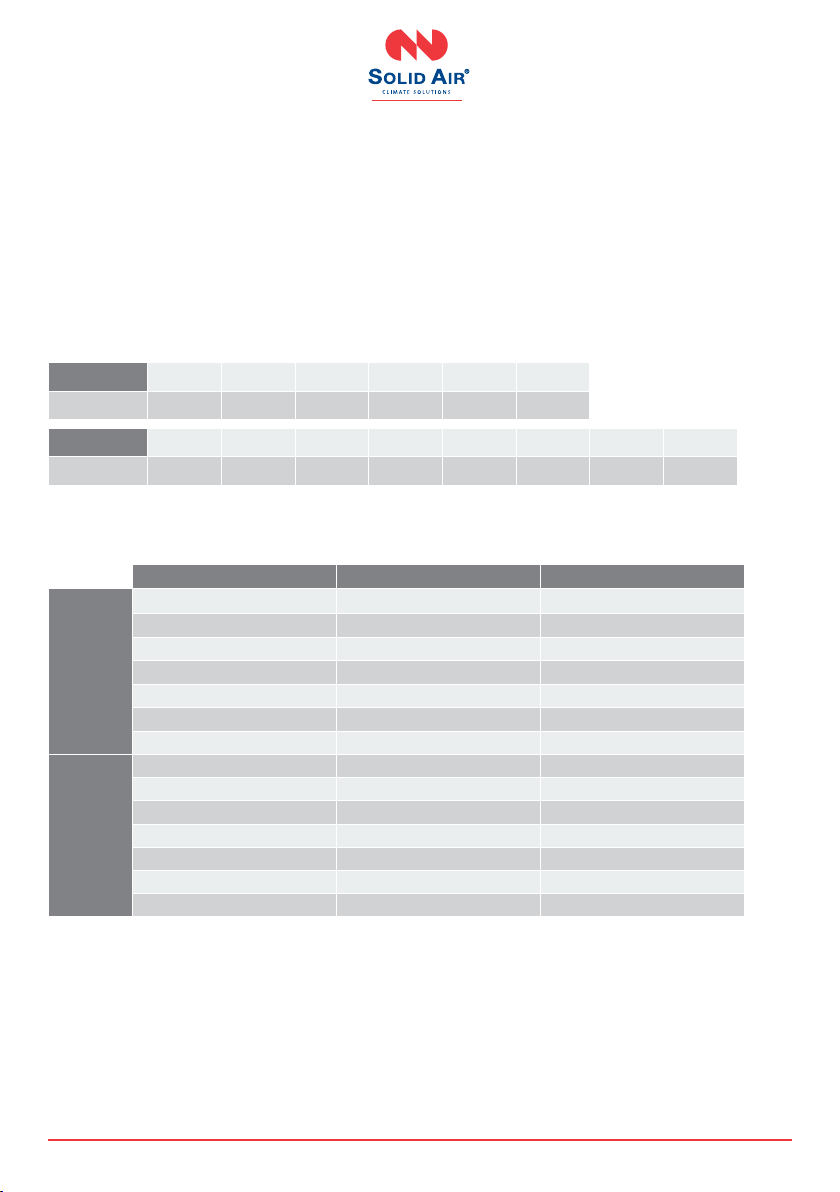

Specications Pressure drop

Pressure drop values are described with the “Zeta” values for each size. The exact pressure drop in

[Pa] is calculated using the following formula:

∆p [Pa]= ζ * v² * 0,6

Where ζis Zeta value from the tables below, v is airow velocity in [m/s].

FDC25 d100 d125 d160 d200 d250 d315

ζ1.759 0.852 0.545 0.445 0.340 0.293

FDC40 d355 d400 d450 d500 d560 d630 d710 d800

ζ0.428 0.389 0.344 0.325 0.312 0.232 0.206 0.179

Dimensional range

7| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

O

M

Casings

FDC25

Cylindrical re damper with 25 mm damper blade

and re classication up to EI120S. Sizes range from

d100 till d315.

FDC40

Cylindrical re damper with 40 mm damper blade

and re classication up to EI120S. Sizes range from

d355 till d800.

FDC25-APP

Cylindrical re damper with integrated Applique

installation frame with 25 mm damper blade

and re classication up to EI90S. Sizes range

from d100 till d315.

FDC25-MF1/MF2

Cylindrical re damper with integrated MF1

installation frame with 25 mm damper blade

and re classication up to EI60S. Sizes range

from d100 till d315.

FDC40-MF2

Fire damper with integrated MF2 installation frame

with 40 mm damper blade and re classication up

to EI90S. Sizes range from d355 till d800.

(1) Damper type (2) Dimension (3) Mechanism type

FDC25 - d250 - M230-S

(1)

(2)

FDC25 - 100 to 315

FDC40 - 355 to 800

FDC25-APP - 100 to 315

FDC25-MF1 - 100 to 315

FDC25-MF2 - 100 to 315

FDC40-MF2 - 355 to 800

Damper diameter 100 till 800 mm

(3) R - manual drive

R-S - manual drive with limit

switches

M230-S - electric actuator AC 230V

M24-S - electric actuator AC/DC 24V

M24-S-ST - electric actuator AC/DC 24V

with connection plug

EMS-S - electromagnetic drive

EX - ATEX rated Schischek

230/24V electric actuator

8| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

P

Actuators

R (R-S)

Manual operating mechanism, optionally with end

switches (R-S). In case of re, the re damper closes

automatically. Damper closing can be initiated

either by thermal fuse melting, or by manual acti-

vation on the operating mechanism. Upon closure,

damper blade is locked in closed position and can

only be opened manually. Thermal fuse melting

point is 72 °C.

EMS-S

Electromagnetic operating mechanism, comes with

end switches as standard. In case of re, the re

damper closes automatically. Damper closing can

be initiated either by thermal fuse melting or remo-

tely by triggering the electromagnet. Electromagnet

is constantly under power and activates closing of

the damper blade in case the power cuts out. Upon

closure, damper blade is locked in closed position

and can only be opened manually. Thermal fuse

melting point is 72 °C.

M230-S

Belimo 230 V electro motor operating mechanism,

comes with integrated end switches. In case of

re, the re damper closes automatically. Damper

closing can be initiated either by thermoelectric

release device or remotely by triggering the electro

motor. Upon closure, damper blade is locked in

closed position and can be opened by sending a

signal to electro motor. Standard thermoelectric

release point is 72 °C, optional 95 °C.

M24-S

Belimo 24 V electro motor operating mechanism,

comes with integrated end switches. In case of

re, the re damper closes automatically. Damper

closing can be initiated either by thermoelectric

release device or remotely by triggering the electro

motor. Upon closure, damper blade is locked in

closed position and can be opened by sending a

signal to electro motor. Standard thermoelectric

release point is 72 °C, optional 95 °C.

M24-S-ST

Belimo 24 V electro motor operating mechanism,

comes with integrated end switches. In case of

re, the re damper closes automatically. Damper

closing can be initiated either by thermoelectric

release device or remotely by triggering the electro

motor. Upon closure, damper blade is locked in

closed position and can be opened by sending a

signal to electro motor. Standard thermoelectric

release point is 72 °C, optional 95 °C. Actuator is

additionally equipped with connection plug for easy

connection with power supply and communication

modules.

EX

ATEX rated re dampers are equipped with

Schischek ExMax actuators, Exbox-TT thermal swit-

ches and ExBox plenum boxes. Optional casing can

be produced in AISI316L stainless steel.

9| Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

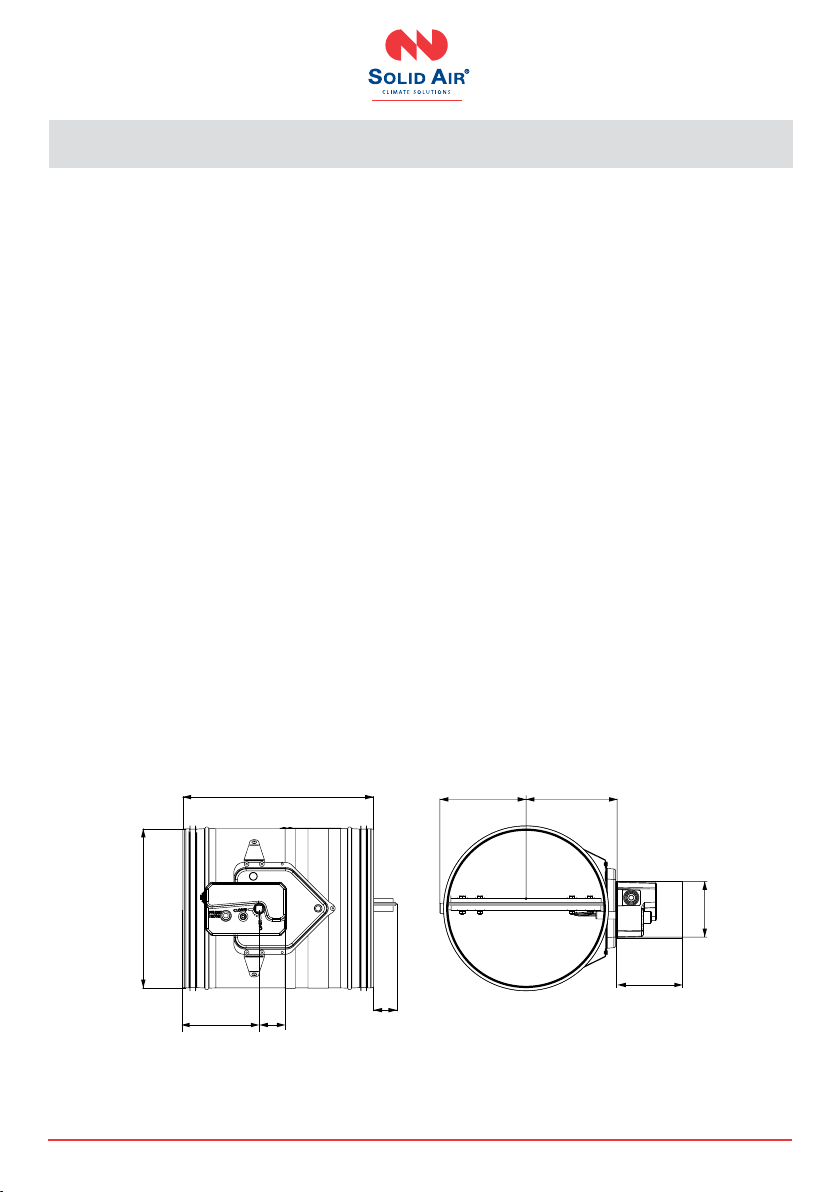

2. D

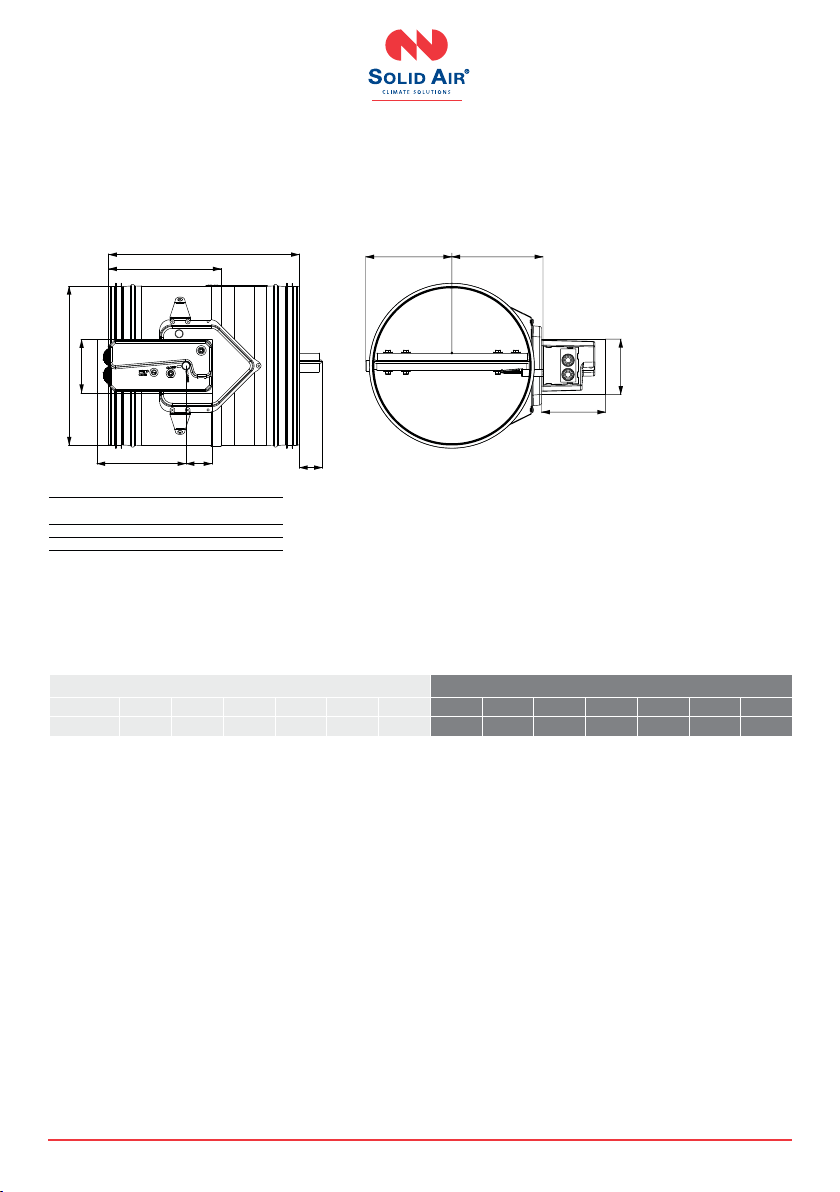

FDC25/FDC40-R

(manual mechanism)

• Automatic closure when the temperaturein the

duct exceeds 72 °C.

• Manual rearming with handle.

• Manual unlocking possible for periodical test of

re damper.

• Optional with end position switches (-R-S).

• FDC25 re dampers are equipped with R25

manual mechanism.

• FDC40 re dampers are equipped with R40

manual mechanism.

380

Ød

C A

Y

Ød/2+12 Ød/2+22

105

150

FDC25-R (up to d315)

10 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

380

220

Ød

D

C A Y

Ød/2+12 Ød/2+22

D

E

FDC40-R (d355 up to d800)

Length of damper blade outside of casing (Y dimension on front side)

FFDC 25/40 Y=(Ø d/2)-110 (mm)

*If the damper is larger than Ø 540 mm, use formula (X dimension on back side)

FDC 40 (> d540) X=(Ø d/2)-270 (mm)

FDC25-R FDC40-R

Ø d (mm) 100 125 160 200 250 315 355 400 450 500 630 710 800

Weight (kg) 3.8 4.2 4.7 5.4 6.3 7.7 11.9 13.5 15.4 17.5 23.6 27.7 33.7

Product

A

[mm]

C

[mm]

D

[mm]

E

[mm]

FDC 25 55 150 105 150

FDC 40 55 200 105 200

11 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

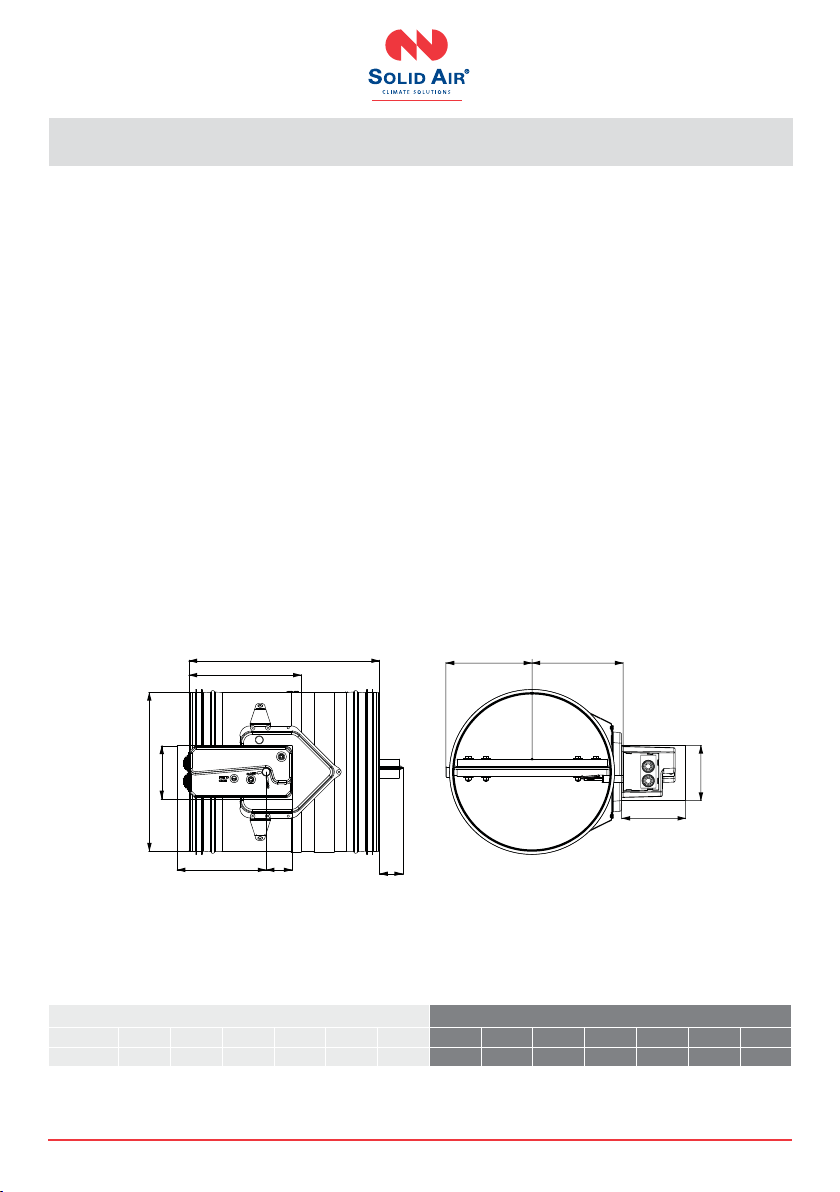

FDC25/FDC40-EMS

(solenoid actuator)

• Electromagnetic actuator with integrated limit

switches and thermal fuse release mechanism

(72 °C).

• Manual rearming with handle.

• Remote closing with electromagnetic actuator.

• Manual closing possible.

• EMS - solenoid actuator is constantly under

power.

• Actuating mechanism is tripped when the power

is interrupted, or thermal fuse is melted.

380

220

Ød

D

C A Y

Ød/2+12 Ød/2+22

D

E

Length of damper blade outside of casing (Y dimension on front side)

FDC 25/40 Y=(Ø d/2)-110 [mm]

*If the damper is larger than Ø 540 mm, use formula (X dimension on back side)

FDC 25/40 X=(Ø d/2)-270 [mm]

D

FDC25-EMS FDC40-EMS

Ø d (mm) 100 125 160 200 250 315 355 400 450 500 630 710 800

Weight (kg) 5.3 5.7 6.2 6.9 7.8 9.2 12.2 13.8 15.7 17.8 23.9 28 34

12 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

Length of damper blade outside of casing (Y dimension on front side)

FDC 25/40 Y=(Ø d/2)-110 [mm]

*If the damper is larger than Ø 540 mm, use formula (X dimension on back side)

FDC 40 (> d540) X=(Ø d/2)-270 [mm]

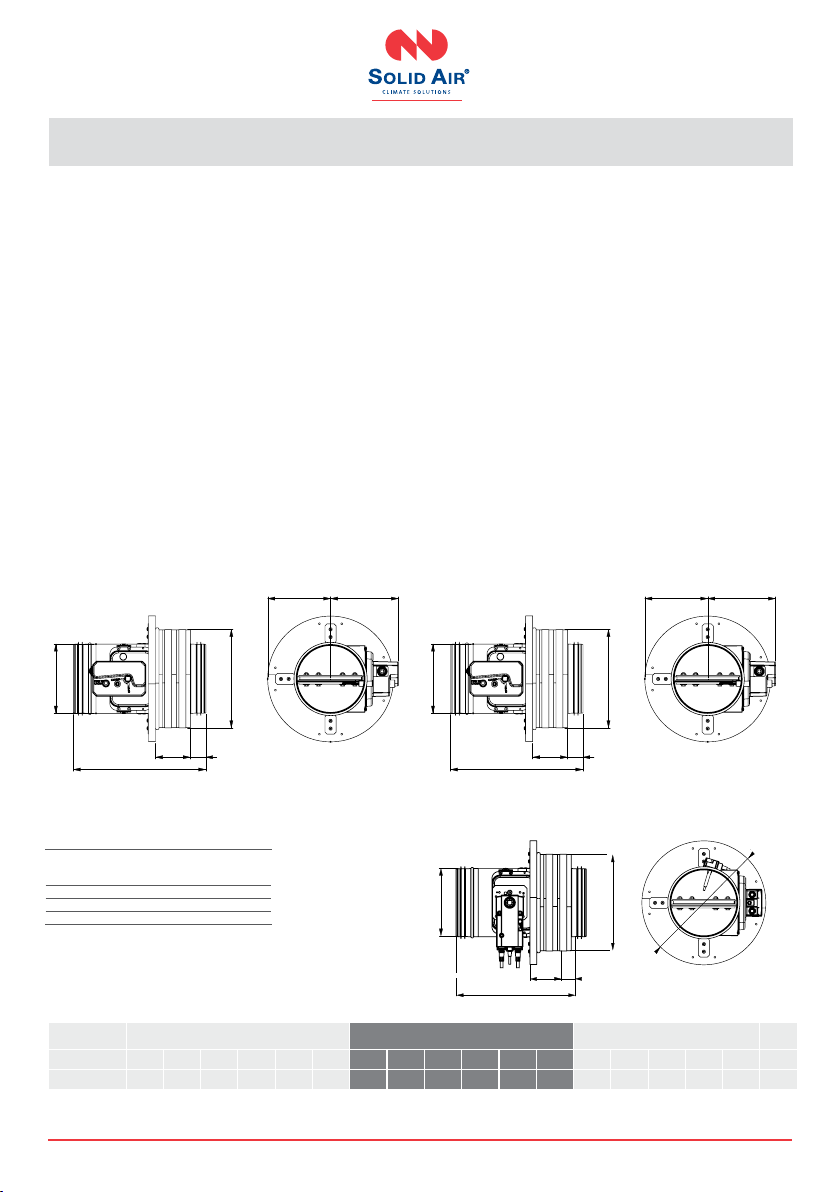

FDC25-M FDC40-M

Ø d (mm) 100 125 160 200 250 315 355 400 450 500 630 710 800

Weight (kg) 4.5 4.9 5.4 6.1 7 8.4 11.7 13.3 15.2 17.3 23.4 29.1 35.1

Servomotor

type BFL BFL BFL BFL BFL BFL BFN BFN BFN BFN BFN BF BF

380

Ød

C A

D

Y

Ød/2+12

E

CA

Ød/2+12

FDC25 / FDC40-M

(electric actuator)

• Thermoelectric release device (72 °C) with electric

actuator and return spring.

• Integrated end switches.

• Fully automatic operation.

• Optional 95 °C thermoelectric release device for

warm air installations (see pg. 53 Accessories).

Product

A

[mm]

C

[mm]

D

[mm]

E

[mm]

BFL (M) 25 200 90 120

BFN (M) 25 225 100 120

BF (M)* 50 250 100 120

13 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

FDC25-APP

Applique installation frame

• Applique kit is an installation subframe for quick

and easy installation in rigid and exible walls.

• Made out of calcium silicate boards.

• Quick wall mounting with screws.

• Factory assembled to the re damper.

(

n/2)+80

(

n/2)+94

380

100

45

n

n+ A

(

n/2)+80

(

n/2)+94

380

100

45

n

n+ A

Ød

380

100 45

Ød +A

(Ød/2)+80 (Ød/2)+94

(

n/2)+80

(

n/2)+94

380

100

45

n

n+ A

(

n/2)+80

(

n/2)+94

380

100

45

n

n+ A

Ød

380

100 45

Ød +A

(Ød/2)+80 (Ød/2)+94

45

145

380

n+160

n+ A

380

Ød +A

Ød+160

100 45

Ød

D

Damper diameter

Ød (mm)

Applique frame

diameter

Ø d + A (mm)

100 Ø d +105 mm

125 - 160 Ø d + 95 mm

200 - 315 Ø d + 80 mm

FDC25-APP-R FDC25-APP-EMS

FDC25-APP-M

FDC25-APP-R FDC25-APP-EMS FDC25-APP-M

Ø d (mm) 100 125 160 200 250 315 100 125 160 200 250 315 100 125 160 200 250 315

Weight (kg) 6.2 6.7 7.8 8.5 10.1 12.3 7.7 8.2 9.3 10 11.6 13.8 6.9 7.4 8.5 9.2 10.8 13

14 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

FDC25

MF1 installation frame

• MF1 is an installation frame for quick and easy

installation in rigid and exible walls.

• Made out of calcium silicate boards.

• Quick wall mounting with screws.

• Factory assembled to the re damper.

62 82

Dn

380

Dn+118

36

62 82

380

Dn+118

Dn+118

36

36

Ød

380

82 62

Ød +118

36

36

Ød +118

R40

62 82

Dn

380

Dn+118

Dn+118

36

36

62 82

Dn

380

Dn+118

Dn+118

36

36

Ød

380

82 62

36

Ød +118

36

R40

62 82

Dn

380

Dn+118

Dn+118

36

36

Ød

82 62

380 Ød +118

62 82

Dn

380

Dn+118

Dn+118

36

36

Ød +118

R40

D

FDC25-MF1-R FDC25-MF1-EMS

FDC25-MF1-M

FDC25-MF1-R FDC25-MF1-EMS FDC25-MF1-M

Ø d (mm) 100 125 160 200 250 315 100 125 160 200 250 315 100 125 160 200 250 315

Weight (kg) 6.6 7.4 8.7 10.3 12.5 15.5 8.1 8.9 10.2 11.8 14 17 7.3 8.1 9.4 11 13.2 16.2

15 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

FDC25

MF2 installation frame

• MF2 is an installation frame for quick and easy

installation in rigid, exible and shaft walls.

• Made out of calcium silicate boards.

• Quick wall mounting with screws.

• Factory assembled to the re damper.

Ød

380

103,5 65

Ød +118

36

36

Ød +118

11

R40

Ød

380

103,5 65

Ød +118

Ød +118

36

36

R40

Ød +118

36

36

Ød +118

11

Ød

380

103,5 65

R40

D

FDC25-MF2-R FDC25-MF2-EMS

FDC25-MF2-M

FDC25-MF2-R FDC25-MF2-EMS FDC25-MF2-M

Ø d (mm) 100 125 160 200 250 315 100 125 160 200 250 315 100 125 160 200 250 315

Weight (kg) 7.1 8.1 9.6 11.4 13.8 17.2 8.6 9.6 11.1 12.9 15.3 18.7 7.8 8.8 10.3 12.1 14.5 17.9

16 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

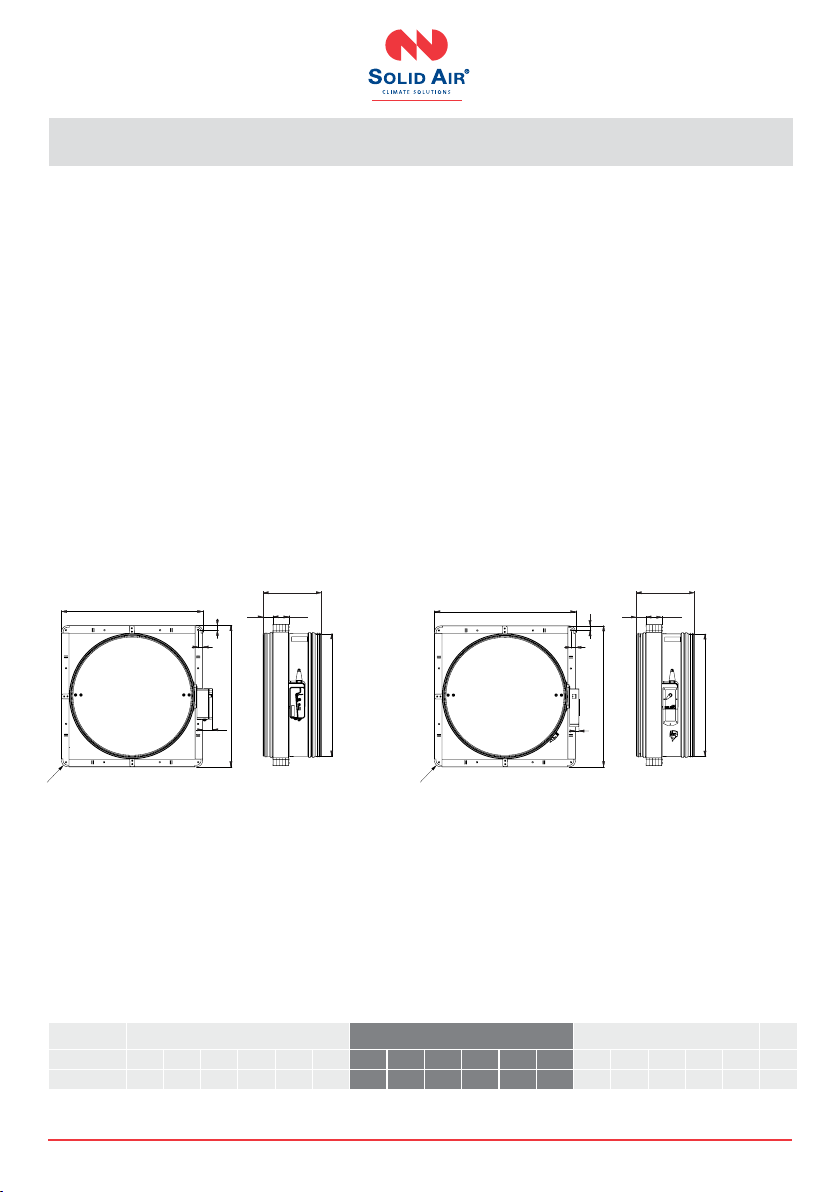

FDC40

MF2 installation frame

• MF2 is an installation frame for quick and easy

installation in rigid, exible and shaft walls.

• Made out of calcium silicate boards.

• Quick wall mounting with screws.

• Factory assembled to the re damper.

Ød

380

103,5

65

Ød +120

30

30

Ød +120

66

R40

Ød

65

Ød +120

30

30

Ød +120

25

380

103,5

R40

D

FDC40-MF2-R/FDC40-MF2-EMS FDC40-MF2-M

FDC40-MF2-R FDC40-MF2-EMS FDC40-MF2-M

Ø d (mm) 355 400 450 500 630 800 355 400 450 500 630 800 355 400 450 500 630 800

Weight (kg) 22.8 25.9 29.6 33.6 45 62.8 23.1 26.2 29.9 33.9 45.3 63.1 22.6 25.7 29.4 33.4 44.8 64.2

17 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

The FDC25 / FDC40 re damper is always tested in

standardized support frames (both in a rigid wall

and in a exible wall) in accordance with EN 1366-2:

2015 table 3/4/5. The results obtained are valid for

all similar support frames which have a thickness

and / or density and / or re resistance similar or

greater than the one on the test.

The duct connected to the re damper must be sup-

ported or hung in such a way that the damper does

not carry its weight. The damper must not support

any part of the surrounding construction or wall

which could cause damage and consequent damper

failure. It is recommended to connect the damper to

a exible connection on either end of the damper.

The damper driving mechanism can be placed

on either side of the wall, however it needs to be

placed so that it ensures an easy access during

inspection.

• Mounting is possible with the blade axis in

horizontal or in vertical position.

• The installation must comply with the tests

that were performed during certication.

• Avoid any obstruction of the moving blade by

the connected ducts.

• The class of air-tightness is maintained in

case the installation of the damper is made in

accordance with the technical manual.

• Operating temperature: 50 °C max.

• For indoor use only.

The gap in the installation opening between the re

damper and the wall/ceiling can be increased by up

to 50 % of the gap area, or decreased to the smallest

dimension that is shown in the table:

Installation in both, vertical and horizontal axis

of rotation of the dampers blade is acceptable

(with the axis angle 0 - 360°).

The re damper must

be installed into a re

partition structure

in such a way that

the damper blade in

its closed position is

located inside this

structure (except for

installation with MF1

installation frame).

To help you nd the suspension plane, a bendable

hinge is provided on the damper body and the red

tape is placed on the casing to mark the location

of the wall limit. This does not apply for Applique/

MF1/ MF2 kit installations.

Check the operation of the re damper before

commencing the installation!

3. I

Wall limit

Damper size

Ø d (mm) Opening size

Ø d + A (minimum)

100 Ø d +105 mm

125 - 160 Ø d + 95 mm

200 - 315 Ø d + 80 mm

18 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

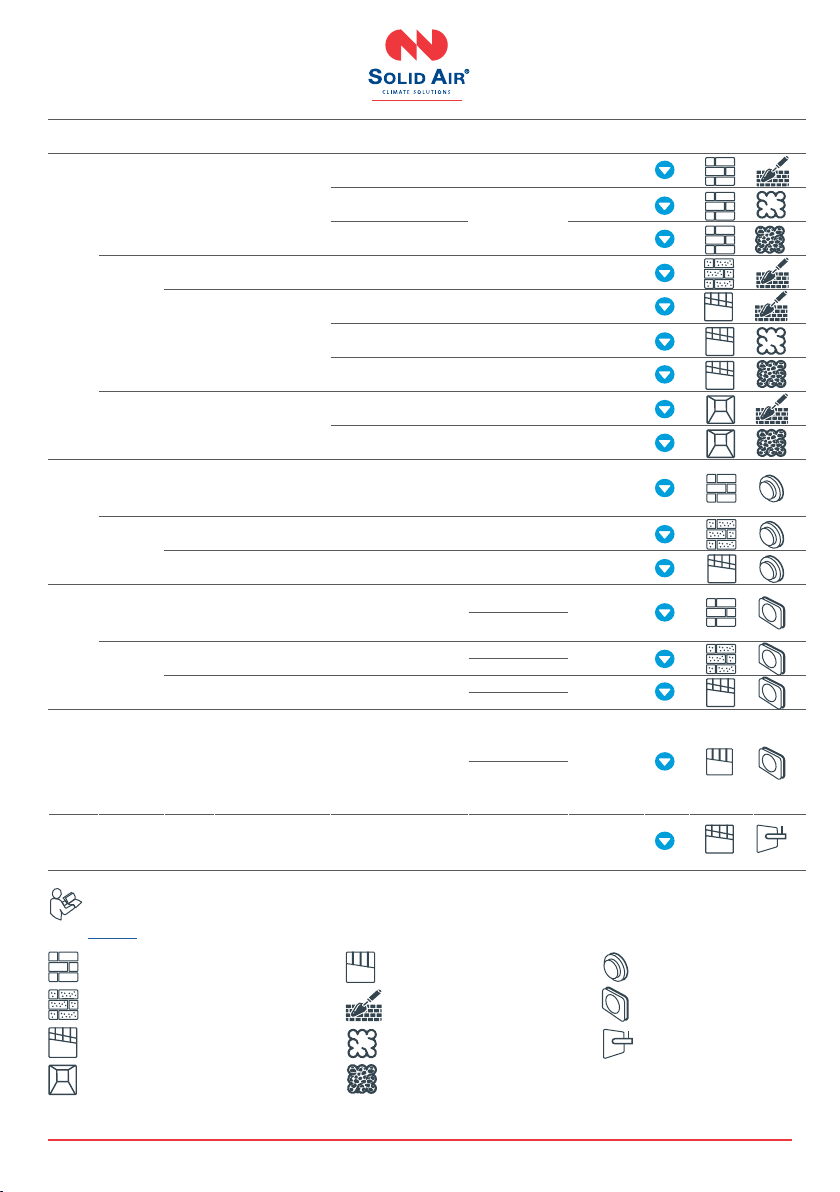

Range

Supporting

construction

Wall

thickness

Supporting construction

details Type of installation Classication Tested

underpressure Details Construction

type

Sealing

type

d100-d800 mm

Rigid wall ≥ 100 mm

Aerated concrete

( ≥ 550 kg/m3)

Reinforced concrete

(≥ 2200 kg/m3)

Gypsum plaster/mortar EI 120 (ve i↔o)S 500 Pa

Mineral wool and cover

boards

EI 90 (ve i↔o)S

500 Pa

Fire Batt/Weichschott 300 Pa

Flexible wall

≥ 70 mm Gypsum blocks

(≥ 995 kg/m3)

Gypsum plaster/mortar and

cover boards EI 120 (ve i↔o)S 500 Pa

≥ 100 mm Plasterboard

type A (EN520)

Gypsum plaster/mortar EI 120 (ve i↔o)S 500 Pa

Mineral wool and cover

boards EI 90 (ve i↔o)S 500 Pa

Fire Batt/Weichschott EI 90 (ve i↔o)S 300 Pa

Floor/

ceiling ≥ 100 mm

Aerated concrete

( ≥ 550 kg/m3)

Reinforced concrete

(≥ 2200 kg/m3)

Gypsum plaster/mortar EI 120 (ho i↔o)S 500 Pa

Fire Batt/Weichschott EI 90 (ho i↔o)S 300 Pa

APP INSTALLATION FRAME

d100-d315 mm

Rigid wall ≥ 100 mm

Aerated concrete

( ≥ 550 kg/m3)

Reinforced concrete

(≥ 2200 kg/m3)

Applique (installation frame) EI 90 (ve i↔o)S 500 Pa

Flexible wall

≥ 70 mm Gypsum blocks

(≥ 995 kg/m3)Applique (installation frame) EI 90 (ve i↔o)S 500 Pa

≥ 100 mm Plasterboard

type A (EN520) Applique (installation frame) EI 90 (ve i↔o)S 500 Pa

MF1/ MF2 INSTALLATION FRAME

FDC25 MF1 d100-d315 mm

FDC40 MF2 d355-d800 mm

Rigid wall ≥ 100 mm

Aerated concrete

( ≥ 550 kg/m3)

Reinforced concrete

(≥ 2200 kg/m3)

MF1 (installation frame)

MF2 (installation frame)

FDC25:EI 60 (ve i↔o)S

500 Pa

FDC40:EI 90 (ve i↔o)S

Flexible wall

≥ 70 mm Gypsum blocks

(≥ 995 kg/m3)

MF1 (installation frame)

MF2 (installation frame)

FDC25:EI 60 (ve i↔o)S 500 Pa

FDC40:EI 90 (ve i↔o)S

≥ 100 mm Plasterboard

type A (EN520)

MF1 (installation frame)

MF2 (installation frame)

FDC25:EI 60 (ve i↔o)S 500 Pa

FDC40:EI 60 (ve i↔o)S

MF2 INSTALLATION FRAME

FDC25 MF2 d100-d315mm

FDC40 MF2 d355-d800 mm

Flexible wall ≥ 90 mm Shaft wall (steel frame)

(type 98/48) MF2 (installation frame)

FDC25:EI 60 (ve i↔o)S

500 Pa

FDC40:EI 60 (ve i↔o)S

ISOVER

d100-d630

mm (only

FDC40)

Flexible wall ≥ 100 mm Plasterboard

type A (EN520) Remote from wall (Isover) EI 60 (ve i↔o)S 300 Pa

Aerated concrete ( ≥ 550 kg/m3) or reinforced concrete

(≥ 2200 kg/m3) wall, more than 100 mm thick.

Gypsum blocks (≥ 995 kg/m3) wall, more than

70 mm thick.

Plasterboard wall, type A (EN520), more than

100 mm thick.

Aerated concrete ( ≥ 550 kg/m3) or reinforced concrete

(≥ 2200 kg/m3) ceiling / oor, more than 100 mm thick.

Gypsum plaster, mortar sealing or mortar

and cover boards.

Sealing with mineral wool and cover boards.

Sealing with mineral wool and reproof

coating - FireBatt/Weichschott.

Applique kit installation.

MF1/MF2 kit installation.

Remote from wall installation.

Shaft wall, steel frame construction.

INSTALLATION

Check for more information about certicate installations in the declaration of performance:

Klik hier

Details

19 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

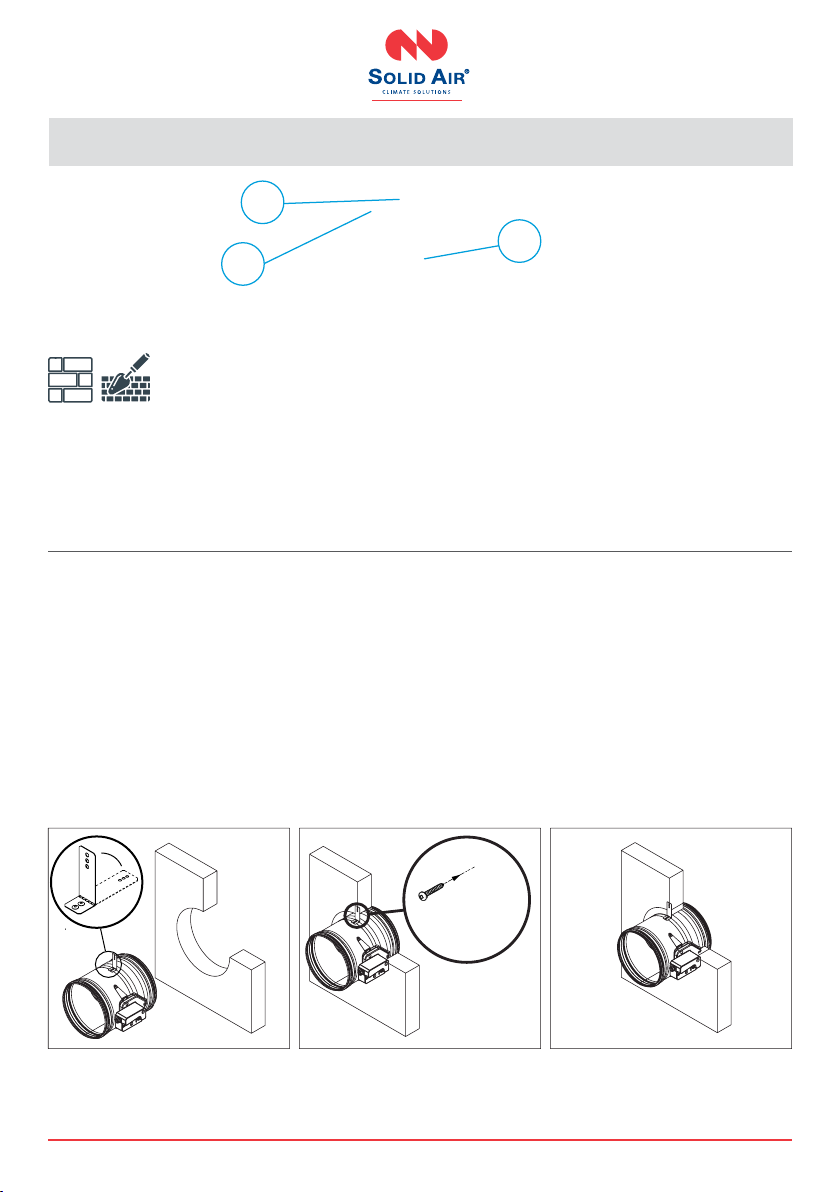

Rigid wall installation (mortar sealing)

The wall is composed of concrete blocks (minimum

density of 550 kg/m³) or reinforced concrete

(minimum density of 2200 kg/m³) and with a

minimum thickness of 100 mm.

Installation material is gpsum plaster or mortar.

I

1

1

2

2

7

3

INSTALLATION

1. Create an opening in the wall (minimal dimen-

sions on page 13). and bend the xing bracket (1)

90°. Place the damper in the opening up to the

wall limit mark (7) on the damper.

Damper blade must be closed during the installation!

2. Fix the damper to the wall using screws. Bracket

screw hole is 6 mm in diameter.

3. Fill the space between the damper and the wall

with gpsum plaster or mortar (2).

*Multiple re dampers can be installed next to each

other or ceiling/wall with the minimal distance of

30 mm between them. See page 42.

Test the operation of the damper blade!

20 | Round re damper manual 02/2021

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.com •mail@solid-air.com

625 625

> 440

625 625

> 440

Rigid wall installation (mineral wool sealing)

The wall is composed of concrete blocks (minimum

density of 550 kg/m³) or reinforced concrete (mini-

mum density of 2200 kg/m³) and with a minimum

thickness of 100 mm. Installation material is mine-

ral wool, covered with plasterboard cover boards.

I

1

1

4

2

3

3

INSTALLATION

1. Create an opening in the wall (Ø d + 80 mm) x (Ø d

+ 80 mm). Bend the xing bracket (1) 90°. Place the

damper in the opening up to the wall limit mark

(7) on the damper.

Damper blade must be closed during the installation!

2. Fix the damper to the wall using screws. Bracket

screw hole is 6 mm in diameter.

3. Fill the space between the damper and the wall

with mineral wool (3) ( ≥ 100 kg/m³). Cover the

mineral wool with GKF gpsum boards (4) (12.5

mm thick), and x them with screws.

*Multiple re dampers can be installed next to each

other or ceiling/wall with the minimal distance of

30 mm between them. See page 42.

Test the operation of the damper blade!

7

This manual suits for next models

1

Table of contents

Other SOLID AIR Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

Trox Technik

Trox Technik FKRS-EU Installation and operating manual

Mandik

Mandik FDML Technical documentation

Greenheck

Greenheck VCD Series Installation, operation and maintenance manual

Madel

Madel FOK-EIS-120 manual

SMAY

SMAY KWP-L Technical documentation

Maico

Maico BSB VC Series Installation, Operating and Maintenance Instruction