SIOX MIDI SMOKE 2 User manual

Product description: MIDI SMOKE 2

Function: Control and supervision of fire and smoke dampers

SIOX module: 8EX2:002 (SX:ACCESS

Table of Content

General..................................................................................................................................................3

System setup.........................................................................................................................................3

Key legends..........................................................................................................................................3

Digital I/O.............................................................................................................................................3

Central unit panel..................................................................................................................................3

Menus...................................................................................................................................................3

Main menu............................................................................................................................................7

Service Mode........................................................................................................................................7

Reset pin code to actory de ault..........................................................................................................7

Change language...................................................................................................................................7

Alarms..................................................................................................................................................7

Fire cells...............................................................................................................................................8

Function test all dampers......................................................................................................................8

Watchdog..............................................................................................................................................8

Functional test setup.............................................................................................................................8

Setting up date/time..............................................................................................................................9

Run indication relay output/Operational mode....................................................................................9

Module addressing................................................................................................................................9

Simple system setup...........................................................................................................................10

Module con iguration.........................................................................................................................10

Change PIN code................................................................................................................................11

Change IP-address..............................................................................................................................11

Change IP-gateway address................................................................................................................11

Change subnet mask...........................................................................................................................11

Change port number or TCP/IP.........................................................................................................11

Set exercise start delay.......................................................................................................................12

Show digital input status.....................................................................................................................12

Show digital output status...................................................................................................................12

Set service mode timeout....................................................................................................................12

Set SIOX Repeats...............................................................................................................................13

Show system program version............................................................................................................13

Step-by-Step instructions to commission a system using MIDISMOKE_02.c g..............................13

Step 1: Addressing the modules.....................................................................................................13

Step 2: Per orm Simple System Setup...........................................................................................14

Step 3: Setup dampers and alarm points........................................................................................14

Step 4: System test.........................................................................................................................14

Step 5: Setup the run indication relay output.................................................................................14

Step 6: Set RTC..............................................................................................................................14

Step 7: Functional test settings......................................................................................................14

Step 8: System test.........................................................................................................................14

Step 9: Change the PIN code.........................................................................................................14

Step 10: Activate watchdog...........................................................................................................14

Profcon AB Page www.smokecontrol.net

Step 11: Set time or automatic exit rom Service Mode...............................................................14

Step 12: Let the system enter normal operation............................................................................14

Step-by-Step instructions to commission a system using SMOKE EDIT..........................................15

Step 1: Addressing the modules.....................................................................................................15

Step 2: Download the con iguration ile........................................................................................15

Step 3: System test.........................................................................................................................15

Step 4: Set RTC..............................................................................................................................15

Step 5: Change Pin Code...............................................................................................................15

Step 6: Activate watchdog.............................................................................................................16

Step 7: Set time or automatic exit rom Service Mode................................................................16

Step 8: Switch the system to normal operation mode....................................................................16

Installation..........................................................................................................................................16

Connection o AC power...............................................................................................................16

Connection o DC power...............................................................................................................16

Three-wire bus...............................................................................................................................16

Grounding......................................................................................................................................16

Digital Inputs.................................................................................................................................17

Digital Outputs...............................................................................................................................17

Ethernet..........................................................................................................................................17

Profcon AB Page 2 www.smokecontrol.net

General

MIDI SMOKE 2 is a supervision system for up to

200 distributed damper control modules. If the

software SMOKE EDIT is used they may be

grouped in up to 99 fire cells. Each cell may have

one or several alarm points from e.g. smoke

detectors or an external fire alarm system. Please

note that a bus amplifier (8R30:004 should be

used after approximately 100 damper modules.

MIDI SMOKE 2 has eight built-in digital I/O (four

inputs and four relay outputs .

MIDI SMOKE 2 has a display and key pad to check

current status, set up the system, carry out function

tests and reset smoke detectors.

MIDI SMOKE 2 may be accessed as a slave

module via Ethernet (SioxNet or Modbus TCP to

connect to other systems.

This document describes the functionality of the

MIDI SMOKE 2 central unit. Please refer to the

Installation section for detailed installation

information.

System setup

There are two ways to setup the system. The MIDI

SMOKE 2 is normally preloaded with a

configuration file (“MIDISMOKE_02.cfg” intended

for simpler systems where the key pad is used for

setup. These systems support up to a maximum of

59 damper modules (addressed from 1-59 in a

single fire cell. Single or dual damper modules

can be used. Default names are used for the

dampers and alarm points. By using the keypad it

is possible to set for each module the number of

dampers (0-2 and also activate it as an Alarm

Point if there is a Smoke Detector connected to it.

However, be careful to document any configuration

changes for future reference.

For more advanced systems the software SMOKE

EDIT should be used. SMOKE EDIT is a PC

program (Windows used to define an installation

and to set up the MIDI SMOKE 2 central unit by

generating a project file and downloading a

compiled version to the unit.

Key legends

Generally the following usage of the key pad

applies:

Up and Down arrows step between menus or

increases/decreases values.

Right and Left arrows changes configurations and

moves the cursor within a menu.

Enter selects a menu/sub menu, saves changes

and carries out commands.

“C” backs one step in the menu tree or aborts a

command.

Digital I/O

MIDI SMOKE 2 includes four digital inputs to be

connected to external open/close contacts. DI1,

terminals 1-2, is the External Fire Input. When the

contact opens it will indicate Fire Alarm to the MIDI

SMOKE 2. This status will be latched. DI2,

terminals 3-4, when closed, (>1,5 s will reset the

latched Fire Alarm. By jumpering DI2 with a wire

automatic reset of fire alarms via DI1 is achieved.

But if there still exists an active Fire Alarm on DI1,

it will remain. DI3, terminals 5-6, when closed,

indicates night mode when dampers are held in a

closed state. DI4, terminals 7-8, when momentarily

closed (>1,5 s requests a Function Test Cycle

(exercise where all dampers will close and then

open. In Night mode the dampers will open and

then close again. In Service Mode no Function Test

Cycle is requested upon activation of DI4.

Further, the central has four relay outputs with

breaking capacity 1A at 30V AC/DC.

DO1, terminals 15-16, opens when there is a Sum

Alarm active (damper failure or communications

failure . DO2, terminals 17-18, opens when there is

a Fire Alarm. DO3, terminals 19-20, opens when

there is a Smoke Detector Service Alarm. DO4,

terminals 21-22, is the Operation Output. The

different events and combinations for the output to

open is fully configurable via the corresponding

menu, see Run indication relay output menu.

Central unit panel

The panel of the central unit consists of a display,

eight keys and three LEDs. The LEDs indicates

system status. The yellow Error LED is lit if the

status for the system is B-ALARM (see Main menu

for details . It will flash if there is no application

loaded or if it is stopped. larm LED is lit if the

system indicates fire. The green OK LED is lit if

there are no errors or fire indication in the system.

If the unit is in Service Mode then the OK LED

will always be off.

Introduced with system software version 1.61 the

green OK LED will be off if the communication

watchdog is not set. The Error LED will flash

syncronously with the warning text “W TCHDOG

IN CTIVE” in the Main menu.

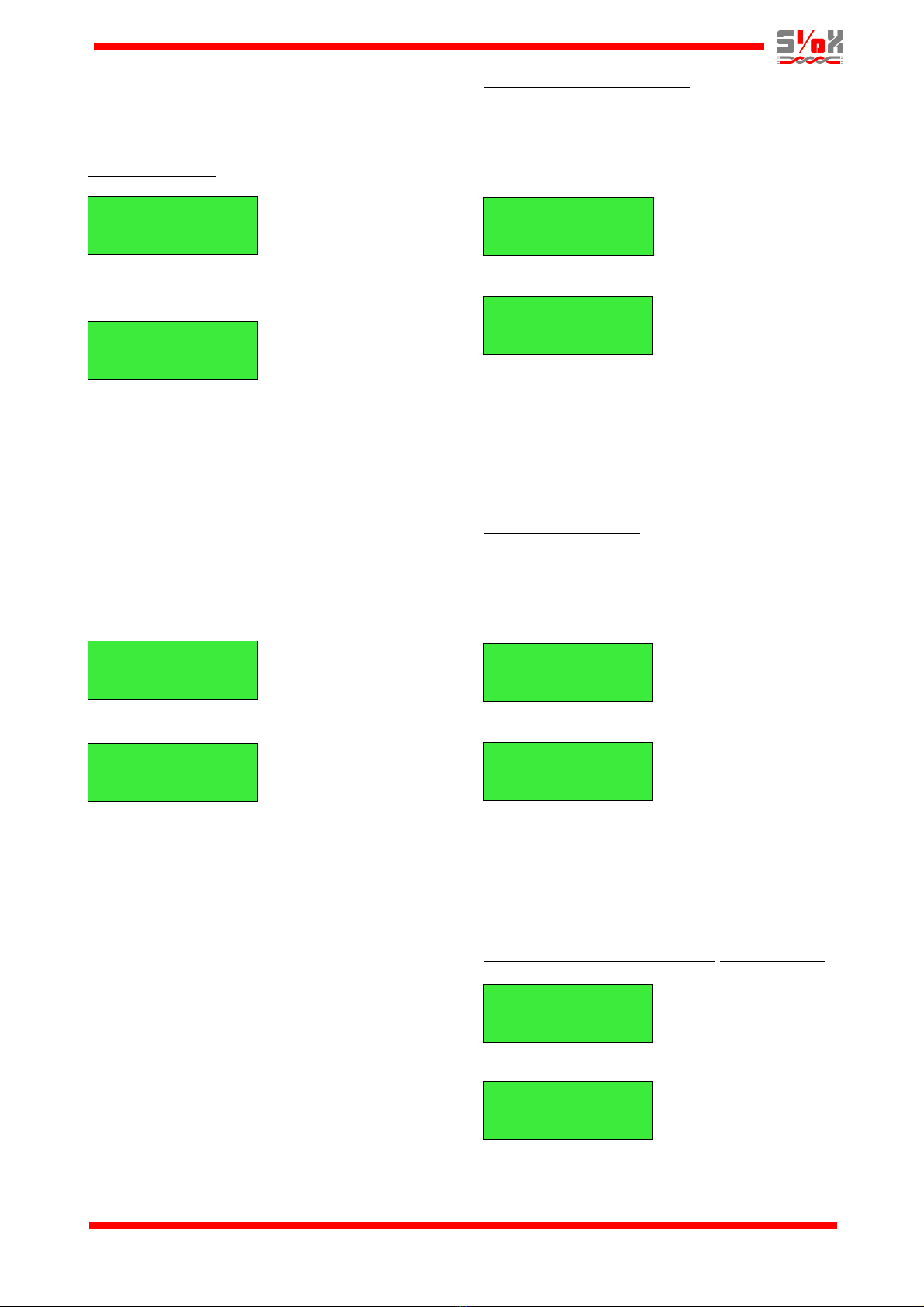

Menus

Most menus have a keyboard inactivity timeout of

3 minutes after which the display returns to the

Main menu. E.g. the Module addressing menu has

no timeout because the operation will take some

time to accomplish.

Profcon AB Page 3 www.smokecontrol.net

Profcon AB Page 4 www.smokecontrol.net

2018-02-20 15:26

SYSTEM: OK

ALARMS FIRE:OTHER

EXT.FIRE 1:1

LANGUAGE:

ENGLISH

DAMPER 2

DAMPER ERROR FC1

FIRE CELL 1

2 AP 10 DAMPERS

ALARM POINT 1

OK R

DAMPER 1

OK Ö T

FUNC. TEST ALL

DAMPERS? <ENTER>

CONFIGURATION OF

WATCHDOG Tc = 5 s

WATCHDOG

30 s (ENT=SAVE

FUNC. TEST

SETTINGS

T W T F S S I FC1

M 06:00

SETTINGS OF

CLOCK/DATE

2012-02-10 16:30

FRIDAY

SETUP RUN IND.

OPEN AT FUNC.TEST

MODULE ADDRESSING ENTER = START

GROUP:0 ADDR:1

ADDRESSING...

GROUP:0 ADDR:1

FIRE CELLS

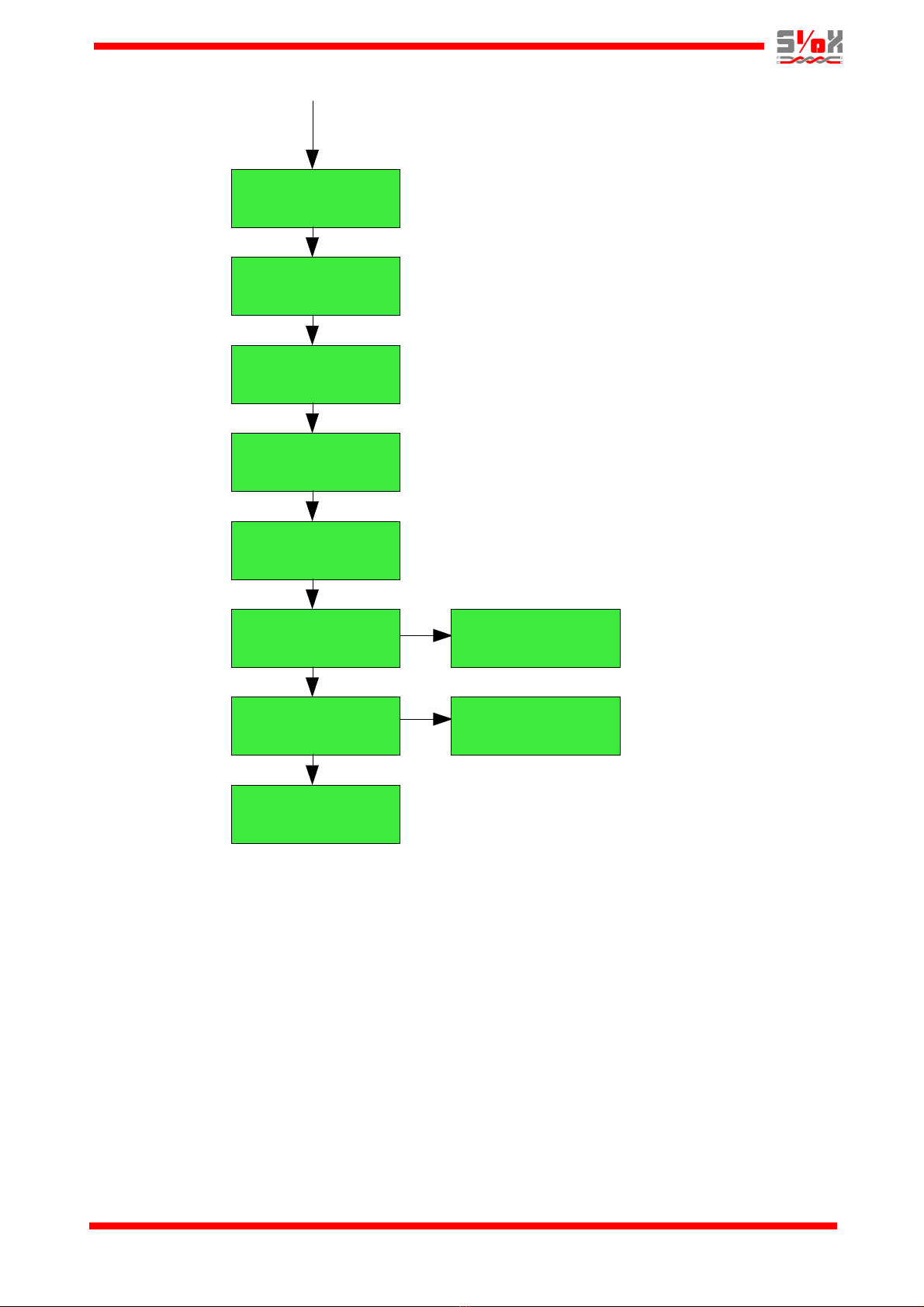

Main menu

Only in

Service Mode

MidiSmoke menu system

Continues on next page

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Profcon AB Page 5 www.smokecontrol.net

SIMPLE SYSTEM-

CONFIGURATION

SEARCHING...

NMBR:2 A:1 SC2

FOUND MODULES

NMBR:2 A:1 SC2

MODULE-

CONFIGURATION

CONFIGURATION FOR

ADDR:1 LP S1 S2

CHANGE PIN-CODE NEW PIN: 5555

C=ABORT

CHANGE IP-ADDRESS C=ABORT,ENTER=OK

192.168.000.234

SET TCP/IP PORT C=ABORT,ENTER=OK

PORT:01024

STATUS EXTERNAL

ALARM DI1:CLOSED

STATUS FIRE RESET

DI2:OPEN

STATUS NIGHT MODE

DI3:OPEN

Only in Service

Mode. Not when

using SmokeEdit

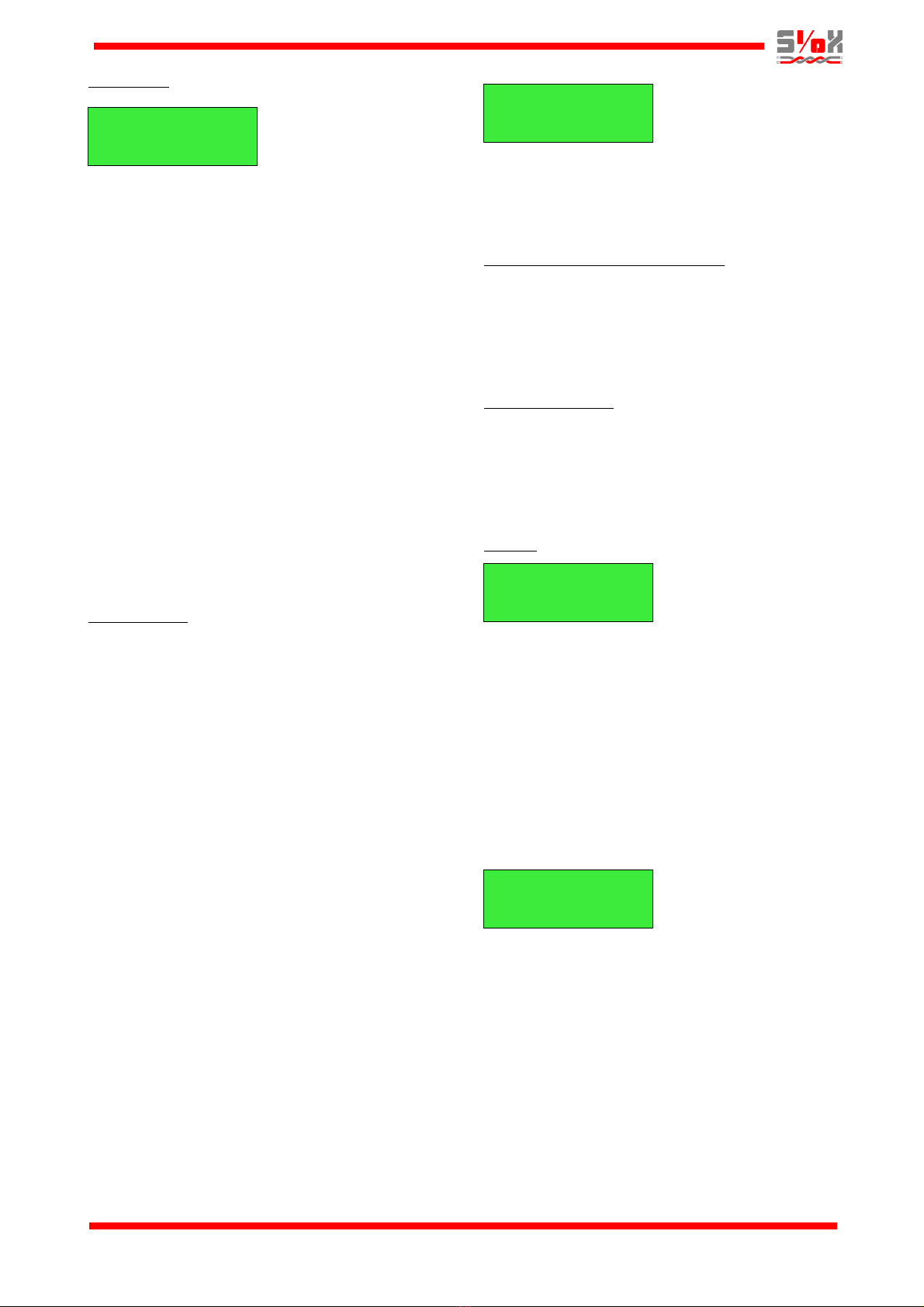

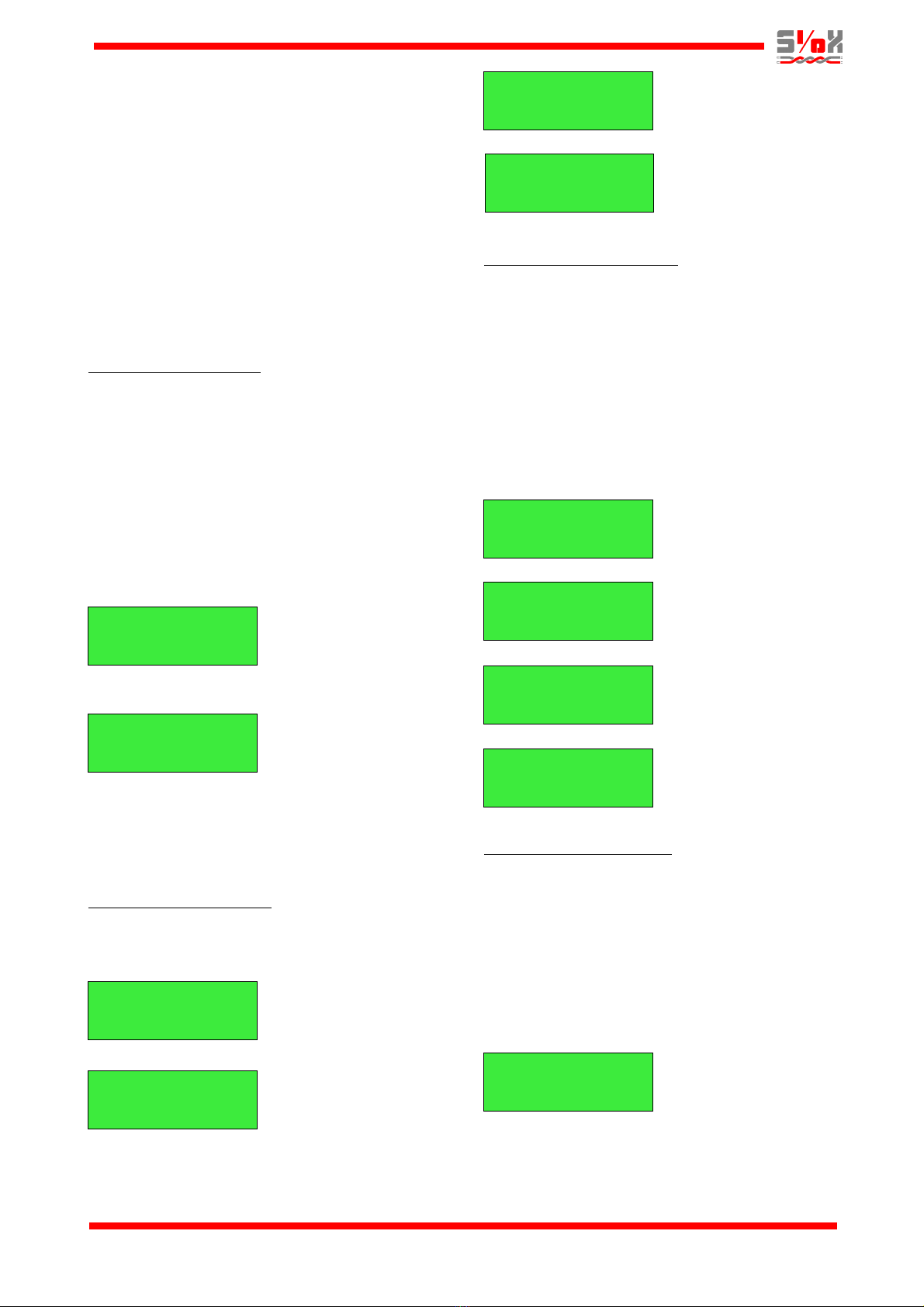

From previous page

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in Service

Mode. Not when

using SmokeEdit

Continues on next page

CHANGE IP-GATEWAY

SET SUBNET MASK

C=ABORT,ENTER=OK

192.168.000.001

C=ABORT,ENTER=OK

255.255.255.000

Only in

Service Mode

Only in

Service Mode

FUNCTION TEST

START DELAY

SET FUNCTION TEST

START DELAY 060 s

Profcon AB Page 6 www.smokecontrol.net

SUM ALARMS

OUTPUT DO1:OPEN

FIRE ALARM

OUTPUT DO2:CLOSED

SD SERVICE

OUTPUT DO3:CLOSED

RUN INDICATOR

OUTPUT DO4:CLOSED

SET SERVICE MODE

TIMEOUT

SET SIOX REPEATS

EX2 VERSION

EX2 v1.61

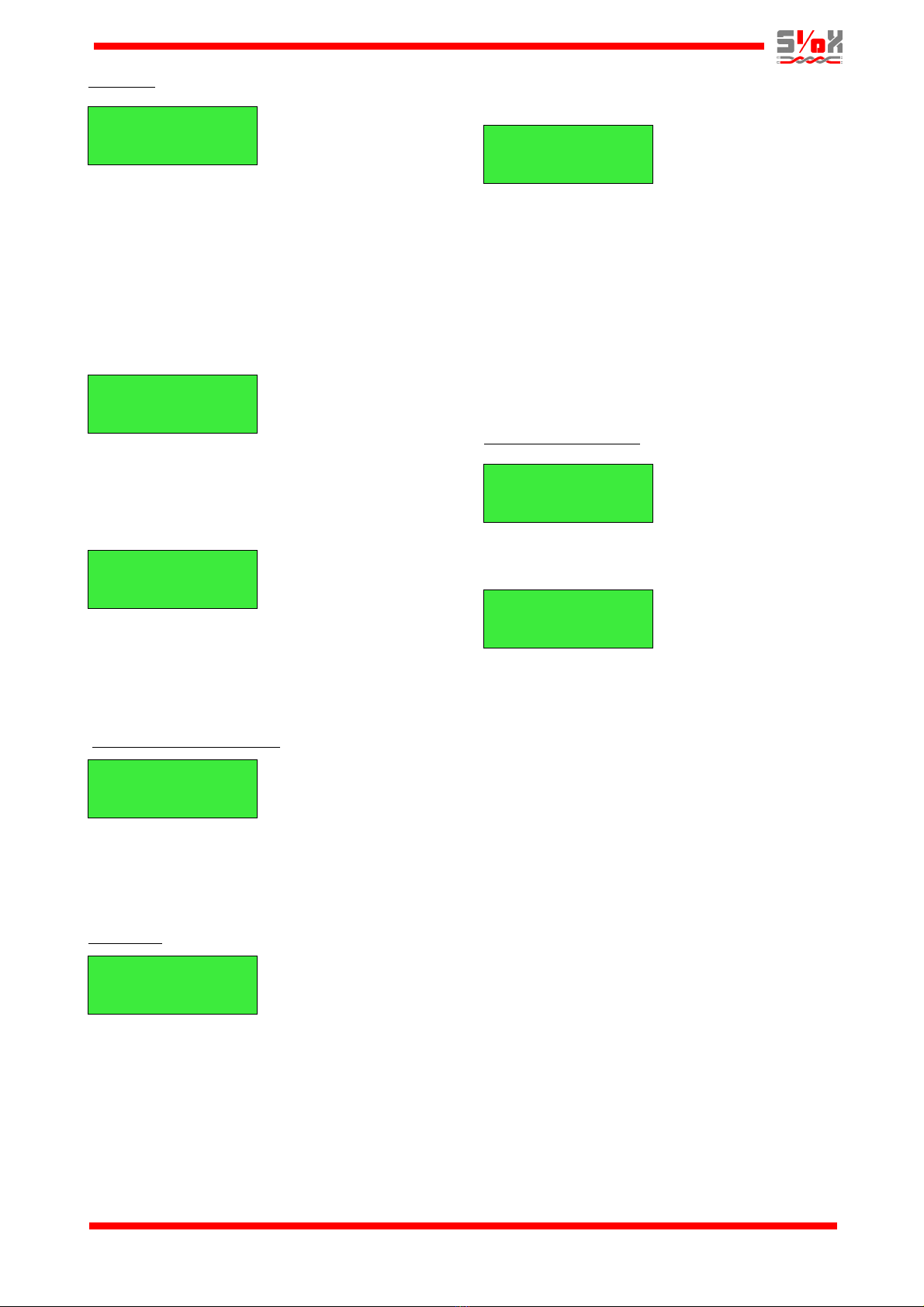

From previous page

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

Only in

Service Mode

STATUS FUNC.TEST

DI4:OPEN

Only in

Service Mode

SERVICE MODE

TIMEOUT INACTIVE

SIOX REPEATS:3

H:3 G:0 A:1

Main menu

OK: No alarms.

OK TEST: Functional damper test is in progress.

FIRE: One or more alarm points detected

a fire alarm or one or more alarm

points are not answering.

B-ALARM: Service alarm from a smoke detector,

damper error from a damper module or

that one or more damper modules are

not answering.

NO APP: No configuration is loaded, or halted.

Could happen if a Smoke Edit

download is aborted for some reason.

In that case just try to download again.

If a small “N” is displayed before the status text

then the system is in Night mode (dampers closed

thru activation of DI3.

If “F1” is pressed, a text is displayed showing the

name of the configuration file. If the configuration

file is customer specified, the text displayed can be

freely chosen, e.g. to display the facility name of

the installation.

Service Mode

By pressing “F2” in the main menu it is possible to

enter the Service Mode. In Service Mode

outgoing fire alarms are blocked but shown in

the display to facilitate fault tracing. Also,

dampers are opened and automatic or via DI4 re-

quested functional tests are suppressed. However,

functional tests (exercise can still be requested via

the Function test all dampers menu, external DI-

modules or thru Modbus TCP.

Unless the Service Mode is entered, only the

larms menu, Fire cells menu and Function test all

dampers menu are available.

When the work is completed it is mandatory to

remember to exit the Service Mode by pressing

key “F2” and then “C” in the main menu.

If the green OK LED is on it indicates normal

alarm free operation and that Service Mode is

not active.

From system software version .6 it is also

required that the communication watchdog be

set for the OK LED to be lit.

To enter Service Mode, press “F2” and the

following text on the display is shown:

Numbers in the pin code are changed using the

arrow keys.

When the correct pin code is entered press Enter.

Default pin code is 5555.

Reset pin code to factory default

If the PIN code has been lost there is a recovery

method: Hold down the “C” key while restarting the

module (cycling the power . When the question

“RESET PIN CODE TO 5555? ENTER=OK” is

shown, press Enter.

Change language

If the Service Mode is active and the Up arrow is

pressed in the Main menu, a menu to change the

language is displayed. Press Right arrow to toggle

the alternatives Swedish and English. Confirm by

pressing Enter.

Alarms

Shows current alarms. Press Enter to display the

alarm list. Press Down arrow to advance to the

next alarm in the list or Up arrow to return to the

previous alarm. EXT.FIRE is the DI1 Fire Alarm

input on the MIDI SMOKE 2 module. DI2 must be

activated (>1,5 s to unlatch this alarm.

Remember: ”C” backs one step in the menues

and/or aborts a command.

In system software version 1.62 a check was

introduced for a very rare error.

If the display shows “MODULE FAIL (SD ” it means

that the damper module on the address shown is

not defined as an Alarm Point but nevertheless is

in Fire status (and its dampers will be closed . The

reason for this is that the local smoke detector

input rises the alarm. Check that the resistor (2,2

kohm , which should be installed between

terminals 4 and 5 on an SC2-module is correctly

installed and that the terminal screws are

tightened.

Profcon AB Page 7 www.smokecontrol.net

ALARM FIRE:OTHERS

EXT.FIRE 1:1

2018-02-20 15:26

SYSTEM: OK

PIN: 5555

C=EXIT SERV. MODE

MODULE FAIL (SD

Address G:0 A:7

Fire cells

The fire cell above includes two alarm points and

10 dampers. The “A” in “AP” is blinking. Right/Left

arrow moves the cursor between “A” and “D”.

Pressing Up arrow will go to the next fire cell.

Pressing Down arrow will go to the previous fire

cell. Pressing Enter will show a list of the

predefined alarm points or dampers in the current

fire cell as in the examples below. Press Down

arrow or Up arrow to move between the different

alarm points or dampers.

On top is shown the name of the alarm point. The

lower line shows its status. If it is a smoke detector,

a blinking “R” will be shown at the extreme right to

indicate that a reset command can be sent by

pressing Enter.

On top is shown the name of the damper. The

lower line shows its status and end point indication

(“O” for open, “C” for closed . A blinking “T” will be

shown at the extreme right to indicate that a

function test can be run by pressing Enter.

Function test all dampers

Pressing Enter will carry out a function test on all

connected damper modules. Normally the dampers

will start with a 5 seconds interval within each fire

cell.

Watchdog (Service Mode)

This is to set up the maximum acceptable com-

munication interruption time before a module

enters fire alarm mode closing its local damper(s

and opening its local alarm relay. Tc is a value

describing the current cycle time for the system.

The selected watchdog time must be higher than

Tc. The time can be set to 0 s, 30 s, 40 s, 50 s up

to 90 s in 10 s increments. If damper modules

have been replaced in the system it is

important that the watchdog configuration is

repeated to initialize the new modules.

Up/Down arrow adjusts the value. Enter sends the

value to all modules. If the value is set to zero the

function is deactivated. This is useful during com-

missioning to stop dampers from closing unex-

pectedly due to disruptions in the execution of the

MIDI SMOKE 2 controller. A cyclically displayed

warning text “W TCHDOG IN CTIVE” will be

shown in the main menu (not if Service Mode is

active to indicate this condition. At a convenient

point during the commissioning the watchdog

should be properly set so that dampers will

close if the communication breaks down.

Functional test setup (Service Mode)

To configure the functional test setup, press the

Enter key.

The lower line shows which days to run a test of

the dampers in the current fire cell and the time of

day. Use the Left/Right arrows to change the day

position and also to enter the hours/minutes field.

Use the Up/Down arrows to pull the day letters to

the upper or lower line and to increase/decrease

the time. If no weekdays are selected for damper

test the modules will be configured to do function

tests on their own at 48 hours interval (time

counting starts when they are powered up . If the

“I” alternative is selected and no weekdays are

selected it means that the 48 hours interval in the

modules are inhibited. This choice is typically used

if the exercise should only be controlled by digital

inputs or thru Modbus TCP.

Press Enter when ready or “C” to exit without modi-

fications.

If there are more fire cells to configure the next one

will be shown in the order they appear in the

configuration file.

Default time for functional test is monday 06.00

hrs.

Profcon AB Page 8 www.smokecontrol.net

FIRE CELL 1

2 AP 10 DAMPERS

DAMPER ST2_1

OK O T

ALARM POINT 1

OK R

FUNC. TEST ALL

DAMPERS? <ENTER>

WATCHDOG SETUP

Tc = 3s

WATCHDOG

30 s (ENT=SAVE

M T T F S S I FC1

O 06:00

FUNC.TEST

SETTINGS

Setting up date/time (Service Mode)

The value to change is blinking. Right/Left arrows

moves the cursor between year, month, day etc.

Up/Down arrows increases/decreases the value.

Press Enter when done. Press “C” key to exit

without modifications.

Run indication relay output/Operational mode

(Service Mode)

There are 15 possible functions for the run

indication relay output DO4. Change mode with

Right / Left arrow:

OPEN AT FUNC.TEST – relay opens as long as at

least one module is performing a function test.

OPEN AT NIGHT – relay opens if system is in night

mode.

NIGHT+FUNC.TEST – relay opens if system is in

night mode or a function test is performed.

OPEN AT SUM ALARM – relay opens if there is

any damper error or communication error in the

system.

SUMALARM+FUNCTEST – relay opens if there is

any damper error or communication error in the

system or a function test is performed.

SUMALARM+NIGHT - relay opens if there is any

damper error or communication error or if system

is in night mode.

SUM+NIGHT+F.TEST – relay opens if there is any

damper or communication error, or if the system is

in night mode or a function test is being performed.

OPEN AT FIRE – relay opens in case of fire alarm.

FIRE+FUNC.TEST – relay opens in case of a fire

alarm or a function test is being performed.

FIRE+NIGHT – relay opens if case of a fire alarm

or if system is in night mode.

FIRE+NIGHT+F.TEST - relay opens in case of a

fire alarm, or if the system is in night mode or a

function test is being performed.

FIRE+SUMALARM - relay opens if there is a fire

alarm, a damper error or a communication error in

the system.

FIRE+SUM+F.TEST - relay opens in case of a fire

alarm or if there is a damper or communication

error in the system or a function test is being per-

formed.

FIRE+SUM+NIGHT - relay opens in case of a fire

alarm, a damper or communication error in the

system or if the system is in night mode.

FIRE+SUM+NIGHT+FT - relay opens in case of a

fire alarm, a damper or communication error in the

system, or if system is in night mode or a function

test is being performed.

Module addressing (Service Mode)

This setup menu is used for addressing damper

control modules. Every module in the system

requires a unique address. The address consists of

a Group address and a Module address. The

Group address is either zero which is used to

address the first 1-59 damper modules or it could

be 61, 62 or 63 that defines three possible

addressing subgroups (only available if SMOKE

EDIT is used). Each group can handle up to 59

damper modules (less if other modules are used

as well .

Please note that if digital I/O-modules are used, for

example S27, they should be addressed from

address 59 and downwards. This means that

correspondingly fewer damper modules can be

installed on group zero.

All modules are at Group address 0 and Module

address 1 when they are delivered from factory.

Press Enter to select Module addressing menu.

The modules should be addressed in the interval

1-59, that's why the addressing starts at 1. If

another start address is desired, just change it by

pressing the Up/Down arrows to increase/decrease

and Left/Right arrows to move between Group and

Module address.

When Enter is pressed the MIDI SMOKE 2 starts

to send addressing commands. All damper control

modules LEDs will start to flash (3 fast on/off . By

pressing the test button on a module it accepts the

address sent by MIDI SMOKE 2. The address in

the display now increments to the next address

and the next module in order can be addressed.

Note that no automatic wrap occurs to next Group

address when Module address 59 has been

passed. It will stay at address 59. If sub-buses are

used, restart the command and increase the

Group address to the desired Group address (61,

62, 63 . Please note that pressing Down arrow is a

quick way to reach the high Group address

numbers (0->63->62->61 . Adjust the Module

address to the desired start address before

pressing Enter to start the transmission of the

addressing commands.

Apply a distinct press on the buttons to avoid

double-activations which otherwise will result

in an address increment and a wrong address

Profcon AB Page 9 www.smokecontrol.net

2018-02-20 16:30

WEDNESDAY

SETUP RUN IND.

OPEN ON ERROR

ENTER = START

GROUP:0 ADDR:1

MODULE ADDRESSING

for the module.

To stop addressing press the “C” key.

Simple system setup (Service Mode)

(not available when using SMOKE EDIT,

only used for simpler systems using the

“MIDISMOKE_02.cfg” and keyboard setup)

The purpose with this command is to learn how

many modules that are located on the bus. Ensure

that all modules have power and that they are

connected to the bus so they can be identified. A

check is also performed that all modules are

sequentially addressed with no missing modules

inbetween.

Activate this setup function by pressing Enter. It

will scan the SIOX bus over the address range 1-

59 and count the number of modules found.

Wait until the search is over.

This menu is useful to ensure that all modules are

communicating. Also, the type of module is shown.

FOUND – total number of found modules.

A – current address.

SC2 – module type (example .

If the number of modules found matches what

is expected, press Enter.

Now a check is performed that the modules found

are sequentially addressed from address 1 and

upwards with no missing modules between the first

and the last one. If the check fails, the command is

still active so the fault could be tracked down.

Press the Up/Down arrow to increment/decrement

the address. If no module is answering on an

address, “ERR” is displayed. “DBL” is displayed if

at least two modules are on the same address. In

this case there should be another address for

which “ERR” is displayed because that module is

wrongly addressed. If a module is missing, check

the wiring, and if necessary abort this command

with the “C” key to invoke the Module addressing

command to readdress any missing modules. Then

run the Simple system setup once again.

When the check passes, the text “OK,

CONFIGURATION FOR nn MODULES” is

displayed.

The next menu Module configuration will be

entered.

Module configuration (Service Mode)

Not available when using SMOKE EDIT,

only used for simpler systems using the

“MIDISMOKE_02.cfg” and keyboard setup.

Press Enter to select Module Configuration.

This menu shows damper control modules that are

addressed in the system. If “AP” for “Alarm Point”

is displayed then the smoke detector input is used

for triggering fire alarm. If all modules will be used

with smoke detectors then pressing F1 will activate

alarm points for all modules. Pressing F2 will have

the reverse effect to deactivate all alarm points.

The selected number of dampers at each module

is not affected. “D1” and “D2” means that both

dampers are used.

To manually activate/deactivate alarm/damper

settings use Up/Down arrow to select the address

for each module to handle. Use Right arrow to

cycle between the different alternatives which are:

One damper only

One damper + Alarm point

Two dampers

Two dampers + Alarm point

Alarm point only

Changes are instant. Exit with Enter or “C” key.

Note that if a two-damper module is used but

configured for one damper, the damper must be

connected to channel 1. The Open and Closed

inputs for damper 2 must be jumpered i.e. be in

active state. For instance, the SC2 module should

have jumpers between terminals 24-25 and

terminals 26-27.

Factory default configuration: no Alarm Points,

one damper per module.

If “COMMERR” is displayed then no module is

answering on that address. Unless some fault has

Profcon AB Page 0 www.smokecontrol.net

CONFIGURATION FOR

ADDR:1 AP D1 D2

FOUND MODULES

FOUND:2 A:1 SC2

SIMPLE SYSTEM

SETUP

ADDRESSING...

GROUP:0 ADDR:1

SEARCHING MODULES

FOUND:2 A:1 SC2

MODULE

CONFIGURATION

occurred that prevents a module to answer, this

means that the address is not used in the system

(and not the addresses above either . Check that

the previous address was the highest in use.

Change PIN code (Service Mode)

Press Enter to change the PIN code.

Numbers in the pin code are changed with the

arrow keys. When the new pin code has been

chosen, press Enter to confirm and store the new

code.

If the PIN code is lost, see Reset pin code to

factory default for advice.

Change IP-address (Service Mode)

If the unit will be connected to Ethernet, the IP-

address may have to be changed from the default

192.168.0.234.

Press Enter to change the IP-address.

Numbers in the IP-address are changed with the

arrows. When the new address has been chosen,

press Enter to confirm and store the new address.

The module must be restarted (power off/on) to

effectuate the change.

Please note: if a direct connection between the

MIDI SMOKE 2 and a PC (Windows is desired, it

will be necessary that the IP-address for the PC

and the MIDI SMOKE 2 shares the same network

address space. Typically this means that the first

three fields in the IP-address must be identical.

The last field must differ.

Either change the IP-address for the PC or the

MIDI SMOKE 2.

Change IP-gateway address (Service Mode)

Introduced in firmware 1.40

If the unit will be connected to Ethernet, the IP-

gateway address can be changed to match the

current network.

Press Enter to change the IP-gateway address.

Numbers in the IP-gateway address are changed

with the arrows. When the new address has been

chosen, press Enter to confirm and store the new

address.

The module must be restarted (power off/on) to

effectuate the change.

Change subnet mask (Service Mode)

Introduced in firmware 1.60

If the unit will be connected to Ethernet, the Subnet

Mask can be changed to match the current

network. Factory default setting is 255.255.255.0.

Press Enter to change the Subnet Mask.

Numbers in the Subnet Mask are changed with the

arrows. When the new address has been chosen,

press Enter to confirm and store the new address.

The module must be restarted (power off/on) to

effectuate the change.

Change port number for TCP/IP (Service Mode)

Press Enter to change the port number.

This port is used for SioxNet TCP/IP

communications used by SioxTools and

Profcon AB Page www.smokecontrol.net

CHANGE PIN CODE

NEW PIN: 5555

C=ABORT

CHANGE IP-ADDRESS

C=ABORT,ENTER=OK

192.168.000.234

CHANGE TCP/IP PORT

C=ABORT,ENTER=OK

PORT:01024

CHANGE IP-GATEWAY

C=ABORT,ENTER=OK

192.168.000.001

SET SUBNET MASK

C=ABORT,ENTER=OK

255.255.255.000

VisualSetup forms but not for Modbus TCP/IP

communications. Modbus TCP/IP communications

should use the standard Modbus TCP/IP port 502.

Please note that normally there is no need to

change the port number. Standard port number is

1024. Lower numbers should not be used. Highest

available is 65535.

The port number is changed with the arrow keys.

When the new number has been chosen, press

Enter to confirm and store the new port number.

The module must be restarted (power off/on) to

effectuate the change.

Set exercise start delay (Service Mode)

Introduced in firmware 1.60

When damper function test (exercise is requested

either thru digital inputs, real time clock controlled

or via the “FUNC. TEST ALL DAMPERS” menu

then a configurable delay (0-500 seconds can be

set to stop fans that are controlled by exercise

status outputs before the actual exercise starts.

For instance, if relay output DO4 is configured to

open during exercise and the time is set to 60

seconds then the relay output will open 60 seconds

before actual exercise starts.

Press Enter to change the time.

Up arrow increases the time in 10 seconds

increments. Down arrow resets the time to zero.

Press Enter to confirm or “C” to exit without any

change.

Show digital input status (Service Mode)

For each of the four digital inputs DI1-DI4 there is a

menu showing current status to aid in fault tracing.

Show digital output status (Service Mode)

For each of the four digital outputs DO1-DO4 there

is a menu showing current status to aid in fault

tracing. To toggle the output status press Left key

or Right key. Please note that as long as these

menues are active, MIDI SMOKE 2 is not able to

control the output statuses. Also be aware that

reversing the output status may affect connected

systems, i.e. a fire alarm could be generated.

Press “C” or Enter to exit command.

Set service mode timeout (Service Mode)

The time for automatic exit from Service Mode

back to normal operation can be set between 1 -

72 hours or be inactivated (no automatic exit .

Factory default is no automatic exit.

If a unit is mistakenly forgotten in Service Mode

then it will return back to normal operation after the

time expires. Please note that pressing any key on

the keyboard will reinit the timeout time.

Press Enter to change the timeout.

Profcon AB Page 2 www.smokecontrol.net

STATUS EXTERNAL

ALARM DI1:CLOSED

STATUS FIRE RESET

DI2:OPEN

STATUS NIGHT MODE

DI3:OPEN

STATUS FUNC.TEST

DI4:OPEN

SUM ALARMS

OUTPUT DO1:CLOSED

FIRE ALARM

OUTPUT DO2:CLOSED

SD SERVICE

OUTPUT DO3:CLOSED

RUN INDICATOR

OUTPUT DO4:CLOSED

SET SERVICE MODE

TIMEOUT

EXERCISE START

DELAY

SET EXERCISE

DELAY 060 s

Pressing Down arrow inactivates the automatic exit

function.

Pressing Up arrow increases the time with 1 hour

for each keypress up to a maximum of 72 hours.

Press “C” to exit the command and keep the old

setting.

Press Enter to save the new setting and exit the

command.

Set SIOX Repeats (Service Mode)

The functions in this menu are only of interest if the

system experiences communication problems.

The number of communication retries (repeats

before a communication is deemed unsuccessful

can be set within the interval 3-30. Normally the

number is 3, which is the factory default. To assist

in troubleshooting the number of repeats can be

increased by pressing Up arrow or decreased by

pressing Down arrow.

In the example above number of repeats have

been increased to 10. For the lower line “H:5”

(“H”=Highest means that the module on

Groupaddress 0 and Module address 8 has

needed at most 5 retries. It is the first module with

most retries that is shown. If the module did not

answer at all then “H:10” would be shown because

all retries had been expended. To reset the

“Highest”-indication and restart a new

measurement, press Right arrow. Fault tracing can

then primarily be directed against the bus section

where the module with most communication

failures is located.

Show system program version (Service Mode)

Shows the version of the system program

(firmware .

Press “C” or Enter to exit the command.

Step-by-Step instructions to commission a

system using MIDISMOKE_02.cfg

Please note: these instructions are not valid when

the SMOKE EDIT software is used. See next

section for information about systems using

SMOKE EDIT for configuration.

The MIDI SMOKE 2 is normally preloaded with a

configuration file (“MIDISMOKE_02.cfg” intended

for simpler systems where the key pad is used for

setup. These systems support up to a maximum of

59 damper modules (addressed from 1-59 in a

single fire cell. Single or dual damper modules

can be used.

Assuming that the electrical installation is ready

with all damper units installed, there are a few

steps necessary to get the system up and running.

For more information about specific menu

functions, please refer to the corresponding

section in this document.

Step : Addressing the modules

Please note: if a PC is connected to the MIDI

SMOKE 2 module, the PC-based software

SioxTools could be used as an alternative to

address the modules.

Enter the Service Mode and continue down to the

MODULE DDRESSING menu.

Press Enter to start the addressing operation and

note that it starts at Group Address=0 and Station

Address=1 which is the address for the first

module. The address range for the modules in the

system will be in the range 1 – 59 depending on

how many modules that actually are installed.

Group Address should always be 0.

When the display shows...

...it means that addressing commands are sent to

the modules. Their LEDs are flashing red in short

bursts while they are receiving addressing

commands.

Now the test buttons on the alarm/damper modules

can be pressed one after the other in the sequence

that matches the desired addressing of the

modules. When the first module's test button is

pressed it will receive address 1. Continue with the

next module that should be at address 2, and so

on. When the test button is pressed, five fast

flashes on the module's LED will indicate that it

received the address and the next module in order

can be handled.

Profcon AB Page 3 www.smokecontrol.net

ADDRESSING

GROUP:0 ADDR:1

EX2 VERSION:

EX2 ver 1.61

SERVICE MODE

TIMEOUT 1 h

SIOX REPEATS:10

H:5 G:0 A:8

If by mistake a test button is pressed more than

once so the address has incremented beyond the

next module's intended address, this can be

corrected by pressing the Down arrow on the MIDI

SMOKE 2 to decrease the address. Then return to

where the module is located and repeat the

addressing operation by pressing the test button

again. Continue to the next module in the

sequence.

When all modules are handled, return to the MIDI

SMOKE 2 unit and check at the display that the

next module it is trying to address is one address

above the last used address in the system. This

means that the operation was successful.

Press the “C” key to back out of the addressing

operation and enter the main MODULE

DDRESSING menu.

Step 2: Perform Simple System Setup

Press Down arrow to display the SIMPLE

SYSTEM SETUP menu.

Press Enter to start the setup process. The

objective it to find the number of damper modules

used in the system.

Step 3: Setup dampers and alarm points

For each module a setup must be performed to tell

the system if it includes an alarm point and/or how

many dampers are connected to it.

To accomplish this, refer to the previous section

Module configuration.

Step 4: System test

At this point the MIDI SMOKE 2 unit is

communicating with the damper modules in the

system and status will now be updated. If there are

alarms use the larm menu and Fire cells menu to

get information about what and where the problem

is.

A Function test all dampers could be attempted to

check that all dampers can manage a close/open

operation.

Step 5: Setup the run indication relay output

The Run indication relay output (DO4 is a

normally closed relay which opens at one of 15

different combinations of events which are a mix of

sum alarm, night mode, functional test and fire

alarm.

If the Run indication relay output (DO4 will be

used it has to be configured for the desired

combination of events, otherwise go to the next

step.

See Run indication relay output menu description.

Step 6: Set RTC

The real-time clock is used for automatic functional

test scheduling.

See Setting up date/time menu description.

Step 7: Functional test settings

Functional tests can be requested in three different

ways:

1. By an activation (>1,5 second of DI4.

2. At specific day(s at a specific time.

3. At 48 hours intervals handled by the modules.

Alternative 3 is valid if no day/time or “I” is

specified.

Please note that an activation of DI4 will always

request a functional test sequence unless Service

Mode is active.

See Functional tests menu description.

Step 8: System test

Check the display for possible errors and correct

them.

If external systems are connected to the digital

inputs and relay outputs their operation can be

checked now.

See Show digital input status and Show digital

output status menu descriptions.

Step 9: Change the PIN code

If required, change the Pin Code in order to avoid

inadvertent access to the system setup. Keep a

note of the new one in a safe place.

See Change PIN code menu description.

Step 0: Activate watchdog

Enter the Watchdog menu and set the watchdog

timeout.

See Watchdog menu description.

Step : Set time for automatic exit from

Service Mode

If desirable, the time for automatic exit from

Service Mode can be set. Factory default is that

automatic exit is inactivated. Time can be set

between 1 – 72 hours.

See Set Service mode timeout menu description.

Step 2: Let the system enter normal operation

Exit the Service Mode by pressing “F2” och ”C” in

the main menut to let the system run in normal

operational mode.

Fire alarms will now be distributed thru DO2 to any

external systems.

Profcon AB Page 4 www.smokecontrol.net

The green OK LED should be on to indicate that

the system is operating normal and error free and

that Service Mode is not active any more.

If the communication watchdog has not been

activated then the display will flash

”WATCHDOG INACTI E!” in the main menu.

Introduced in software version .6 the green

OK LED will be off during normal operation

(unit not in Service Mode) if the communication

watchdog has not been activated. Also, the

ERROR LED will flash at the same rate as the

warning text in the main menu.

Note that the flashing has higher priority than other

errors that otherwise would give a constant

activation of the ERROR LED.

Remedy this by activating the communication

watchdog.

This concludes the setup and configuration task.

Step-by-Step instructions to commission a

system using SMOKE EDIT

Assuming that the electrical installation is ready

with all damper units installed, there are a few

steps necessary to get the system up and running.

It is also assumed that a SMOKE EDIT project has

been created that can be compiled error free.

For more information about specific menu

functions, please refer to the corresponding

section in this document.

Step : Addressing the modules

Please note: if a PC is connected to the MIDI

SMOKE 2 module, the PC-based software

SioxTools could be used as an alternative to

address the modules.

Enter the Service Mode and continue down to the

MODULE DDRESSING menu. Press Enter to

start the addressing operation. Note that it starts at

Group address=0 and Station address=1. The

Station address range is 1-59 depending on how

many modules that are installed. The Group

Address is normally zero but for large systems it

could also be 61, 62 or 63. Refer to relevant

project data to find out details about the planned

module addressing in the system.

See Module ddressing menu description.

Step 2: Download the configuration file

Use SMOKE EDIT to open the project file. Check

that the project file has the MIDI SMOKE 2 IP-

address set correctly. Do this by clicking on the

”Modules” tab and then right-click on the ”Midi

Smoke” symbol and select ”Properties”. Check the

watchdog time by clicking on the ”Modules” tab

and then right-click on the ”Smoke Control” symbol

and select ”Properties”. Default time when creating

a new project is 30 seconds.

Please note that the configuration of the Run

indication relay output is done in SMOKE EDIT by

clicking on the ”Modules” tab and then right-

clicking on the ”Midi Smoke” symbol and select

”Properties”.

The configuration can also be changed by using

the key pad on the MIDI SMOKE 2, see Run

indication relay output menu description. But the

project file should be updated as well.

The functional test settings are handled in a similar

manner. Start by clicking on the ”Modules” tab. For

each fire cell right-click on the fire cell symbol and

select ”Properties”. This can also be changed by

using the key pad on the MIDI SMOKE 2 but the

project file should be updated as well. To download

a corrected project file is of course the preferred

method.

Please note that an activation of DI4 will always

request a functional test sequence unless Service

Mode is active.

Now the configuration file can be downloaded to

the MIDI SMOKE 2.

Step 3: System test

At this point the MIDI SMOKE 2 unit is

communicating with the damper modules in the

system and status will now be updated. If there are

alarms use the larm menu and Fire cells menu to

get information about what and where the trouble

is and correct it.

If external systems are connected to the digital

inputs and relay outputs their operation can be

checked now. See the earlier sections Show digital

input status and Show digital output status.

A Function test all dampers could be attempted to

check that all dampers can manage a close/open

operation.

Step 4: Set RTC

The real-time clock is used for automatic functional

test scheduling.

See Setting up date / time menu description.

Step 5: Change Pin Code

If required, change the Pin Code in order to avoid

inadvertent access to the system setup. Keep a

note of the new one in a safe place.

See Change PIN code menu description.

Profcon AB Page 5 www.smokecontrol.net

Step 6: Activate watchdog

Enter the Watchdog menu and set the watchdog

timeout. Refer to the earlier section Watchdog.

See Watchdog menu description.

Step 7: Set time for automatic exit from Service

Mode

If desirable, the time for automatic exit from

Service Mode can be set. Factory default is that

automatic exit is inactivated. Time can be set

between 1 – 72 hours.

See Set Service mode timeout menu description.

Step 8: Switch the system to normal operation

mode

Exit the Service Mode by pressing “F2” och ”C” in

the main menu to let the system run in normal

operational mode.

Fire alarms will now be distributed thru DO2 to any

external systems.

The green OK LED should be on to indicate that

the system is operating normal and error free and

that Service Mode is not active any more.

If the communication watchdog has not been

activated then the display will flash

”WATCHDOG INACTI E!” in the main menu.

Introduced in software version .6 the green

OK LED will be off if the communication

watchdog has not been activated during

normal operation (unit not in Service Mode).

Also, the ERROR LED will flash at the same

rate as the warning text in the main menu.

Note that the flashing has higher priority than other

errors that otherwise would give a constant

activation of the ERROR LED.

Remedy this by activating the communication

watchdog.

This concludes the setup and configuration task.

Installation

MIDI SMOKE 2 is intended for installation on

standard 35 mm DIN-rails conforming to EN50022

(DIN46277-3 . The unit should be located inside an

enclosure prohibiting access by unauthorized

personnel.

The module can be AC- or DC-powered. The AC

input voltage range is 12-24 V AC and the DC input

voltage range is 18-35 V DC. Power consumption

at normal operation is approximately 3,5 W.

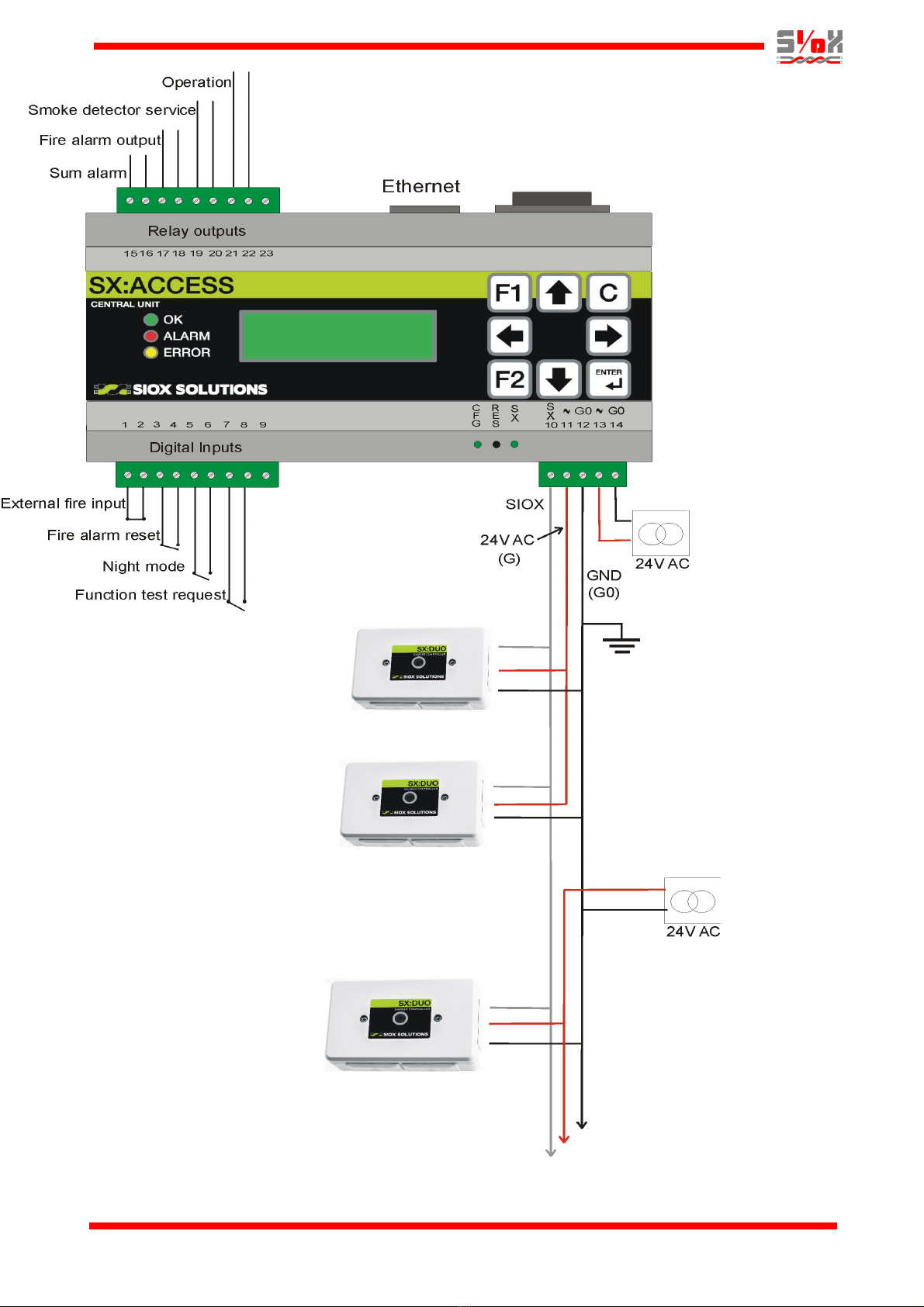

Connection of AC power

The secondary transformer winding should be

connected between terminals 13 (G and 14 (G0 .

Connection of DC power

Connect the negative supply wire to terminal 14

and the positive supply wire to terminal 13.

Three-wire bus

MIDI SMOKE 2 supports the three-wire concept

that is used by the Smoke Control products. The

three wires are SIOX, power (G and ground (G0 .

Terminal 10 is used for the outgoing SIOX bus.

Power to the first section of damper modules

(before another transformer handles next section

can be taken from terminal 11 (G and terminal 12

(G0 .

Please note that screw terminal 14 (incoming

power ground, G0 is internally connected to screw

terminal 12, as well as screw terminals 9 and 23 at

the I/O-connectors. Screw terminal 13 (incoming

power, G is internally connected to screw terminal

11.

For other types of modules, e.g. S45 and S27 that

must be separately powered by 24 V DC, their

SIOX bus connection should be connected

between terminal 10 (SIOX and terminal 12 (G0 .

The ground wire (G0 should always be routed

thru the whole system, only interrupted if R30

Bus Expander Modules are used that provides

galvanic isolation between bus sections.

The third wire (G is used to power the modules.

Depending on the size of the installation this wire is

usually divided into segments. Each segment has

its own power transformer and is powering a group

of damper modules.

Three-wire bus connection:

Screw terminal 10 is the SIOX bus.

Power to the damper modules comes out via screw

terminal 11 (G .

Screw terminal 12 is the power ground (G0 .

For more information about cable selection, please

refer to:

http://www.telefrang.se/download/pdf/CableSelecti

on.pdf

Grounding

To avoid that the system will electrically “float”, the

power ground wire (G0 at terminal 12 should be

connected to a grounded point nearby the MIDI

SMOKE 2 unit.

Because the ground potential between different

Profcon AB Page 6 www.smokecontrol.net

points in a large building could differ, ensure that

there are no other ground connections along the

three-wire bus/power cable in order to avoid the

risk of high ground currents which could lead to

disturbances or malfunction.

However, if R30 Bus Expanders are used that

provide galvanic isolation between the bus

sections, the outgoing AC/DC ground wire from the

R30 (secondary side should be grounded.

Digital Inputs

The four inputs are intended to be connected to

open/close switches. See page 1 for a functional

description.

Digital Outputs

There are four relay outputs on the MIDI SMOKE

2. Their breaking capacity is 1 A at 30 V AC/DC.

They are normally closed and opens during alarm

conditions. See page 1 for a functional description.

Ethernet

Ethernet is connected to the module thru the RJ-45

connector on the upper side of the module and is

used for Modbus TCP or SioxNet communi-

cations.

Loading of SMOKE EDIT configurations are also

done using the Ethernet connection.

The picture on the next page shows the electrical

connections for the MIDI SMOKE 2.

Profcon AB Page 7 www.smokecontrol.net

MidiSmoke2_ProdDescr_12en.odt 2018-05-30 /YE

Profcon AB Page 8 www.smokecontrol.net

Table of contents

Popular Fire And Smoke Damper manuals by other brands

KOOLAIR

KOOLAIR CCR Series manual

Ideal Heating

Ideal Heating EVOMAX 2 40 Installation

Swegon

Swegon REACT Pa Instructions for use

mercor

mercor mcr FID S Operation and maintenance manual

aldes

aldes CF1 Installation, operation and maintenance manual

MAT

MAT Roto-Twist RT-150 Series Installation & operation instructions