SOLID AIR FDC25 User manual

1| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

TECHNICAL MANUAL

Rectangular Fire Damper

FDC25 |FDC40

TABLE OF CONTENTS

1. PRODUCT PRESENTATION ..................................................................................................2

2. DIMENSIONAL RANGE.......................................................................................................... 3

3. DIMENSIONS ............................................................................................................................4

4. STORAGE AND HANDLING .................................................................................................6

5. INSTALLATION AND IMPLEMENTATION........................................................................6

6. CONTROL MECHANISM..................................................................................................... 21

7. ELECTRICAL CONNECTIONS.............................................................................................23

8. OTHER MECHANISMS ........................................................................................................24

9. EVOLUTION OF SERVICE KITS......................................................................................... 26

10. MAINTENANCE..................................................................................................................... 26

2| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

1. P

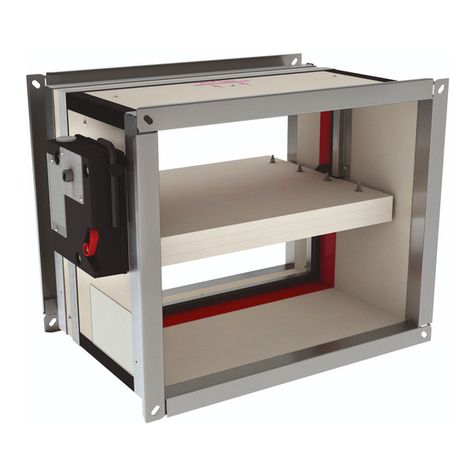

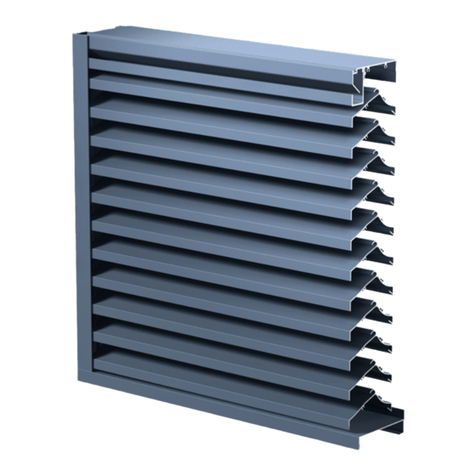

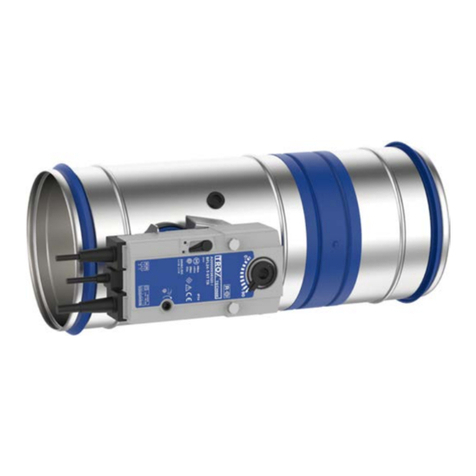

Fire dampers FDC25/FDC40 are installed in ventilation ducts between re compartments in order

to stop the spread of re and smoke trough the duct. They have a modular (manual or magnet)

or motorized mechanism, entirely outside the wall. Casing is made out of galvanized steel sheet,

damper blade is made of special insulating material, and damper blade shaft and push rod are made

of stainless steel. Bearings are made of brass, seals of polyurethane and elastomer. The re damper

can be equipped with a simple mechanism with thermal fuse, or with solenoid actuator mechanism

or with electric actuator mechanism..

• Tested according to EN 1366-2 up to 500 Pa

• Airtightness according to standard EN 1751 class C

• Approved for installation in a concrete wall, a concrete slab, plasterboard wall and gpsum

blocks wall

• Operating mechanism completely outside the wall

• Easy to install

• Maintenance free

1. Galvanized steel casing

2. Fire resistant damper blade

3. Control mechanism

4. Intumescent joint

5. Connection anges

6. Product marking on the casing

7. Thermal fuse

1. Gypsum layers

2. Intumescent joint

3. Cold smoke seal

4. Boundary layer

1

3

4

5

2

6

7

1

2

3

4

3| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

2. D

In decimeters:

Free area for dimensions Ø100 - 315 (blade 25 mm) (dm²) = [(π x (Ø-3)2/4)-25 x (Ø-5)]/10 000

Free area for dimensions Ø350 - 800 (blade 40 mm) (dm²) = [(π x (Ø-3)2/4)-40 x (Ø-5)]/10 000

In meters:

Free area for dimensions Ø100 - 315 (blade 25 mm) (m²) = [(π x (Ø-3)2/4)-25 x (Ø-5)]/1 000 000

Free area for dimensions Ø350 - 800 (blade 40 mm) (m²) = [(π x (Ø-3)2/4)-40 x (Ø-5)]/1 000 000

Diameter (mm) Gross section (dm²) Netto area (dm²)

FDC25

100 0.74 0.50

125 1.17 0.87

160 1.93 1.55

200 3.05 2.56

250 4.79 4.18

300 6.18 5.74

315 7.64 6.87

FDC40

355 9.73 8.33

400 12.37 10.79

450 15.69 13.91

500 19.39 17.41

630 30.86 28.36

710 39.24 36.42

800 49.86 46.68

Diameter (mm) Gross section (dm²) Netto area (dm²)

FDC

Applique

100 3.30 0.50

125 3.80 0.87

160 5.11 1.55

200 6.16 2.56

250 8.55 4.18

315 12.25 6.87

4| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

3. D

380 ∅D/2+12 ∅D/2+22

220

Y

D

AC

D

∅D

E

380 ∅D/2+12 ∅D/2+22

∅D

Y

101

E

A

E

Y

D

AC ∅D

380 ∅D/2+12

C

∅D/2+22

FDC25-R

FDC40-R

FDC25/40 M

Product A C D E

Belimo BFL (M) 25 200 90 120

BFN (M) 25 225 100 120

Klimaoprema

-R (FDC 25) 55 150 105 150

-R (FDC 40) 55 200 105 200

-EMP (FDC 25/40) 55 200 105 200

5| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

∅D

380 100 45

∅D+A

(∅D/2)+80 (∅D/2)+94

(∅D/2)+80 (∅D/2)+124

380 100 45

∅D

∅D+A

45

∅D+A

380

145

∅D+160

45

∅D+A

380

145

∅D+160

(∅D/2)+80 (∅D/2)+124

380 100 45

∅D

∅D+A

∅D

380 100 45

∅D+A

(∅D/2)+80 (∅D/2)+94

FDC APPLIQUE

Damper diameter ØD [mm] Applique frame diameter [mm]

100 Øn + 105 mm

125 - 180 Øn + 95 mm

200 - 315 Øn + 80 mm

Y = (Øn/2) - 110 (mm)

X* = (Øn/2) - 270 (mm)

*(dimension X is same as Y

(blade lenght outside of housing)

but opposite side

6| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

4. S

As a safety element, the re damper must be stored, handled and installed carefully.

Pay attention to:

• unload in a dry area

• avoid any shocks

• do not use the damper as a workbench or scaolding

• do not t the small dampers in the large one

The damper must be stored in a dry place, and kept out of water and frost. It should not be

stacked beyond the original packaging. It must be properly stowed so as to prevent any damage or

deformation resulting from an impact or high humidity. It must not be exposed to direct sunlight to

prevent premature aging of the thermal fuse. Once the damper is installed, the mechanism should

be kept away from any projections (cement, paint, ocking, water, dust) that may harm its operation.

The damper must be protected against the risk of heavy condensation. The intumescent joints are

essential for the re resistance of the damper, all mechanical actions on the refractory parts are to

be excluded. All precautions shall be taken to ensure that premature aging of the damper does not

occur before it is actually installed. The actions of wedging and caulking during the sealing of the

dampers must not cause deformations that will alter the good functioning of the damper and in

particular the closing of the blade.

5.

5.1

• Mounting is possible with the blade axis in horizontal or in vertical position

• The installation must comply with the tests that were performed during certication,

as explained in 8.2

• Avoid any obstruction of the moving blade by the connected ducts

• The class of air-tightness is maintained in case the installation of the damper is made in

accordance with the technical manual

• Operating temperature: 50 °C max

• For indoor use only

The FDC25/FDC40 re damper is always tested in standardized support frames (both in a concrete

wall and in a exible wall) in accordance with EN 1366-2: 1999 table 3/4/5. The results obtained are

valid for all similar support frames which have a thickness and/or density and/or re resistance

similar or greater than the one of the test.

Minimum opening hole for re damper instalation:

Damper size - ØD [mm] Opening size - A (minimum)

ØD < 160 ØD + 85

180 < ØD < 315 ØD + 75

315 < ØD < 450 ØD + 65

ØD > 450 ØD + 55

7| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2 I

5.2.1 Concrete wall and reinforced concrete wall installation

The wall is composed of concrete blocks (minimum density of 550 kg/m³) and with a minimum thickness

of 100 mm.

5.2.2 Aerated concrete ceiling installation and reinforced concrete ceiling installation

The ceiling is made of aerated concrete with a minimum density of 550 kg/m³ and a minimum thickness

of 100 mm.

Place the damper in an opening

according to table (on page 6)

Fix the damper to the wall using screws

(screw hole is 6 mm in diameter)

Fill the space between the damper

and the wall with mortar

Place the damper in an opening

according to table

(on page 6)

Fix the damper to the slab using

screws (screw hole is 6 mm in

diameter)

Fill the space between the damper

and the slab with mortar

8| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.3 Gypsum blocks wall 70 mm

The wall is composed of gpsum blocks (minimum density of 995 kg/m³), and with minimum thickness

of 70 mm.

Place the damper in an opening

according to table (on page 6)

Fix damper and GKF gpsum boards

(12.5 mm thick) to wall with screws

(screw hole is 6 mm in diameter)

Fill the space between the damper

and the wall with mortar

Cover the mortar with GKF gpsum

boards (12.5 mm thick)

*The Kit is universal for

all dimensions and must

be cut to t the specic

dimensions of the damper

Diameter of the

damper (mm)

Mounting

kit

100 60061429

125 60061430

160 60061431

200 60061432

250 60061433

315 60061435

355 60061436

400 60061437

450 60061438

500 60061439

560 60061440

630 60061441

710 60061442

800 60061443

9| Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.4 Gypsum blocks wall 100 mm

The wall is composed of gpsum blocks (minimum density of 995 kg/m³), and with minimum thickness

of 100 mm.

Fix the damper to the wall using screws

(screw hole is 6 mm in diameter)

Fill the space between the damper and

the wall with mortar

Cover the mortar with GKF gpsum

boards (12.5 mm thick)

Place the damper in an opening

according to table (on page 6)

*The Kit is universal for

all dimensions and must

be cut to t the specic

dimensions of the damper

Diameter of the

damper (mm)

Mounting

kit

100 60061429

125 60061430

160 60061431

200 60061432

250 60061433

315 60061435

355 60061436

400 60061437

450 60061438

500 60061439

560 60061440

630 60061441

710 60061442

800 60061443

10 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.5 Flexible wall mounting (mineral wool sealing)

The wall is composed of 2 x 2 GKF plates, 12.5 mm thick, installed on a 48 mm wide steel construction.

The interior of the wall is lled with mineral wool of 100 kg/m³ density.

625 625

> 440

Realization of the steel

construction

Place the damper in an opening

according to table (on page 6)

Fix the damper to the wall using screws

(screw hole is 6 mm in diameter)

Fill the space between the damper

and the wall with mineral wool

(100 kg/m³ of density)

Cover the mineral wool with GKF

gpsum boards (12.5 mm thick)

*The Kit is universal for

all dimensions and must

be cut to t the specic

dimensions of the damper

Diameter of the

damper (mm)

Mounting

kit

100 60061429

125 60061430

160 60061431

200 60061432

250 60061433

315 60061435

355 60061436

400 60061437

450 60061438

500 60061439

560 60061440

630 60061441

710 60061442

800 60061443

11 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.6 Flexible wall mounting (mortar sealing)

The wall is composed of 2 x 2 GKF plates (example PROMATECT 100, 12.5 mm thick), installed on a steel

construction of 48 mm width.

625 625

> 440

Realization of the steel

construction

Place the damper in an opening

according to table

(on page 6)

Fix the damper to the wall using

screws (screw hole is 6 mm in

diameter)

Fill the space between the damper

and the wall with mortar

Cover the mortar with GKF gpsum

boards (12.5 mm thick)

*The Kit is universal for

all dimensions and must

be cut to t the specic

dimensions of the damper

Diameter of the

damper (mm)

Mounting

kit

100 60061429

125 60061430

160 60061431

200 60061432

250 60061433

315 60061435

355 60061436

400 60061437

450 60061438

500 60061439

560 60061440

630 60061441

710 60061442

800 60061443

12 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.7 Installation in exible wall (Weichschott)

Installation material: Fire damper FDC, Mineral wool > 140 kg/m³, re protection coating,

(HILTI weichschott system).

Recommended wall opening for

re damper installation is

Ø + 400 mm, but openings from

Ø + 80…600 mm can also be used

Insert re damper into wall

Damper blade must be closed

during installation!

Space between casing and wall

close with two layers of mineral

wool (density 140 kg/m³ or more,

coated on one side)

Connections of mineral wool seal with

intumescent re resistant sealant (e.g.

Promastop-I or Hilti CFS-CT). Mineral

wool and damper casing must be coated

with 2 mm thick re protection coating

13 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.8 Installation remote from exible/rigid wall

The wall is composed of 2 x 2 GFK plates, 12.5 mm thick, installed on a 48 mm wide steel construction.

The interior of the wall is lled with mineral wool of 100 kg/m³ density.

700

Øn+80

Øn+80

Arrangement of steel proles Place the damper in an opening

according to table (on page 6)

(wall cover with gpsium plates)

Place ventilation duct trough wall

(thickness of threaded rod for

suspension should be M12 or more)

Install re damper and secure it with

self-tapping screws 4,3 x 10 to duct

(every 300 mm)

Fill space between duct and wall with

mineral wool (Isover U protect, min. 80 mm

thickness). Additionally paint wool with

Isover BSF in thickness of 1 mm

Repeat the same procedure on the

other side. Place the wool on

ventilation duct in lenght of 80 mm

Close installation with L proles 30 mm x

30 mm x 3 mm. Additionally x proles to

duct with self-tapping screws, and screw

them to wall with 4,5 x 50 screws with

200 mm distance between them

Place steel protection on place where

insulation on damper ends (80 mm x

80 mm, 1 mm thick metal sheet cover)

On connection wool-wall apply

glue Isover BSK in thickness of 2 mm

14 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.9 Installation in ceiling (Weichschott)

The ceiling is composed of concrete blocks (minimum density of 550 kg/m³) and with a minimum thickness

of 100 mm.

Recommended ceiling opening

for re damper installation is

Ø+ 400 mm, but openings from

Ø + 80…600 mm can also be used

Insert re damper into ceiling

Damper blade must be closed

during installation!

Space between casing and wall

close with two layers of mineral

wool (density 140 kg/m³ or more,

50 mm thick, coated on one side)

Connections of mineral wool should be sealed

with intumescent re resistant sealant (e.g.

Promastop-I or Hilti CFS-CT). Mineral wool and

damper casing must be coated with 2 mm thick

re protection coating

5.2.10 Suspension for mortarless installation

Suspension systems are required for the dry mortarless installation of the re damper with mineral wool in solid walls,

exible walls and ceiling slabs. Fire dampers can be suspended from solid ceiling slabs using adequately sized threaded

rods. Load the suspension system only with the weight of the re damper. Ducts must be suspended separately.

1

3

2

1

45

Dn + 70

Dn + 70

Wall installation Ceiling installation Threaded rod (M10),

galvanized steel

Washer, galvanized steel

Nut, galvanized steel

Bracket, 45x30x1,5 mm,

galvanized steel

L shaped prole (50x50x1)

secured with self tapping

screw to damper housing

1

2

3

4

5

15 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.11 Installation in gpsum blocks wall 70 mm

The wall is composed of gpsum blocks (minimum density of 995 kg/m³), and with minimum thickness

of 70 mm.

30

30

30

45º

30

150

150

Prepare opening in the wall according

to dimension table (on page 6) Insert re damper into wall

Fire damper can be installed with

minimal distance of 30 mm between

wall, ceiling or other dampers.

Cover the mortar with GKF gpsum

boards (12.5 mm thick)

Space between casing and wall

close with mortar

16 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.12 Installation in gpsum blocks wall 100 mm

The wall is composed of gpsum blocks (minimum density of 995 kg/m³), and with minimum thickness

of 100 mm.

30

30

30

45º

30

150

150

Prepare opening in the wall according

to dimension table

(on page 6)

Insert re damper into wall

Fire damper can be installed with

minimal distance of 30 mm between

wall, ceiling or other dampers.

Mineral wool and damper casing

must be coated with 2 mm thick

re protection coating

Space between casing and wall

close with mortar

17 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.13 Installation in rigid wall 100 mm

The wall is composed of concrete blocks (minimum density of 550 kg/m³) and with a minimum thickness

of 100 mm.

30

30

30

45º

30

Prepare opening in the wall according

to dimension table

(on page 6)

Insert re damper into wall

Fire damper can be installed with

minimal distance of 30 mm between

wall, ceiling or other dampers.

Space between casing and wall

close with mortar

18 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.14 Flexible wall mounting

The wall is composed of 2 x 2 GKF plates, 12.5 mm thick, installed on a 48 mm wide steel construction.

The interior of the wall is lled with mineral wool of 100 kg/m³ density.

30

30

30

45º

30

Arrangement of steel proles

according to drawing. Prepare opening

in the wall according to dimension

table (on page 6)

Insert re damper into wall

Mineral wool and damper casing

must be coated with 2 mm thick

re protection coating

Space between casing and wall

close with two layers of mineral

wool (density 140 kg/m³)

Fire damper can be installed with

minimal distance of 30 mm between

wall, ceiling or other dampers.

19 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.15 Installation in rigid oor 100 mm

The oor is composed of concrete blocks (minimum density of 550 kg/m³) and with a minimum thickness

of 100 mm.

30

30

30

45º

30

Prepare opening in the wall

according to dimension table

(on page 6)

Insert re damper into oor

Fire damper can be installed with

minimal distance of 30 mm between

wall, ceiling or other dampers.

Space between casing and wall

close with mortar

20 | Circular re damper user manual 05/2020

SOLID AIR

®

CLIMATE SOLUTIONS • T +31 598 36 12 21 • www.solid-air.nl •mail@solid-air.nl

5.2.16 Flexible wall installation

The wall is composed of 2 x 2 GKF plates, 12.5 mm thick, installed on a 48 mm wide steel construction.

The interior of the wall is lled with mineral wool of 100 kg/m³ density.

5.2.17 Concrete wall and reinforced concrete wall installation

The wall is made of aerated concrete with a minimum density of 550 kg/m³ and a minimum thickness

of 100 mm.

Arrangement of steel proles. Installation hole is

Øn + A + 10 mm (see page 5)

Insert re damper into wall

and fasten with screws

(8 pcs, 4.8 mm x 60 mm)

625 625

n +A

n +A

Installation hole is

Øn + A + 10 mm (max)

Insert re damper into wall

and fasten with screws

(8 pcs, 4.8 mm x 60 mm)

Wall opening dimensions

Damper diameter Øn[mm] Applique frame diameter D [mm] Wall opening [mm]

100 Øn + 105 Øn + 115 mm

125 - 180 Øn + 95 mm Øn + 105 mm

200 - 315 Øn + 80 mm Øn + 90 mm

Other manuals for FDC25

1

This manual suits for next models

5

Table of contents

Other SOLID AIR Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

Greenheck

Greenheck EHM-601 Installation, operation and maintenance manual

Stuv

Stuv AW1200100300 installation manual

Advanced Air

Advanced Air 2530 Installation, operation and maintenance manual

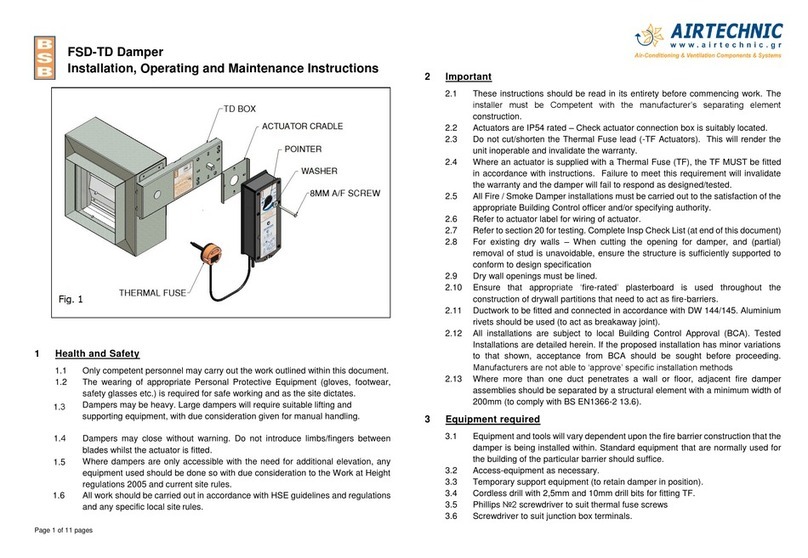

BSB

BSB FSD-TD Damper Installation, Operating and Maintenance Instructions for the Installer and the User

Lindab

Lindab CFDM technical information

Trox Technik

Trox Technik FKRS-EU Installation and operating manual