Solid Strike EVO User manual

Solid Bikes Europe Rudolf-Diesel-Straße 13 D-72250 Freudenstadt

Solid Bikes Europe T +49 (0) 7441 / 952-450

Inhaber Peter Schmid F +49 (0) 7441 / 952-451

D –72250 Freudenstadt www.solidbikes.de

Sie erreichen uns Montag bis Freitag von 8:00 Uhr bis 13:00 Uhr und von 14:00 Uhr bis 17:15 Uhr

Owner’s Manual Solid Strike EVO

Congrats on your new Solid Strike EVO Downhillbike!!

You’ve decided to go for a expertly engineered, high spec DH machine. Technical work and bike

maintenance need to be performed by specifically trained personnel.

Adjustability of the frame

The Solid Strike has been designed for the use of 27.5“-wheels. Rear wheel travel is 203 mm / 8“.

We recommend the use of fork that is designed for the use of 27.5”-wheels and has a travel of

around 200 mm.

If you have purchased a new Solid Strike Evo as a complete bike, a suitable fork is already installed.

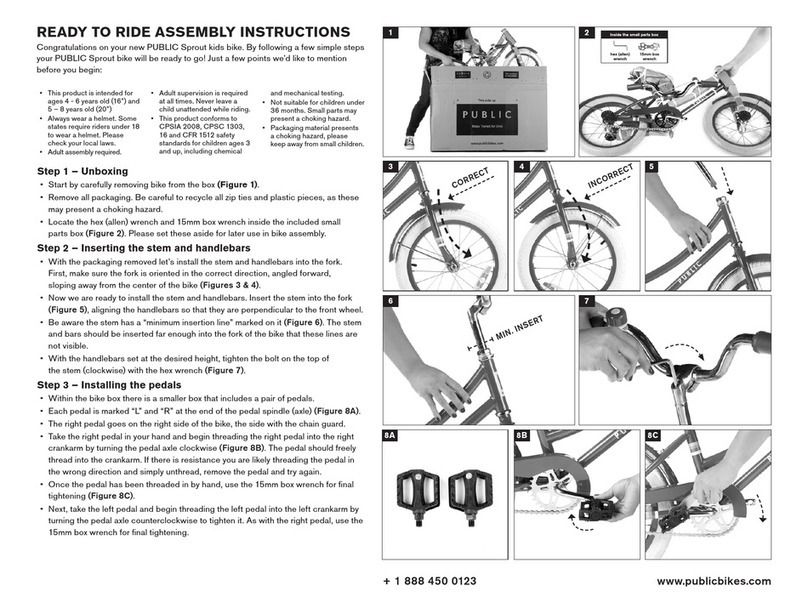

When taking your new Solid out of the box, the stem needs to be mounted to the upper fork crown

and the pedals need to be fitted to the cranks.

Assembly of stem on upper fork crown:

-Apply medium strength screw locking system (e.g Loctite)

-Tighten the screws which attach the stem to the upper fork crown with a torque of 7Nm

Mounting of the pedals

-Please consider that the left pedal is equipped with a left-handed thread –it needs to be

tightened counterclockwise. The right pedal possesses a regular thread, meaning it can be

tightened clockwise.

-Tighten your pedals with a torque of 38 to 43 Nm at the cranks (if there are no different

information available from the manufacturer). Please consider also all other claims by the

manufacturer and use the washers included in the package and apply some grease on the

thread in order to avoid contact corrosion.

Tires

CAUTION: Some models of the Solid Strike Evo are equipped tubless as standard, i.e. on these bikes,

there is no tube inside the tire. In case you purchased one of our tubeless-models (e.g. Solid Strike

Evo Factory), please consider the following:

This technology deriving from racing saves weight and leads to a better flex behaviour of the tire.

Unfortunately, tubeless tires are never 100% sealed –this is why you should check your tire pressure

before riding.

Solid Bikes Europe Rudolf-Diesel-Straße 13 D-72250 Freudenstadt

Solid Bikes Europe T +49 (0) 7441 / 952-450

Inhaber Peter Schmid F +49 (0) 7441 / 952-451

D –72250 Freudenstadt www.solidbikes.de

Sie erreichen uns Montag bis Freitag von 8:00 Uhr bis 13:00 Uhr und von 14:00 Uhr bis 17:15 Uhr

After each run, we recommend a short manual pressure check as well –air might escape due to “tyre

burping”, this phenomenon can be caused by hard cornering or large impacts. It is normal that during

tire burping, some sealant fluid can escape as well.

In each of your tubeless tires, there is around 60 to 80 ml of sealing fluid. This can dry out over time

or can escapes with impacts, this is why you should check your fluid every 3 months.

In order to inflate the tire, a compressor can be helpful.

Delivered as standard on the Strike EVO Factory, the tire is sealed by latex-based sealing fluid,

traditionally called “tubeless milk”. Tubeless milk is NOT a food and must never be consumed under

any circumstances!

By the way, slight “sweating”of the tire is normal. A tiny amount of the sealing fluid transpires

through the tire casing.

Before your first ride, make sure your bike is in a working condition:

-Check functionality of your brakes (is there a defined force point on the lever? Is there

sufficient deceleration when applying the brake?)

-Is the tire pressure ok? (the required tire pressure depends on your riding style, track

conditions and personal preferences –as a rough recommendation, you can inflate to around

1.8 bar at the front tire and 2.0 bar at the rear tire (26/29psi).

-Are there any anomalies like loose bolts, oil leaks at the brakes or suspension components?

-Set-up your air pressures in your suspension components according to your body weight:

Setup of your sag

The Strike has been designed for a sag of 30% (plus-minus 3 percent) at the rear wheel and works

best this way.

It must be taken into account that this means approximately 30% of the total travel and NOT 30% of

the shock stroke.

The total rear wheel travel of the Solid Strike EVO is 203 mm, 30% of that is 60.9 mm. Approx 61 mm

corresponds to a stroke of 19.5 mm at the piston rod of your shock. Please DO NOT set your bike

with a sag of 23 mm (=30% of 76 mm), because this will lead to too much sag and overly soft

suspension.

In order to avoid trial-and-error, we recommend the use of our set-up chart on solidbikes.de: use the

correct air pressure for your body weight.

Your damping parameters have to be set according to your air pressure. Please proceed as follows:

1.) Check your body weight and choose the proper airpressure / spring rate according to the

recommendation on the Solid webpage

2.) Make your suspension adjustments in accordance with the manufacturers recommendations

( e.g Rockshox, Fox , etc)

Solid Bikes Europe Rudolf-Diesel-Straße 13 D-72250 Freudenstadt

Solid Bikes Europe T +49 (0) 7441 / 952-450

Inhaber Peter Schmid F +49 (0) 7441 / 952-451

D –72250 Freudenstadt www.solidbikes.de

Sie erreichen uns Montag bis Freitag von 8:00 Uhr bis 13:00 Uhr und von 14:00 Uhr bis 17:15 Uhr

Disassembly of the rear wheel

For the disassembly/removal of the rear wheel, please proceed in the sequence as follows:

-Remove M6 counter screw on drive side (4-mm hex key) (1)

-Loosen radial clamping screw(pinch bolt) on non drive side (4-mm hex key) (2)

-Loosen axle from non-drive-side via 6-mm hex key and take out (3)

1 3 2

Assembly is performed the other way around.

Please be aware that you should not pull the brake levers while the wheels are not assembled. The

pistons in the caliper may close and be difficult to prise apart.

Maintenance

Due to the high loads a downhill bike experiences, it is important to get your bike checked-up by

qualified personnel on a regular basis.

After the first few runs, we recommend to check the spoke tension, the correct adjustment of your

head set and all bolts.

For the service intervals for your suspension components, we recommend to consult the individual

manufacturer’s webpage.

HAVE FUN RIPPING!

Yours,

Solid Bikes Team

Table of contents