Chromalox 2104 User manual

2104 Chromalox®

Temperature Controller

Technical Manual

0037-75276

Issue Date

May 1996

C

iChromalox 2104 Technical Manual

1 Getting Started..................................................... 1

2 Installation ........................................................... 3

3 Operation ............................................................. 21

4 Controller Setup Pages ........................................33

5 Ramp/Soak Operation ......................................... 41

6 Alarms ................................................................. 47

7 Digital Input and AUX Function ......................... 59

8 Remote Setpoint & Analog Process Output ........67

9 Digital Communications...................................... 71

10 Calibration ........................................................... 75

11 Specifications ...................................................... 83

12 Troubleshooting................................................... 87

13 Warranty and Return............................................ 89

Appendices

I Setup Pages..........................................................91

Menu Index

Index .............................................................................................. 103

Table of Contents

Sections

Section Topic Page

ii Chromalox 2104 Technical Manual

Illustrations

Figure Topic Page

1.1 Application............................................................. 1

1.2 Model Identification............................................... 2

2.1 Sensor Selection Dip Switch Settings ................... 3

2.2 Mounting Dimensions............................................ 5

2.3 Mounting Diagram ................................................. 5

2.4 Wiring Terminal Identification.............................. 7

2.5 Thermocouple Connections................................... 8

2.6 3-Wire RTD Connections...................................... 9

2.7 2-Wire Connections............................................... 9

2.8 Current Input Wiring (Self-powered).................... 9

2.9 Voltage Input Wiring.............................................. 10

2.10 Current Input Wiring (Loop-power) ..................... 10

2.11 Event Input Connections External Switch............ 10

2.12 Momentary Contact Pushbutton for Ramp/Soak.. 10

2.13 Relay Output Connections .................................... 11

2.14 SSR Drive Output Jumper Positions...................... 12

2.15 Solid State Relay Drive Output Connections ....... 13

2.16 Current/Voltage Output Jumper Positions............. 14

2.17 Triac Output Connections ..................................... 15

2.18 4-20mA Analog Output Connections................... 15

2.19 1-5 Vdc Output Connections ................................ 15

2.20 Dual Relay Output Wiring ..................................... 16

2.21 Dual Triac Output Wiring ...................................... 16

2.22 Dual Analog Output Wiring .................................. 16

2.23 Dual SSR Drive Output Wiring............................. 16

2.24 Dual 1-5 Vdc Output Wiring ................................. 17

iiiChromalox 2104 Technical Manual

Illustrations

Figure Topic Page

2.25 Dual Output SSR/Relay Wiring............................. 17

2.26 Dual Output SSR/Triac Wiring.............................. 17

2.27 Dual Output Analog/Relay Wiring........................ 18

2.28 Dual Output Analog/Triac Wiring......................... 18

2.29 100-240 Vac Instrument Power Connections........ 19

2.30 12-24 Vac/Vdc Instrument Power Connections.... 19

2.31 Alarm/Event Outputs #3 and #4............................ 19

2.32 Alarm/Event Output #5 ......................................... 20

3.1 Front Panel Identification...................................... 22

3.2 PAGE/MENU Setup Structure .............................. 23

3.3 Sample of PAGE/MENU Table.............................. 25

3.4 Security Levels and PAGE/MENU Contents........ 26

3.5 Security Codes and View/Adjust Levels ................ 27

5.1 Ramp/Soak Profile.................................................. 41

5.2 Event Outputs in Ramp/Soak Profile..................... 41

5.3 Looping Intervals.................................................... 42

5.4 Guaranteed Soak .................................................... 42

6.1 CLP Alarm Connections........................................ 55

8.1 Remote Setpoint Input Signal ............................... 67

8.2 2-Wire 4-20mA Transmitter (Loop-powered)....... 68

8.3 2-Wire 4-20mA,1-5Vdc Transmitter (Self-powered)... 68

8.4 3-Wire 4-20mA, 1-5 Vdc Transmitter ................... 68

8.5 Analog Process Output Signal ............................... 69

8.6 Process Output Wiring ........................................... 70

9.1 RS422/RS485 Communications Switches............. 72

9.2 RS232 Wiring Connections ................................... 72

9.3 RS422A Wiring Connections (4-wire) ................. 73

9.4 RS485 Wiring Connections (2-wire)..................... 73

iv Chromalox 2104 Technical Manual

Chromalox 2104 Technical Manual 1

Shutdown

Contactor

Section 1

Getting Started

The Chromalox 2104 1/4 DIN temperature and

process controller is a low-cost, high-performance,

single-loop controller that can be used for

temperature, flow, pressure and level control

applications. With universal sensor inputs and front

panel operator setup, one 2104 controller can be easily

field configured for a wide variety of applications, and

simply reconfigured as application needs change. This

makes it an exceptional choice for OEMs with

multiple control needs, manufacturing facilities,

testing facilities and testing applications.

Figure 1.1

Typical Application

Process

SCR

SCR

High Alarm-Output #3

Shutdown

Low Alarm-Output #4

ChromaSoft™

Computer High Alarm-Output #3

Shutdown

Low Alarm-Output #4

RS485

Digital

Com.

21042104

21042104

2104

21042104

21042104

2104

21042104

21042104

2104

21042104

21042104

2104

Heat

Output #1

Cool

Output #2

Heat

Output #1

Cool

Output #2

Output #5

Control Loop

Protection

Remote/Local

Setpoint Switch

Remote Setpoint

from DCS

Recorder

2 Chromalox 2104 Technical Manual

Model Temperature Controller

2104 Microprocessor-based 1/4 DIN Temperature Controller. Universal Sensor Input

accepts Thermocouple, RTD, Current or Voltage Inputs. PID, ON/OFF with

Fuzzy Logic Control Capability. One Digital Input and Analog Remote Set Point.

Figure 1.2 Model Identification

Model Identification

Before installation, please identify your controller model number. The model

number is written on the tag on the side of the housing.

Code Outputs #1—Single Output Control

RO Output #1 Single Output Control Relay/SSR Drive (jumper selectable)

Relay—N.O. Form A Contact, 1A at 120 or 230 Vac

SSR Drive—24Vdc at 40mA

TO Triac—1 Amp at 120 or 230 Vac

AO Analog—4-20mA or 1-5 Vdc, non-isolated

Outputs #1 & #2 - Heat/Cool Control

RR Relay/Relay

TT Triac/Triac

AA Analog/Analog

SS SSR Drive/SSR Drive

AR Analog/Relay

AT Analog/Triac

SR SSR Drive/Relay

ST SSR Drive/Triac

0 None

1 Dual Relay—Two (2) Form A contacts, 1A at 120 or

230 Vac with shared common terminal

Code Outputs #3 & #4 (Alarm/Event Outputs)

Code Isolated Digital Communications,

Output #5 (Alarm/Event Output),

and Analog Output Option

0 None

1 RS-422/485 Digital Communications and

Output #5

2 RS-232 Digital Communications and

Output #5

3 Analog Output Option

4 RS-422/485 Digital Communications,

Output #5 and Analog Output Option

5 RS-232 Digital Communications,

Output #5 and Analog Output Option

2104- RO 1 1 0 Typical Model Number

Code Power Supply

0 100 - 240 Vac or Vdc

1 12-24 Vdc or Vac

Chromalox 2104 Technical Manual 3

Section 2

Installation

On receipt of your 2104 controller, immediately make

note of any visible damage to the shipment packaging

and record this damage on the shipping documents.

Unpack the controller and carefully inspect it for

obvious damage due to shipment. If any damage has

occurred, YOU must file a claim with the transporter,

as they will not accept a claim from the shipper.

If the controller will not be immediately installed and

placed into operation, it should be stored in a cool, dry

environment in its original protective packaging until

time for installation and operation. Temperature

extremes and excessive moisture can damage the

instrument.

Inspection

and

Unpacking

Switch

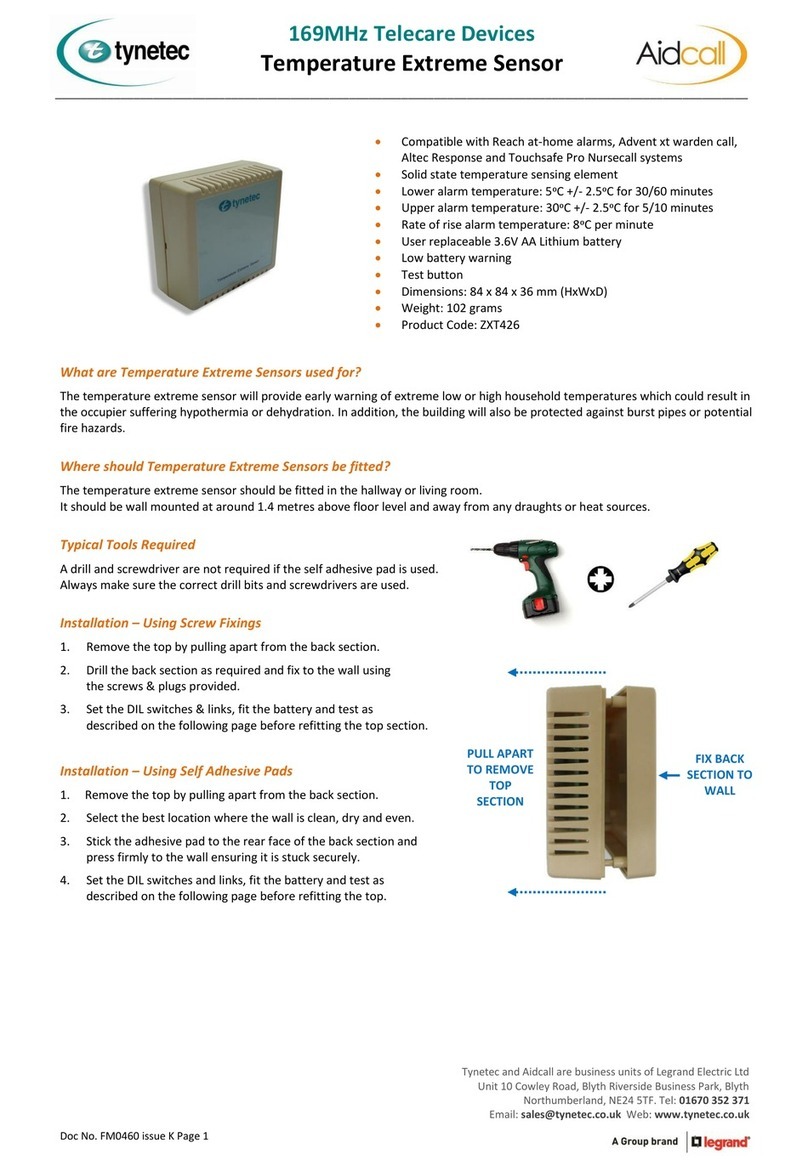

Settings The 2104 has up to seven (7) hardware switches

located on the bottom of the controller. The switches

are accessible through cutouts in the controller

housing and do not require that you remove the

controller from its housing to access the switches.

Figure 2.1 identifies the switches. Instructions for

switch settings are given in the corresponding sections

of the manual.

Figure 2.1

Sensor Selection

Dip Switch

Settings

Controller

Bottom Surface

Switches #1 and #2

Digital Communications

RS422/RS485

Switches #1, #2 and #3

Sensor Input Switch #4

Remote Setpoint

Input Signal

Switch #5

Analog Output

Signal

4 Chromalox 2104 Technical Manual

Sensor

Selection

Switches

Sensor selection requires that you:

1.Set the sensor switches for the correct sensor

type.

2.Program the input sensor type in sensor

selection setup on the INPT Page (see page 36).

It is much easier to set the sensor input switches

before you mount and wire the controller.

To set the sensor switches:

1.Locate the sensor switches—#1, #2 and #3—

on the bottom of the controller, as shown in

Figure 2.1 on the previous page.

2.Place the switches in the appropriate Up or

Down position for your input type:

Switch #

Input Type 1 2 3

T/C Up Up Up

RTD Down Up Up

4-20mA Up Down Down

1-5 Vdc Up Up Down

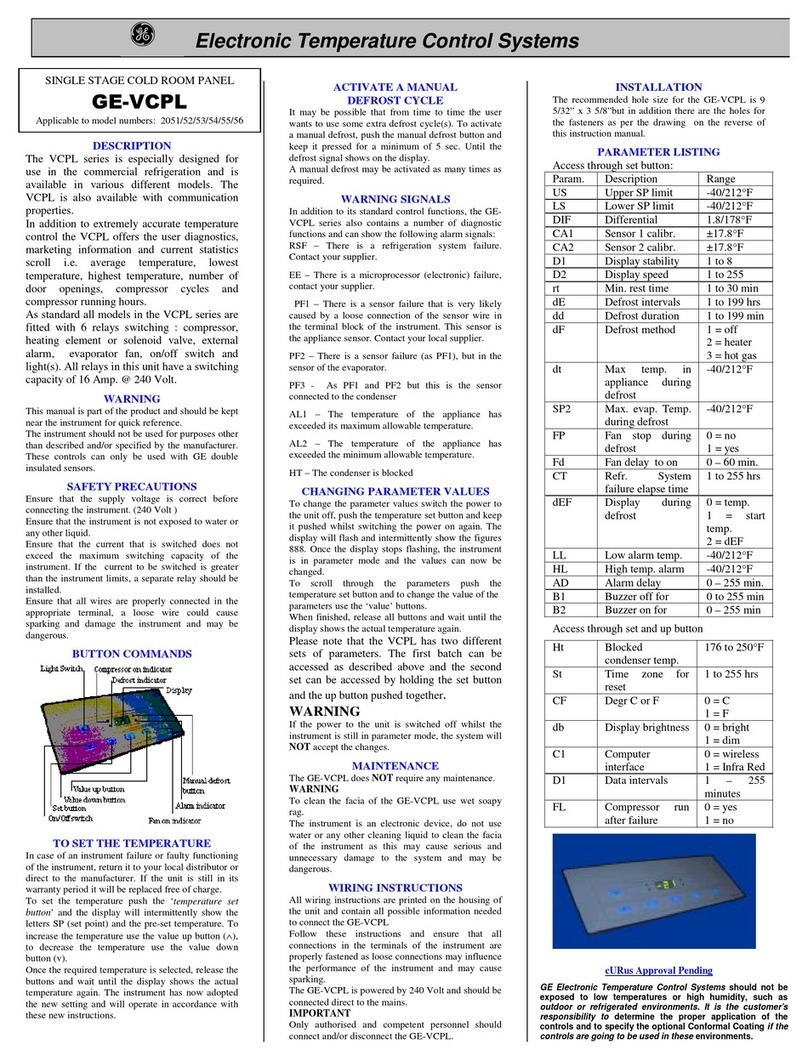

Figure 2.2, on the following page, shows the

mounting dimensions for the controller:

1.Cut out the square “panel cutout” mounting

hole and install the unit as shown in

Figure2.3.

2.Place the controller through the square

panel cutout and replace the mounting clip.

3.Tighten the mounting clip screw (do not

over- tighten) to secure the controller firmly

against the mounting surface.

Mounting

Chromalox 2104 Technical Manual 5

4.0

(102)

Measurements are shown in inches. Millimeters are shown in parentheses.

3.5

(90) 3.6

(92)

3.6

(92)

3.8

(96)

3.8

(96)

Figure 2.2 Mounting Dimensions

0.8

(19)

Figure 2.3 Mounting Diagram

Panel Cutout

Mounting Hole

Mounting Tab

Mounting Clip

6 Chromalox 2104 Technical Manual

Good Wiring Practices

1. When planning the system wiring, separate wiring

into functionally similar bundles - i.e., power leads,

sensor leads, output signal lines, etc. If the power leads

and sensor leads must cross, they should cross at a 90°

angle to each other (perpendicular).

2. Locate all sources of electrical noise in your system,

and separate these sources from the control systems—

motors, contacts, solenoids, etc. Electrical noise can

affect the function of any control system. When

driving a contactor coil or other inductive load, an

appropriately rated AC snubber circuit is

recommended (Chromalox Part. No. 0149-01305), as

described on page 11, “Relay Output Wiring.”

3. For sensor wiring practices, see Sensor Wiring

Notes, next page.

4. Additional information on good wiring practices is

available from IEEE, 345 East 47th St., NY, NY

10017. Request IEEE Standard No. 518-1982.

Wiring

Instructions

Make all electrical wiring connections to the back of

the controller before power is applied to the unit.

All wiring must comply with local codes, regulations

and ordinances. This instrument is intended for panel

mounting and the terminals must be enclosed within

a panel. Use National Electric Code (NEC) Class 1

wiring for all terminals except the sensor terminals.

Check the wiring decal on the side of the unit to

verify the model number. The wiring decal shows the

wiring terminations. All wires will be connected to the

terminals on the back of the instrument case. Specific

wiring instructions for different input and output types

are given in this section.

Chromalox 2104 Technical Manual 7

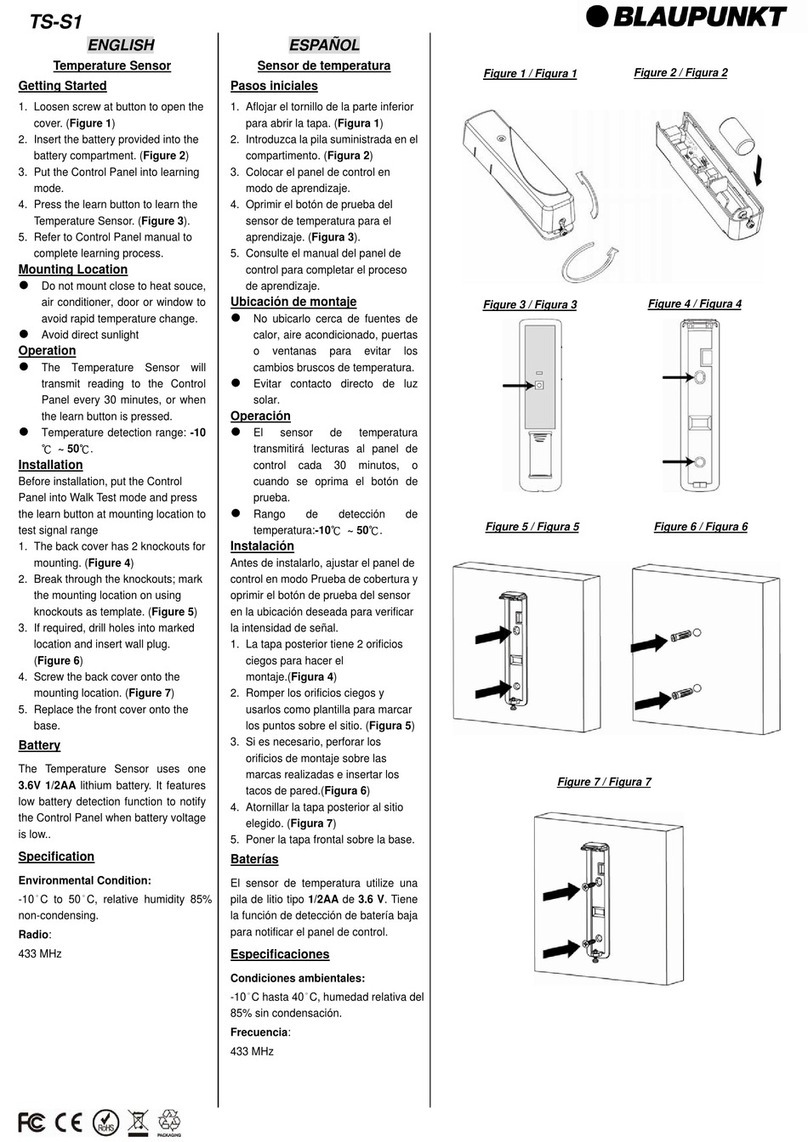

Figure 2.4 Wiring Terminal Identification

Sensor Input Wiring

Sensor Input Wiring Notes:

•Sensor leads (thermocouple and RTD) should not

be run together in the same conduit as power

wiring.

•Twisted pair, shielded wire is recommended for

sensor connections.

•False process readings can occur if the sensor wire

is exposed to electrical noise.

•Ungrounded thermocouples are recommended.

•If thermocouple extension wire is required, it must

be the same type as the thermocouple (i.e., if a

Type K thermocouple is used, then Type K

extension wire must be used).

•Thermocouple wires should connect directly to

the controller terminals. Do not use copper crimp

terminals or solder terminals to make connections.

•If shielded thermocouple wire is used, the shield

must be grounded at one end only, preferably at

the shield ground terminal on the controller, as

shown in Figure 2.5.

•Three wire RTDs are recommended for greatest

accuracy.

•Standard shielded copper wire is recommended for

RTD extensions.

Digital

Input

+24 Vdc Output

Analog Output

Remote Setpoint Input

Common

Sensor Input

RTD TC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Digital

Communications

Not Used

Output #5

Common

Output #4 Relay

100/240 Vac or

12/24 Vac/Vdc

AC Common

Shield Ground

Output #1

and #2

Output #3 Relay

Instrument

Power

4-20mA

8 Chromalox 2104 Technical Manual

Thermocouple Inputs

It is important to observe polarity (+, -) when

connecting thermocouple leadwires. The table

below shows ANSI color coding for the

thermocouples used with this instrument.

Make the thermocouple wiring connections to

terminals as shown in Figure 2.5.

T/C Type Material Polarity (+) Polarity (-)

B Plat, 30% Rhodium/ Gray Red

Plat, 6% Rhodium

J Iron/Constantan White Red

K Chromel/Alumel Yellow Red

E Chromel/Constantan Purple Red

T Copper/Constantan Blue Red

R Plat, 13% Rhodium/Plat Black Red

S Plat, 10% Rhodium/Plat Black Red

Figure 2.5

Thermocouple

Connections

3-Wire RTD Inputs

When making the 3-wire RTD input connection, it is

important to make the resistance of all three extension

leadwires equal by using the same gauge and same

length of wire for optimum leadwire compensation.

Chromalox recommends 3-wire RTDs for greatest

accuracy, and standard shielded copper wire for RTD

extensions. Make 3-wire RTD connections to

terminals 7, 8 and 9 as shown in Figure 2.6 on the

following page.

8

9

+

-

Shield Gnd 18

2104

Chromalox 2104 Technical Manual 9

8

9

18

7

Figure 2.6

3-Wire RTD

Connections

2-Wire RTD Inputs

If using a 2-wire RTD input, use heavier gauge

leadwires to reduce leadwire resistance. Any

leadwire resistance adds directly to sensor resistance,

thus adding error to the process temperature

measurement. It is also necessary to jumper

terminals 8 and 9 on the instrument to complete a

2-wire hookup.

Figure 2.7

2-Wire

Connections

7

8

9

Shield Grnd

2104

2104

Current/Voltage Inputs

7

8

9

4-20mA

+

Figure 2.8

Current

Input Wiring

(Self-powered)

2104

10 Chromalox 2104 Technical Manual

7

8

9

Figure 2.9

Voltage

Input Wiring

(Self-powered)

4-20mA

3

7

+24 Vdc

+

The 2104 has a +24 Vdc power supply which can be

used to power a 4-20mA transmitter.

1-5 Vdc

0-5 Vdc

+

Figure 2.10

Current

Input Wiring

(Loop-powered

by controller)

2104

2104

The digital input can be used in a number of ways:

•to control ramp/soak operations

•to switch between two setpoints, PID

parameters, or Auto/Manual control

•to reset an alarm

•to disable the control output.

Setup for the digital input is shown on the CTRl setup

page. An external switch, pushbutton or dry contact

can be connected to this input. Use isolated switches

only. Do not tie the Digital Input terminals to ground.

Digital Input

Connections

1

2

{

External

Input

+

-

Figure 2.11

Digital Input

Connections

External Switch

2104

1

2

+

-

Figure 2.12

Momentary

Contact

Pushbutton for

Ramp/Soak

2104

Chromalox 2104 Technical Manual 11

The 2104 is supplied with either:

•1 Control Output for Single Output

Control (#1)

•2 Control Outputs for Heat/Cool Control

(#1 and #2)

The output wiring varies depending on the control

type and applications. The wiring instructions are

presented separately for each of these two controller

types/applications.

Output

Wiring

Warning

Incorrect output wiring may cause system/process

damage.

☛

Single Output Control Wiring

Relay Output

Output Code “RO” on the 2104 (2104 - RO***)

gives you the option of SSR Drive or Relay control

for output #1. When shipped from the factory, the

relay output is active.

Figure 2.13

Relay Output Connections

SSR Drive Output

For SSR drive output applications, you must move

an internal jumper on the Output #1 module to

select SSR drive output. Remove the controller from

its housing, and locate the output module as shown

in Figure 2.14 on the following page. Reposition the

jumper to select SSR Drive output.

120 or 230 Vac

AC Neutral

10

11

{

Relay

Contacts

Load

Snubber

Internal

MOV

12 Chromalox 2104 Technical Manual

Figure 2.14

SSR Drive Output

Jumper Position

Relay

(as shipped from factory)

SSR Drive

Output Module

Controller Rear View

Top

Output #1 Module

Chromalox 2104 Technical Manual 13

Solid State Relay Drive Connections

The solid state relay drive output drives solid-state

relays, such as the Chromalox 4115 or 4117 power

modules, which accept 3 to 32 Vdc input ON signals

and 0 Vdc OFF signals. See Figure 2.15 for solid

state relay drive output connections.

Note: Negative lead connects to Terminal #2.

Figure 2.15

Solid State Relay Drive Output Connections

Load

12

2

{

Output 1 120 or 230 Vac

AC Neutral

+

-

Fuse

4115

Current/Voltage Output

Controllers with output codes “AO,” “AA,” “AR”

and “AT” give you the option of 4-20mA or 1-5 Vdc

output. When shipped from the factory, these

control outputs are configured for 4-20mA output.

For 1-5 Vdc output, you must access the internal

output board and move the jumper(s) to the 1-5

Vdc position, as shown in Figure 2.16 on the

following page.

14 Chromalox 2104 Technical Manual

Figure 2.16

Current/Voltage

Output Jumper Positions

Top

Controller Rear View

Output #1*

Output #2

4-20mA 1-5 Vdc

4-20mA 1-5 Vdc

*All controllers with Analog Output (output codes AR, AT) for

output #1 use same 4-20mA/1-5 Vdc jumper positions as shown here.

Output Module

Chromalox 2104 Technical Manual 15

Figure 2.17

Triac Output Connections

AC Neutral

10 Heat Load

120 Vac or 230 Vac

11 Fuse

Figure 2.18

4-20mA Analog Output Connections

10

11

+24 Vdc

4-20mA

Power

Controller

or Valve

(0-800 ohms)

-

+

Figure 2.19

1-5 Vdc Output Connections

10

11

12

Input

GND

NC

1-5 Vdc

-

+

2104

2104

2104

Table of contents

Other Chromalox Temperature Controllers manuals

Chromalox

Chromalox 2002 PLUS! User manual

Chromalox

Chromalox 3204 User manual

Chromalox

Chromalox 1604 User manual

Chromalox

Chromalox 8003 User manual

Chromalox

Chromalox TEMPERATURE CONTROLLER 1604-7 User manual

Chromalox

Chromalox 1601 User manual

Chromalox

Chromalox ETR-3400 User manual

Chromalox

Chromalox LIMIT User manual

Chromalox

Chromalox 6020 Instruction manual

Chromalox

Chromalox 2110 User manual