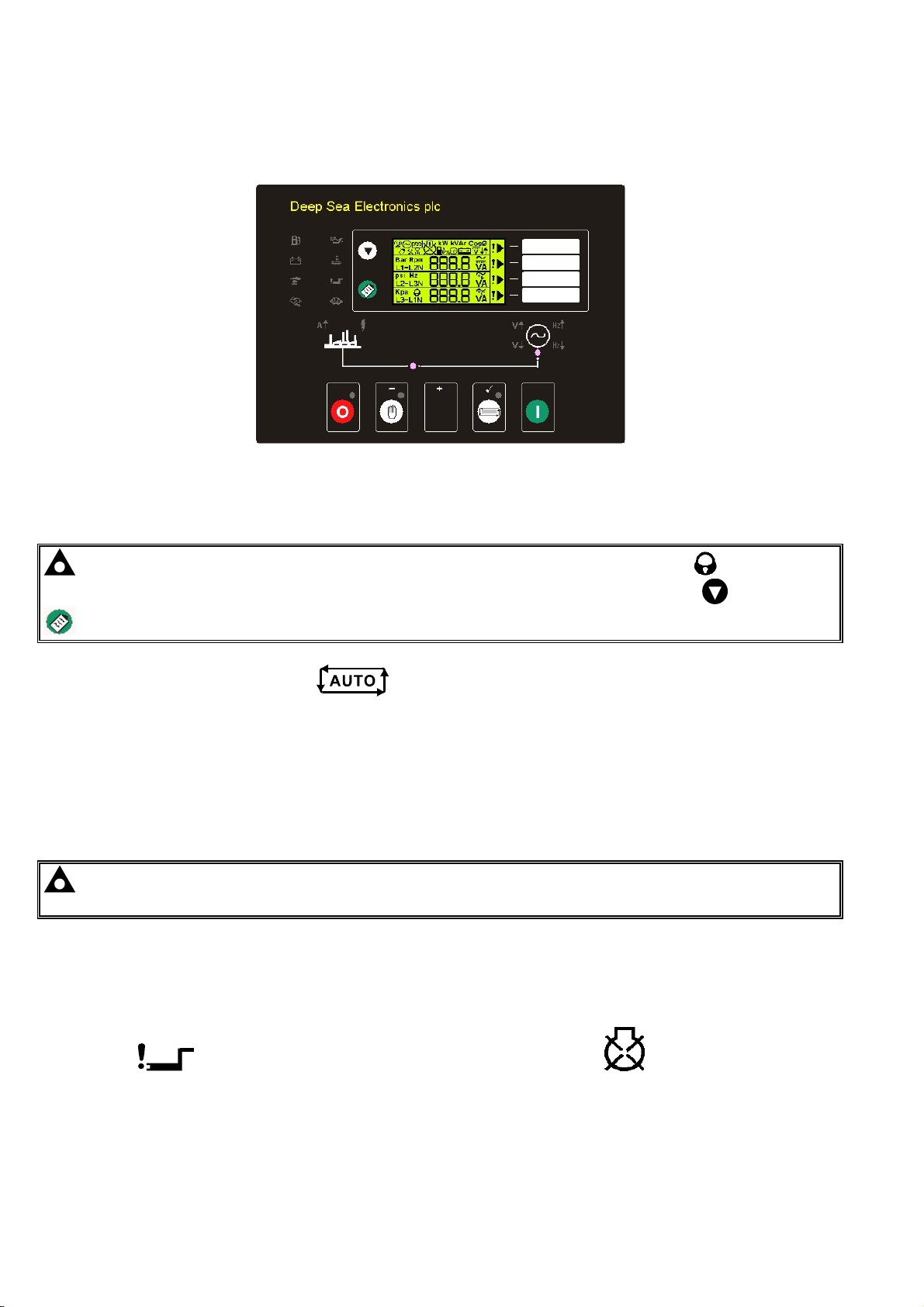

DSE Model 5210 Automatic Start Engine Management and Instrumentation System Operators Manual

057-011 5210 OPERATING MANUAL ISSUE 5.1 18/06/2007 AM 3

TABLE OF CONTENTS

Section Page

1INTRODUCTION ..............................................................................................5

2CLARIFICATION OF NOTATION USED WITHIN THIS PUBLICATION.........5

3OPERATION ....................................................................................................6

3.1 AUTOMATIC MODE OF OPERATION ...............................................................................6

3.2 MANUAL OPERATION.......................................................................................................8

4PROTECTIONS................................................................................................9

4.1 WARNINGS .......................................................................................................................10

4.2 ANALOGUE PRE-ALARMS..............................................................................................10

4.3 HIGH CURRENT WARNING ALARM...............................................................................11

4.4 SHUTDOWNS....................................................................................................................12

4.5 HIGH CURRENT SHUTDOWN ALARM ...........................................................................14

4.6 ELECTRICAL TRIPS.........................................................................................................14

5LCD INDICATORS AND LOGO INSERT.......................................................15

6DESCRIPTION OF CONTROLS ....................................................................16

6.1 TYPICAL LCD DISPLAY SCREENS ................................................................................17

6.2 LCD DISPLAY AREAS......................................................................................................18

6.3 VIEWING THE INSTRUMENTS ........................................................................................19

6.4 VIEWING THE EVENT LOG..............................................................................................20

6.5 INDICATORS.....................................................................................................................21

6.6 CONTROLS.......................................................................................................................21

7FRONT PANEL CONFIGURATION...............................................................22

7.1 ACCESSING THE FRONT PANEL CONFIGURATION EDITOR.....................................22

7.1.1 ENTERING THE CONFIGURATION EDITOR PIN NUMBER ...................................22

7.2 EDITING AN ANALOGUE VALUE....................................................................................23

7.2.1 EDITING THE CURRENT DATE/TIME......................................................................25

8INSTALLATION INSTRUCTIONS..................................................................26

8.1 PANEL CUT-OUT..............................................................................................................26

8.2 COOLING...........................................................................................................................26

8.3 UNIT DIMENSIONS...........................................................................................................26

8.4 FRONT PANEL LAYOUT..................................................................................................27

8.5 REAR PANEL LAYOUT....................................................................................................27

9ELECTRICAL CONNECTIONS......................................................................28

9.1 CONNECTION DETAILS...................................................................................................28

9.1.1 PLUG “A” 8 WAY........................................................................................................28

9.1.2 PLUG “B” 11 WAY......................................................................................................28

9.1.3 PLUG “D” 4 WAY (OPTIONAL) ..................................................................................29

9.1.4 PLUG “F” 4 WAY ........................................................................................................29

9.1.5 PLUG “G” 5 WAY........................................................................................................29

9.1.6 PLUG “H” 4 WAY........................................................................................................29

9.1.7 PC CONFIGURATION INTERFACE CONNECTOR..................................................29

9.1.8 EXPANSION OUTPUT CONNECTOR.......................................................................29

9.2 CONNECTOR FUNCTION DETAILS................................................................................30

9.2.1 PLUG “A” 8 WAY........................................................................................................30

9.2.2 PLUG “B” 11 WAY......................................................................................................30

9.2.3 PLUG “D” 4 WAY (OPTIONAL, FITTED TO RS485 CONTROLERS ONLY) ............31

9.2.4 PLUG “F” 4 WAY ........................................................................................................31

9.2.5 PLUG “G” 5 WAY........................................................................................................31

9.2.6 PLUG “H” 4 WAY........................................................................................................31

9.2.7 PURCHASING ADDITIONAL CONNECTOR PLUGS FROM DSE............................31

10 SPECIFICATION.........................................................................................32

11 COMMISSIONING.......................................................................................34

CALL US TODAY

1-888-POWER-58

SHOP ONLINE

www.genpowerusa.com