Sonatest Masterscan D-70 User manual

Document Number: Issue 0 September 2014

Masterscan D-70

User’s Guide

17/09/2014

Masterscan D-70 user’s manual

1

How to contact Sonatest?

Visit our website: www.sonatest.com or contact our offices.

Sonatest Limited (International)

Dickens Road

Milton Keynes

MK12 5QQ

England

+44 (0)1908 316345

+44 (0)1908 321323

Sonatest Inc

. (America)

12775 Cogburn

San Antonio, Texas

78249

USA

+1 (210) 697 0335

+1 (210) 697 0767

Masterscan D-70 user’s manual

2

Disclaimers and Notices

The following information must be read and understood by users of the Sonatest Masterscan D-70

ultrasonic flaw detector and thickness gauge. Failure to follow these instructions can lead to serious

errors in test results or damage to the flaw detector. Decisions based on erroneous results can lead

to property damage, personal injury or death. Anyone using this instrument should be fully qualified

by their organization in the theory and practice of ultrasonic testing, or under the direct supervision

of such a person.

General Warnings

Proper use of the ultrasonic test equipment requires four essential elements:

Knowledge of the specific tests or inspections and applicable test equipment.

Selection of the correct test equipment based on knowledge of the application.

Competent training of the instrument operator.

This user’s guide provides instruction in the basic operation of the Masterscan D-70 flaw

detector. In addition to the methods included, many other factors can affect the use of

this flaw detector. Specific information regarding these factors are beyond the scope of

this manual. The user should refer to appropriate textbooks on the subject of ultrasonic

testing and thickness gauging for more detailed information.

Specific Warnings

The Masterscan D-70 contains a high-energy, precision pulser allowing optimum test

results to be obtained by matching the pulse width to the probe characteristics. This

circuitry may be damaged by voltage spikes. It is recommended that the instrument be

switched off, or the pulser stopped (by pressing the

[Freeze/Peak]

key) before changing

probes.

Operator Training

Operators must receive adequate training before using this ultrasonic flaw detector.

Operators must be trained in general ultrasonic testing procedures, and in the set-up and

performance required by each specific test or inspection. Operators must understand: Sound

wave propagation theory.

Must understand the effects of the velocity of sound in the test material.

Must know the behaviour of the sound wave at the interface of two different materials.

Must have an understanding of Sound wave spread and mode conversion.

More specific information about operator training, qualification, certification and test specifications

can be obtained from technical societies, industry groups and government agencies.

Masterscan D-70 user’s manual

3

Testing Limitations

In ultrasonic testing, information is obtained only from within the confines of the sound beam as it

propagates into the test material. Operators must exercise great caution when making inferences

about the nature of the test material outside the limits of the sound beam. The condition of

materials can vary significantly and the results can be erratic if operators don’t exercise good

judgment.

Critical Operating Factors

The following procedures must be observed by all users of the Masterscan D-70 in order to obtain

proper, accurate and consistent results.

Calibration of the Sound Velocity

An ultrasonic flaw detector operates on the principle of measuring the time of flight of a burst of high

frequency sound through the test piece, as well as evaluating the amplitude of reflected or

transmitted echoes. The sound velocity of the test piece multiplies this time in order to obtain an

accurate distance or thickness reading. Since the actual sound velocity in materials can vary from the

published values, the best result is obtained when the instrument is calibrated on a reference block

made from the same material as the test piece. This block should be flat, smooth and as thick as the

maximum thickness expected of the test piece.

Users should also be aware that the sound velocity might not be constant throughout the test piece

due to effects such as heat-treating. This must be taken into consideration when evaluating the

results of ultrasonic thickness testing. The calibration should always be checked after testing to

minimize errors.

Transducer (Probe) Zero Procedure

The transducer calibration procedures must be performed as described in this manual. The

calibration block must be clean, in good condition and free of noticeable wear. Failure to perform

the transducer zero and calibration procedure will cause inaccurate thickness readings.

Flaw Detection Calibration

When performing a flaw detection test, it is important to note that the amplitude of indications is

not only related to the size of the discontinuity; the depth of a discontinuity below the test piece

surface will also have an effect on the amplitude due to characteristics of the sound beam spread

and near field zone of the transducer. In addition, the characteristics of the discontinuity such as

orientation and classification can alter the expected amplitude response. For these reasons,

calibration should be performed on test blocks made of the same material as the test piece with

artificial discontinuities within the range of size and depth in the material to be detected. The user is

again cautioned to refer to reference books which are beyond the scope of this manual.

Masterscan D-70 user’s manual

4

Effects of Temperature on Calibration

The sound velocity in test pieces and the transducer wear face changes with temperature variations.

All calibrations should be performed on site with test blocks at or near the same temperature as that

expected on the test piece, to minimize errors.

Transducer Condition

The transducer used for testing must be in a good condition, without noticeable wear of the front

surface. The specified range of the transducer must encompass the complete range of the thickness

to be tested and/or the types of discontinuities to be investigated. The temperature of the material

to be tested must be within the transducer’s specified temperature range.

Use of Couplant

Operators must be familiar with the use of ultrasonic couplant. Testing skills must be developed so

that couplant is used and applied in a consistent manner to eliminate variations in couplant thickness

which can cause errors and inaccurate readings. Calibration and actual testing should be performed

under similar coupling conditions, using a minimum amount of couplant and applying consistent

pressure to the transducer

Disclaimer of Liability

All statements, technical information and recommendations contained in this manual or any other

information supplied by Sonatest Limited in connection with the use, features and qualifications of

the Masterscan D-70 are based on tests believed to be reliable, but the accuracy or completeness

thereof is not guaranteed. Before using the product you should determine its suitability for your

intended use based on your knowledge of ultrasonic testing and the characteristics of materials. You

bear all risk in connection with the use of the product. You are reminded that all warranties as to

merchantability and fitness for purpose are excluded from the contract under which the product and

this manual have been supplied to you. The Seller’s only obligation in this respect is to replace such

quantity of the product proved to be defective.

Neither the seller nor the manufacturer shall be liable either in contract or in tort for any direct or

indirect loss or damage (whether for loss of profit or otherwise), costs, expenses or other claims for

consequential or indirect compensation whatsoever (and whether caused by the negligence of the

company, its employees or agents or otherwise).

Your product package may include optional documentation, such as warranty flyers, that may have

been added by your dealer. These documents are not part of the standard package.

Masterscan D-70 user’s manual

5

Copyright

Copyright © 2006 –2014 Sonatest Limited. All rights Reserved

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording or

otherwise, without the prior written permission of Sonatest Limited.

Sonatest limited or its filial provides this manual “AS IS” without warranty of any kind, either express

or implied. Included but not limited to the implied warranties or conditions of merchantability or

fitness for a particular purpose. In NO events shall Sonatest Limited, its filial, its directors, officers,

employers or agents be liable for indirect, special, incidental, or consequential damage, even if

Sonatest limited or its filial has been advised of the possibility of such damages arising from any

defect or error in this manual or product.

Specifications and information contained in this manual are furnished for informational use only, and

are subject to change at any time without notice, and should not be construed as a commitment by

Sonatest limited or its filial.

Masterscan D-70 user’s manual

6

Electromagnetic Compatibility

This product has been design to the following European Directives:

-Directive 2002/95/EC on the Restriction of the Use of certain Hazardous Substances in Electrical and

Electronic Equipment (RoHS).

-Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE)

-Low Voltage Directive (LVD) 73/23/EEC

-CE Marking Directive 93/68/EEC

-EMC Directive 89/336/EEC. However, in order to ensure the equipment meets the requirements, the

following should be read:

This is a “CLASS A” product. In a domestic environment, this product may cause radio

interference. In which case the user may be required to take adequate measures.

This product should not be connected to cables (i.e. probe or encoder cable) longer than three

(3) meters in length. If this is necessary, the installation may require further EMC testing to

ensure conformity.

The Masterscan D-70 also complies with EN 12668-1, non-destructive testing and verification of

ultrasonic examination equipment –Part 1: Instruments. For any questions relating to the proper

use of this product, please contact your distributor or Sonatest.

Masterscan D-70 user’s manual

7

About this guide

How this guide is organised

This guide contains the following parts:

Chapter 1: Product Introduction

Chapter 2: Detailed Menu Description

Chapter 3: Flaw testing

Chapter 4: Thickness Gauging

Chapter 5: Standard Features

Chapter 6: Interface connection

Chapter 7: Optional Features

Chapter 8: Accessories

Chapter 9: Products Specifications

Chapter 10: Warranty

Chapter 11: Troubleshooting and Support

Chapter 12: Maintenance

Chapter 13: Index

Convention used in this guide

To ensure that you perform certain tasks properly, take note of the following symbols used

throughout this manual.

DANGER/WARNING: information to prevent injury to yourself when

trying to complete a task.

NOTE: Information to help you complete the task

TIPS: Additional information to help you complete a task

Typography

text on screen

Refer to the name of the menu, Tab or sub-menu as it

appears on the screen

(Italics)

Used to emphasis comment during a procedure

[keys/Menu]

Refer to the key/button to press on the unit

Masterscan D-70 user’s manual

8

Contents

Disclaimers and Notices .......................................................................................... 2

General Warnings ...............................................................................................2

Specific Warnings ...............................................................................................2

Operator Training ............................................................................................... 2

Testing Limitations .............................................................................................3

Critical Operating Factors ....................................................................................3

Calibration of the Sound Velocity..........................................................................3

Transducer (Probe) Zero Procedure......................................................................3

Flaw Detection Calibration ...................................................................................3

Effects of Temperature on Calibration................................................................... 4

Transducer Condition ..........................................................................................4

Use of Couplant.................................................................................................. 4

Disclaimer of Liability..............................................................................................4

Copyright5

Electromagnetic Compatibility..................................................................................6

About this guide..................................................................................................... 7

How this guide is organised................................................................................. 7

Convention used in this guide ..............................................................................7

Typography .......................................................................................................7

Chapter 1 : Product Introduction ............................................................................... 11

1. Welcome! .............................................................................................. 11

2. Features of the Masterscan D-70 ............................................................. 11

Functional Testing Methods ............................................................................... 11

3. Front Panel ............................................................................................ 12

4. Back Panel............................................................................................. 14

5. Masterscan D-70 Memory........................................................................ 15

Reset to factory defaults ................................................................................... 15

6. Key Names and functions ........................................................................ 16

Chapter 2 : Detailed Menu Description ....................................................................... 19

1. Main Menu............................................................................................. 19

Main Menu Selection ......................................................................................... 19

2. CAL Menu .............................................................................................. 20

CAL (Calibration) Tab........................................................................................ 20

Amp (Amplifier) Tab ......................................................................................... 20

Tx (Transmitter) Tab ........................................................................................ 20

Gate 1 & Gate 2 Tab......................................................................................... 21

Auto-CAL Tab................................................................................................... 21

Interface Trigger (IFT) Tab ............................................................................... 21

3. MEAS Menu ........................................................................................... 22

Meas (Measurement) Tab.................................................................................. 22

Trig Tab 24

Probe Tab........................................................................................................ 24

T-Comp (Temperature compensation) Tab.......................................................... 24

Sizing Tab........................................................................................................ 24

DAC (Distance Amplitude Correction) Tab ........................................................... 25

TCG (Time Corrected Gain) Tab ......................................................................... 26

AVG (Amplituden Vergleichs Größe) Tab ............................................................. 27

API (American Petroleum Institute) Tab.............................................................. 29

AWS (American Welding Society) Tab................................................................. 30

BChart Tab ...................................................................................................... 31

4. MEMORY Menu ...................................................................................... 32

PANEL Tab....................................................................................................... 32

A-LOG Tab....................................................................................................... 32

REF Tab 33

BChart Tab ...................................................................................................... 33

TLogging Tab................................................................................................... 33

T-LOG Tab....................................................................................................... 34

Grid Tab 35

Grid Plan Tab ................................................................................................... 35

5. UTIL Menu............................................................................................. 36

Masterscan D-70 user’s manual

9

MENU Tab ....................................................................................................... 36

Waveform Tab ................................................................................................. 36

User Keys Tab .................................................................................................. 37

MISC Tab 37

VIDEO Tab....................................................................................................... 38

BEA (Backwall Echo Attenuator) Tab .................................................................. 38

AGC (Automatic Gain Control) Tab ..................................................................... 39

Encoder tab ..................................................................................................... 40

CLOCK Tab ...................................................................................................... 40

6. Storage & Recall of Calibration Setups...................................................... 41

How to store a panel set?.................................................................................. 41

How to recall a panel set? ................................................................................. 43

How to delete a panel set? ................................................................................ 43

Adding NOTES to PANEL and A-LOG sets............................................................ 44

Edit Notes Summary ......................................................................................... 45

Chapter 3 : Flaw testing ........................................................................................... 46

1. Basic Operation ...................................................................................... 46

2. Flaw Tester Calibration ........................................................................... 47

Chapter 4 : Thickness Gauging.................................................................................. 51

1. Basic thickness Gauging .......................................................................... 51

2. Thickness Gauging Calibration ................................................................. 52

3. Auto-Cal ................................................................................................ 55

4. TCG for Reliable Gauging ........................................................................ 56

5. Thickness Logging Without Grid ............................................................... 57

Record mode ................................................................................................... 57

Chapter 5 : Standard Features .................................................................................. 58

1. Distance Amplitude Correction (DAC) ....................................................... 58

2. Temperature Compensation .................................................................... 61

Over view61

The Calculation ................................................................................................ 61

Configuring Temperature compensation ............................................................. 61

Using Temperature Compensation...................................................................... 62

3. Weld Inspection Using Trigonometry Mode ............................................... 63

4. Flank- Flank Measurement Mode.............................................................. 65

Overview 65

Setting up Flank - Flank Mode............................................................................ 65

Using Flank - Flank Mode .................................................................................. 66

5. A-LOG, A-scan Storage ........................................................................... 67

How to Store An A-Scan.................................................................................... 67

How to Recall an A-Scan ................................................................................... 68

How to Delete a Stored A-Scan.......................................................................... 69

How to Recall an A-Scan as a Reference Waveform ............................................. 69

6. Contour, Peak Echo & Hold Dynamics....................................................... 70

7. B-Chart Measurement Technique ............................................................. 72

Overview 72

Configuring B-Chart Measurement Mode ............................................................. 72

Using B-Chart Mode.......................................................................................... 73

8. BCHART, Bchart Storage ......................................................................... 75

Chapter 6 : Interface Connection............................................................................... 78

1. USB connector ....................................................................................... 78

2. Encoder................................................................................................. 78

Chapter 7 : Optional Features ................................................................................... 79

1. Entering License Key to Activate Options .................................................. 79

2. Time Correction Gain (TCG)..................................................................... 80

3. Distance Gain Size (DGS)/Amplituden Vergleichs Größe (AVG) .................... 82

Theory 83

DGS/AVG Frequency, NFL and ERS..................................................................... 84

DGS/AVG T-Loss, Ref dB and Mat dB.................................................................. 85

DGS/AVG dVK, REF TYPE and REFSIZE............................................................... 86

DGS/AVG Calibration (SET SIG) ......................................................................... 88

Adjustment ...................................................................................................... 89

Measurement ................................................................................................... 90

4. American Welding Society (AWS) ............................................................. 91

5. Evaluating Pipe Imperfections using American Petroleum Institute (API) 5UE94

Masterscan D-70 user’s manual

10

6. Grid Thickness Logging ........................................................................... 97

7. Interface Trigger IFT .............................................................................. 98

Immersion Testing............................................................................................ 98

Problems associated with immersion testing........................................................ 98

8. Backwall Echo Attenuator (BEA)............................................................. 102

9. Split Distance Amplitude Correction (Split DAC) ....................................... 104

10. Dryscan ............................................................................................... 106

Dry Coupling .................................................................................................. 106

Transducer Characteristics............................................................................... 107

How the System Works ................................................................................... 107

Interpretation of the Results............................................................................ 108

Setting up a Dry Coupling................................................................................ 109

Chapter 8 : Accessories .......................................................................................... 111

Lithium-Ion Battery Pack..................................................................................... 111

Battery Cautions............................................................................................. 111

Battery Charging ................................................................................................ 112

Charging Caution............................................................................................ 112

Battery Charger.................................................................................................. 113

Chapter 9 : Products Specifications.......................................................................... 114

Chapter 10 : Warranty............................................................................................ 118

Chapter 11 : Troubleshooting and Support ............................................................... 119

Chapter 12 : Maintenance....................................................................................... 121

Casing 121

Screen 121

Traveling 121

Chapter 13 : Index................................................................................................. 122

Masterscan D-70 user’s manual

11

Chapter 1 : Product Introduction

1. Welcome!

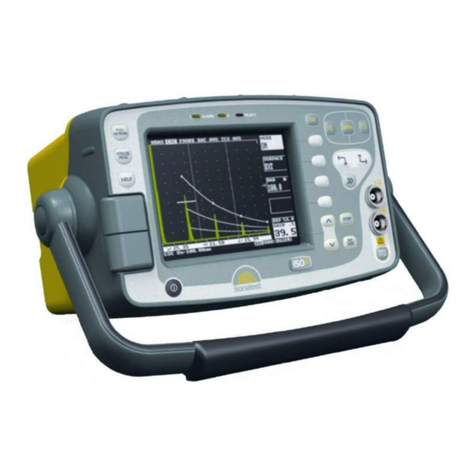

Thank you for purchasing a Sonatest Masterscan D-70!

This manual provides information for the Sonatest Masterscan D-70 device. The information contain

herein allows usage of the Masterscan to its full capability in order to take advantage of its numerous

and user-friendly features.

The user guide has been designed so that people with good knowledge of basic ultrasonic non-

destructive testing may understand how to operate the Masterscan. It is crucial that users

understand the critical nature of ultrasonic non-destructive testing.

2. Features of the Masterscan D-70

The Masterscan D-70 is a user-friendly ultrasonic digital flaw detector and thickness gauge, which is

simple to use and provides the experienced ultrasonic operator with a full-function device that

incorporates many productivity enhancing features. All of the features of the Masterscan D-70 are

accessed through a menu system using the front panel keypad.

Functional Testing Methods

The Masterscan D-70 supports the following ultrasonic testing methods:

Pulse-Echo Flaw Detection

Transmit-Receive Flaw Detection

Time of flight measurement

Contact or Immersion Methods

Angle Beam (Shear Wave) Testing

Angle Beam (Surface Wave) Testing

Crack Diffraction Meth

Depth of Flaw Measurement

Single Transducer Thickness Measurement

Dual Transducer Thickness Measurement

Indirect Measurement of Sound Velocity in Materials

Phase change display in un-rectified mode

Through transmission testing

Creep wave testing

Pitch and catch technique

Masterscan D-70 user’s manual

12

3. Front Panel

The main control on the front of the unit is the scroll-wheel that is used to navigate through the

menus and to adjust parameters this, along with the [OK]key in the middle of the wheel allows

quick and intuitive navigation.

Displays context

specific help

Select main menu

group

On/Off Switch

Changes between

Normal & Full

screen views

Changes between Normal,

Freeze, Trail, Peak & Hold

display of A-Scan

4 user definable buttons that

can have various features

assigned

Up, down left and right arrows allow

single steps through the menus and

change of parameters

Selects gain,

reference gain or

gain step

Selects gate menu

2 alarm LEDs for gate

1 & 2

Reject LED illuminated

when reject is applied

Selects panel

memory list

Scroll wheel allowing navigation

through the menus and changing of

parameter values

Moving your finger in a clockwise direction increases a selected parameter. Moving your finger in an

anticlockwise direction decreases a selected parameter.

The [right] arrow key moves the tab menu selection right by one increment at a time, the [left]

arrow key moves it left by one increment.

The [down] arrow key moves down the four parameter boxes on the right of the display while the

[up] arrow key moves up.

Masterscan D-70 user’s manual

13

After a parameter is selected, press shortly the [OK] button (valid only for parameters with windows

sign) to open a list windows, [up]and [down] arrows keys will move up and down the drop-down

list.

If a parameter is selected by holding the [OK] button down for more than 2 seconds then the [up]

and [down] arrows keys change the value by small increments while the [right] and [left] arrows

keys change the value by a bigger increment.

The remaining front panel controls consist of an array of sealed, pressure sensitive, tactile buttons

that have specific functions assigned to them; the exception to this are the four "user" buttons that

can be assigned to any menu item or a list of useful features. A more detailed description of each

button is shown further below.

The above picture is for reference only. The menu and the button layout may vary

with models, nevertheless the key function remain the same.

When the term “highlighted” is used, it refers to text with a green background (blue in

this manual) and Black letters (white letters) which is the selected item on your flaw

detector.

Masterscan D-70 user’s manual

14

4. Back Panel

The back panel is where the battery pack, the TX/RX and RX connectors (LEMO or BNC) are located.

Additionally a quadrature encoder can be used with the unit when attach to the encoder connector.

There is also a USB connector which allows a bi-directional connection between the unit and a PC via

an adapter. For more details please read Interface connection section.

When connecting to a PC via the USB cable, firmware and software update can be

updated.

Post-analysis can done as well as other functions related to post test.

For more information about the UT-lity software please refer to the manual.

Masterscan D-70 user’s manual

15

5. Masterscan D-70 Memory

The settings of the Masterscan D-70 always remain in memory when the instrument is turned off,

even if the battery pack is removed. That is, whatever the settings are just prior to turning the

instrument off will be the settings in place the next time the instrument is turned on.

At times it may be desirable to start with default settings. This is especially true when beginning a

new test procedure or going from flaw detection to a thickness gauging procedure. Otherwise, it

may be necessary to go through all of the menus to reset various functions. A reset function is

provided to facilitate the returning of all panel calibration settings to the factory defaults.

Reset to factory defaults

1. Switch the instrument off.

2. Press the [Full Screen] button and hold while switching the instrument on until the confirmation

display is seen.

3. Press the [OK] button to reset the instrument to factory defaults. alternatively press the [Menu]

button to cancel factory reset.

Before performing this procedure, be sure to save any favourite settings to memory by using

the procedure outlined in Storage & Recall of Calibration Setups.

4. When resetting to factory default settings the following dialogue is displayed allowing the user

to choose imperial or metric defaults:

Masterscan D-70 user’s manual

16

6. Key Names and functions

Icon

Function Name

Short Function Description

ON/OFF

Power on & off push button for switching the instrument on and off. Operates as

a toggle.

OK

This button operates in conjunction with the memory menus to accept a store or

to accept a recall of a memory already in storage. In the print mode, [OK].

Navigation

Arrow button

Navigation arrows are parameter adjustment and navigation. These buttons

move the highlighted cursor along the top of the screen left and right to the sub

menu to be selected. These are momentary buttons with no repeat. The

parameter boxes along the right hand side of the screen change as the sub menu

is selected.

Menu

The [MENU] button is used to display the 4 main menu levels (CAL, MEAS,

UTIL and MEMORY) on the right hand side of the screen. The [MENU]

button can be pressed at any time.

GATE

Gate

This button takes you directly to the GATE Tab and turns on the gate in positive

trigger mode and highlights the G1 START parameter box.

dB

dB

This button caused the GAIN parameter to be highlighted so that the scroll-

wheel can then adjust the value. Pressing the button again highlights the REF

parameter. Pressing for a third time selects the gain step size.

Freeze/Peak

Press this button once to select freeze mode for the A-Scan display. This is a

useful feature for holding an echo for evaluation.

When in this mode a box is highlighted showing FREEZE below the graticule.

Pressing the button a second time selects the trail (persistence) mode which acts

in a similar way to peak mode (see below) but instead of the envelope remaining

on the display it disappears over time. The decay time of the envelope can be

adjusted by selecting TRAIL in the MISC menu in the UTIL main menu only

when the display is in trail mode.

Pressing the button a third time selects peak mode, which holds and updates all

echoes on the display during inspection. This feature allows an envelope or echo

dynamic pattern to be drawn on the screen with the "live" signal shown within,

which is useful for angle beam inspection to locate the peak signal.

Pressing the key again invokes the Hold mode that captures the current A-Scan

in white allowing a comparison to be made with the live A-Scan that is shown in

green.

Pressing the button a fourth time returns the A-Scan display to normal mode.

This is a momentary button with no repeat action.

Any of the freeze, peak or hold modes can be exited quickly by pressing and

holding the [FREZE/PEAK] key.

Masterscan D-70 user’s manual

17

Full screen

button

The full screen button is used to toggle between showing the A-Scan on the full

display and showing it with the menus and parameter boxes. Full display is useful

for maximising the size of the A-Scan while performing inspections.

While in full screen mode the user can still change the gain in the normal way

and use the [Freeze/Peak] button; all other buttons are disabled.

1

.

.

4

User buttons

These four “USER”buttons can be assigned to any parameter on the Masterscan

D-70. To use this function simply select the parameter that you want to assign

to the button and then hold down the user button until you see the following

message:

In addition the following quick access functions can be assigned from the

User-Keys tab’s parameters in the UTILS menu: Panel, User, N/A, Auto

80%, QSave-A, WheelLK, +/- 6dB, Gain Up, Gain Dn, GainStp,

Sngl/Dbl, Clr TMin, Clr Peak, AWS Visible, API Visible and

AutoZero.

By default the user buttons are assign as follow:

Button1 (Gain Up)

Button2 (GainStp)

Button3 (Gain Dn)

Button4 (Sngl/Dbl)

RECALL

Recall

This button is a shortcut to the PANEL storage list enabling the quick recall or

saving of the current panel settings.

HELP

Help

This button selects the help menu which overlays the display.

The Help Screen displays the Instrument serial number & software version

N/A

Single/Double

This button toggles between single and double element transducers. The user

should switch the unit off or stop the pulser by pressing the [Freeze/Peak]

key before changing transducers.

N/A

Gain Step

Press to select the dB step value of amplifier gain as 0.1, 0.5, 1, 2, 6, 10, 14, or

20dB. The selected value is indicated at the top right-hand corner of the gain

box, which is always located at the bottom right side of the screen. This will

increase the gain step value.

N/A

Gain Up

Press to increment the gain value indicated in the gain box. This is always

located at the bottom right side of the screen. This is a repeat button with

Masterscan D-70 user’s manual

18

acceleration to facilitate quick changing of the value.

N/A

Gain Down

Press to decrement the gain value indicated in the gain box. This is always

located at the bottom right side of the screen. This is a repeat button with

acceleration to facilitate quick changing of the value.

N/A

Transmitter/Re

ceiver

BNC or LEMO 1 connector is the transmitter and receiver socket used for single

transducers or as the transmitter only, for twin or dual transducer operation.

N/A

Receiver

BNC or LEMO 1 connector is the receiver socket used for twin or dual transducer

operation.

USB

A socket to connect various USB devices such as the user’s PC.

Power supply/

Battery

Charger

A socket used to connect the battery charger for recharging the battery pack. A

red dot is provided on both the socket and plug to facilitate alignment. Refer to

Power Supply for information on power supplies and charging of the battery

pack.

Masterscan D-70 user’s manual

19

Chapter 2 : Detailed Menu Description

Before proceeding with this section, the user should be familiar with the front panel controls

described in Chapter 1(Front Panel). Furthermore it is assumed that the user has a good

understanding of the theory and practice of ultrasonic testing.

1. Main Menu

When the Masterscan D-70 is switch on, the unit will perform an initial check test. And a similar

screen will appear.

During that test the screen may flick momentarily. When the test is finished the following screen

should appears:

As shown above the main menus are on the right hand side of the screen. To select a particular

menu press the [up] or [down] navigation arrow keys. You can return to the main menu at any time

by pressing the [Menu] button.

Main Menu Selection

Select Cal menu to access the following items: Cal, Amp, Tx, Gate 1, Gate 2, Auto Cal and

IFT

Select Meas menu to access the following items: : Meas, Trig, Probe,

Sizing,(DAC,TCG,AVG,AWS,API) , BChart and T-Comp.

Select Mem menu to access the following items: Panel, A-Log, Ref, Bchart, TLogging,(Grid,

Grid Plan) or T-Log.

Select Util menu to access the following items: Menu, Waveform, Misc, Video, BEA, AGC,

Encoder, Clock and User Keys

The Ref/Gain box always appears at the bottom right of the screen and can be changed using

the [Userkey 2]

(factory setting)

or press [dB] twice and the [Up]/ [Down] keys.

Some sub-menu have a pop-up windows sign on the left hand side. If you push

again the [OK] button after the sub-menu is highlighted, another window will

appear.

Table of contents

Other Sonatest Test Equipment manuals

Sonatest

Sonatest Sitescan 150 User manual

Sonatest

Sonatest RapidScan2 User manual

Sonatest

Sonatest Wave User manual

Sonatest

Sonatest SOFRANEL WheelProbe 2 User manual

Sonatest

Sonatest Microgage III Series User manual

Sonatest

Sonatest Steelgage II User manual

Sonatest

Sonatest Sitescan 250 User manual

Sonatest

Sonatest Sitescan D-50 User manual