Sontay MW-U Series User manual

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

Ultrasonic Flow Sensors & Integrator

Page 1 of 8

MW-U

Issue: 5.0

Date Of Issue: 17/11/2010

© 2010 Sontay Limited. All rights reserved.

Features

Specification Product Codes

Simply operation

Long life ultrasonic flow meter

Integral wall and DIN-rail mounting bracket

Pulsed or M-Bus output options

Meter:

Nominal flow rate qp 0.6 to qp 60m³/h

Max. static pressure:

Screwed 16bar

Flanged 25bar

Body materials Brass

Cable length 1.5m (meter to electronics)

Temperature range: 1 to 130°C

Temperature diff: 3 to 120K

Calculator:

Supply 3.6V Lithium battery

Battery life 6 years

Display Multifunction 8-digit + characters

LCD

Cable length 2m (electronics to calculator)

Sensors: & pockets

Sensor length:

Meter size 15-32mm 1.5 meters

Meter size 40-100mm 3 meters

Sensor pockets:

Meter size 15-32mm 45mm

Meter size 40-100mm105mm

Sensor type PT500 Matched pair

Pocket thread ½” BSP

Output:

Output pulse 30Vdc max. @ 20mA

Pulse duration 400m/s <TP<600m/s

M-Bus Baud rate 2400

General:

Ambient range:

Temperature 5 to 55°C

RH 95% non-condensing

Conformity EN1434, MID

Protection IP54

MW-U

Heat Meter Integrator

(build unit with following options)

Output type (add to above code)

-P

Pulsed output

-M

M-Bus output

Flow Sensor (add to above code)

-4

Qp 0.6m³/h, G¾” (R½”) screwed

-5

Qp 1.5m³/h, G¾” (R½”) screwed

-6

Qp 2.5m³/h, G1” (R¾”) screwed

-7

Qp 3.5m³/h, G1 ¼” (R1”) screwed

-8

Qp 6m³/h, G1 ¼” (R1”) screwed

-9

Qp 10m³/h, G2” (R1 ½”) screwed

-E

Qp 10m³/h, DN40 flanged

-F

Qp 15m³/h, DN50 flanged

-G

Qp 25m³/h, DN65 flanged

-H

Qp 40m³/h, DN80 flanged

-J

Qp 60m³/h, DN100 flanged

Page 2 of 8

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

MW-U

Issue: 5.0

Date Of Issue: 17/11/2010

© 2010 Sontay Limited. All rights reserved.

Technical Overview General Information (continued)

Ultrasonic flow sensors have no moving parts in the volume

flow, this makes them almost wear free and noiseless. They

measure the flow by using the transit time principle, one

ultrasonic signal is launched in the flow direction and one

against the flow direction. The flow rate is concluded by the

delay time measured, this information is then transmitted to

the calculator by the way of electronic pulses.

The calculator uses the latest innovative technology to cal-

culate heat usage from heating systems. With its dynamic

measuring cycle even the smallest energy consumptions are

reliably collected. The large multifunction display perma-

nently shows the heat consumption total, and by using the

button is it possible to scroll through the display to show all

data.

General Information

Initial verification

The MW-MD is produced and tested in compliance with the

new European measuring instruments directive (MID).

According to this directive, devices do no longer carry an

initial verification stamp, but rather the year of the device’s

declaration of conformity (recognizable on the front of the

device, for example: M09). The MID controls the use of heat

meters up to the moment they are placed on the market

resp. their first putting into use. After this, the national

regulations for devices subject to legal verification apply

within the EU.

The duration of initial verification validity in Germany

remains 5 years for heat meters. After this period has

expired, the measuring device may no longer be used for

billing in commercial use. The regulations resp. validity

period may vary in other countries of the EU.

Electro-magnetic interference

The MW-MD fulfils the national and international

requirements for interference resistance. To avoid

malfunctions due to other interferences, do not install

fluorescent lamps, switch cabinets or electric devices such

as motors or pumps in the immediate vicinity of the meter

(minimum distance 1 m). Cables leaving the meter should

not be laid parallel to live cables (230V, minimum distance

0.2 m).

Care instructions

Clean plastic surfaces with a damp cloth only. Do not use

any scouring or aggressive cleaning agents!

The device is maintenance-free during the service life.

Repairs can only be made by the manufacturer.

Declaration of Conformity

Sontay Ltd declares that this product with the number of the

EC type examination certificate DE-08-MI004-PTB012

complies with the requirements of the EC directives

2004/22/EC (Measuring instruments directive) and 89/336/

EEC (electro-magnetic compatibility).

Page 3 of 8

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

MW-U

Issue: 5.0

Date Of Issue: 17/11/2010

© 2010 Sontay Limited. All rights reserved.

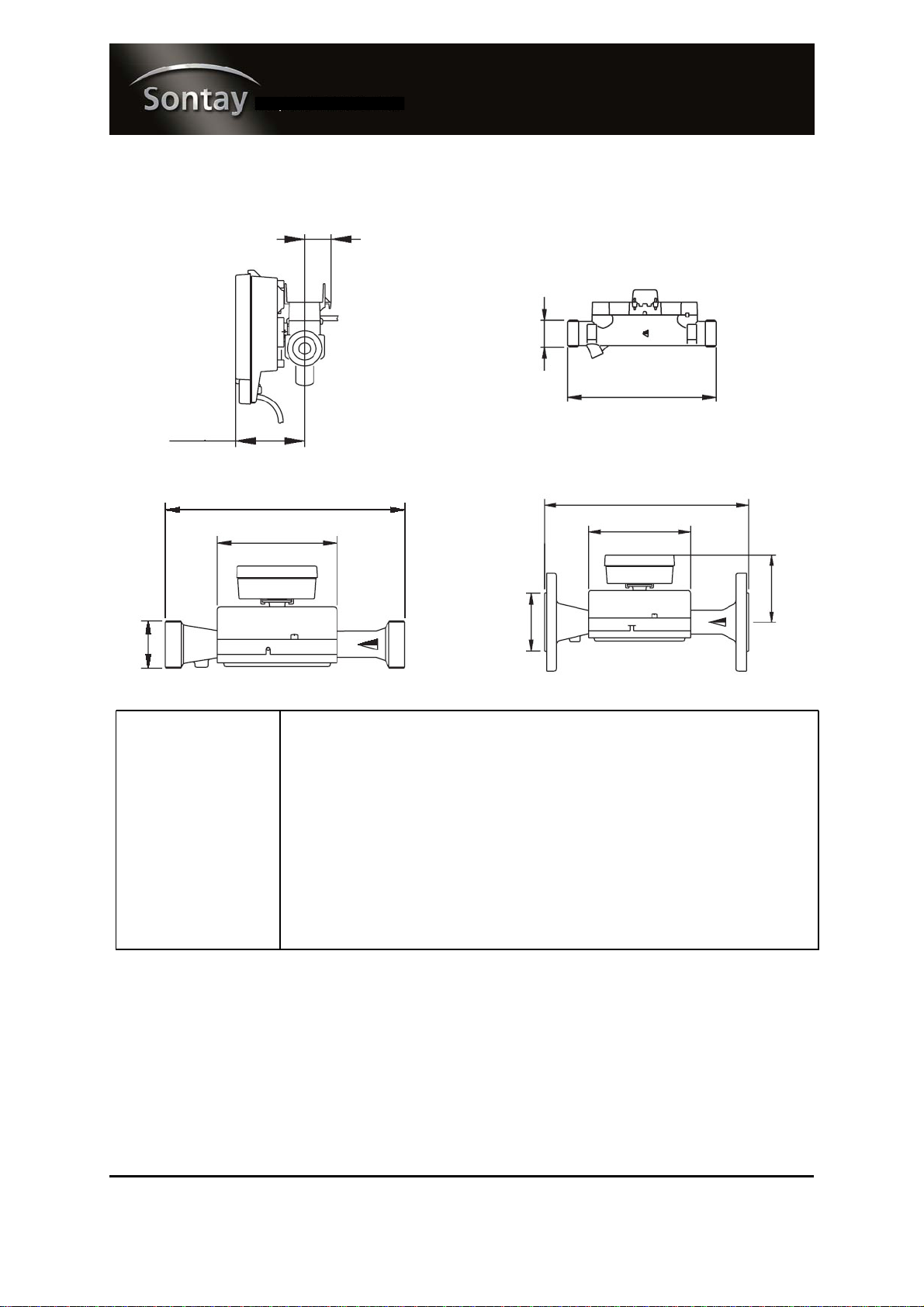

Flow Sensor Data

L

L

L

H

DN

150

150

GxB

22.6

GxB

59.5

Nominal Flow qp m³/h 0,6 1 1,5 2,5 3,5 6 10 15 25 40 60

Nominal Diameter DN mm 15 15 15 20 25 25 40 50 65 80 100

lnch½½½¾1 1 1½ - - - -

Inst. Length without conn. L mm 110 110 110 130 260 260 300 270 300 300 360

Thread meter G x B D1 lnch ¾ ¾ ¾ 1 1 ¼ 1 ¼ 2 Flange Flange Flange Flange

MaximumFlow qim³/h1,22357122030 50 80120

MinimumFlow qs l/h 12 20 30 50 35 60 100 150 250 400 600

OperatingPressure,max.PNbar16161616161616 25 25 25 16/25

Pressure loss at Qn bar 0,14 0,06 0,13 0,2 0,06 0,15 0,12 0,1 0,1 0,16 0,14

Weight kg 1 1 1 1,5 3 3 4 8 11 13 22

Page 4 of 8

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

MW-U

Issue: 5.0

Date Of Issue: 17/11/2010

© 2010 Sontay Limited. All rights reserved.

Status / Error Codes Installation

The symbols in the table below show the meter’s operational

status. The status messages only appear in the main display

(energy)! The temporary display of the warning triangle can

be caused by special operating states and does not always

mean that the device is malfunctioning. However, should the

symbol be displayed over a longer period of time you should

contact Sontay.

Symbol Status Event

Flow existent -

Attention Check for errors

Data transmission -

Emergency operation Exchange device

External power supply -

Error codes show faults detected by MW-MD. If more than

one error appears, the sum of the error codes is displayed:

Error 1005 = error 1000 and error 5.

Code Error Event

1 Short-circuit return sensor Check sensors

2 Interruption return sensor “

3 Short circuit supply sensor “

4 Interruption supply sensor “

5 Hardware error Exchange device

6 Battery empty/wrong temp sensor Check

7 Temp. out of measuring range Correction of heating

system

100 Emergency operation Exchange device

1000 Battery life time exceeded “

2000 Initial verification expired “

>8000Internal hardware error “

Safety instructions

The installation has to be done by qualified personnel.

Read the instructions carefully right up to the end before

starting to mount the device.

The current laws and regulations have to be observed,

especially EN 1434 part 1+6.

At devices with communication interfaces or mains supply

the general technical rules and the correspondent

regulations have to be followed.

While demounting flow sensors and temperature sensors

care should be taken to ensure that no heating water

escapes from the pipe – this can cause burns!

Close valves and release pressure before installation.

Take care of:

The display must readable at all times, to avoid malfunc-

tions due to other interferences do not install fluorescent

lamps, switch cabinets or electric devices such as mo-

tors or pumps in the immediate vicinity of the meter

(minimum distance 1 m).

All welding must be finished.

The ambient temperature must not exceed 55°C.

The type of temperature sensor must correspond with

the calculator.

The pulse value of the flow sensor must correspond with

the one from the calculator.

The calculator has 7 screwed cable glands for wires with

a diameter between 4.2 and 10 mm. Keep unused

glands closed.

Mind the connection order: temperature sensors first,

flow sensor afterwards!

The MW-MD is delivered ready for operation. It does not

need any settings or adjustment.

Page 5 of 8

UK Sales Tel: 0845 345 7253 International Tel: +44 1732 861225

MW-U

Issue: 5.0

Date Of Issue: 17/11/2010

© 2010 Sontay Limited. All rights reserved.

Installation (continued) Installation (continued)

Connection flow sensor

The total length of the wire between flow sensor and

calculator should not exceed 10 m.

Mind the polarity at electronic flow sensors.

Operation test

Check the calculator for any error codes in the display after

installation (see Page 2 for error codes). Most of the errors

can be deleted by pressing the button.

If the error appears permanently, it will be detected at the

next measuring cycle and displayed again. Check whether

the volume information is updated and the displayed

temperatures correspond to the present ones while the

system is running (measuring cycle 2 minutes max.).

When attaching the top cover on the housing pulses on the

inputs can possibly be generated. Check readings of the

inputs and correct if necessary.

Sealing

Seal the device with the included seals to prevent

unauthorized opening.

Maintenance

Repairs or overhaul are only allowed by the manufacturer or

companies authorized by the manufacturer.

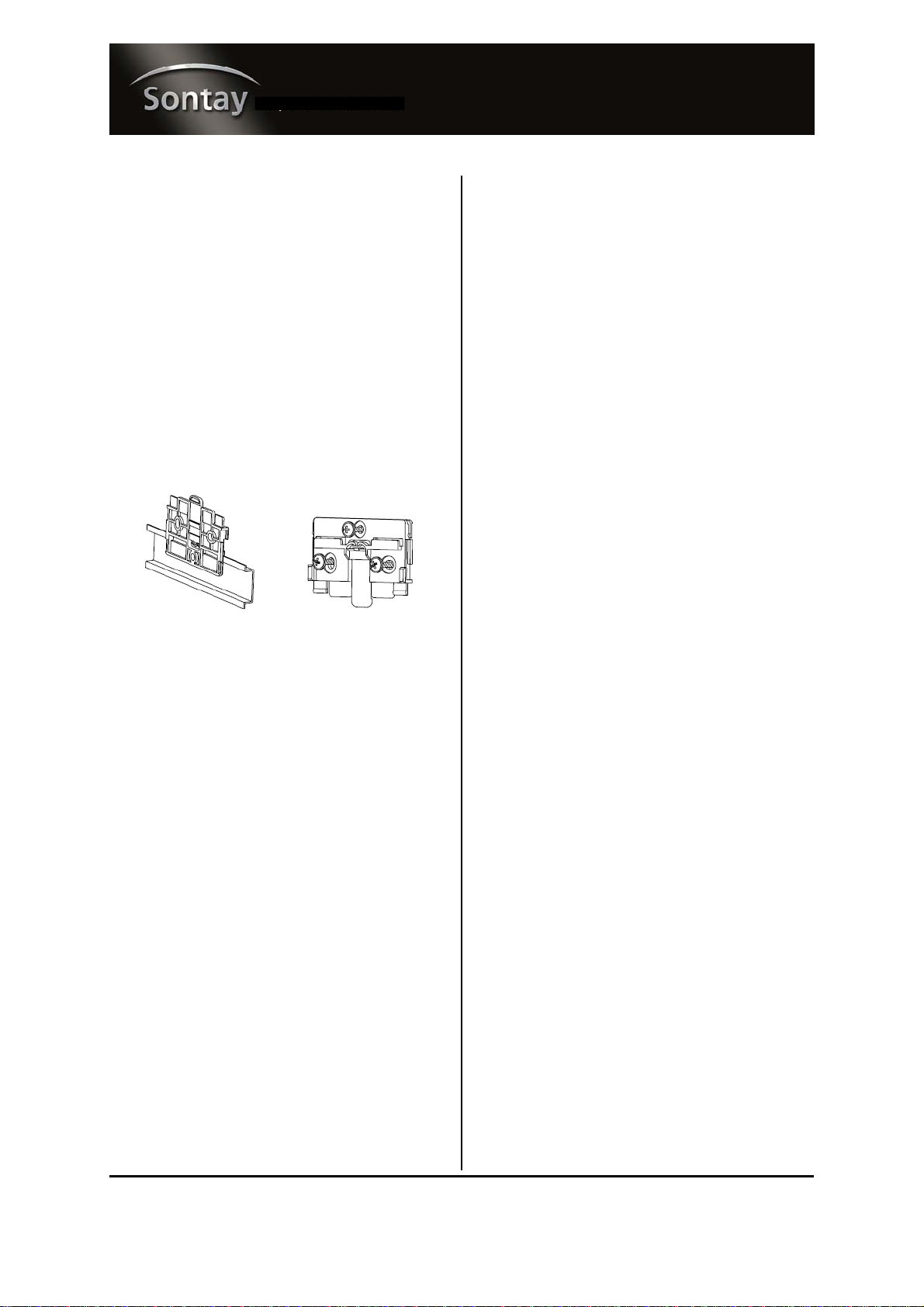

Installation heat calculator

Sontay recommends to mount the calculator on the wall. Do

not mount the device at the pipe or attach it directly on the

flow sensor.

The mounting adapter at the backside of the calculator can

be used for DIN-rail mounting or “reverse” for wall

mounting.

For wall mounting attach the adapter with at least two

screws to the wall and clip the calculator on it.

For rail mounting lift the adapter a little bit, place the

calculator on the rail and push the adapter back until it

locks.

DIN-rail mounting Wall mounting

Connection sensors

The mounting of the temperature sensors should be done

symmetrical with direct immersion. If immersion sleeves are

used they have to be checked for conformity to MID and

have to be marked accordingly. The installation of immersion

sleeves has to be done according to DIN EN 1434-2.

The sensor cables are marked with colours

(red = supply, blue = return). Do not buckle, extend or

shorten the wires!

Do only use paired sensors with the same serial number

on it.

Supply and return sensors must be inserted into the

immersion sleeves completely.

Installation points in the flow sensor can be used for

symmetrical installation of the temperature sensors.

Seal temperature sensor after installation to prevent

unauthorized demounting (seals included).

Do not wrap or install wires along hot pipes.

This manual suits for next models

2

Table of contents

Other Sontay Accessories manuals